The automotive industry is undergoing a significant transformation, and one of the key changes is the shift from traditional 12-volt electrical systems to 48-volt architectures, an evolution driven by the increasing power demands of modern vehicles, the need for better fuel efficiency, and stricter emissions regulations.

For decades, cars have relied on 12-volt electrical systems to power everything from headlights to the radio. However, as vehicles have become more advanced, this system has started to struggle to keep up with the power needs of newer technologies. So, this is where 48-volt systems come in as a more powerful electrical system that can handle the growing demands of today’s cars.

Moreover, as we move towards a future where electric and hybrid vehicles become increasingly more common, 48-volt systems will play a vital role in ensuring cars can meet the requirements of modern technology. Eventually, this new electrical architecture is poised to replace the old 12-volt system, paving the way for more advanced, efficient, and sustainable vehicles.

Since we’ll eventually have to repair these systems, we thought it would be a good idea to start exploring what 48-volt vehicle architecture is and how it differs from the traditional 12-volt systems it is set to replace. After all, you can’t fix what you don’t understand, right?

So, to help you with that, here is everything you need to know about 48-volt automotive systems.

The Evolution of Automotive Electrical Systems

The journey of modern automotive electrical systems began in the 1950s when cars transitioned from 6-volt to 12-volt systems. This change was primarily driven by the need to support more powerful electrical components, especially the ignition systems required for higher-compression engines. The 12-volt system quickly became the industry standard due to its ability to provide a stable and reliable power supply for various vehicle functions.

For over 70 years, the 12-volt system has been the backbone of automotive electrical architecture. It powers essential components such as headlights, wipers, radios, and, more recently, high-tech infotainment systems and electronic safety features. Despite its long-standing dominance, the 12-volt system is now reaching its limits. Modern vehicles are equipped with a growing number of power-hungry devices, from heated seats and steering wheels to adaptive suspensions and driver-assistance systems. This increased demand has highlighted the limitations of the 12-volt architecture.

Why Transition to 48-Volt?

With the traditional 12-volt systems struggling to keep up with these demands, leading to inefficiencies and performance bottlenecks, enters the 48-volt system. This higher-voltage system offers a significant boost in power delivery while addressing the shortcomings of its predecessor.

The primary advantage of a 48-volt system is its ability to deliver higher power with a lower current. According to Ohm’s Law (V=IR), increasing the voltage reduces the current required for a given power output, assuming a fixed resistance. Lower current means smaller, lighter wiring can be used, reducing both weight and cost. Additionally, higher voltage systems reduce energy loss as heat, further improving efficiency.

Automakers began exploring higher voltage systems in the late 1990s and early 2000s to support the growing power needs of modern vehicles. However, the industry was initially hesitant due to the costs associated with retooling manufacturing lines and supply chains. As technological advancements continued, the benefits of 48-volt systems became undeniable, leading to a gradual shift in adoption.

Regulatory pressures have also played a crucial role in driving the transition to 48-volt systems. Governments worldwide are implementing stricter fuel economy and emissions standards to combat climate change and reduce pollution. By supporting hybridization and enabling more efficient power management, 48-volt architectures help reduce the load on internal combustion engines (ICEs). This results in better fuel economy and lower emissions, making it easier for automakers to comply with stringent regulations.

What is 48-Volt Vehicle Architecture?

48-volt vehicle architecture represents a significant upgrade from the traditional 12-volt systems that have powered vehicles for decades. At its core, a 48-volt system involves a higher voltage electrical network within the vehicle that provides more power for modern automotive features and components. This system includes several key components that work together to deliver this improved performance:

- Electric Generator: Unlike traditional alternators, the electric generator in a 48-volt system is designed to handle higher voltage, converting mechanical energy from the engine into electrical energy more efficiently.

- Larger Battery: The battery in a 48-volt system is typically larger and more powerful than a 12-volt battery. It stores the electrical energy needed to power various vehicle systems and provides a reliable source of power during engine-off conditions, such as start-stop operations.

- Regenerative Brakes: Regenerative braking is a crucial feature of 48-volt systems. It captures and stores energy that would otherwise be lost during braking, improving overall energy efficiency and extending the vehicle’s range.

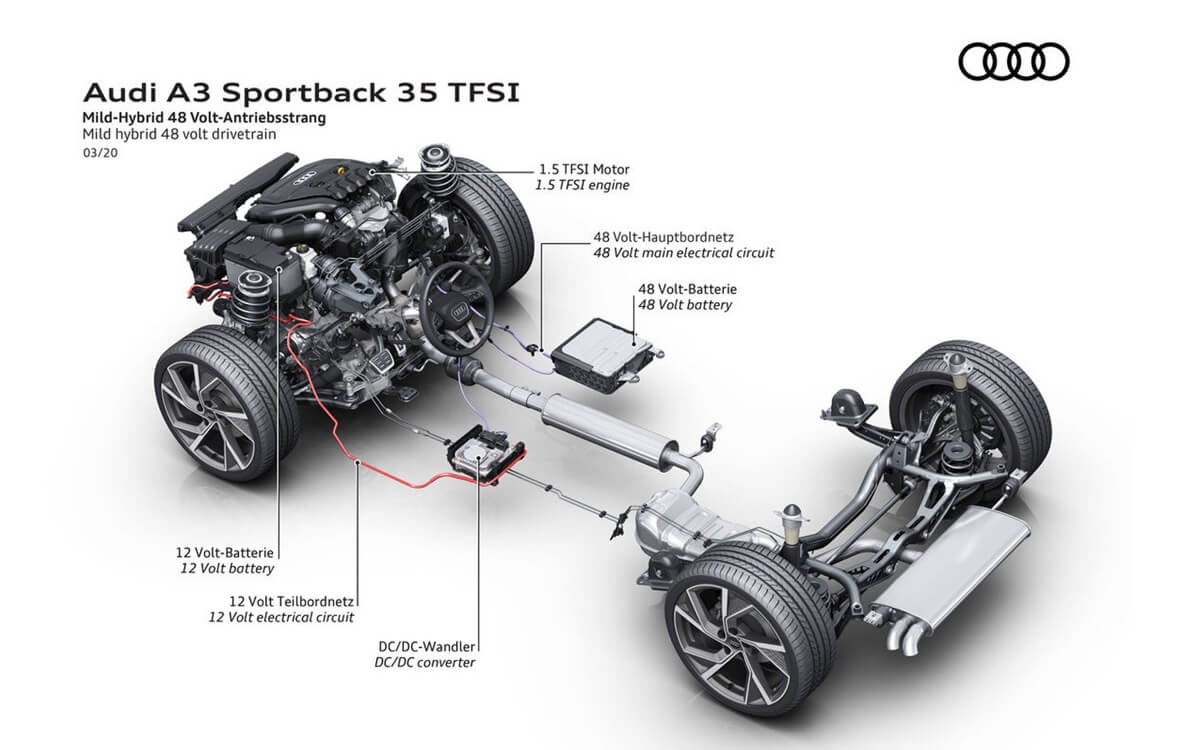

- DC-DC Converters: These converters are essential in vehicles with mixed voltage systems. They step down the 48 volts to 12 volts (or lower) to power traditional components that have not been upgraded to 48 volts. This allows for a gradual transition without requiring a complete overhaul of all vehicle systems.

How Does It Compare with Traditional 12-Volt Systems

Component |

12-Volt System |

48-Volt System |

|---|---|---|

| Battery | Standard 12-volt lead-acid battery | Larger, more powerful battery |

| Electric Generator | Traditional alternator | High-efficiency electric generator |

| Regenerative Brakes | Not common | Standard feature, improves energy efficiency |

| DC-DC Converters | Not needed | Essential for step-down to 12 volts |

| Start-Stop Systems | Basic, slower restart | Advanced, smoother and faster restart |

| Infotainment Systems | Basic functionality | Advanced, power-hungry features |

| Advanced Safety Systems | Limited support | Full support for high-tech systems |

| Air Conditioning | Standard | More efficient, maintains performance during engine-off |

The primary difference between 48-volt and 12-volt systems is the amount of power they can deliver. While a 12-volt system has been sufficient for basic vehicle functions, it struggles to meet the demands of modern automotive technologies. In contrast, a 48-volt system can handle higher power requirements with greater efficiency and reliability.

For example, in a 12-volt system, powering a 950-watt load would require a substantial current of about 79 amps, necessitating thick and heavy 4 AWG wiring. This not only adds weight to the vehicle but also increases costs. On the other hand, a 48-volt system can deliver the same power with just 20 amps, allowing for much thinner and lighter 10 AWG wiring. This results in an 85% weight reduction in the wiring alone.

Additionally, higher voltage systems like 48 volts reduce resistive losses. In a 12-volt system, significant power is lost as heat due to the high current passing through the wiring. With 48 volts, the current is lower, reducing these losses and improving overall energy efficiency. This efficiency gain is crucial for electric and hybrid vehicles, where maximizing range and performance is a top priority.

Current Adoption and Future Prospects

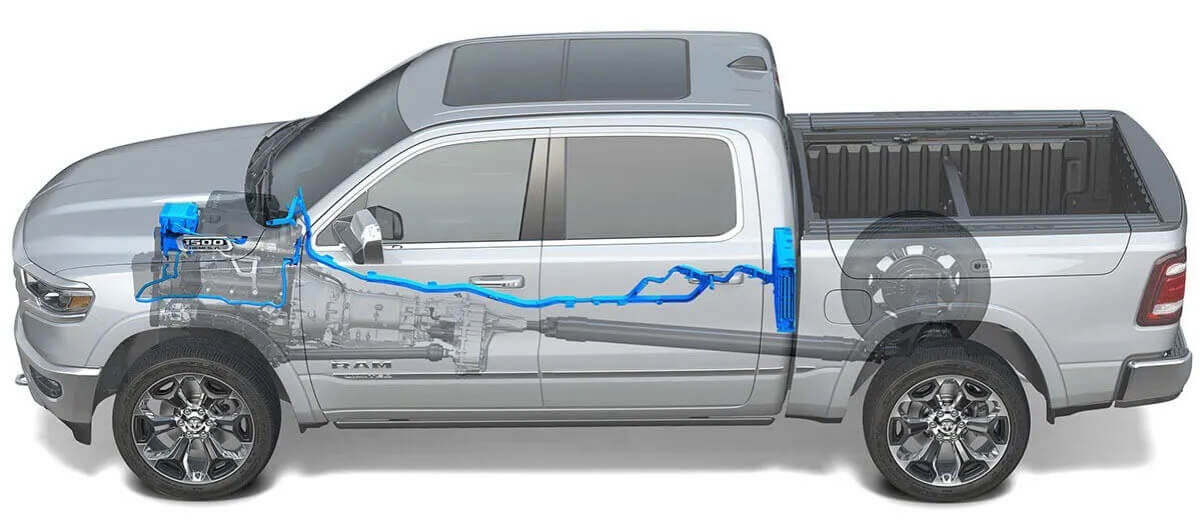

Since 2011 German car manufacturers like BMW, Mercedes-Benz, and Volkswagen decided to add a 48V system alongside the existing 12V one. This change was mainly to help with powering the vehicle’s electronics more efficiently.

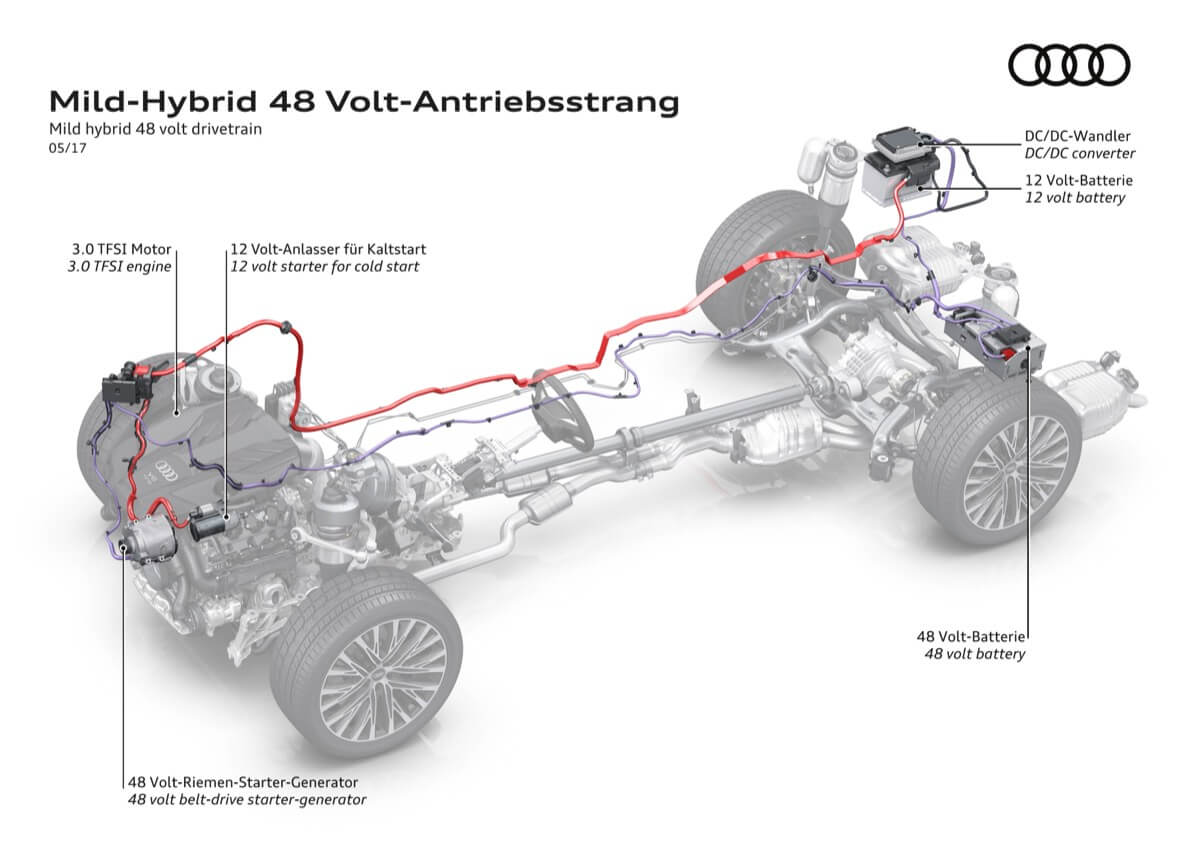

By 2018, this 48V subsystem was operational in mass-produced mild-hybrid vehicles (MHEVs), including Audi vehicles with the 3.0 TDI 48V mild-hybrid and Mercedes with the M256 3.0 Turbo Otto 48V Mild-Hybrid. The following year, Hyundai and Kia followed suit, with models like the Tucson, Santa Fe, Ceed, and Sportage equipped with 48V mild-hybrid technology in their 1.6 and 2.0 turbodiesel engines.

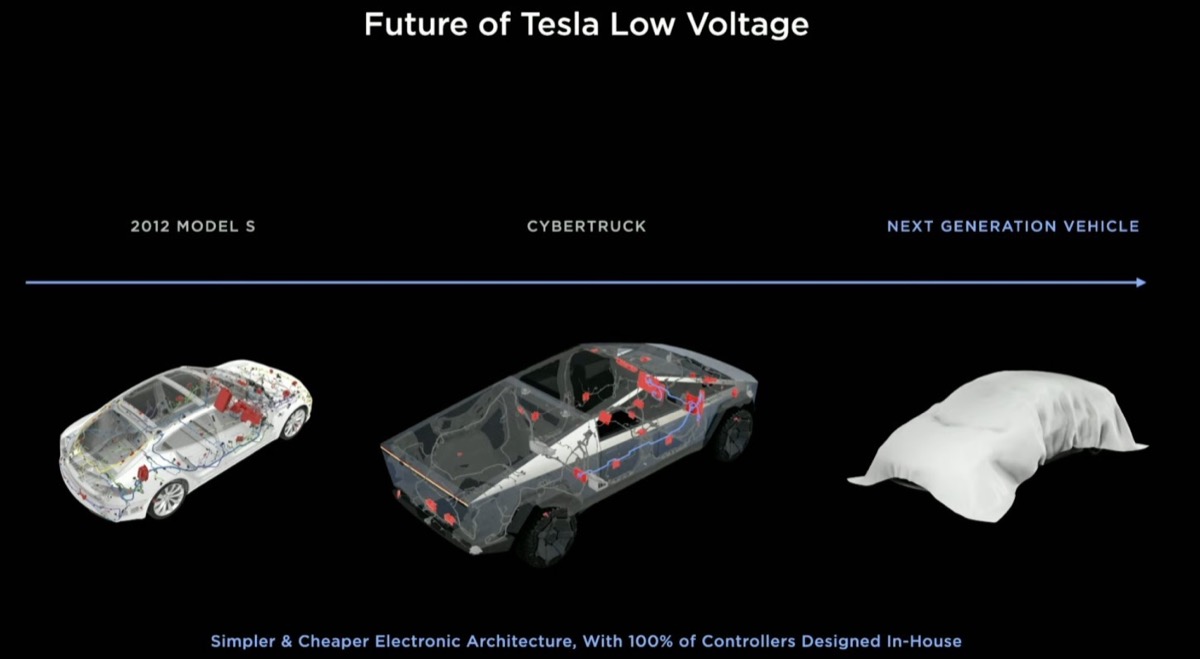

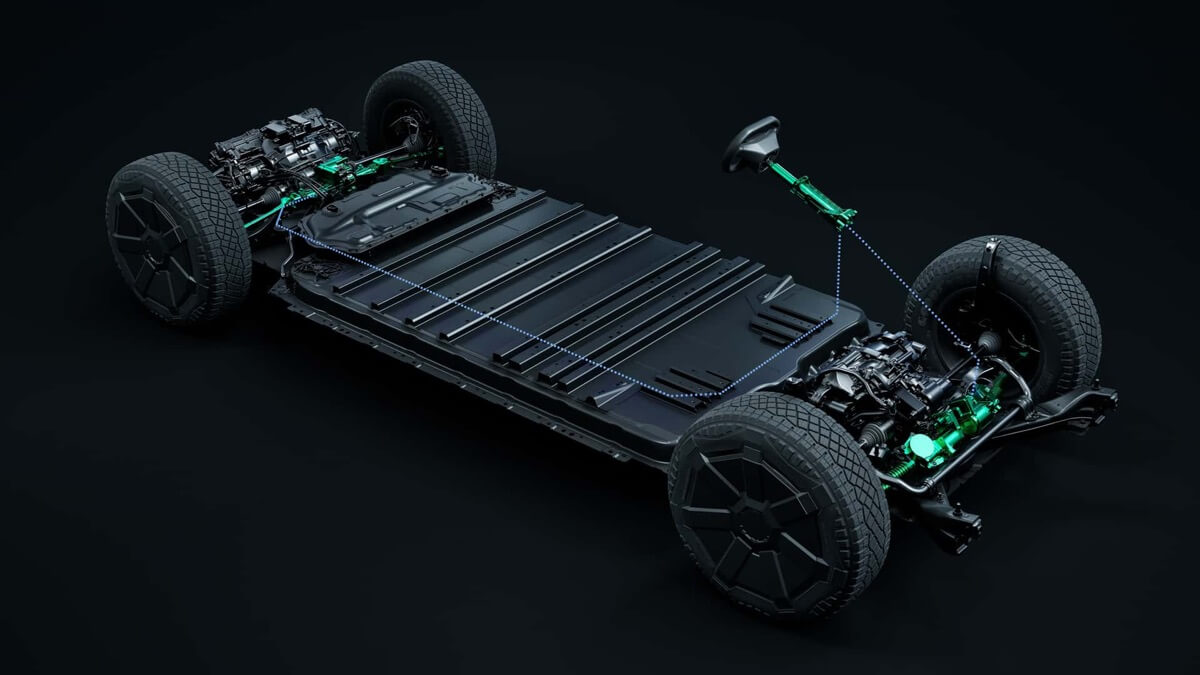

And with the re-release of the Tesla Cybertruck in late 2023, the world now has its first vehicle to utilize a 48-volt system to power low-voltage components, that would’ve otherwise been powered by a 12V system. Tesla then kindly shared a detailed guide, called “48-volt electrical system whitepaper”, to all industry leaders so they could all make a smooth transition too.

The future of 48-volt systems looks promising as more automakers recognize the benefits and begin to implement this technology in their new models. As battery technology improves and costs decrease, the adoption of 48-volt systems is expected to accelerate, paving the way for more efficient, powerful, and sustainable vehicles. In fact, the European Association of Automotive Suppliers (CLEPA) projected one in every ten new cars would have at least one 48-volt component by 2025, amounting to about 15 million vehicles a year.

Benefits of 48-Volt Systems

The shift to 48-volt systems in automotive design brings numerous advantages that address the limitations of traditional 12-volt systems, such as:

Improved Efficiency and Performance

One of the most significant benefits of 48-volt systems is their ability to improve vehicle efficiency and performance. It’s been proven many times that 48-volt systems can handle the power demands of modern vehicles more efficiently while using less energy. Not to mention the higher voltage systems also reduce the current required for a given power output, which lowers resistive losses where energy is wasted as heat in the wiring.

Additionally, by supporting hybridization and enabling the use of electric motors to assist the ICE, 48-volt systems can significantly improve fuel economy. MHEVs, for example, use 48-volt motor generators to provide additional torque during acceleration and to recover energy during braking, leading to better fuel efficiency.

Cost and Weight Savings

The transition to 48-volt systems also brings considerable cost and weight savings, highly beneficial for both automakers and consumers. Higher voltage allows for the use of thinner, lighter wiring, which reduces the overall weight of the vehicle. This weight reduction translates into better fuel economy and performance.

Furthermore, compared to high-voltage systems, 48-volt systems are relatively inexpensive to implement. They don’t require the stringent safety measures and costly components needed for systems above 60 volts, making them a cost-effective solution for improving vehicle performance and efficiency.

Enhanced Electrical Features

Modern vehicles are equipped with a wide range of electrical features that demand more power than ever before. The increased power capacity of 48-volt systems can support more sophisticated infotainment and safety systems, providing a better driving experience and improved comfort. For instance, features like adaptive cruise control, lane-keeping assist, and advanced infotainment systems benefit from the higher power availability.

Additionally, 48-volt systems enhance the performance of everyday convenience features, such as faster seat heating, quicker windshield defrosting, and more efficient air conditioning. The system even made it possible for carmakers to unlock unseen features like the steer-by-wire found on the Tesla Cybertruck, making maneuvering such a large vehicle easier than ever.

Improved Reliability and Durability

Another critical benefit of 48-volt systems is their potential to increase the reliability and durability of vehicle components. Electrical components in a 48-volt system often have fewer moving parts compared to their lower-volt counterparts. For example, electric water pumps and electric power steering systems are more reliable over time than traditional belt-driven systems, as they are not subject to the same wear and tear.

Moreover, the reduced current in 48-volt systems places less stress on electrical components, extending their lifespan. This can lead to fewer repairs and lower maintenance costs over the lifetime of the vehicle.

Environmental Benefits

Indeed, the environmental impact of vehicles is a major concern for both automakers and consumers. 48-volt systems contribute to reducing the environmental footprint of modern vehicles. By improving fuel economy and enabling the use of hybrid technologies, this newer systems help reduce greenhouse gas emissions. Mild hybrids with 48-volt architectures can achieve significant reductions in CO2 emissions, contributing to cleaner air and a healthier environment.

Moreover, as the automotive industry moves towards greater electrification, 48-volt systems play a crucial role in this transition. They provide an intermediate step between traditional ICEs and fully electric vehicles, making it easier for manufacturers to adopt electrification technologies and meet regulatory standards.

Challenges and Limitations

That said, 48-volt systems do have their limitations, which need to be addressed at some point for a smoother transition from the traditional 12V. Here are some of them:

Technical and Financial Hurdles

One of the primary obstacles to transitioning from 12-volt to 48-volt systems is the initial cost associated with retooling manufacturing lines and supply chains. Automakers have invested heavily in 12-volt infrastructure over the past decades, and switching to a new standard requires significant financial outlays. This includes developing new components, redesigning vehicle platforms, and ensuring compatibility with existing systems.

Another technical hurdle is the need for robust connectors and shielding to handle the higher voltage. While 48 volts is still considered safe and falls under the Safety-Extra Low Voltage (SELV) category, it does increase the risk of arcing and requires better insulation and protection. Developing these components to meet stringent safety standards while keeping costs low is a considerable challenge for manufacturers.

Integration with Existing Systems

One practical constraint of adopting 48-volt systems is integrating them with the existing 12-volt components still prevalent in many vehicles. Most modern vehicles have numerous low-power components designed specifically for 12 volts, such as lights, sensors, and various electronic modules. Completely overhauling these components to work with a 48-volt system is neither practical nor cost-effective in the short term.

To address this, manufacturers use DC-DC converters to step down the voltage from 48 volts to 12 volts for these legacy components. While this allows for a gradual transition, it also adds complexity and potential points of failure. So, balancing the new 48-volt architecture with the existing 12-volt systems requires careful planning and precise engineering to ensure seamless operation.

Practical Constraints

Despite the advantages of higher voltage, there are practical limits to how small the wiring can be reduced. While 48-volt systems do allow for thinner wiring compared to 12-volt systems, the physical limits of materials and the need to handle peak loads prevent wires from being infinitely small. Moreover, even though 48-volt systems reduce the current, they still require connectors and components capable of handling these reduced but still significant currents.

Another practical limitation is the need for stronger connectors and better shielding to prevent electrical arcing. Sure, 48 volts is still below the threshold that would require high-voltage safety standards, but it’s high enough to pose a risk if not properly managed. Ensuring all components meet these safety requirements adds complexity and cost to the manufacturing process.

Limited Immediate Benefits for EVs

While 48-volt systems offer substantial benefits for hybrid and ICE vehicles, the immediate advantages for all-electric vehicles are less clear. EVs already operate on high-voltage systems, typically between 400 and 800 volts, to power their electric motors and major systems. In this context, the addition of a 48-volt system primarily supports auxiliary functions and does not significantly impact the main propulsion system.

For EVs, the primary benefit of a 48-volt system lies in reducing the load on the high-voltage battery and improving the efficiency of auxiliary systems. However, since EVs inherently have a large high-voltage battery, the need for an intermediate voltage system is less pressing. This makes the adoption of 48-volt systems in EVs more of an incremental improvement rather than a game-changing innovation.

Market Adoption and Consumer Awareness

Another significant challenge is market adoption and consumer awareness. Many consumers are not yet familiar with the benefits of 48-volt systems, and there is a learning curve associated with understanding how these systems work and their advantages. Automakers must invest in educating consumers about the benefits of 48-volt technology to drive adoption and acceptance.

In addition, the automotive market is highly competitive, and introducing new technologies requires convincing both consumers and industry stakeholders of their value. This involves demonstrating real-world benefits, such as improved fuel economy, enhanced performance, and long-term reliability. Building consumer trust and market acceptance is crucial for the widespread adoption of 48-volt systems.

Key Vehicle Features Enabled by 48-Volt Systems

The transition to 48-volt electrical systems in vehicles is unlocking a range of advanced features that were previously unattainable or inefficient with traditional 12-volt systems. Here are some of the main examples:

Mild Hybrid Capabilities

Mild hybrid vehicles leverage the 48-volt system to enhance traditional ICEs by integrating electric motor assistance. This combination offers several key functions:

- Regenerative Braking: This system captures energy during braking and stores it in a 48-volt battery. This stored energy can then be used to assist the engine, reducing overall fuel consumption and enhancing efficiency.

- Electric Boost/Turbochargers: 48-volt systems can power electric turbochargers, providing immediate boost pressure and improving engine responsiveness. This reduces turbo lag and enhances performance, as seen in models like the Mercedes-Benz C-Class and Honda Civic (1.6L i-DTEC).

- Advanced Start-Stop Systems: By integrating a 48-volt motor generator, these systems enable smoother and faster engine restarts during stop-start operations. This reduces fuel consumption and emissions while maintaining comfort and performance. Vehicles like the Audi A6 benefit significantly from this technology.

Active Suspension Systems

Active suspension systems, powered by 48-volt architectures, offer significant enhancements in ride comfort and vehicle handling. These systems continuously adjust the suspension settings to respond to driving conditions, providing a smoother and more controlled ride.

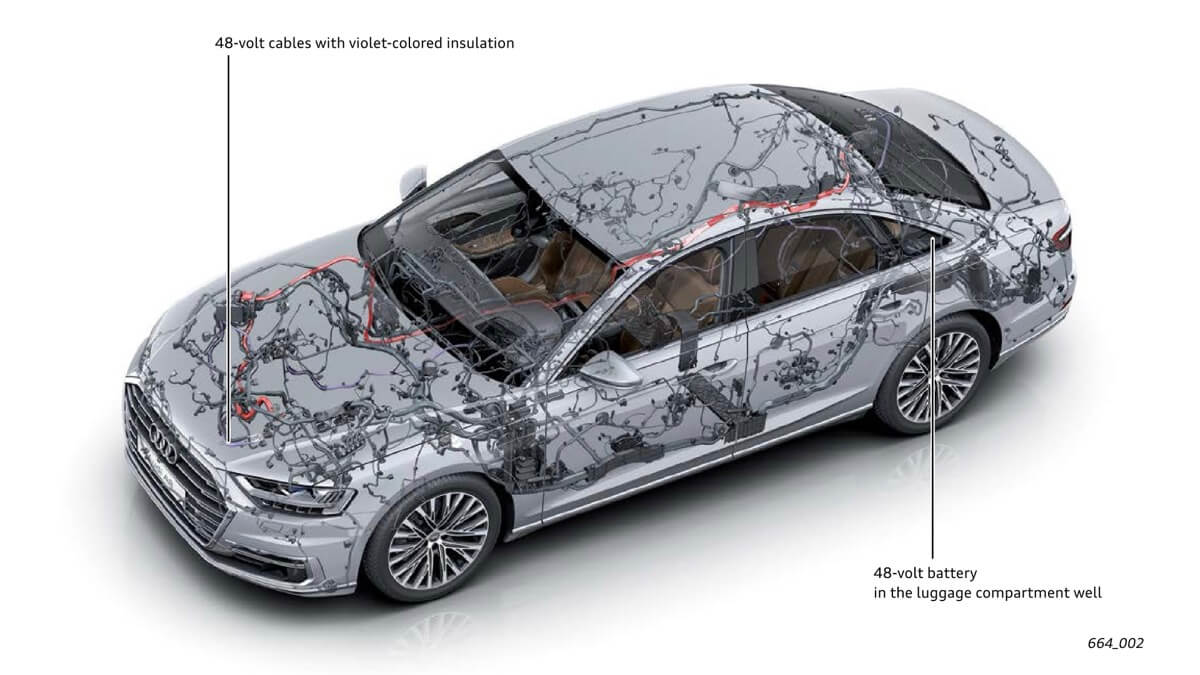

The Audi A8, for instance, utilizes its 48-volt system to power an advanced active suspension that adjusts each wheel independently, enhancing both comfort and performance. This technology improves handling by reducing body roll during cornering and adjusting ride height based on speed and road conditions.

Similarly, the new generation Porsche Panamera employs a 48-volt active suspension system to improve its dynamic capabilities, adjusting damping rates in real-time to ensure optimal performance whether the vehicle is navigating tight corners or cruising on the highway.

Steer-by-Wire

Steer-by-wire technology represents a significant advancement in vehicle steering mechanisms. This technology eliminates the mechanical connection between the steering wheel and the wheels, instead using electronic controls to steer the vehicle.

The Tesla Cybertruck is a notable example of a vehicle utilizing steer-by-wire technology. This system improves steering precision and response while allowing for more flexible vehicle design. By eliminating the traditional steering column, it also enhances safety by reducing the potential for mechanical failures.

Additionally, Lexus is developing steer-by-wire systems for its future models. This technology is expected to improve vehicle handling and provide a more customizable driving experience, as electronic controls can be easily adjusted to suit different driving conditions and preferences.

Last Words

It seems the future prospects of 48-volt architecture in the automotive industry are incredibly promising. As the demand for more efficient and powerful vehicle systems continues to grow, the adoption of 48-volt systems is expected to increase significantly. It’s fairly possible that over the next decade, we’ll see a substantial rise in the number of vehicles equipped with 48-volt systems.

Potential advancements in 48-volt technology and applications are likely to include further enhancements in hybrid functionalities and more sophisticated electronic systems, improving vehicle performance, safety, and efficiency. And with automakers like Audi, Mercedes, and Tesla leading the charge in incorporating these systems into their vehicles, this trend is expected to continue as more manufacturers recognize the benefits of 48-volt architecture and invest in developing compatible technologies.

As the industry continues to innovate, 48-volt systems will become more prevalent, driving improvements in efficiency, performance, and sustainability. We are only beginning to see the full potential of what 48-volt systems can achieve, and the future looks bright for this transformative technology.