Amplitex has many advantages over carbon fiber, including lower price, lower emissions, and easier manufacturing, without sacrificing strength.

Carbon fiber is a popular material in the automotive industry to produce lightweight components with high tensile strength. Higher-end cars have loads of carbon fiber in them, and it’s easily one of the most significant discoveries in automobile manufacturing. Companies love using the material due to the various aspects it brings to a vehicle. The material is strong, rigid, and lightweight, a necessary thing to build a high-performance machine.

However, producing carbon fiber comes with a lot of disadvantages. The cost of production is high, and the materials are hard to come by. Thus, many companies have been looking into cheaper alternatives to carbon fiber for a while now. Enter Bcomp, a Swiss company, and its natural fiber called Amplitex.

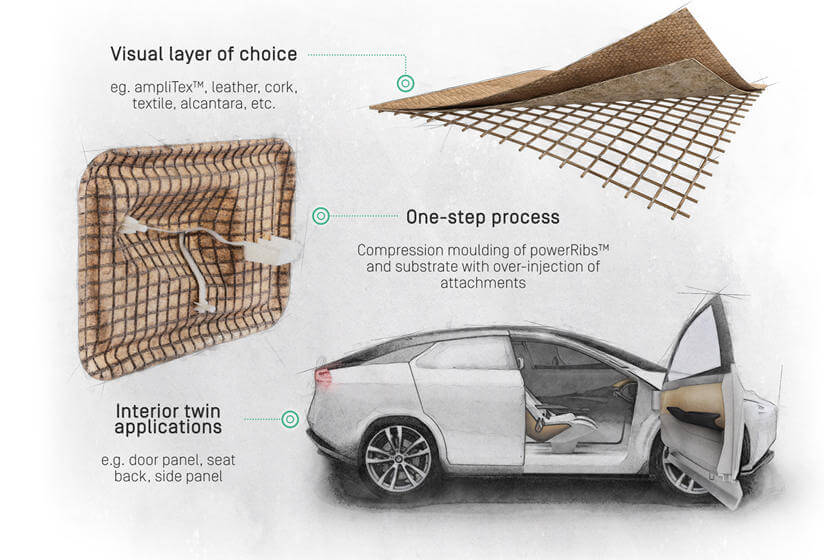

Bcomp creates Amplitex by combining flax and epoxy resin, producing a super-strong material. Amplitex, like carbon fiber, can be woven into almost anything, with just the right thickness and rigidness. For the production of body parts, Amplitex is lined with ‘Powerribs’ on the inner side to give a 3-D structure rigidness to the component.

Meanwhile, carbon-fiber production emits a lot of CO2. To kickstart the carbonization process, manufacturers need to ramp up the temperature from 1000 °C to 3000 °C, which requires a lot of energy. Moreover, there is no way to recycle carbon fiber to make new parts. Furthermore, Amplitex and Powerribs reduce carbon emission by 75% compared to carbon fiber. Amplitex really seems to be a win-win here, considering it requires less energy and emits less CO2.

All these factors make the production of Amplitex 30% cheaper than carbon fiber. These are big numbers in the industry and can decrease mass production costs by a lot.

Interestingly, the innovative material already saw its racing debut. McLaren’s Formula 1 team used Amplitex to build seats for Carlos Sainz’s and Lando Norris’ cars this year. Also, Porsche’s new Nürburgring 24-hour race car, the Cayman 718 GT4 CS MR, has a body made from Amplitex and Powerribs.

But its use doesn’t stop in racing. Swedish Polestar has partnered with Bcomp to produce its concept’s interior only using Amplitex and Powerribs, which is moving to mass production in 2021. Amplitex is making lots of waves in the automotive industry, and we can’t wait to see how manufacturers use it.

To be continued…