Ah, the dreaded diesel engine. After VW’s dieselgate scandal, people can’t stop hating them, even though they are an ingenious solution. How is that? Well, for starters, a diesel engine is much more efficient than a gasoline engine – there is no comparison there.

Furthermore, diesel produces much more torque at lower revolutions, making daily driving less stressful. The torque also helps with hauling and towing, which is why most heavy-duty trucks still use diesel engines. If you’ve driven a modern turbodiesel, you’ll know what we’re talking about here.

But what is the difference between a diesel and a gas engine? You arrived just at the right place to learn everything there is to know about these machines. This article won’t only help you brag to your friends but also learn how to maintain it if you have one.

Moreover, we will show you the critical components of a diesel engine and how they work, so you can begin to diagnose problems yourself.

The Basics: The Diesel Engine Cycle

In a gasoline engine, fuel is injected into the cylinder and is then compressed before being ignited. In a diesel engine, the air is compressed, which raises the temperature. Fuel is then injected near the top of the compression stroke, causing ignition. Specifically, the fuel ignites due to high pressures instead of a spark. There is no need for a spark plug due to the high compression ratio. For that reason, many refer to diesel engines as Compression-Ignition.

Diesel engines typically have a compression ratio between 15:1 and 25:1. Most production gasoline engines are only capable of producing ratios lower than 11:1. In a gasoline engine, higher compression ratios can lead to pre-ignition, a condition commonly called pinging. The condition can cause the internal engine components to tear apart, leading to catastrophic failure. Diesel engines do not suffer from pre-ignition since the fuel itself resists high pressures better.

The Diesel Engine at Work

The diesel engine cycle begins at the bottom-dead-center. Intake and exhaust valves are closed. The piston rises in the cylinder, compressing atmospheric air. Near the top-dead-center, the injectors spray fuel into the compressed, heated air through the open intake valve. The pressure causes the fuel to ignite, expanding the air and pushing the piston back down. Near bottom-dead-center, the exhaust valve opens, causing a rapid pressure drop. The piston then forces the spent gases out of the cylinder.

Download your diesel engine repair manual here!

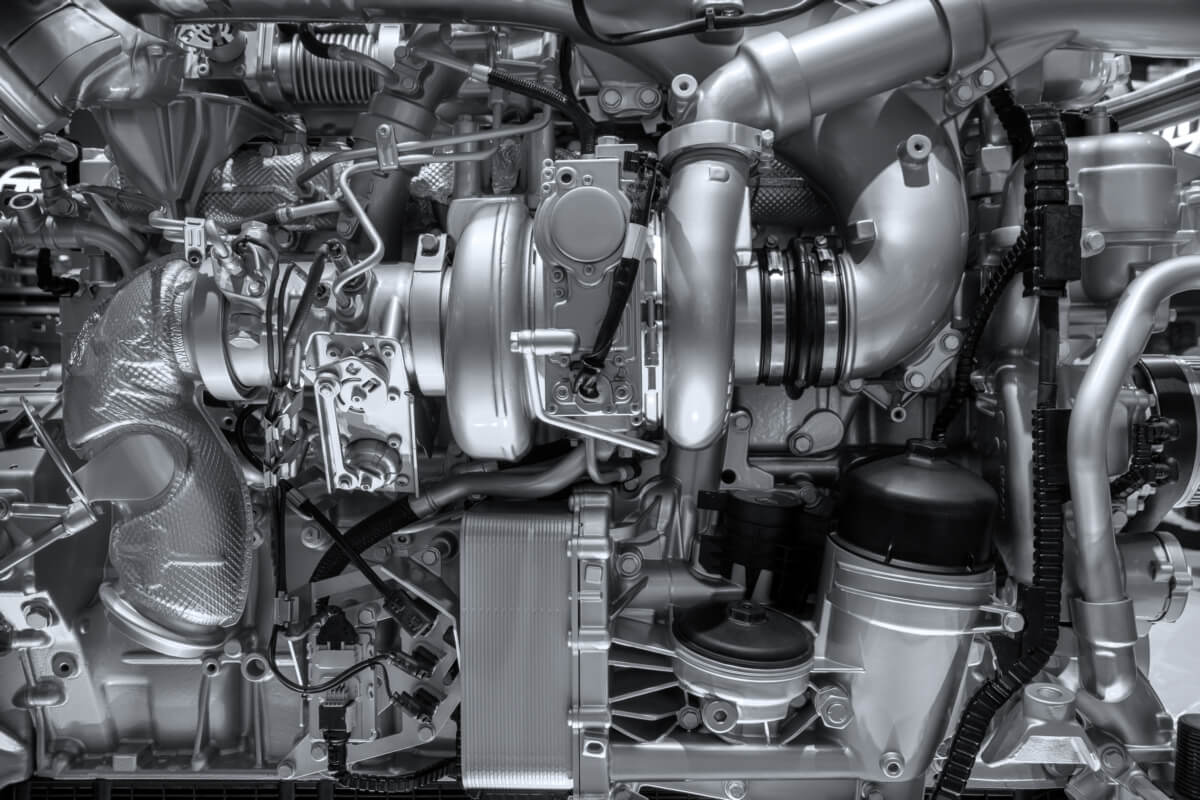

Components of a Diesel Engine

Most diesel-engine internal parts are similar to gasoline engines. The engine uses a block that houses the crankshaft and a cylinder head with camshafts and valves. Also, most diesel engines feature water cooling, although some small industrial engines are air-cooled.

A diesel fuel pump is different from a gas one. The pump is responsible for providing fuel at the proper time to each cylinder, much like a spark-ignition distributor provides ignition. As a result, it is more expensive and complex than a gas pump.

What is Diesel Fuel?

You’ve probably noticed the (usually) green gas pump handle at the gas station. You might have even heard stories about what happens when you put diesel fuel in a gasoline engine. But what makes diesel fuel different from gasoline, anyway?

The most common type of diesel commercially available is petroleum diesel. This fuel is a by-product of the distillation of crude oil at specific temperatures. In most countries, refineries further process petroleum diesel, or petrodiesel, to reduce sulfur. This diesel fuel is called Ultra-Low Sulphur Diesel, commonly abbreviated ULSD. It was developed to reduce harmful exhaust emissions, specifically sulfur dioxide, contributing to acid rain.

Biodiesel is increasingly common in many countries today, and it comes from processing vegetable or animal fat to remove glycerin and water. Rapeseed oil and soybean oil are the most common vegetable oils made into biodiesel. This variant is naturally low in sulfur content but does not provide as much power as petrodiesel.

Other types of synthetic diesel fuels include processing used fryer oil, which produces a fuel similar to biodiesel. Dimethyl ether, or DME, is a synthetic gaseous diesel that produces greatly reduced emissions.

The Many Uses of Diesel Engines

Diesel engines are commonly used in large trucks and tractors because of the tremendous amount of torque. Torque is the rotational equivalent of linear force. In layman’s terms, torque translates into pulling power, while horsepower relates to acceleration. Diesel engines are a good choice for trucks because they provide the necessary power to haul heavy loads.

Small diesel engines are also common in Europe and other parts of the world for use in passenger cars. Diesel engines are also more fuel-efficient than gasoline engines. Small displacement diesel motors commonly achieve 50 mpg or better.

However, these engines lack acceleration and are unpopular in the United States, where decades of relatively low gasoline prices and emissions taxes, regulations, and fees stymied small diesel engines’ commercial viability.

Diesel engines are also commonly used for locomotives and ship engines. In fact, the largest engine in the world is a diesel engine that powers a cargo ship. The engine produces a staggering 107,000 horsepower and 5.6 million ft-lbs of torque.

Advantages of Diesel Engines

There are several important advantages to a diesel engine over gasoline competition. They are more efficient, which translates into more miles per gallon.

Furthermore, they produce less CO2 than gas engines, although the amount of noxious gases and particulate matter is higher. The use of cleaner-burning synthetic diesel fuels and a rising trend in new legislation requiring emissions certification produce efficient and clean-burning diesel engines.

The construction is also simpler than gasoline engines since there is no spark-ignition system. However, some combustion-ignition engines use glow plugs. Glow plugs are electric warming devices that help with ignition during a cold start. The inherent simplicity translates into fewer breakdowns and fewer replacement parts.

There is also much more power and torque at lower RPM than gasoline engines. Meanwhile, the lower rotational speed results in less wear and tear on engine parts. Well-maintained diesel engines can exceed 500,000 miles before requiring major engine repair.

Disadvantages of Diesel Engines

Diesel engines do not build power the same way as gasoline engines. Most produce high torque levels but not the high horsepower that results in fast vehicles. Many of the most fuel-efficient diesel cars will never be called quick.

They also require specific lubricants different from gasoline engines. In particular, you’ll need to use different motor oil. For instance, Ford and Dodge units can have an oil capacity of 12 to 15 quarts. That means more expensive oil changes and lots more used oil to deal with.

Besides, not all gas stations sell diesel fuel, and in some areas, it is more expensive than gasoline. Drivers sometimes must go miles out of their way to get fuel, which is a disadvantage.

Diesel engines, particularly those in large trucks and older vehicles, tend to be noisy and smelly. For some people, the loud and noxious operation is a disadvantage. Nonetheless, carmakers use advanced emissions systems and noise baffling to create quieter, better-smelling diesel cars and trucks lately.

Performance Diesel Engines

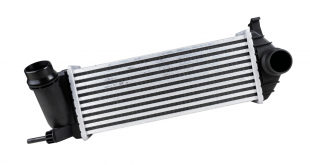

Just because most diesel cars are slow doesn’t mean they have to be. Diesel engines benefit from turbochargers, which increase the atmospheric pressure, leading to big gains in power. With enough forced induction, a turbodiesel can make tons of horsepower for fast acceleration through the RPM range.

Many other modifications that owners make to increase their vehicles’ performance are similar to gas-engine modifications. Upgrading the air intake is a great way to increase horsepower and torque and may even boost mileage.

You can also upgrade the injectors for better performance. Increasing the exhaust pipe size can have a positive impact, but only after other upgrades. Like gasoline engines, too much exhaust volume reduces performance.

Last Words

There are lots of differences between diesel and gasoline engines. Once you have an idea of how diesels work, it makes repairing much easier. Keep in mind there is no substitute for a high-quality repair manual for your specific vehicle. A workshop manual will give you all the information you need to diagnose problems and fix them yourself, saving thousands of dollars on expensive repair bills at a shop.