1998-2009 Sterling Acterra MX Trucks OEM Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

ACTERRA WORKSHOP MANUAL

Models: MX

STI-414, S19 (7/10P)

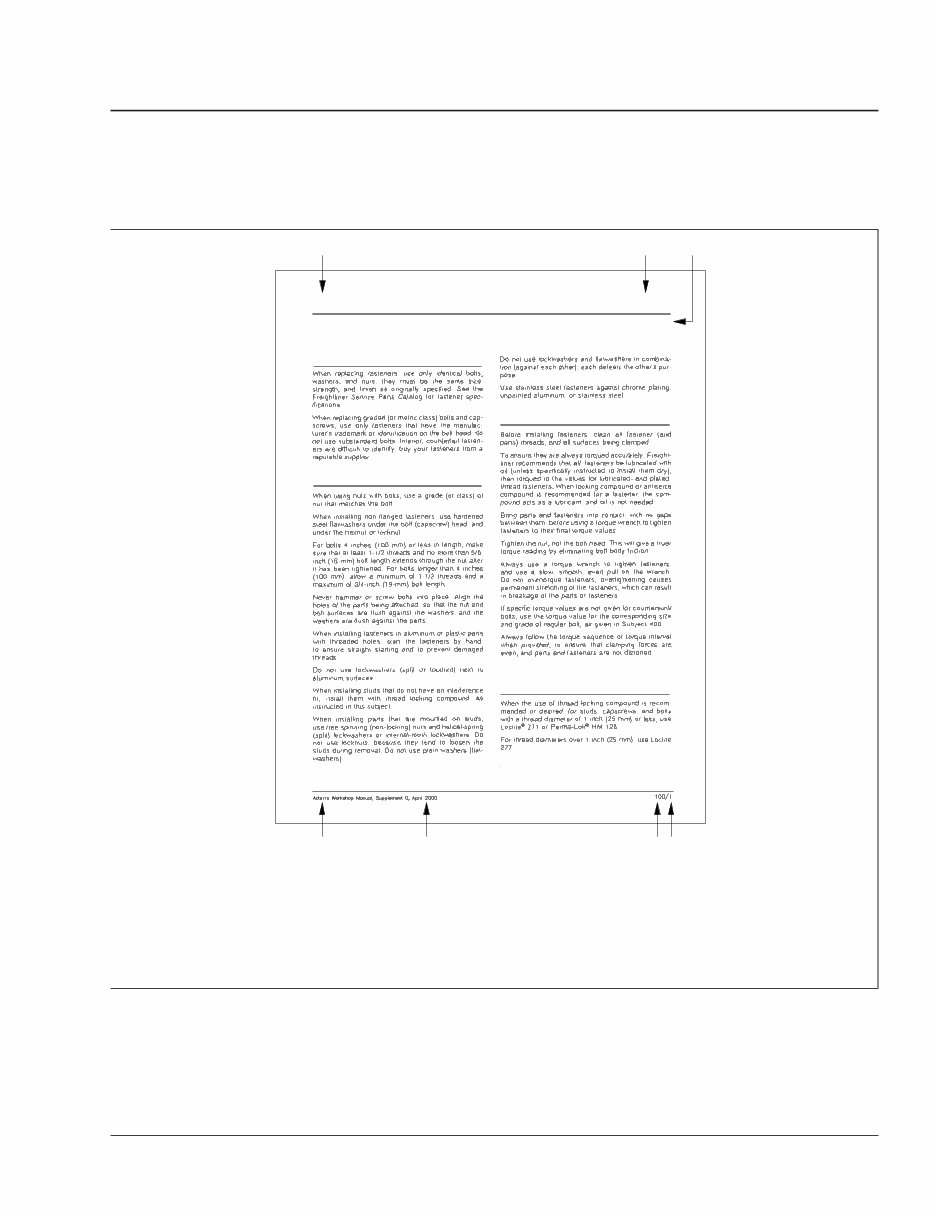

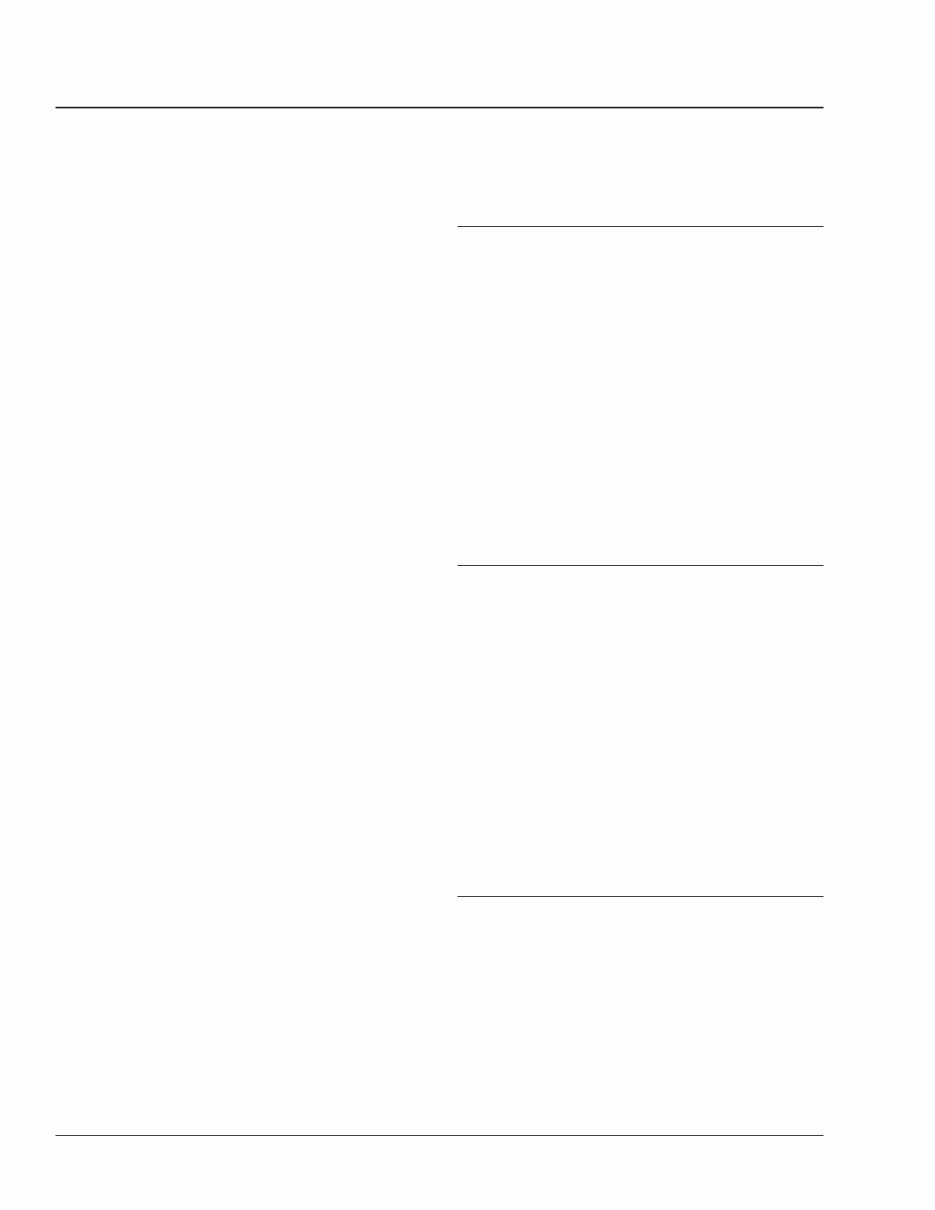

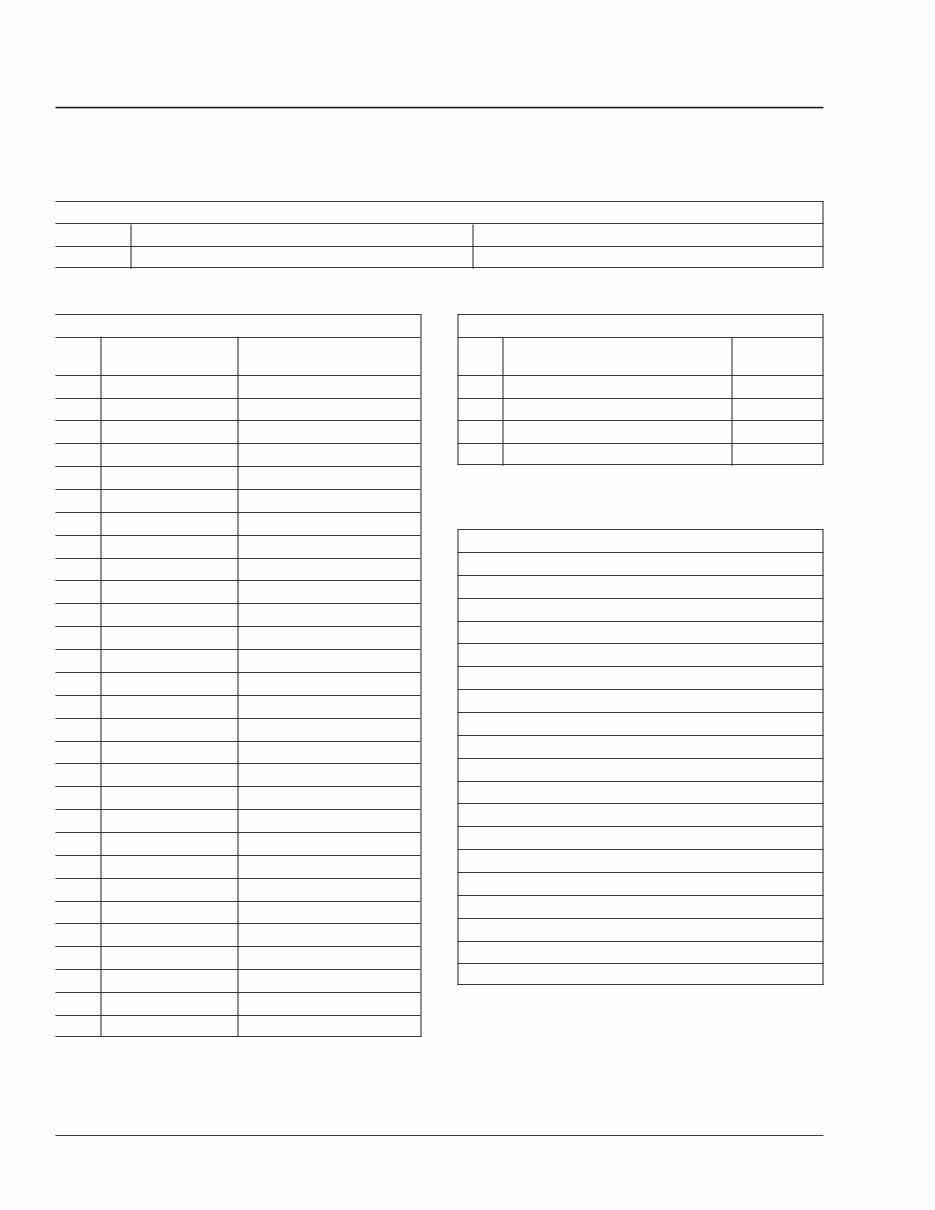

For an example of an Acterra Workshop Manual page, see Fig. 1.

B C A

F G D E

Threaded Fasteners

Fastener Replacement

Fastener Selection and Installation

Fastener Tightening

Thread Locking Compound

Application

General Instructions

00.04

01/20/2000

f020104

A. Section Title

B. Section Number (made up of the Group Number—first two digits, followed by a sequence number—last two digits)

C. Subject Title

D. Manual Title

E. Release (Supplement) Date

F. Subject Number

G. Subject Page Number

Fig. 1, Example of an Acterra Workshop Manual Page

Introduction

Page Description

Acterra Workshop Manual, Supplement 19, July 2010 I–3

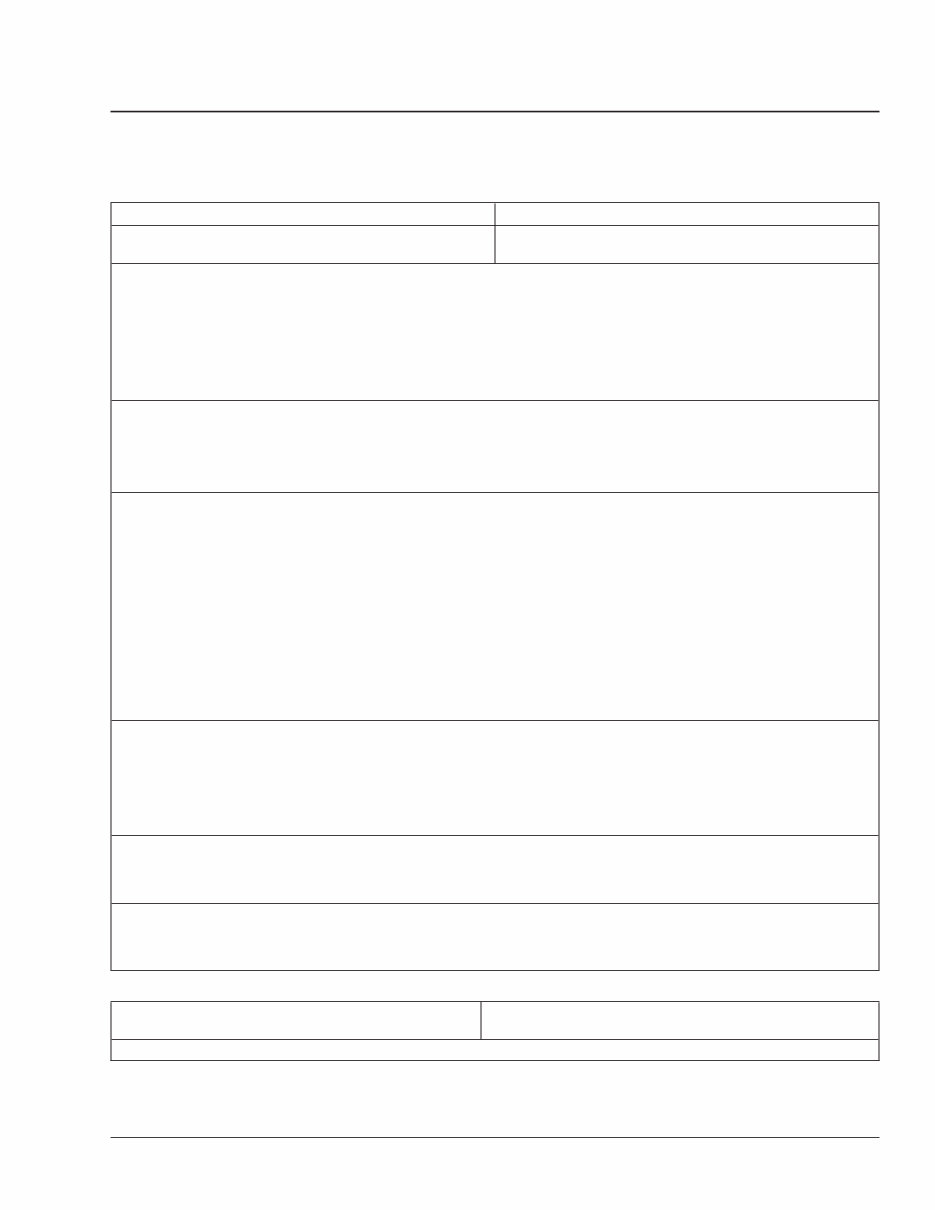

Group No. Group Title

00 ...................... General Information

01 ................................ Engine

09 .............................. Air Intake

13 ......................... Air Compressor

15 ................... Alternators and Starters

20 ................... Engine Cooling/Radiator

25 ................................ Clutch

26 ........................... Transmission

30 ......................... Throttle Control

31 ............. Frame and Frame Components

32 ............................ Suspension

33 ............................. Front Axle

35 ............................. Rear Axle

40 ........................ Wheels and Tires

41 .............................. Driveline

42 ................................ Brakes

46 ............................... Steering

47 ................................. Fuel

49 ............................... Exhaust

54 .......... Electrical, Instruments, and Controls

60 .................................. Cab

72 ................................ Doors

82 ............. Windshield Wipers and Washer

83 ................. Heater and Air Conditioner

88 .............. Hood, Grille, and Cab Fenders

90 ................. Fire Suppression Systems

91 ............... Seats and Restraint Systems

98 ................................. Paint

Introduction

Workshop Manual Contents

I–4 Acterra Workshop Manual, Supplement 19, July 2010

Vehicle Receipt

Prior to signing for vehicle delivery from a transporter

company, the dealer is responsible for checking for

transporter-related shortages or damages, and noting

these discrepancies on the transporter’s delivery re-

ceipt.

The dealer is also responsible for ensuring that the

vehicle was built according to the Truck Sales Order/

Invoice.

Refer to Section 3 of the Daimler Trucks North

America LLC Warranty Manual for details.

Vehicle Storage

There may be times when a vehicle is stored for long

periods before customer delivery. To protect all ve-

hicles from deterioration and weather, they must be

properly maintained. Adequate protection and stor-

age of new vehicles is the responsibility of the

dealer.

Claims arising from loss and damage to improp-

erly stored vehicles will not be reimbursed.

See Section 3 of the Daimler Trucks North America

LLC Warranty Manual for instructions on storage of

new vehicles.

Pre-Delivery Information

All pre-delivery inspections and services must be

performed at an authorized Daimler Trucks North

America LLC facility, assigned to fully qualified ser-

vice personnel and recorded on the "New Vehicle

Pre-Delivery Inspection" form.

Refer to Section 3 of the Daimler Trucks North

America LLC Warranty Manual for details.

It is recommended the pre-delivery inspection be per-

formed within 30 days of vehicle receipt.

Vehicle Receipt, Storage, and Pre-Delivery Information 00.01

General Information

Acterra Workshop Manual, Supplement 15, January 2008 050/1

Cooling System

1. Cooling system hoses must clear all moving

parts by a minimum of 1/4 inch (6 mm).

2. The 1-inch (25-mm) hose from the surge tank to

the engine must be free of sumps and have al-

lowance for engine torque.

3. All hoses from the engine hard pipes must be

wrapped in convoluted tubing.

4. Hoses that are protected with convoluted tubing

may be secured with tie straps to clear the inner

fenders.

5. Cooling system hoses should not be twisted or

kinked.

6. Cooling system hoses must be routed at least 6

inches (152 mm) from a heat source if the heat

source does not have a heat shield. If a heat

shield is provided, the hose must be routed at

least 3 inches (76 mm) from the heat source.

HVAC System

1. Cushion clamps are required to support all A/C

lines. Butterfly or figure-8 clamps (two cushion

clamps) may be used to prevent rubbing or chaf-

ing.

2. Heater hoses that are protected with convoluted

tubing may be fastened with tie straps. If not pro-

tected with convoluted tubing, only cushion

clamps or butterfly clamps may be used for

heater hoses.

3. A/C lines cannot be secured to air lines, fuel

lines, or electrical wires.

4. HVAC hoses should be protected from damage

by routing them away from hazards of heat,

wheel splash (water, gravel, ice), human traffic,

and moving parts of the vehicle.

5. HVAC hoses should be routed away from sharp

points and edges (such as nuts, bolts, brackets,

and frame rail edges), moveable parts, and

sources of abrasion, cutting, pinching, or crush-

ing.

NOTE: If hoses are covered with convoluted

tubing, they may touch any of the above.

6. Hoses that are protected with convoluted tubing

may come in contact with the bends on frame

rails and filters.

7. HVAC hoses must be routed at least 6 inches

(152 mm) from a heat source if the heat source

does not have a heat shield. If a heat shield is

provided, the hose must be routed at least 3

inches (76 mm) from the heat source.

8. All HVAC hoses must be routed so that regularly

serviced components, such as fuel filters, fuel/

water separators, oil filters, air filters, belts, and

fill and drain plugs, are readily accessible for ad-

justment or replacement without the need to relo-

cate or remove the hoses.

9. All A/C hoses in the engine compartment must

have convoluted tubing.

10. If cushion clamps are used over convoluted tub-

ing at existing clamp points, no additional tie

straps or tape is needed.

11. When convoluted tubing is installed on the

heater hose where it routes past the splash

shield on the front right-hand side of the firewall,

and if it uses existing clamps, no additional tie

straps or tape is needed.

Auxiliary Heater

All auxiliary heater lines are deck-mounted hard pip-

ing with rubber hose at both ends. No additional tie

straps are required.

Engine Plumbing

1. On vehicles equipped with the Cummins ISM

engine and power steering, no additional tie

straps or tape are needed if convoluted tubing is

installed on the power steering hose where it

routes under the frame rail.

2. The engine oil pressure line should not rub or

chafe against the Teflon

®

discharge line.

Electrical Wiring

1. Wires that are bundled together should be fas-

tened at 8- to 12-inch (203- to 305-mm) intervals.

If anchor clamps are more than 12 inches (305

Vehicle Receipt, Storage, and Pre-Delivery Information 00.01

Hoses and Electrical Wiring Routing Standards

Acterra Workshop Manual, Supplement 5, September 2002 100/1

mm) apart, a tie strap must be used between the

anchor clamps.

2. Bundles of wires that are located in an exposed

area, such as under the cab or outside the frame

rail, need to be fastened with heavy-duty cable

ties

3. Any wiring that will be exposed to water or heat

must be covered with either loom or convoluted

tubing. Loom or convoluted tubing need not butt

up against Weather Pack

®

connectors.

4. Any wiring routed across the vehicle, on the en-

gine crossmember, or across the rear of the en-

gine, must be secured with a clamp or tie strap,

and covered with either convoluted tubing or a

loom.

5. Any wiring that may come into contact with sharp

points and edges (such as nuts, bolts, brackets,

and frame rail edges), moveable parts, and

sources of abrasion, cutting, pinching, or crush-

ing, must be protected by either a loom or con-

voluted tubing.

6. Unprotected breakouts (individual wires) of up to

8 inches (203 mm) are acceptable as long as

these wires are routed safely away from sharp

points and edges, moveable parts, and sources

of abrasion, cutting, pinching, or crushing.

7. Gray, flame-retardant convoluted tubing may be

used to protect wiring in the cab or the chassis.

Black nylon convoluted tubing may only be used

in the chassis.

8. All wiring must be routed so that regularly ser-

viced components, such as fuel filters, fuel/water

separators, oil filters, air filters, belts, and fill and

drain plugs, are readily accessible for adjustment

or replacement without the need to relocate or

remove any wiring.

9. In exposed locations, such as the road light har-

ness near the headlights, loose loops of wire

must be secured with tie straps.

10. All wiring should be routed a minimum of 4

inches (102 mm) from the exhaust. In situations

where the wiring is less than 4 inches (102 mm)

from the exhaust, a heat shield must be placed

between the wiring and the exhaust.

Battery Cables

1. Battery cables must be routed along an unob-

structed path from the starter to the battery box.

The cables must not rub or chafe on brackets,

tanks, air lines, or fuel lines.

2. Battery cables and electrical wiring cannot be

tied or secured to fuel lines, discharge lines, or

air lines.

3. Battery cables must have support brackets no

more than 30 inches (762 mm) apart. Tie straps

must be within 6 inches (152 mm) of both sides

of the support brackets, and every 12 inches

(305 mm) between the brackets.

4. Battery cables must have convoluted tubing from

the frame bracket to the batteries, and from the

frame bracket to the starter.

Fuel Lines

1. Fuel lines must not be clamped to A/C lines, bat-

tery cables, jumper cables, or any other electrical

wiring.

2. Stand-off brackets or clamps may be used to

prevent fuel lines from rubbing against the frame.

3. Fuel lines must be routed at least 6 inches (152

mm) from a heat source. If a heat shield is pro-

vided, the fuel line must be at least 3 inches (76

mm) from the heat source.

4. Fuel lines that are parallel may be fastened to-

gether. Fuel lines that cross or that rub on metal,

plastic, or electrical parts, need to be separated

with butterfly clamps.

Chassis Air Lines and Brake

Hoses

1. Hoses may come in contact with each other if

they are parallel, or if they are bundled together.

2. If the hoses lie on the curve or flat surface of a

bracket or crossmember, they do not need con-

voluted tubing.

3. Brake hoses may be clamped at the top of the

axle housing, and touch or lie against the axle

housing in its path to the brake chamber as this

assembly moves together.

Vehicle Receipt, Storage, and Pre-Delivery Information 00.01

Hoses and Electrical Wiring Routing Standards

Acterra Workshop Manual, Supplement 5, September 2002 100/2

4. Brake hoses must have slack between the last

clamping point on the frame rail and the brake

chamber to allow for full range of suspension

travel.

5. Brake hoses should have butterfly clamps at

breakout points.

6. Air lines and brake hoses that are bundled to-

gether should be fastened at 8- to 12-inch (203-

to 305-mm) intervals. If anchor clamps are more

than 12 inches (305 mm) apart, a tie strap must

be used between the anchor clamps. Tie straps

may be closer than 12 inches (305 mm) apart.

7. Hoses or lines that may come into contact with

the sharp edge of a bracket or frame rail are to

be protected by convoluted tubing.

8. Air lines and brake hoses that are parallel may

be fastened together. Air lines and brake hoses

that cross or that rub on metal, plastic, or electri-

cal parts need to be separated with butterfly

clamps.

9. Nylon or STX (wire braid) chassis air lines may

be fastened together to prevent rubbing, as long

as the lines are stationary.

Vehicle Receipt, Storage, and Pre-Delivery Information 00.01

Hoses and Electrical Wiring Routing Standards

Acterra Workshop Manual, Supplement 5, September 2002 100/3

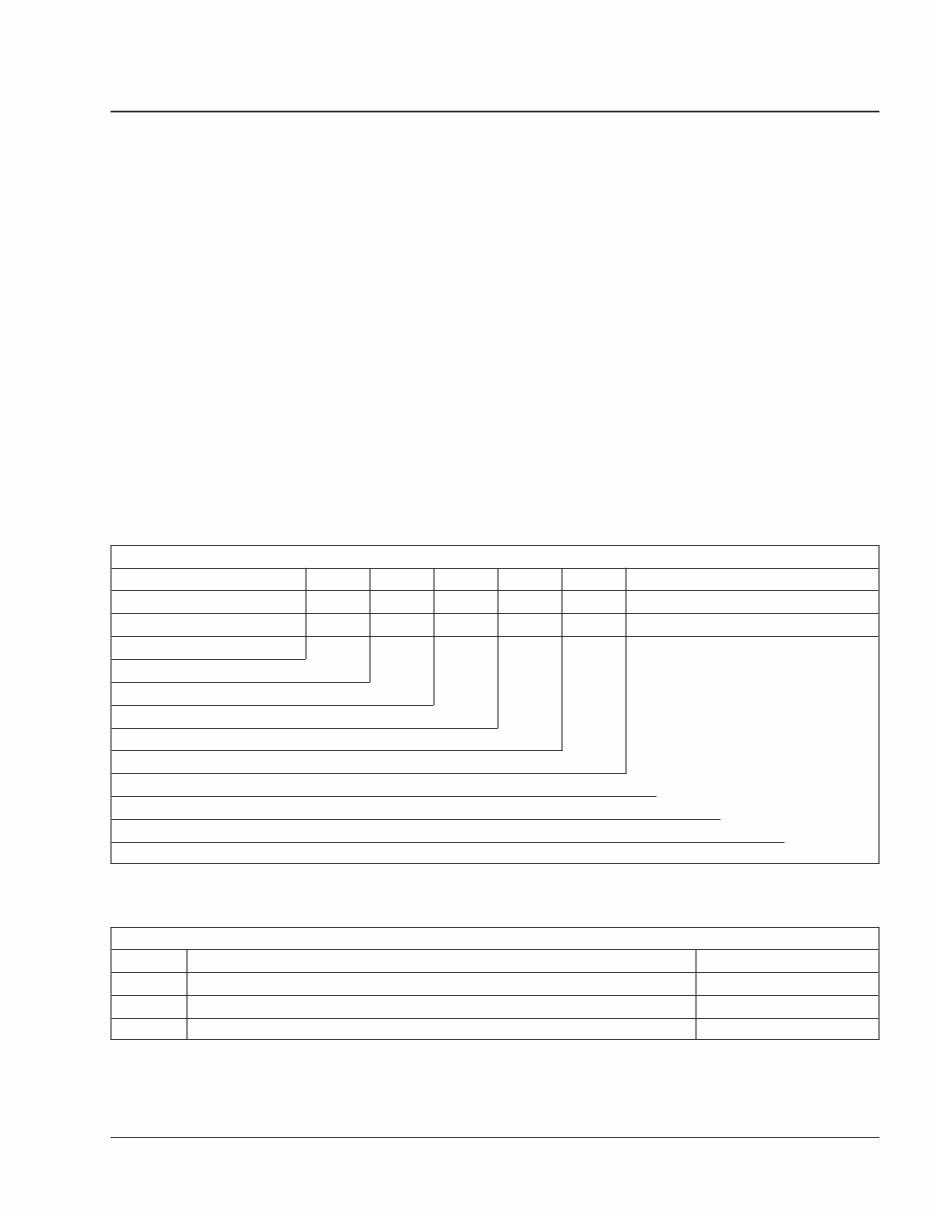

U.S. Customary to Metric Metric to U.S. Customary

When You Know

Multiply

By

To Get When You Know

Multiply

By

To Get

Length

inches (in) 25.4 millimeters (mm) 0.03937 inches (in)

inches (in) 2.54 centimeters (cm) 0.3937 inches (in)

feet (ft) 0.3048 meters (m) 3.281 feet (ft)

yards (yd) 0.9144 meters (m) 1.094 yards (yd)

miles (mi) 1.609 kilometers (km) 0.6215 miles (mi)

Area

square inches (in

2

) 645.16 square millimeters (mm

2

) 0.00155 square inches (in

2

)

square inches (in

2

) 6.452 square centimeters (cm

2

) 0.15 square inches (in

2

)

square feet (ft

2

) 0.0929 square meters (m

2

) 10.764 square feet (ft

2

)

Volume

cubic inches (in

3

) 16387.0 cubic millimeters (mm

3

) 0.000061 cubic inches (in

3

)

cubic inches (in

3

) 16.387 cubic centimeters (cm

3

) 0.06102 cubic inches (in

3

)

cubic inches (in

3

) 0.01639 liters (L) 61.024 cubic inches (in

3

)

fluid ounces (fl oz) 29.54 milliliters (mL) 0.03381 fluid ounces (fl oz)

pints (pt) 0.47318 liters (L) 2.1134 pints (pt)

quarts (qt) 0.94635 liters (L) 1.0567 quarts (qt)

gallons (gal) 3.7854 liters (L) 0.2642 gallons (gal)

cubic feet (ft

3

) 28.317 liters (L) 0.03531 cubic feet (ft

3

)

cubic feet (ft

3

) 0.02832 cubic meters (m

3

) 35.315 cubic feet (ft

3

)

Weight/Force

ounces (av) (oz) 28.35 grams (g) 0.03527 ounces (av) (oz)

pounds (av) (lb) 0.454 kilograms (kg) 2.205 pounds (av) (lb)

U.S. tons (t) 907.18 kilograms (kg) 0.001102 U.S. tons (t)

U.S. tons (t) 0.90718 metric tons (t) 1.1023 U.S. tons (t)

Torque/Work Force

inch-pounds (lbf·in) 11.298 Newton-centimeters (N·cm) 0.08851 inch-pounds (lbf·in)

foot-pounds (lbf·ft) 1.3558 Newton-meters (N·m) 0.7376 foot-pounds (lbf·ft)

Pressure/Vacuum

inches of mercury (inHg) 3.37685 kilo Pascals (kPa) 0.29613 inches of mercury (inHg)

pounds per square inch (psi) 6.895 kilo Pascals (kPa) 0.14503 pounds per square inch (psi)

When You Know Subtract

Then

Divide By

To Get When You Know

Multiply

By

Then

Add

To Get

degrees Fahrenheit (°F) 32 1.8 degrees Celsius (°C) 1.8 32 degrees Fahrenheit (°F)

Metric/U.S. Customary Conversion Charts 00.02

General Information

Acterra Workshop Manual, Supplement 6, September 2004 050/1

IMPORTANT: See Subject 060 for the vehicle

identification numbering system for vehicles built

May 1, 2000, or later.

Federal Motor Vehicle Safety Standard 115 specifies

that all vehicles sold in the U.S. be assigned a 17-

character Vehicle Identification Number (VIN). Using

a combination of letters and numerals, the VIN de-

fines the manufacturer, model, and major characteris-

tics of the vehicle. See Table 1 for the character po-

sitions of a typical Sterling VIN,

480ALEBDXWA345678.

The VIN can be found on the Vehicle Specification

Decal (see the driver’s manual for decal location)

and stamped on the outside of the left-hand frame

rail about 24 to 40 inches (60 to 100 cm) aft of the

front axle centerline. On Sterling vehicles built before

July 1998, the VIN is stamped on the frame rail near

the front axle position.

IMPORTANT: A new VIN-code structure will be

used for all vehicles built after April 30, 2000.

Character positions 1 through 4 and 9 through

17 are nearly the same in both versions, but

positions 5 through 8 have been assigned

slightly different parameters. As a result, the

build date of a vehicle must be determined be-

fore the VIN can be decoded.

For all vehicles, a check digit (9th character) is deter-

mined by assignment of weighted values to the other

16 characters. These weighted values are processed

through a series of equations designed to check va-

lidity of the VIN and to detect VIN alteration.

NOTE: Always specify the VIN when ordering

parts.

Seventeen-Character Vehicle Identification Number (VIN)

Typical VIN 480 A L EB D X W A 345678

Character Position 1, 2, 3 4 5 6, 7 8 9 10 11 12 thru 17

Decoding Table

*

Table 2 Table 3 Table 4 Table 5 Table 6 — Table 7 Table 8 —

Code Description

Manufacturer, Make, Vehicle Type

Chassis, Front Axle Position, Brakes

Vehicle Model Series, Cab

Engine Model, Horsepower Range

Gross Vehicle Weight Rating (GVWR)

Check Digit

Vehicle Model Year

Plant of Manufacture

Production Number

* For corresponding decoding information, see the applicable tables in this subject.

Table 1, Seventeen-Character Vehicle Identification Number (VIN)

VIN Positions 1, 2, and 3 (Manufacturer, Make, Vehicle Type)

Code Vehicle Manufacturer Vehicle Make Vehicle Type

2FW Sterling, Canada-built Sterling Truck-Tractor

2FZ Sterling, Canada-built Sterling Incomplete Vehicle

480 Sterling, U.S.-built Sterling Truck-Tractor

Vehicle Identification Numbering System 00.03

VIN for Vehicles Built through April 30, 2000

Acterra Workshop Manual, Supplement 1, June 2000 050/1

VIN Positions 1, 2, and 3 (Manufacturer, Make, Vehicle Type)

Code Vehicle Manufacturer Vehicle Make Vehicle Type

49H Sterling, U.S.-built Sterling Incomplete Vehicle

Table 2, VIN Positions 1, 2, and 3 (Manufacturer, Make, Vehicle Type)

VIN Position 4 (Chassis, Front Axle Position, Brakes)

Code Chassis

Front Axle

Position

Brakes

A 4 x 2 Truck Forward Hydraulic

B 8 x 4 Truck-Tractor Setback Air

C 6 x 6 Truck-Tractor Setback Air

D 4 x 4 Truck Setback Hydraulic

E 4 x 4 Truck Setback Air

F 8 x 4 Truck Forward Air

G 8 x 4 Truck-Tractor Forward Air

H 4 x 2 Truck Forward Air

J 10 x 4 Truck All Air

K 4 x 2 Truck-Tractor Forward Air

L 6 x 2 Truck Forward Air

M 6 x 2 Truck-Tractor Forward Air

N 6 x 4 Truck Forward Air

P 6 x 4 Truck-Tractor Forward Air

R 10 x 6 Truck Forward Air

S 10 x 6 Truck-Tractor Forward Air

T 6 x 6 Truck Setback Air

U 8 x 6 Truck All Air

V 8 x 6 Truck-Tractor All Air

W 4 x 2 Truck-Tractor Setback Air

X 6 x 4 Truck Setback Air

Y 6 x 4 Truck-Tractor Setback Air

Z 6 x 2 Truck Setback Air

1 4 x 2 Truck Forward Air/Hydraulic

2 4 x 4 Truck Setback Air

3 4 x 2 Truck Setback Hydraulic

4 8 x 4 Truck Setback Air

5 6 x 2 Truck-Tractor Setback Air

6 4 x 2 Truck Setback Air

VIN Position 4 (Chassis, Front Axle Position, Brakes)

Code Chassis

Front Axle

Position

Brakes

7 Glider Setback Air

8 Glider Forward Air

9 4 x 2 Truck Setback Air/Hydraulic

0 Glider Setback Hydraulic

Table 3, VIN Position 4 (Chassis, Front Axle Position,

Brakes)

VIN Position 5 (Vehicle Model Series, Cab)

Code Sterling Models

A L7500 series

B L8500 series

C L9501

D L8511

E L9500 series

F L9522

G A9522

H A9500 series

J A9513

K L9513

L L8501

M L8513

N L9511

R L7501

S ST9500

W SC8000

2 SC6000

7 SC7000

Table 4, VIN Position 5 (Vehicle Model Series, Cab)

Vehicle Identification Numbering System 00.03

VIN for Vehicles Built through April 30, 2000

Acterra Workshop Manual, Supplement 1, June 2000 050/2

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 65 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

This is a comprehensive factory service repair workshop manual for the 1998-2009 Sterling Acterra MX Trucks OEM. Available for instant access on your computer, tablet, or smartphone, this manual provides detailed instructions for all repairs, servicing, and troubleshooting procedures specific to the Acterra MX Trucks. It features step-by-step guidance, detailed photos, exploded diagrams, and clear instructions—the same advanced reference used by professional mechanics and technicians.

FAQs:

- Q. Can I print out a page?

A. Yes, you can print out a single page or the entire manual, as per your choice. - Q. Can I use this manual on more than one computer?

A. Yes, this manual can be used on as many computers as required. - Q. Is this a trial or a limited version?

A. No, this is the full manual without any limitations or trial periods and can be used for life. - Q. Will this manual expire in 12 months or will I have to pay a renewal fee?

A. NO, absolutely not! You can continue to use this manual for life without the need to renew or pay any extra. - Q. Will this manual work on Windows & MAC computers?

A. Yes, it is fully compatible with all Windows & all MAC computers.

Thanks for considering this item. Please click on the button for more information.