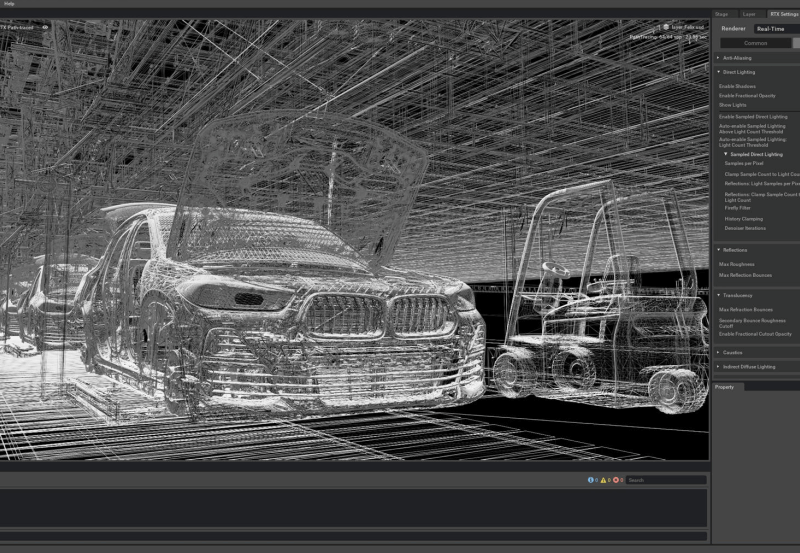

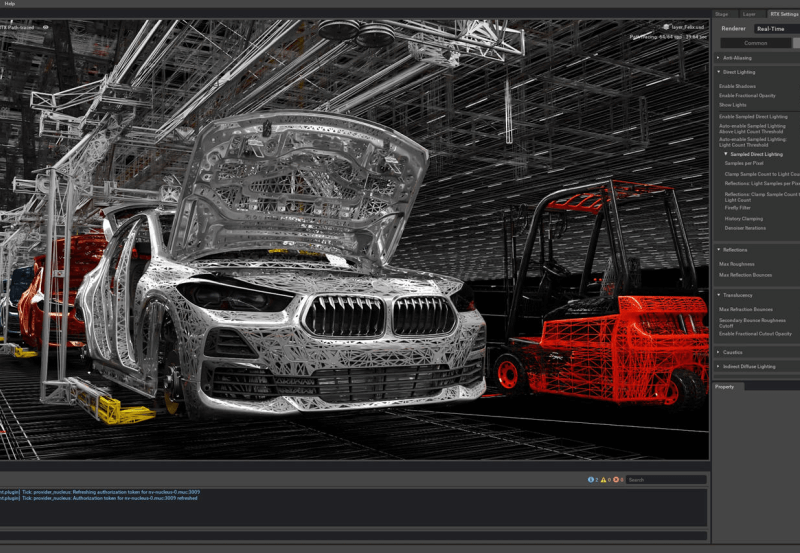

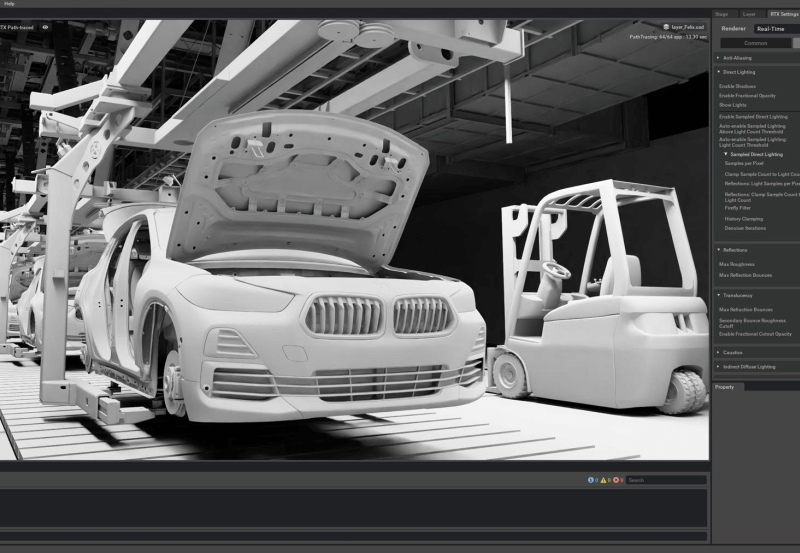

Nvidia developed a virtual factory platform called Omniverse, helping BMW simulate how the new Regensburg plant works even before opening it.

Anyone familiar with the video gaming industry has definitely heard about Nvidia, the most popular graphics card manufacturer globally. However, the brand is increasingly focusing on the mobility industry. Indeed, we have already seen it partner with major players like Hyundai and Mercedes on different projects. And now, Nvidia has teamed up with BMW to create an AI-assisted virtual factory using its Omniverse platform. The innovative project could very well change the way we look at virtual factory planning.

The German automaker already announced it would begin electric powertrain development in Regensburg, Bavaria, later this year. However, designing a new production line from scratch is never an easy task. Luckily, BMW was able to plan the complete production process in a virtual factory built using Nvidia’s Omniverse technology.

Omniverse makes use of AI to display the process and evaluate how the workers would move around in the factory. To minimize issues and find the most suitable procedures, it even simulates workers holding tools and assembling equipment.

With the help of Nvidia’s platform, BMW can plan, simulate and optimize the complete manufacturing process from start to finish. And thanks to artificial intelligence, the platform can even predict how changes in a specific stage in the process would harm other areas.

If there’s anything that Nvidia excels at, it is its realistic graphics, and that’s what this technology incorporates. Thanks to these graphics, the factory can be visualized quite accurately—it’s like being there really.

Of course, we have seen many players in the industry use this type of factory planning over the years. However, what makes this technology stand out is that it also enables 3D design teams spread across the world, working across multiple software suites to collaborate together on highly complex projects. Besides, the changes happen in real-time in a shared virtual space with unrestricted compatibility. More importantly, it eliminates the need for the teams to be present physically in a meeting to collaborate on a project—quite an interesting feature in those “remote work” times.

When it comes to standard digital planning platforms, the data often has to be imported from various applications, which takes a significant amount of time, leading to confusion and complications. But this can be prevented with the help of the Nvidia Omniverse platform, as customers can create a joint simulation by collecting live data from all the necessary databases.

BMW also intends to use this technology to make robots learn how to perform complex tasks in the future.

Learn more about Omniverse here