Running a repair shop isn’t just about fixing cars; it’s about building a reputation for trust and quality service. And, of course, the right tools and equipment are at the heart of that mission. They will allow you to diagnose problems, perform repairs, and carry out routine maintenance with confidence. Sure, pretty much any tool would also help you to do just that, but the right tools will save you time, effort, and money in the long run — 3 things you will never have enough of when running a shop.

But when you are just starting out running your own garage, you might be wondering, “What tools and equipment do I really need for my auto repair shop?” This is a fundamental question every budding auto shop owner grapples with, especially if, like me, they started with a very limited budget — there’s no way around it; this is where all repair shops begin.

Now, I’ve been a master mechanic and running my own shop for over a decade, and I can definitely vouch that having the right tools and equipment truly matters. Indeed, your tools will be your companions, helpers, and most trusted allies in the shop — so much so that they can literally make the difference between a struggling repair shop and a profitable one.

Of course, I totally understand that, when starting out, you can’t buy the absolute best tools or all of the tools you might want; you will need to set priorities straight and make tough choices.

So, to help you with that, I will guide you through the essentials, the must-haves, the can’t-do-withouts, all the tools you’ll need to get your hands on to get your auto repair shop off the ground. I’ll break it down, step by step, in simple terms so you can make informed decisions and set up a shop that’s not only efficient but also profitable enough to keep you going and growing until you can finally buy all the tools you are dreaming of. Yep, that wall-to-wall Snap-On tool chest can be yours one day, but before you get there, you’ll have to make do with cheaper alternatives — haha.

But I digress… So, without further ado, let’s get started!

Essential Equipment for Your Auto Repair Shop

Before launching your repair shop, it’s important to list the essential equipment that will form the core of your operations. Each garage will eventually end up with a different list depending on the most common jobs you tackle and the type of vehicle that gets through the door everyday, but some of them are staples in the industry. If you run a general repair shop, you just can do without those.

Let’s have a look:

Tire Machine and Balancer

A tire machine, which you will use to mount and dismount tires, is indispensable in any auto repair shop. This one seems quite obvious for mechanics, but keep in mind that unless you run a detailing shop, you will definitely need one. Even if you run a body shop and think, “I don’t install and replace winter tires like a repair shop, so I don’t need that’, trust me, you are mistaken. Indeed, even if you do not have to suffer through the usual “tire rush” twice a year, and mostly repair crashed vehicles, you’ll eventually come across smashed cars that will need to have their tires replaced every once in a while.

And you really don’t want to have to rely on a manual tire changer either — these things just plain suck, no to mention that they can be quite dangerous, and unless you only need to replace tires once or twice a year, go for a normal tire machine. They aren’t cheap, but they will easily pay for themselves with time.

Read more: Best Tire Changers for Amateurs and Professionals

Of course, you’ll also need a tire balancer to balance the tires once they have been installed. Same here; I would highly suggest going for quality. There’s nothing worse than comebacks for a budding shop, and balancing tires, while relatively simple, still requires quality equipment if you don’t want to start seeing clients complaining about “vibrations at high speed” after a tire replacement.

AC Recovery Machine

The AC recovery machine is a key piece of equipment, especially since pretty much every new modern car now comes equipped with AC as a standard feature. This machine performs several functions: it recovers the refrigerant, recycles it by removing contaminants, and then recharges the system with clean refrigerant. It’s not only essential to maintain and repair AC systems, but it’s also required everytime you need to open an AC system for one reason or another.

Once again, while you may think that’s something only repair shops would need, it couldn’t be farther from the truth. For instance, in a body shop, you will frequently need to remove components of an AC system to replace another component — and since it’s highly illegal, and quite amateurish to be honest, to simply release refrigerant into the atmosphere, you simply can’t do without this one either.

*Quick note: depending on where your repair shop is located, you might need special certification to work on an AC system and operate the related equipment.

Battery Charger and Tester

A professional-grade battery charger and tester are vital tools in diagnosing and resolving battery-related issues. The charger ensures that batteries are fully charged prior to testing while the tester does exactly what you expect it to do: run some tests.

And while you may think a basic “load test” would be more than enough, I strongly recommend a dedicated charger & tester for several reasons. For starters, modern cars are increasingly complicated, now equipped with more electronic equipment than ever before. And while it’s true that a basic load test used to be more than enough when working on a 1983 Ford Escort, it won’t allow you to test for parasitic current drains, capacity, deep discharge and recharge cycles, etc.

Read more: Best Commercial Battery Charger For Professional Auto Mechanics

Also, let’s not forget that once winter is just around the corner, you’ll be seeing “charging system test” quite a lot on your work orders, and when it comes to “fast-moving” tasks, your best bet is always to ensure they get out the door as fast as they get in. And for that, there’s nothing better than a dedicated battery tester. In some cases, mostly with higher-end models, they even have a “charging system test” function that will charge the battery, run all the tests without requiring human input, and print a complete report automatically.

Once you have one of those, you can easily start testing the charging system on pretty much every car that lands in your bay while you do whatever else the client came for. Once you bring the keys back to the owner, you can then easily give him the report and set a future appointment if needed — you will never have sold charging systems services that easily.

Booster Pack

A booster pack, or jump starter, is a portable power source used to start a vehicle when the battery is dead and is essential for providing on-the-spot assistance to customers who face battery issues — or just to boost the cars left with a dead battery in your parking lot by clients and tow truck drivers. No need to say that you will be seeing a lot of those in a repair shop, so it’s better not to cheap out on this one, either.

Modern booster packs are compact (consumer models can sometimes even fit in a glove box nowadays) yet powerful enough to start even large engines. They are a quick and convenient solution and will prevent you from having to push and pull your full-fledged charger around in the rain and snow.

Get a good one and move on.

Read more: 10 Best Portable Car Jump Starters Out There!

Transmission Flush Machine

Let’s talk about a piece of equipment that’s absolutely non-negotiable in today’s auto repair landscape – the transmission flush machine.

In the good old days, checking and changing transmission fluid was a straightforward task. You had a dipstick, you checked the fluid, and if it needed changing, you did it the old-fashioned way. But any mechanic worth his salt knows that many of today’s vehicles, especially the newer models, don’t even come with a transmission fluid dipstick. Sounds like they’re making it hard for the sake of it, right? Well, it’s more about the evolution of automotive technology than anything else.

The reason why modern cars often don’t have a dipstick is due to the complexity and precision of contemporary transmission systems. These systems are designed to be more efficient and provide smoother gear shifts, but they also require a more sophisticated approach to maintenance. This is where your transmission flush machine becomes invaluable.

A transmission flush machine doesn’t just change the fluid; it completely sucks out the old fluid from the transmission system and replaces it with new, clean fluid. Of course, there’s always a way to DIY the whole thing and skip the flush machine, but honestly, if you are serious about your shop, just get one.

Modern transmission systems are tightly sealed and need precise fluid levels to operate correctly. The flush machine ensures that the fluid exchange is done right without leaving any old fluid behind. This level of precision is something you just can’t achieve with traditional methods. Plus, the machine helps to maintain the hydraulic pressure necessary for the transmission to function properly, which is crucial for vehicles that rely on automatic transmission fluid (ATF) for more than just lubrication.

All in all, investing in a quality transmission flush machine isn’t just a good idea; it’s essential for any auto repair shop that wants to keep up with the modern automotive landscape. Not only does it allow you to provide a necessary service for newer cars, but it also helps prevent future transmission issues, ensuring your customers leave happy and their vehicles run smoothly.

In the long run, a transmission flush machine is a smart investment. It enables you to service a wider range of vehicles, keeps your shop up-to-date with the latest automotive technology, and most importantly, it’s a critical step in extending the life of your customers’ vehicles. And in this business, a happy customer with a smooth-running car is the best advertisement you can have.

Lifts and Air Compressors

When it comes to setting up your own garage, two things you can’t skimp on are lifts and air compressors. These aren’t just tools; they’re the backbone of your operation. From personal experience, having reliable lifts and compressors is like having a good right hand in the shop – indispensable.

Having spent years in the trenches, I can tell you firsthand that choosing the right ones isn’t just a matter of preference; it’s about efficiency and reliability.

Let’s talk lifts first. You might be used to working with different types at various shops, but owning one? That’s a whole different story. The key here is to invest in quality. Remember, a lift isn’t just a piece of equipment; it’s what keeps you and the cars safe. Whether it’s a two-post, four-post, or scissor lift, choose one that aligns with the type of work you’ll do most. Think about the vehicles you’ll be handling – will you be dealing more with compact cars, SUVs, trucks? Your lift choice should reflect this. And don’t forget about ceiling height and floor space in your shop when choosing.

Read more: Best 2-Post Car Lifts for DIYers and Professional Mechanics

Now, onto air compressors. These workhorses of the shop power everything from impact wrenches to spray guns. Here’s a tip – bigger isn’t always better. Sure, you want enough power, but you also need something that fits your space and doesn’t drain your energy resources. Look for compressors with a good balance between PSI (pounds per square inch), CFM (cubic feet per minute), and tank size. This balance will ensure you have enough power for your tools without overkilling your energy bill.

A personal bit of advice? Don’t overlook maintenance. Regular servicing of your lift and air compressor can prevent a world of headaches down the line. Keep those moving parts lubricated, check for leaks, and always keep an ear out for any strange noises.

One more thing – as tempting as it may be to go for cheaper, off-brand models to save a few bucks, think long-term. Reliable, well-known brands might be a bigger investment upfront, but they pay off with fewer breakdowns and repair costs. And in this business, time lost is money lost.

Hydraulic Shop Press

A hydraulic shop press is a must-have, especially for tasks like replacing pressed wheel bearings. This piece of equipment may not be in constant use, but when you need it, there’s no substitute.

Pressed wheel bearings are a common feature in modern vehicles, and they require precise force to remove and install. This is where the hydraulic shop press comes in, offering controlled power, allowing you to handle bearings without damaging the bearing or the hub. I’ve learned over the years that trying to hammer out a pressed bearing not only takes more time but also risks damaging the components. The shop press, on the other hand, does the job cleanly and efficiently.

Here’s a bit of advice from someone who’s been there: when choosing a shop press, don’t just go for the highest tonnage you can find. Consider the space you have in your shop and the types of vehicles you’ll be servicing. A 12-ton press is often more than enough for most light to medium-duty tasks, including wheel bearings.

One of the tricks of the trade I’ve picked up is to invest in a good set of bearing press kits and adapters. These kits are lifesavers, making the job easier and helping to prevent damage to the bearings or hubs. They come in various sizes and shapes, allowing you to work on a wide range of vehicles.

Maintenance of your shop press is straightforward but crucial. Keep it clean, regularly check for hydraulic fluid levels, and ensure the moving parts are well-lubricated. A well-maintained shop press is a reliable tool that can last years, even in the busiest of garages.

It’s one of those investments that might not see daily use but proves its worth in efficiency and professionalism when tackling jobs like replacing pressed wheel bearings. Plus, it opens up the scope of services you can offer, adding value to your business.

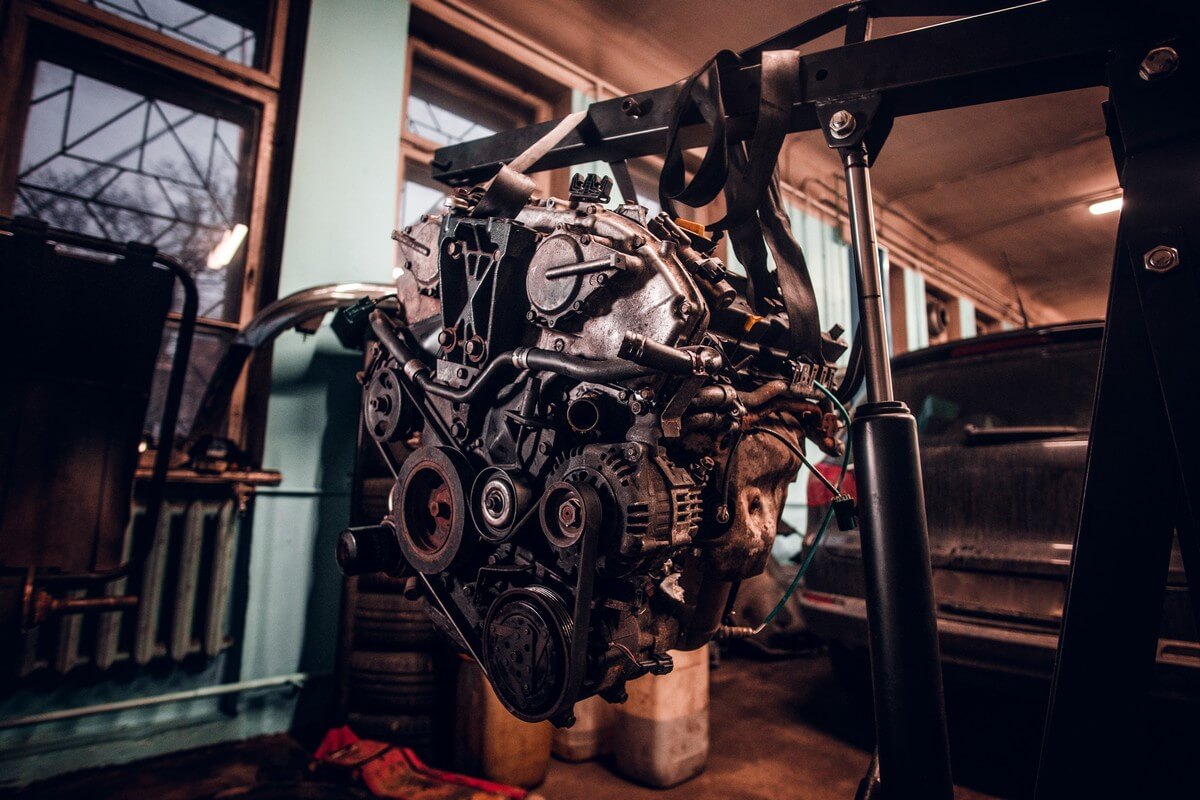

Engine Crane

An engine crane is also one of those tools you might not use every day, but when you need one, you really need one. This is especially true if you’re planning to open your own shop and anticipate doing significant engine work, including engine removals or installations.

When selecting an engine crane, consider the weight capacity and the space you have in your shop. A typical 2-ton engine crane is usually sufficient for most standard passenger vehicles and light trucks. However, if you plan to work on larger vehicles, you might need something with more lifting power. Another factor to consider is the crane’s reach and how far it can extend; this is crucial for properly aligning and maneuvering engines, especially in tight spaces.

Look for an engine crane with a sturdy build, good hydraulic ram, and smooth casters. The smoother the crane moves, the easier your job will be, especially when navigating a heavy engine around the shop. Also, consider a model with foldable legs if your shop space is limited; it makes storage much easier.

Welding Machine (MIG)

This one really depends on the kind of work you’ll be doing on a regular basis and how good your welding skills are, but if it’s your style, a MIG welder can make a world of difference in a repair shop. I have to admit I was never much of a welder and basically found ways to do what I needed to do without a welding machine, let’s say, 99% of the time, but I know it would have saved me a bunch of headaches at times.

Still, it’s important to mention that I was able to reach this point in my career without really needing to learn to weld myself mostly because I worked for several years as a mechanic in a body repair shop, and body repairmen are usually quite good at welding (a lot better than I am, at least), and they were always happy to help.

But in the end, no matter whether you are the master welder yourself or prefer to do like me and ask for help instead, in any case, you’ll still need a welding machine!

So, as you set out to equip your shop, consider a MIG welder a priority. Why MIG, specifically? Well, based on my personal experience, MIG welding strikes the perfect balance between versatility, ease of use, and efficiency. It’s ideal for a range of applications, from thin sheet metal to thicker structural components, making it a go-to for most auto repair tasks — and bonus, it’s also probably the easiest type of welding and you don’t really need to be a master welder when working on an exhaust.

When choosing a MIG welder, think about the type of work you’ll be doing most. If you’re mainly dealing with car body repairs, a welder with a good range for thinner metals is key. For more heavy-duty tasks, you’ll want a machine that can handle thicker materials without a hiccup. Also, consider a welder with adjustable settings; it allows for more precision and control, which is crucial for quality workmanship.

Don’t overlook the importance of a good wire feed system. A smooth, consistent wire feed is crucial for stable and clean welding. And speaking of consumables, always keep a good stock of welding wire and replacement tips – there’s nothing more frustrating than running out in the middle of a job.

Oxyacetylene Torch

In a repair shop, the oxyacetylene torch holds a special place. As a mechanic, you might be well-acquainted with its power and versatility, and if you’re setting up your own shop, you know it needs to be on top of your shopping list. But if you are just starting out in the field, you might not have seen yet everything it can do and why you just can’t live without one.

The oxyacetylene torch is a go-to tool for cutting through thick metal, which can be crucial when dealing with parts that are too tough for standard saws or cutters; think of sway bar links here. It’s also particularly useful to remove rusted, seized or stripped bolts – a common headache in auto repair.

Welding is another area where the oxyacetylene torch excels, especially when filling a hole or joining two exhaust pieces; the torch provides the control needed for strong, clean welds. But its utility doesn’t stop at cutting and welding. The oxyacetylene torch is also excellent for heating and bending metal components, enabling custom modifications or repairs that would be difficult to achieve otherwise. This flexibility is particularly valuable in a repair shop, where each job can bring unique challenges.

As a mechanic stepping into running your own shop, mastering the oxyacetylene torch is all about enhancing the services you can offer and speeding up the whole process

Still, never forget that, while the torch is incredibly useful, it’s also a tool that demands respect and caution. Always adhere to safety protocols while using it. Proper ventilation, fire safety measures, and personal protective equipment are non-negotiable when it comes to using an oxyacetylene torch.

Strut Compressor

A strut compressor is an essential tool in any auto repair shop, especially for those handling suspension work. This tool lets you safely compress the springs on a vehicle’s strut to remove and reinstall the components. If you’ve ever tried it before, you know very well that attempting to work on struts without a compressor is not just challenging but downright dangerous. And if you never tried it, well, don’t.

The springs in the strut assembly are under significant tension, and the compressor is what allows you to handle this tension safely. I know some guys will tell you that you can just put your weight on it or hold it on the floor with your foot while removing the nut, but yeah, nah… that’s not the kind of shop you want to run, right?

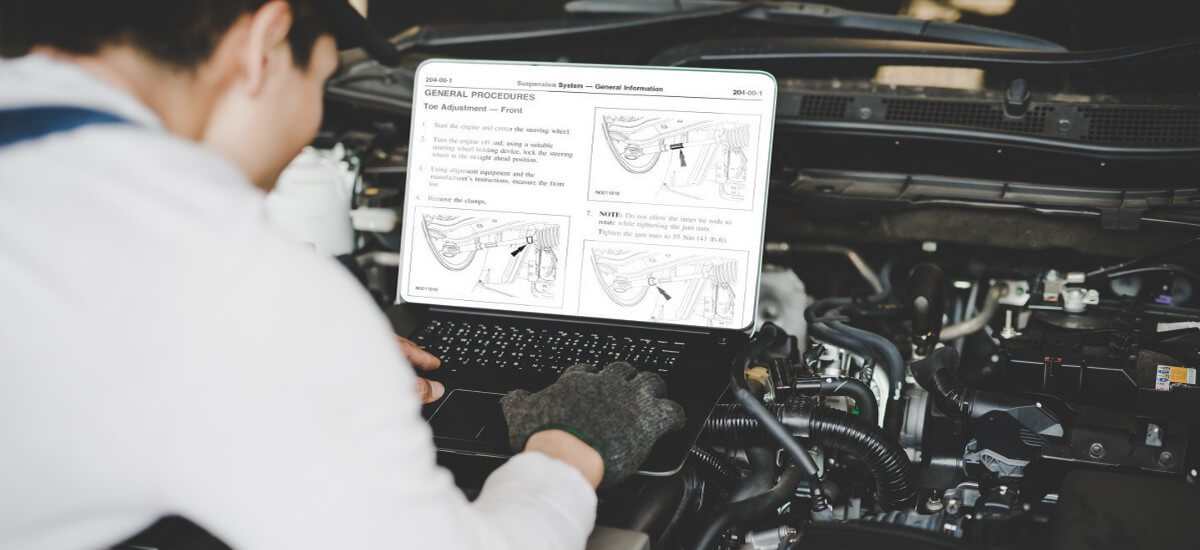

Repair Manuals

Now, I know what you might be thinking: we sell these manuals, so of course, we’re going to say they’re essential. But bear with me – there’s a good reason why they’re indispensable in a professional garage, and it’s not just because it’s our business.

In all my years turning wrenches, I’ve found that having the right repair manual at hand is like having an old, wise mentor guiding you. These manuals are more than just books; they’re a comprehensive source of information for diagnosing and fixing cars. With vehicles getting more complex by the day, a detailed repair manual is your best friend in decoding the mysteries under the hood.

Think about it – every car that rolls into your shop is a unique challenge. Different makes, models, and years, each with their own quirks and systems. A repair manual cuts through the guesswork, offering step-by-step instructions, from troubleshooting to detailed repair processes. It’s not just about saving time; it’s about doing the job right the first time.

Now, sure, we’ve all been in situations where I thought I could wing it without the manual, and I sure did it too — when you don’t have it, you don’t have it. This car will still not fix itself. Still, more often than not, it ended up costing me more time and headaches. And in a repair shop, those two cost money, a lot of it. So in the end, of course, you can still keep doing all those jobs you’ve done a million times by heart. But when you are working on something new or a bit more tricky than usual, just get the manual.

You’ll thank me later.

➤ Download all the repair manuals your shop needs here!

Tools for Effective Operations

In addition to the main equipment, there are essential tools that a shop owner should provide to his mechanics to ensure effective and efficient operations. These tools play a critical role in the day-to-day functioning of an auto repair shop.

For those just starting out in the trade, remember this article is not meant to be a beginner’s guide to filling your personal tool chest. This is about the tools you, as an aspiring shop owner, need to provide to keep your shop humming along without a hitch.

If you are indeed looking for recommendations regarding the tools you want to have in your tool chest, as well as tips and tricks on how to make sure you get your money’s worth, you’ll find everything you need right here!

OBD2 Scan Tool

First off, the OBD2 scan tool. In today’s world, where cars are practically computers on wheels, this tool is your key to unlocking a vehicle’s health status. It’s the bridge between you and the complex electronic systems of modern vehicles. The OBD2 scanner is your first line of defense against the maze of error codes and electronic issues you’ll face.

Investing in a quality OBD2 scanner is non-negotiable. Go for one with wide vehicle coverage and ensure it’s regularly updated. The right scanner can mean the difference between a quick diagnostic and hours of guesswork. It’s all about getting to the heart of the problem efficiently and accurately.

Jack

Now, let’s talk about jacks. No shop can function without a reliable jack. It’s your basic, go-to tool for lifting vehicles, whether it’s for a quick tire change, brake job, or something more. The variety here is vast – floor jacks, bottle jacks, scissor jacks – but the key is to choose one that’s robust and reliable. Look for jacks with a smooth lifting mechanism and a stable base. Safety and stability are paramount here – a failing jack under a two-ton vehicle? That’s a nightmare you don’t want.

Read more: 10 Best Floor Jacks for Amateurs and Professionals

Jack Stands

Hand in hand with a good jack are jack stands. These aren’t just accessories; they’re essential safety gear. Once a vehicle is hoisted up, jack stands keep it securely in place, allowing safe access underneath. This isn’t the place to cut costs – sturdy, reliable jack stands can save lives and prevent accidents. Make sure they’re rated for the weight and types of vehicles your shop will handle.

Oil Drain Pan

An oil change might seem mundane, but it’s the bread and butter of many auto repair shops. And nothing makes oil changes easier than a good oil drain pan. You want one that’s large enough to catch oil without spills and easy to maneuver under different vehicles. Some of the best pans out there come with features like spouts or pumps for transferring used oil – a small detail that can make disposal a whole lot cleaner and environmentally friendly.

Brake Bleeder Kit

Lastly, let’s touch on the brake bleeder kit. Brake work is a staple in any auto repair shop, and a good bleeder kit is crucial for this task. It’s about more than just bleeding brakes; it’s about ensuring the brake system operates safely and effectively. A quality kit can transform brake maintenance from a two-person chore into a streamlined, one-person job. Efficiency and safety in brake work? That’s what a good bleeder kit brings to the table.

Investing in Specialized Tools for Advanced Repairs

If you’re aiming to set your auto repair shop apart and truly go pro, then gearing up with some specialized tools is a game-changer and will allow you to offer a broader range of services. Let’s dive into some of these specialized tools that can transform your shop into a one-stop auto repair hub.

Cooling System Testing Kit

In my years on the job, I’ve seen my fair share of engine overheating issues. A reliable cooling system testing kit is your first line of defense here. It typically includes a pressure tester to spot leaks in the system and a thermometer to gauge coolant temperature. But here’s a pro tip: get a kit with a variety of adapters for different radiator caps. This way, you’re ready for whatever rolls into your shop, be it an old beater or the latest model.

Fuel Line Disconnect Kit

Next up is the fuel line disconnect kit. This toolkit is essential for working on fuel systems with precision and safety. Whether it’s replacing fuel filters or fixing leaks, these tools help you disconnect lines without causing damage. Remember, the variety of connectors in different vehicles can be vast, so a comprehensive kit is your best bet. It’s about being prepared for any job, big or small.

Noid Lite Kit

Now, let’s talk about a tool that’s a bit of a secret weapon in the mechanic’s arsenal: the Noid Lite Kit. This handy diagnostic tool might not be the star of the show every day, but when it comes to fuel injection issues, it’s your unsung hero, helping you pinpoint if the issue is electrical or if it’s time to dig deeper.

For instance, if you’re dealing with a stubborn no-start situation, a Noid Lite can quickly tell you if the injectors are getting the signal they need. It’s about pinpointing problems with precision, saving you time, and eliminating guesswork.

The beauty of the Noid Lite Kit lies in its simplicity and effectiveness. It’s a small tool that packs a big punch in diagnostic capabilities, especially in an era where electronic fuel systems are the norm. Adding this to your shop’s tool chest marks you as a mechanic who knows the ins and outs of modern auto repair.

AC System Leak Detector Kit

Air conditioning repair is not just common; it can be quite profitable. An AC system leak detector kit is critical for finding those elusive leaks. Many kits include UV dyes and a UV light, which make spotting leaks a breeze. Some even come with sniffers to detect refrigerant gases. Quick detection and repair of AC leaks can save a customer’s system and make you their go-to mechanic for AC issues.

Hydraulic Tubing Flaring Tool Set

Although significantly less used nowadays, if you work on older vehicles, classics, racecars, or anything with some serious mods, you’ll a good brake line flaring kit.

What I’ve learned over the years is that the right flaring tool doesn’t just make the job easier; it also makes the job A LOT easier. Haha.

I used to HATE flaring brake lines, but that was before I learned about hydraulic flaring tools. I’m not exactly sure if they were not invented when I started or if I was the only one who had no idea there was an alternative to the metal clamp-like device with a screw-in cone that presses into the tube and never works quite well so you have to start over twice or what but, anyway, the hydraulic ones actually work right.

So yeah, get one of those, even if you don’t think you need one. When you do, you’ll be a happy camper.

Work smarter. Not harder.

Read more: 7 Best Brake Line Flaring Tools

Tips and Tricks on How to Shop for Tools

When setting up your auto repair shop, knowing how to choose the right tools is as crucial as the tools themselves. Here are some seasoned tips to guide you in making wise tool investments, especially when budget constraints are in play.

Understand Your Needs First

Before diving into purchases, take a moment to consider the services your shop will focus on. What tools are essential for these jobs? This step is about being strategic – it’s easy to get carried away with flashy gadgets, but it’s smarter to invest in high-quality essentials that align with your shop’s core services.

Quality Over Quantity

In the toolbox of a seasoned mechanic, quality tools are the backbone. They last longer, ensure safety, and maintain accuracy in repairs. Don’t be swayed into thinking the most expensive tools are always the best. Instead, seek out tools that offer the best balance of quality and cost, ones that bring true value to your daily operations.

Consider the Long-Term Cost

Looking at the price tag is just the beginning. Think about the long-term – maintenance, repair costs, and the lifespan of the tool. Sometimes, a cheaper option ends up being more expensive in the long run due to frequent repairs or replacements. A sturdy, slightly pricier tool can often be the more economical choice over time.

Research and Compare

Do some digging before you buy. Read reviews, compare prices, and get a feel for different brands’ reputations. Don’t underestimate the wealth of knowledge in mechanic forums and online communities – these places can offer invaluable insights and real-world experiences with various tools and equipment.

Look for Deals and Discounts

Keep an eye out for deals. Sales, off-season discounts, and bulk purchase offers can significantly reduce costs. Also, don’t discount the idea of refurbished or gently used tools for tasks that are less critical. These can be cost-effective options that still perform well.

Warranty and After-Sales Service

A solid warranty and reliable after-sales service are not just add-ons; they’re key factors in your purchase decision. A good warranty can be a lifesaver if a tool breaks down. Also, consider how readily available spare parts are and the ease of servicing the tool.

Don’t Rush Your Purchases

Finally, take your time with these decisions. As your shop grows, so too will your understanding of what tools best suit your specific needs. Rushed decisions often lead to regretted purchases. Patience and careful consideration are your allies in building a well-equipped shop.

Frequently Asked Questions (FAQ)

What are the must-have tools for starting an auto repair shop?

When kicking off an auto repair shop, certain tools are non-negotiable. You’ll need a dependable jack and sturdy jack stands for safe vehicle lifting. An OBD2 scan tool is crucial for modern diagnostic work. Don’t forget a comprehensive set of wrenches and screwdrivers – these are your daily drivers in the shop. A tire machine and balancer are key for tire services, and an air compressor is essential for powering various pneumatic tools. Lastly, a reliable welding machine is indispensable for metalwork and repairs. Remember, the exact toolkit may vary depending on the range of services your shop intends to offer.

What should I consider when choosing a supplier for my tools and equipment?

Selecting the right supplier is critical. Look for a supplier known for quality and stellar customer service. The ideal supplier offers a diverse range of products at competitive prices, coupled with strong after-sales support. Choose suppliers who have a deep understanding of the auto repair industry and can offer valuable insights and advice on tool selection. This relationship is not just transactional; it’s a partnership that can significantly impact the quality of service you provide.

Should your shop provide hand tools for mechanics?

Providing basic hand tools in your shop can be a smart move. It’s particularly beneficial for apprentices or entry-level mechanics who may not have their own set yet. However, seasoned mechanics often prefer to use their personal tools. If you decide to provide hand tools, focus on high quality and regular maintenance. This not only ensures efficiency but also helps in creating a professional and respectful work environment, which is key to attracting and retaining skilled mechanics.

Should you buy or lease equipment needed for an auto repair shop?

The decision between buying or leasing equipment boils down to your shop’s budget and long-term strategy. Purchasing equipment is a long-term investment that can be more economical over time. Leasing, however, demands less upfront capital and offers flexibility, especially for high-cost equipment or items that might require frequent upgrades due to technological advancements. Weigh the pros and cons based on your shop’s specific needs and growth plans.

How do you maintain your shop’s tools and equipment so they last?

Tool and equipment longevity hinge on regular maintenance. Establish a maintenance routine in line with the manufacturer’s guidelines. This includes keeping tools clean, lubricating moving parts, and proper storage. Regular inspections for wear and timely repairs or replacements are crucial. Also, educating your staff on correct tool handling and care extends the life of your equipment and ensures operational efficiency in your shop.

Last Words

Embarking on the journey to open and run your own auto repair shop is like setting off on a grand adventure. It’s a road filled with twists and turns, challenges and triumphs. The tools and equipment you choose? They’re not just purchases. They’re the bedrock of your future business, the trusty companions you’ll rely on every step of the way. The choices you make now in equipping your shop are going to echo down the road of your business’s journey.

But here’s the real kicker: it’s not just about cost, quality, or necessity. It’s about striking a balance. Every tool, every piece of equipment you bring into your shop is a testament to the service you’re going to provide. It’s about ensuring customer satisfaction, not through flashy gadgets or the biggest showroom, but through dependable, efficient, high-quality service.

Think of your shop like a well-oiled machine, and your tools are the cogs that keep it running smoothly. You’re not just a mechanic; you’re a conductor, and your tools are the orchestra. The symphony you create is what brings customers back and builds your reputation.

So, as you stand at the threshold of this new venture, remember: the heart of a thriving auto repair shop beats with the ability to deliver reliable and superior services. This capability is deeply rooted in your choices of tools and equipment.

End your day with the satisfying clink of tools well used, the hum of a job well done, and the knowledge that you’re not just building cars; you’re building dreams on four wheels. That’s the spirit of a true mechanic, and that’s the spirit that will turn your shop from a mere workspace into a legend in its own right.