Diesel trucks are the workhorses of the global economy, performing heavy-duty tasks day in and day out. These road titans play a pivotal role in transporting goods and services, accounting for more than 70% of all freight transportation in the United States and serving as the lifeblood of numerous industries. From long-haul trucking companies delivering essential goods across the country to construction crews relying on their trusty diesel-powered trucks to tackle rugged terrains, the significance of these diesel workhorses is immeasurable.

Imagine a bustling metropolis awakening to another day. As dawn breaks, fleets of diesel trucks come to life, their rumbling engines echoing through the city streets. These mechanical giants embark on a daily mission to transport goods, ensuring store shelves are stocked with essentials, construction sites are well-equipped, and countless businesses continue to operate smoothly. These diesel-powered heroes are the backbone of our modern world.

In this article, we delve into the world of diesel truck maintenance, unveiling the key to keeping these formidable machines running smoothly year-round. Much like a well-conducted orchestra, a meticulous maintenance routine, when paired with a truck repair manual and the manufacturer’s recommended maintenance schedule, ensures that every component operates harmoniously. Diesel trucks, with their robust capabilities, deserve no less than top-notch care to minimize downtimes and unforeseen failures.

As a result, preventive maintenance is a truck owner’s best friend. And it isn’t just about extending your truck’s life; it’s about saving you from those wallet-wrenching breakdowns. We’ll break down the basics of diesel truck maintenance, provide you with a handy diesel truck maintenance checklist (the same thing I used during my countless years working as a diesel mechanic), and even show you how to whip up a simple maintenance schedule. After all, when it comes to diesel trucks, staying prepared is the name of the game.

So, let’s have a look into the world of diesel truck maintenance. We’re not talking rocket science here; it’s all about the nitty-gritty details and a dash of dedication. Whether you’ve been around trucks for years or you’re just starting to rev up your interest, we’ve got some golden nuggets of wisdom to keep those big rigs humming along smoothly.

Let’s go!

Diesel Truck Maintenance – Why Should You Do It?

When you own a diesel truck, you expect it to get the work done. You want it to be consistently dependable and safe, with the engine starting as you turn the key and running smoothly without any annoying issues — there’s nothing worse than a truck that doesn’t do what it’s supposed to do, right? Therefore, staying on top of your truck’s recommended service schedule is by far your best bet to achieve exactly that.

Indeed, performing preventive maintenance on your truck brings a lot of benefits. Not only will it extend its lifespan, but routine maintenance will also prevent your truck from breaking down and needing costly (and often time-consuming) repairs. Not to mention your engine will thank you with excellent performance and improved fuel economy for keeping it healthy.

And it’s not just the running cost of the truck you’ll be saving. Maintaining your truck regularly while keeping proper records of that will also help you sustain its resale value. And, of course, regular inspection and maintenance will also prevent you from being fined for Department of Transportation (DOT) violations in commercial trucking applications.

Speaking of cost savings, you can also save even more by doing most of the work yourself instead of relying on an expensive mechanic. Spare some garage tools, buy the parts you need to replace, and use a truck repair manual as a guide. Additionally, you can utilize this manual to learn about your truck’s components, how they work, and how to test and repair them when there’s an issue.

Diesel vs. Gasoline Truck Maintenance

Maintaining a diesel-powered truck shares many similarities with its gasoline counterpart, but recent stringent emissions standards have placed new demands on diesel trucks, necessitating a more comprehensive maintenance approach.

One notable difference lies in the availability and cost of replacement parts. Diesel truck components can be both pricier and trickier to find compared to their gasoline counterparts, making it essential to plan ahead when it comes to repairs and replacements.

Another area where diesel trucks differ is in the frequency of oil changes. Due to the nature of diesel fuel and its combustion process, diesel engines require more frequent oil changes than gasoline engines. For instance, while a gasoline truck might benefit from an oil change every 5,000 miles, a diesel truck could require one at a shorter interval, say, every 3,000 miles. This is because diesel fuel tends to leave more combustion deposits in the engine, which can affect its performance over time.

The type of driving you do can also impact your maintenance needs. If your truck primarily covers long-distance routes, those extended journeys often help clear out combustion deposits from the engine, reducing the urgency for frequent maintenance. However, if your truck is mainly used for local deliveries with shorter trips, these deposits can accumulate faster, demanding more frequent attention to keep the engine running smoothly.

Yet, it’s not all added maintenance hassle with diesel trucks. They come with their fair share of advantages. Unlike gasoline engines that rely on spark plugs, diesel engines use high compression to ignite fuel, resulting in less wear and tear over time. This durability can lead to a longer overall engine life and less need for component replacements.

Diesel trucks also boast impressive low-end torque, delivering substantial pulling power at lower RPMs. This characteristic makes them ideal for heavy towing applications, where the ability to move substantial loads efficiently is a significant advantage. Moreover, the fuel efficiency of diesel engines often shines in the long term, translating to cost savings for long-haul truckers.

So, while diesel trucks do require extra care and attention in maintenance due to evolving emission standards and specific fuel properties, they offer durability, towing capacity, and fuel efficiency, making them the preferred choice for certain applications.

Diesel Truck Maintenance Checklist

I won’t sugarcoat it; there’s a long list of items to inspect when it comes to maintenance for trucks. Thus, you’ll need a proper truck maintenance checklist to keep track of everything.

Remember that ensuring every component is in good condition before heading out will allow you to avoid problems that may cripple your truck during operation, which could potentially cost even more (tow trucks are never cheap). Besides, by allowing it to work at its best state, your diesel truck would be less prone to unexpected breakdowns that will cost more than a quick inspection with minor fixes.

Preventive Maintenance Checklist for Common Diesel Trucks

The following is a general diesel truck maintenance checklist applicable to any diesel truck. Although your mechanic commonly holds this checklist, having a copy for yourself or your truck driver is still advisable. Note that the more often these inspections are done before going on a trip, the better.

Engine

- Change the oil and filter

- Check for engine oil leaks

- Clean the engine

- Check engine mounts

- Check the fuel line and gas cap

- Check the fuel filter

- Check the air filter

- Check radiator mounts

- Check all hoses

- Check all belts: v-belt, timing, and serpentine

- Check the water pump and fan bearing

- Perform a cooling system pressure test

- Drain fuel/water separator (if equipped)

- Check the vibration damper (if equipped)

Underhood Fluid Levels

- Engine oil

- Radiator/coolant

- Battery

- Power steering

- Transmission

- Brake

- AC freon

- Windshield washer

Chassis

- Check power steering hoses

- Check for steering play

- Check tie rod ends

- Check ball joints

- Check front shocks and springs

- Check rear shocks and springs

- Check lift blocks (if equipped)

- Check flywheel housing bolts

- Check transmission mounts

- Check the drive shaft

- Check and grease u-joints

- Check and lubricate slip joints

- Check carrier bearings

- Check wheels and axle seals

Brakes

- Check for brake fluid leaks

- Check front pads and rotors

- Check rear drums

- Check the parking brake operation

- Check brake lights

Exterior Checks

- Check the tires’ pressure and condition

- Check the rims and torque the lug nuts

- Check and tighten the fuel cap

- Check mudguards/mudflaps and reflectors

- Check the exhaust system for smoke or unusual noise

- Check and lube all hinges, latches, and locks

- Check windows and side mirrors

- Check wiper blades and test the windshield washer

- Check exterior lights: DRLs, headlights (low and high beams), taillights, fog lights, reverse lights, indicators and hazards, and number plate lights.

- Check parking sensors and the backup camera (if equipped)

Interior

- Check door lock operation

- Check door seals

- Check and adjust mirrors

- Check the AC, heater, climate control, and fans

- Check interior lights: cabin, driver’s instrument cluster, buttons, and switches

- Check gauges: fuel, oil, volt, temperature

- Check fuel level

- Check for any warning lights on the dash

- Test the horn

- Check the radio and stereo system

- Adjust the seating and steering position

- Check the seatbelt function

- Check foot pedals: accelerator, brake, and clutch (for manual transmission)

- Check the transmission selector or gear stick

Safety/Emergency Items

- Emergency glass breaker

- Seatbelt cutter

- Fire extinguisher

- Toolkit

- Flashlight

- Reflective triangle

- First aid kit

- Tire repair kit

- Spare tire

- Truck owners manual

- Registration and insurance papers

Final Checks

- Check for undercarriage leaks

- Check for unusual noises

- Recheck oil level

- Set a reminder for the next inspection/maintenance

- Wash and clean the exterior and interior

- Note any upcoming repairs required

➤ Download your truck repair manuals here!

Additional Maintenance Checklist for Specific Truck Types

Commercial Vehicle Maintenance Checklist

- All of the above

- Check records for VIN, make and model, model year, vehicle owner, assigned driver, and maintenance history.

Semi Truck Maintenance Checklist

- All of the above

- Check trailer air hoses and couplers

- Check safety bars and pins

- Check hydraulic lines

- Check hydraulic reservoirs

- Check the air/vacuum brake system for leaks (both on the truck and trailer)

- Check the lights on the trailer: side marker lights, brake lights, taillights, indicators, and hazards

- Test the air horn

- Check the tires’ condition on the trailer

How to Create a Truck Maintenance Schedule

Not every item on the truck maintenance checklist above is due for inspections simultaneously. Hence a truck maintenance schedule is super helpful for tracking when you’ll need to conduct each of those checks and services. Luckily, you can easily create this schedule by referring to your government’s DOT website or your truck service manual.

Generally, any vehicle maintenance schedule template should include the maintenance checklist’s items and periodic intervals suggesting when to inspect each item. The intervals can be mileage-based or time-based.

Mileage-Based Truck Maintenance Schedule

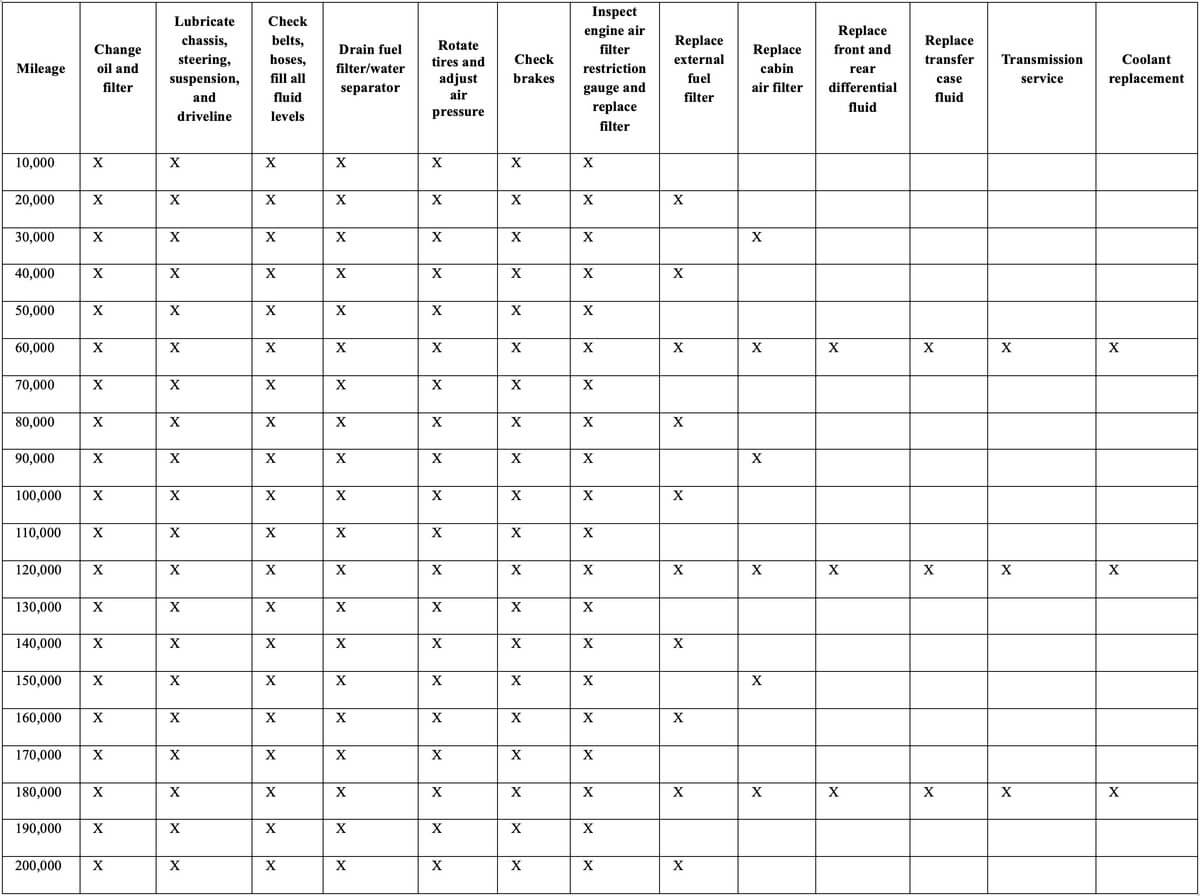

Since a truck’s component wear is mainly affected by mileage, many preventative measures are easier to schedule using this checklist. The following table shows a great example of a mileage-based truck maintenance schedule.

Every 10,000 miles

- Change oil and oil filter

- Reset oil life monitor

- Lubricate chassis, steering, suspension and driveline (grease all zerks)

- Check belts, hoses and fill all fluid levels (including DEF)

- Drain fuel filter/water separator

- Rotate tires and adjust air pressure

- Check brakes

- Inspect engine air filter restriction gauge and replace filter

Every 20,000 miles

- Replace external fuel filters (diesel & gas when light appears or every 20,000 miles)

Every 30,000 miles

- Replace cabin air filter (if equipped)

Every 60,000 miles

- Replace front and rear differential fluid

- Replace transfer case fluid

- Transmission Service (no transmission fluid flushing)

- Coolant replacement

Time-Based Truck Maintenance Schedule

A time-based maintenance schedule uses time intervals as checkpoints, ideal for keeping track of daily-driven commercial and fleet trucks’ maintenance. The time interval could be daily, monthly, or yearly, depending on how your company manages its armada.

The weekly vehicle checklist below is a good sample of a time-based maintenance schedule application, as some truck components are worth checking daily, before and after use.

- Engine oil and coolant levels

- Windshield & mirrors

- Doors & windows

- Emergency brake

- Tires — wear and pressure (+spare)

- Inspection and license plate stickers

- Check ground under vehicle for fluid leaks

- Emergency equipment

- First aid kit

- Fire extinguisher

- Warning reflectors and flares

- Flashlight

- Jack, lug wrench, and spare tire

- Communication device

- Documentation

- Insurance card

- Registration

- Check for cleanliness and damages (interior & exterior)

- Fuel level, gauges, and dah warning lights

- Windshield wipers

- Horn

- Headlights, taillights, turn signals, flashers, warning lights

Mileage-Based Vs. Time-Based – Which is Better?

Honestly, both mileage- and time-based schedules have their ideal use cases. For example, a mileage-based maintenance schedule is perfect for most underhood and chassis services. In contrast, a time-based schedule is more beneficial for inspecting the truck equipment’s function and availability. So, choosing between the two templates will heavily depend on your needs, though I recommend using both.

However, if you’re wondering which intervals are better to follow — mileage or time — the answer is whichever comes first and provides a shorter interval. For instance, a heavy-duty diesel truck’s recommended engine oil and filter change is every 5,000 miles or every six months. Suppose six months flew by and you haven’t yet driven 5,000 miles; in that case, use time as the basis. Contrarily, if you hit 6,000 miles in only 3 months, use mileage as your service interval.

Last Words

Running a trucking business can be quite a challenge, with various operating expenses to manage. From driver fines to unexpected damages, the costs can quickly add up. That’s where maintaining your fleet becomes crucial, as it’s an area where you can significantly impact your bottom line with relative ease.

In the world of modern diesel trucks, proper maintenance is the key to longevity and performance. By diligently following a maintenance checklist and keeping records for each truck in your fleet, you’re not only safeguarding your investment but also ensuring smooth operations.

As many fleets comprise models from different manufacturers, it’s wise to have a truck repair manual for each of them. Knowledge is power, and understanding your vehicles inside and out can make a world of difference.

To sum it up, following these maintenance practices will keep your fleet in a healthier state, ultimately contributing to a more profitable and successful business in the long run. We’d love to hear your thoughts and experiences with truck maintenance in the comments section below. Share your tips, insights, and stories with our community to help others on their journey in the world of running a trucking business.

➤ Download your truck repair manuals here!