STRUCTURE

©

200338

0

1

2

3

4

5

6

7

ΧΦ65/75/85 series

0

Structure

TECHNICAL DATA

SAFETY INSTRUCTIONS AND WARNINGS

THREADED CONNECTIONS

SEALS AND BEARINGS

GENERAL OPERATIONS

PAINT TREATMENT

CONVERSION TABLES

©

200338 1

Contents

TECHNICAL DATA

ΧΦ65/75/85 series

0

0

0 Technical data

CONTENTS

Page Date

1. VEHICLE MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200338

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200338

2. LOCKING COMPOUNDS AND SEALANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200338

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200338

3. THREADED CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200338

3.1 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200338

4. PAINT TREATMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200338

4.1 Overview of plastics used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200338

TECHNICAL DATA

2

©

200338

Contents

0

ΧΦ65/75/85 series

0

©

200338 1-1

Vehicle models

TECHNICAL DATA

ΧΦ65/75/85 series

0

0

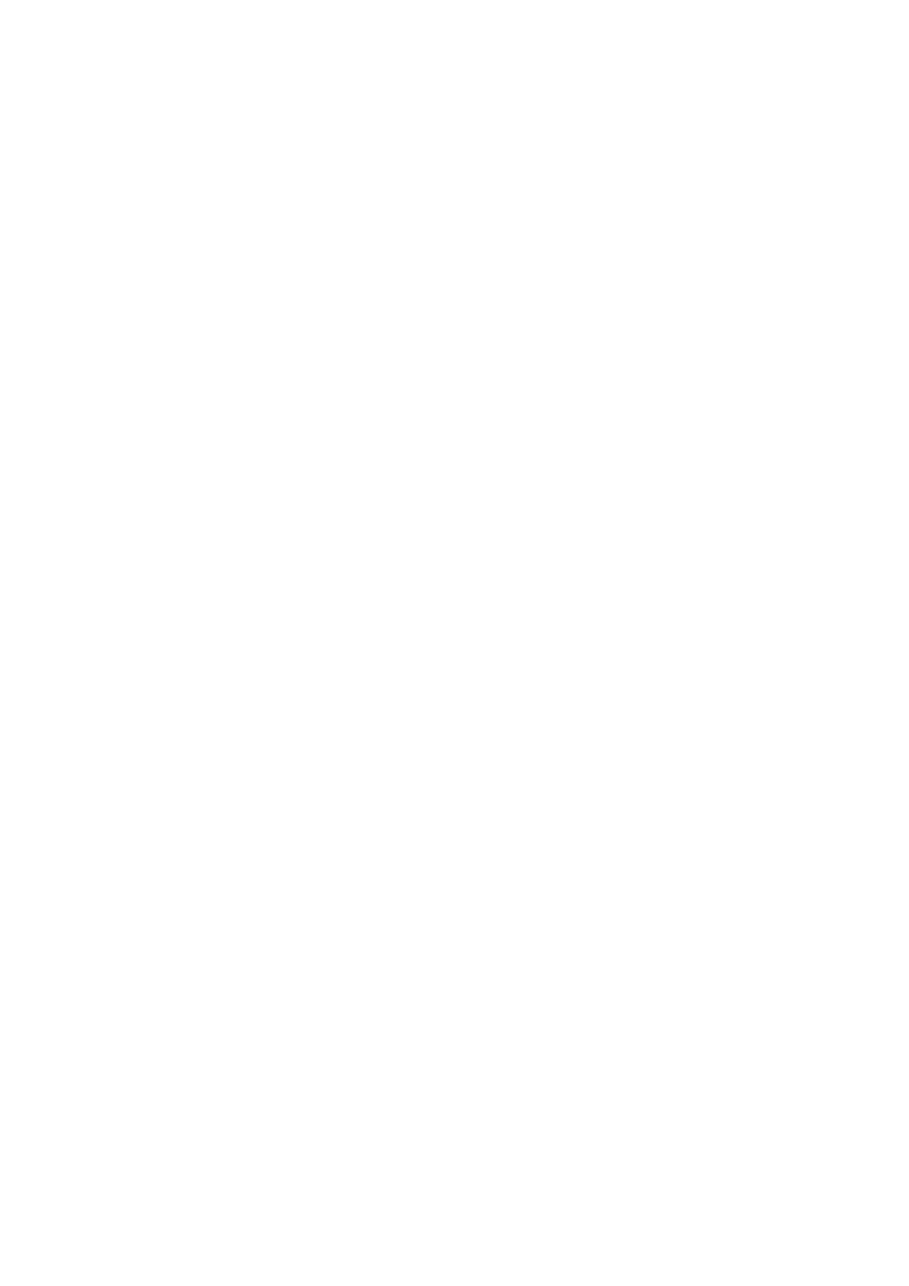

1. VEHICLE MODELS

1.1 OVERVIEW

G0 00 259

TECHNICAL DATA

1-2

©

200338

Vehicle models

0

ΧΦ65/75/85 series

0

©

200338 2-1

Locking compounds and sealants

TECHNICAL DATA

ΧΦ65/75/85 series

0

0

2. LOCKING COMPOUNDS AND SEALANTS

2.1 GENERAL

}

Certain cleaning agents have a

negative effect on the functioning of

locking compounds. The general

rule is therefore that fasteners and

components which have been

cleaned with a cleaning agent must

be treated with a cleaning liquid to

ensure that the locking compound

functions properly.

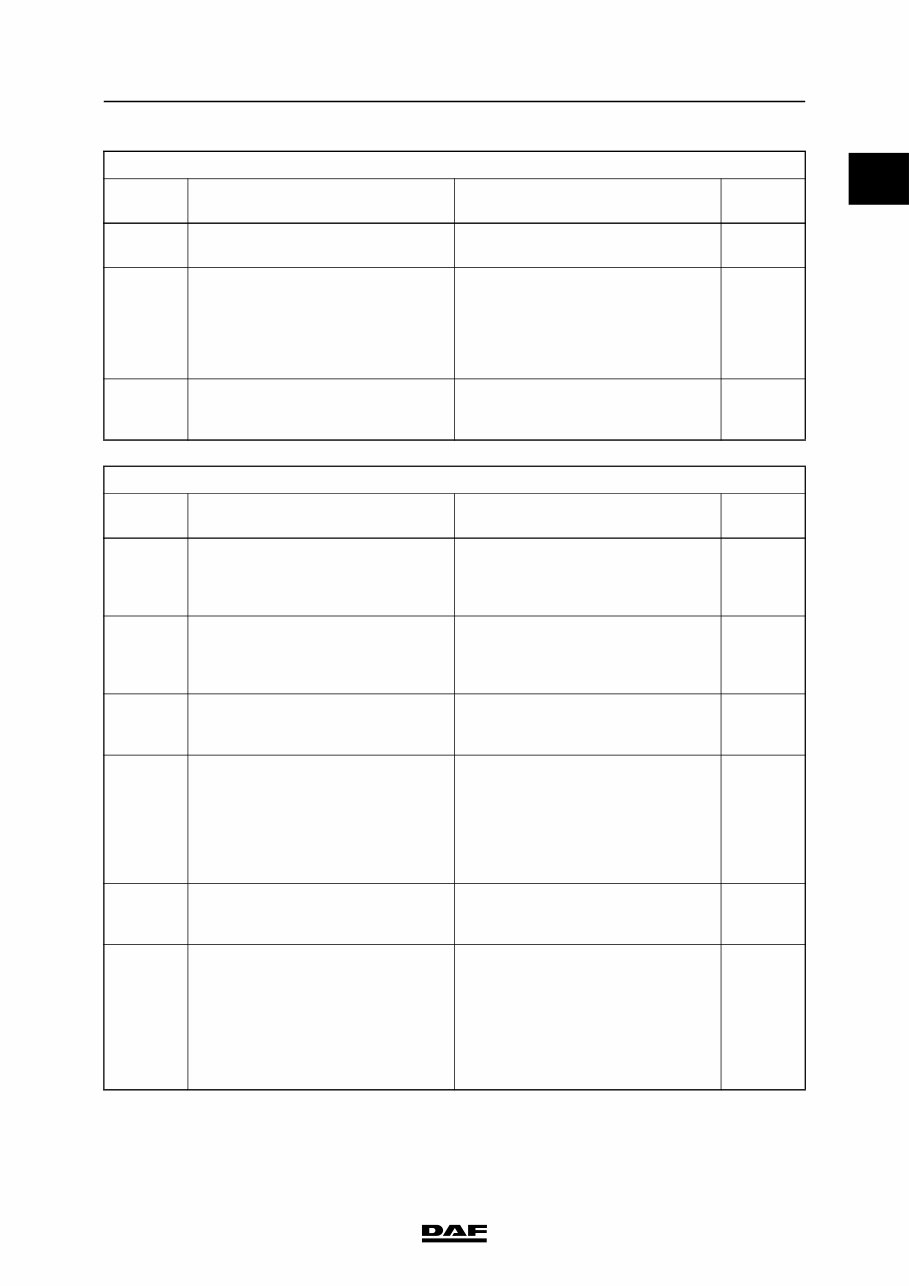

OVERVIEW OF LOCKING COMPOUNDS

Product

name

Properties Applications DAF

number

Loctite

243

- Locking with an average

detaching strength

- Detachable with normal tools

Locking of threaded connections 0068197

Loctite

2701

- Locking with a high detaching

strength

- Repairs the fit in bearing

housings

- Seals against leaks

- Difficult to detach

Locking of threaded connections,

gear lever ball, freeze plugs

1340646

Loctite

638

- Locking with a high detaching

strength under dynamic load

- Difficult to detach

Locking of cylindrical connections 0645557

Loctite

648

- Locking with an average

detaching strength

- Resistant to high temperatures

Locking of threaded connections in

warm places

1357032

Loctite

262

- Locking with a high detaching

strength

- Difficult to detach

Locking of threaded connections,

such as the pinion nut

1279841

TECHNICAL DATA

2-2

©

200338

Locking compounds and sealants

0

ΧΦ65/75/85 series

0

Applying the locking compound

1. Clean both the internal and external threads.

Degrease the thread with a suitable

degreasing agent which leaves no residue

that could affect proper functioning.

2. Apply one or more drops of locking

compound to the thread, depending on the

diameter. Never dip the bolt or stud fully into

the locking compound.

3. Apply a drop of oil under the bolt head.

Locking compounds also reduce the

frictional resistance, which means that

applying a drop of oil to the thread is not

required.

4. Tighten the connection to the specified

torque.

OVERVIEW OF SEALING COMPOUNDS

Product

name

Properties Applications DAF

number

Dirko D - Resistant to temperatures up to

180 ″ C

- Resistant to oil, coolant

Sealing of surface connections 1345014

Loctite

510

- Resistant to temperatures up to

200 ″ C

- Resistant to oil, brake fluid,

coolant

Sealing of surface (flange)

connections that are subjected to high

operating temperatures, such as the

flywheel housing

0697149

Loctite

574

- Resistant to high pressures (up to

350 bar)

- Resistant to oil, brake fluid,

coolant

Sealing of surface connections

against high pressures

1246867

Loctite

Blue

- Resistant to temperatures from

60 ″ C to 260 ″ C

- Resistant to oil

Sealing of flexible constructions such

as (valve) covers

1242895

Loctite

ultra grey

- Silicone sealant, good resistance

to coolant

- Resistant to temperatures up to

325 ″ C

Sealing of (surface) connections in

the cooling system

1284123

Loctite

ultra

copper

- Silicone sealant, good resistance

to oil

- Resistant to temperatures of up

to 350 ″ C

Sealing of surface connections such

as hub covers

1284122

Loctite

5910

- Silicone sealant, good resistance

to oil

- Resistant to temperatures up to

200 ″ C

Sealing of surface connections, such

as front and rear covers of gearboxes,

differential housings, hub covers, stub

axle flanges and oil cooler

1360102

©

200338 2-3

Locking compounds and sealants

TECHNICAL DATA

ΧΦ65/75/85 series

0

0

Loctite

572

- Seals against low pressure

immediately after fitting

Threaded connections 0292336

Loctite

5205

- Surface sealant, specially

designed for sealing aluminium

parts

- Resistant to temperatures up to

150 ″ C

- Resistant to water, coolant and oil

Sealing of aluminium parts 1441339

Loctite

Form a

gasket

- Hardens on contact with metal

and on full closure

For locking, fastening and sealing 1322823

OVERVIEW OF SEALING COMPOUNDS

Product

name

Properties Applications DAF

number

OTHER PRODUCTS

Product

name

Properties Applications DAF

number

Tectyl Protects the cavities of the cab body

against corrosion.

Post-treatment of cab parts to protect

against corrosion.

Can also be used as protection for

metal parts

1343888

Contact

spray

Cleaning agent for cleaning and

degreasing electronic and electrical

connections. Removes moisture and

dirt from electrical contacts

Cleaning of electrical contacts 1387608

Loctite

cleaner

7063

- Cleans and degreases

- Non-inflammable and non-

corrosive

For cleaning/degreasing of materials

to which a locking compound must be

applied

1322827

Molykote

BR 2

PLUS

- Lubricating grease is heat-

resistant from -30 ″ C to +130 ″ C

- Wherever grease lubrication is

appropriate and normal

- For almost all ball and roller

bearings, plain bearings, guides,

couplings, splined shafts,

threaded spindles, sprocket

drives with a low speed

1389512

Molykote

P37

- Grease protects against

corrosion and is heat-resistant to

1400 ″ C.

For threaded connections that are

exposed to high temperatures, as

used for exhaust systems

1391619

Copaslip - Copper paste with an excellent

bond, is anti-corrosive and heat-

resistant from -35 ″ C to 1100 ″ C.

- Resistant to water, salts and

acids.

- Prevents wear, oxidation, rust,

corroding and locking of metal

surfaces.

For connections that are vulnerable to

oxidation or corrosion, such as battery

terminals, exhaust couplings, etc.

1284344

TECHNICAL DATA

2-4

©

200338

Locking compounds and sealants

0

ΧΦ65/75/85 series

0

Renolit

HLT2

- Grease (white) Disc brake adjustment device 1448907

Syntheso

GL EP1

- Grease (green) Rubber guides for disc brake 1448908

Gleitmo

805

- Protects untreated metals

against corrosion

For parts which are attached with a fit

such as wheel hub units

1443160

OTHER PRODUCTS

Product

name

Properties Applications DAF

number

You're Reading a Preview

What's Included?

Lifetime Access

Access Contents & Bookmarks

Print one or all pages of your manual