2006 Cub Cadet 4x4 Utility Vehicle (w/ Kohler Engine) OEM Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Professional

Shop Handbook

4x4 Utility Vehicle w/Kohler Engine

MTD Products Inc. - Product Training and Education Department

FORM NUMBER - 769-03026

12/2006

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outdoor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperi-

enced individuals should seek the assistance of an experienced and trained professional. Read, understand, and follow all

instructions and use common sense when working on power equipment. This includes the contents of the product’s Oper-

ators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete and accurate as possible at the time of publication. However, due to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2006 MTD Products Inc. All Rights Reserved

1

Chapter 1: Introduction.....................................................................................................1

Chapter 2 - Drive Sytem: CVT and Transfer Case............................................................9

Kohler Enclosed CVT Addendum..............................................................................63

Caterpillar Enclosed CVT Addendum........................................................................75

Chapter 3 - Drive System: Drive Shafts and Differentials................................................89

Chapter 4 - Front Suspension and Steering..................................................................123

Chapter 5 - Rear Suspension........................................................................................159

Chapter 6 - Hydraulic Brakes........................................................................................173

Chapter 7 - Kohler Engine Service Access and Fuel System........................................195

Kohler Engine Speed and Throttle Adjustment Addendum.....................................215

Chapter 8 - Caterpillar Engine and Related Systems....................................................219

Chapter 9 - Electrical.....................................................................................................275

Addendum - Front Drive System Differential Gearcase: Hillard.....................................323

Table of Contents

Chapter 1: Introduction

1

1. INTRODUCTION: PRODUCT LINE

6X4

Cub Cadet entered the utility vehicle market in the

2003 season with a 6X4 vehicle having fully indepen-

dent suspension and Honda power (20 H.P.). The Big

Country 6X4 continues in production with evolutionary

changes and a switch to Kohler power. See Figure 1.1.

Steel-bed 4X2

In 2004, a 4X2 vehicle was introduced. The 4X2

shares the 6X4 front suspension, has an 18 H.P.

Honda engine and a push-button controlled transmis-

sion. Evolutionary changes include a switch to Kohler

power. See Figure 1.2.

Big Country 6X4

Figure 1.1

Figure 1.2

4X2 Steel Bed

Poly bed 4X2

For 2005, a lighter-duty version of the 4X2 was intro-

duced, using a plastic cargo box and a 9.5 H.P. drives

system sourced from Kawasaki. See Figure 1.3.

All of these first-generation utility vehicles share a com-

mon structure from the cargo box forward. The 6X4

carries a fully enclosed rear structure with swing-arm

suspension. The 4X2s carry the engine and transaxles

on a pivoting cradle that acts as the rear suspension.

4X4

The 4X4 vehicle that is the subject of this handbook

represents a complete departure from the first genera-

tion vehicles. See Figure 1.4.

Figure 1.3

4X2 “Poly Bed”

Figure 1.4

New 4X4

CHAPTER 1: INTRODUCTION

Chapter 1: Introduction

2

2. UNDERSTANDING UTILITY VEHICLE MODEL

NUMBERS

e.g.: 37AJ467D710

• 37 - - - - - - - - - indicates that this is a U.V.

• - - A - - - - - - - - indicates the engineering level

• - - - J - - - - - - - indicates the engine type

• - - - - 4 - - - - - - indicates the number of wheels

• - - - - - 67 - - - - indicates the series and trim

• - - - - - - - D - - - indicates the type of tires

• - - - - - - - - 710 indicates that it is Cub Cadet

2.1. Engine type detail:

• B = Kohler Command 18 H.P. V-twin

• C = Kohler Command 20 H.P. V-twin

• J = Caterpillar Diesel 20 H.P. liquid cooled

• N = Kawasaki 9.5 H.P. single, inclined

• R = Honda 18 H.P. V-twin

• S = Honda 20 H.P. V-twin

2.2. Series detail:

• 1 = poly-bed 4 x 2

• 3 = steel bed 4 x 2

• 4 = 6 x 4

• 6 = 4 x 4

2.3. Trim detail:

• 0 = yellow on 6 x 4 and 4 x 2

• 1 = camouflage on 6 x 4 and 4 x 2

• 2 = fire rescue red on 6 x 4 and 4 x 2

• 6 = yellow on 4 x 4

• 7 = camouflage on 4 x 4

2.4. Tires

• A = turf tires

• B = knobby tires

• C = heavy-duty tires

• D = trail tires

• E = Fire Rescue: f. run-flat tires, r. trail tires

• G = poly-bed trail tires

3. PROFESSIONAL SHOP MANUAL INTENT

This Manual is intended to provide service dealers with

an introduction to the mechanical aspects of the new

vehicle.

This Professional Shop Manual covers the second

generation Cub Cadet Utility Vehicles more specifically,

and in greater depth than the origanal Shop Handbook.

• The content in this manual supersedes any con-

tent in the handbook.

• Detailed service information about the engine

will be provided by the engine manufacturer, in

most cases.

Disclaimer: This manual was written using second

generation vehicle. The information contained in this

handbook is correct at the time of writing. Both the

product and the information about the product are sub-

ject to change without notice.

About the text format:

NOTE: is used to point-out information that is

relevant to the procedure, but does not fit as a

step in the procedure.

CAUTION: is used to point-out potential danger

to the technician, operator, bystanders, or sur-

rounding property.

• Bullet points: indicate sub-steps or points.

Disclaimer: This Professional Shop Manual is

intended for use by trained, professional technicians.

• Common sense in operation and safety is

assumed.

• In no event shall MTD or Cub Cadet be liable for

poor text interpretation, or poor execution of the

procedures described in the text.

• If the person using this manual is uncomfortable

with any procedures they encounter, they should

seek the help of a qualified technician or Cub

Cadet Technical Support.

Chapter 1: Introduction

3

Fasteners:

• Most of the fasteners used on the vehicle are

sized in fractional inches. Some are metric.

For this reason, wrench sizes are frequently

identified in the text, and measurements are

given in U.S. and metric scales.

• If a fastener has a locking feature that has

worn, replace the fastener or apply a small

amount of releasable thread locking compound

such as Loctite® 242 (blue).

• Some fasteners like cotter pins are single-use

items that are not to be reused.

Other fasteners such as lock washers, retaining

rings, and internal cotter pins (hairpin clips) may

be reused if the do not show signs of wear or

damage. This manual leaves that decision to

the judgement of the technician.

Assembly:

Torque specifications may be noted in the part of the

text that covers assembly, they may also be summa-

rized in tables along with special instructions regarding

locking or lubrication.

Whichever method is more appropriate will be used. In

many cases, both will be used so that the manual is

handy as a quick-reference guide as well as a step-by-

step procedure guide that does not require the user to

hunt for information.

The level of assembly instructions provided will be

determined by the complexity and of reassembly, and

by the potential for unsafe conditions to arise from mis-

takes made in assembly.

Some instructions may refer to other parts of the man-

ual for subsidiary procedures. This avoids repeating

the same procedure two or three times in the manual.

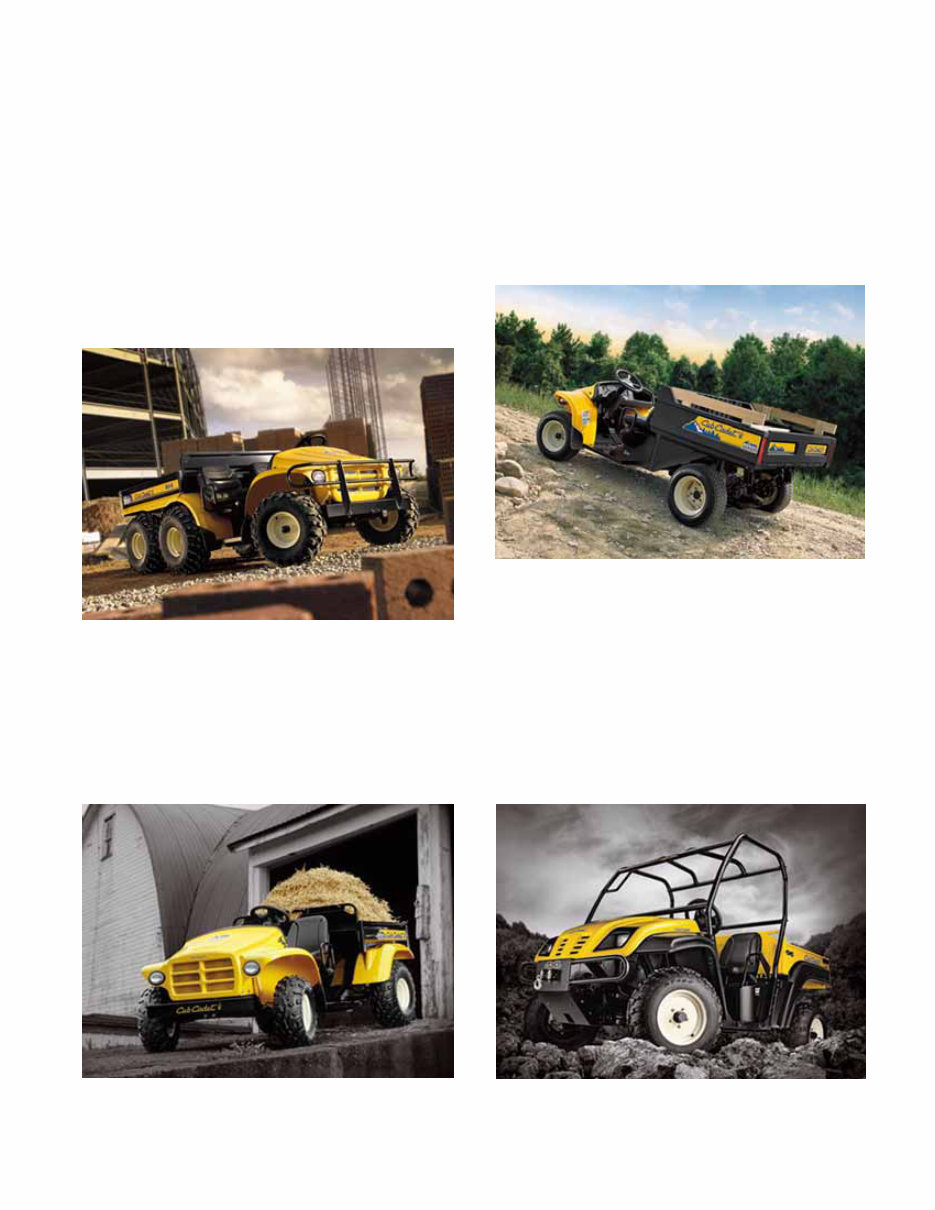

4. LIFTING AND SUPPORTING

CAUTION: Use common sense and safety when

lifting and supporting any equipment:

• Always work on a firm, level surface that will

support the load to be placed on it.

• Never leave equipment supported by hydraulic

means: hydraulic jacks are for lifting. Once

lifted, the equipment should be positioned on

and supported by jack stands of sufficient capac-

ity to ensure safety.

• Confirm that the equipment is firmly seated on

the jack stands before doing any work that

results in exposure to falling or crushing hazard.

• Use caution when positioning jacks and jack

stands, so as not to damage any fuel lines,

brake lines, electrical conduits, or linkages.

• Do not lift or support the vehicle by the cradle

that the engine and transfer case are mounted

to. It is vibration-isolated from the rest of the

vehicle. The rubber isolator mounts are not

designed to support the weight of the vehicle.

The utility vehicle may be lifted from the rear by placing

a jack under the rear-most cross-member. This cross-

member also provides a mounting point for the 2” class

1 hitch receiver. See Figure 1.5.

Figure 1.5

Rear cross-member

Accessory

receiver

Chapter 1: Introduction

4

Jack stands can safely be positioned beneath the up-

right frame members that are roughly even with the

centerline of the tray that supports the engine and

transfer case. See Figure 1.6.

The front of the vehicle may be safely lifted by placing a

jack directly under the mounting point where the front

differential joins the frame. See Figure 1.7.

Jack stands will safely support the front of the vehicle if

positioned beneath the frame, where the front out-rig-

ger extends to meet the base of the OPS.

See Figure 1.8.

Alternatively, the vehicle may be lifted by positioning a

jack along the outer frame channel, where the rear

out-rigger extends to meet the base of the OPS .

See Figure 1.9.

NOTE: The center of gravity for the vehicle is

beneath the seat support structure.

NOTE: The outer frame channel will support the

vehicle without damage.

Figure 1.6

Figure 1.7

Figure 1.8

Figure 1.9

Chapter 1: Introduction

5

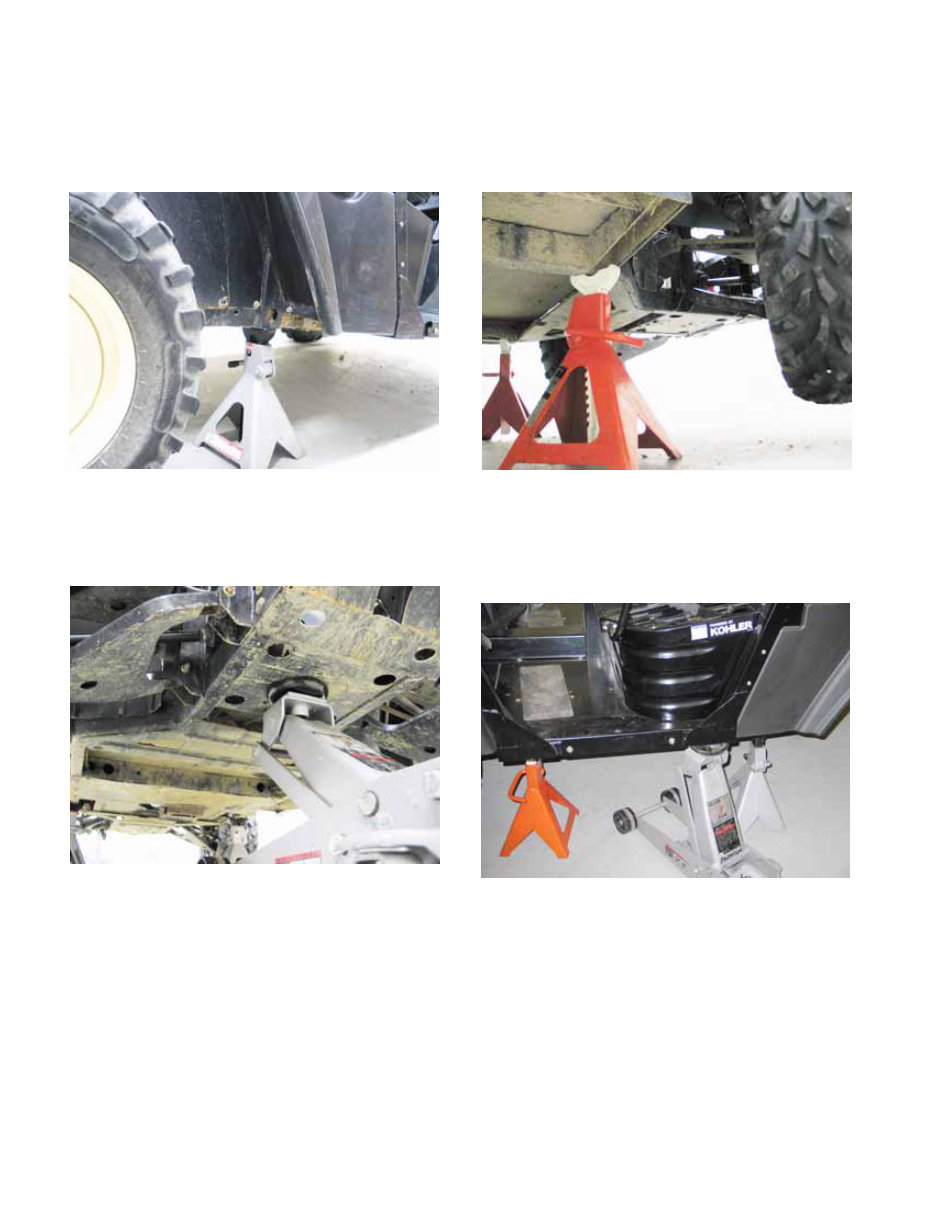

5. DRIVE SYSTEM DESCRIPTION

• A belt-type CVT (Continuously Variable Trans-

mission) system carries power from the engine

crankshaft to the transfer case.

See Figure 1.10.

• The CVT range provides strong torque and

acceleration, limiting speed to 25 MPH (40

KPH).

• The driving clutch on the engine crankshaft uses

centrifugal force to operate a mechanism that

pulls the sheaves closer together.

The faster the engine spins, the closer the

sheaves get.

As the sheaves close-down on the belt, the belt

is forced outward.

As the belt is forced outward, the drive ratio

decreases so that fewer crankshaft revolutions

equate to more input shaft revolutions at the

input shaft of the transfer case.

NOTE: A lower numeric ratio results is fre-

quently referred to as a “steeper” or “taller” drive

ratio, yielding in increased top speed.

• As the effective diameter of the driving pulley

increases, the belt has less available length to

reach the driven pulley.

The sheaves of the driven pulley is spring-

loaded so that it can absorb the additional ten-

sion.

An additional effect is that the belt is drawn

deeper into the sheaves, reducing the effective

diameter of the driven pulley.

Reducing the diameter of the driven pulley fur-

ther reduces the drive ratio.

Figure 1.10

CVT driving element

CVT belt

CVT driven

element

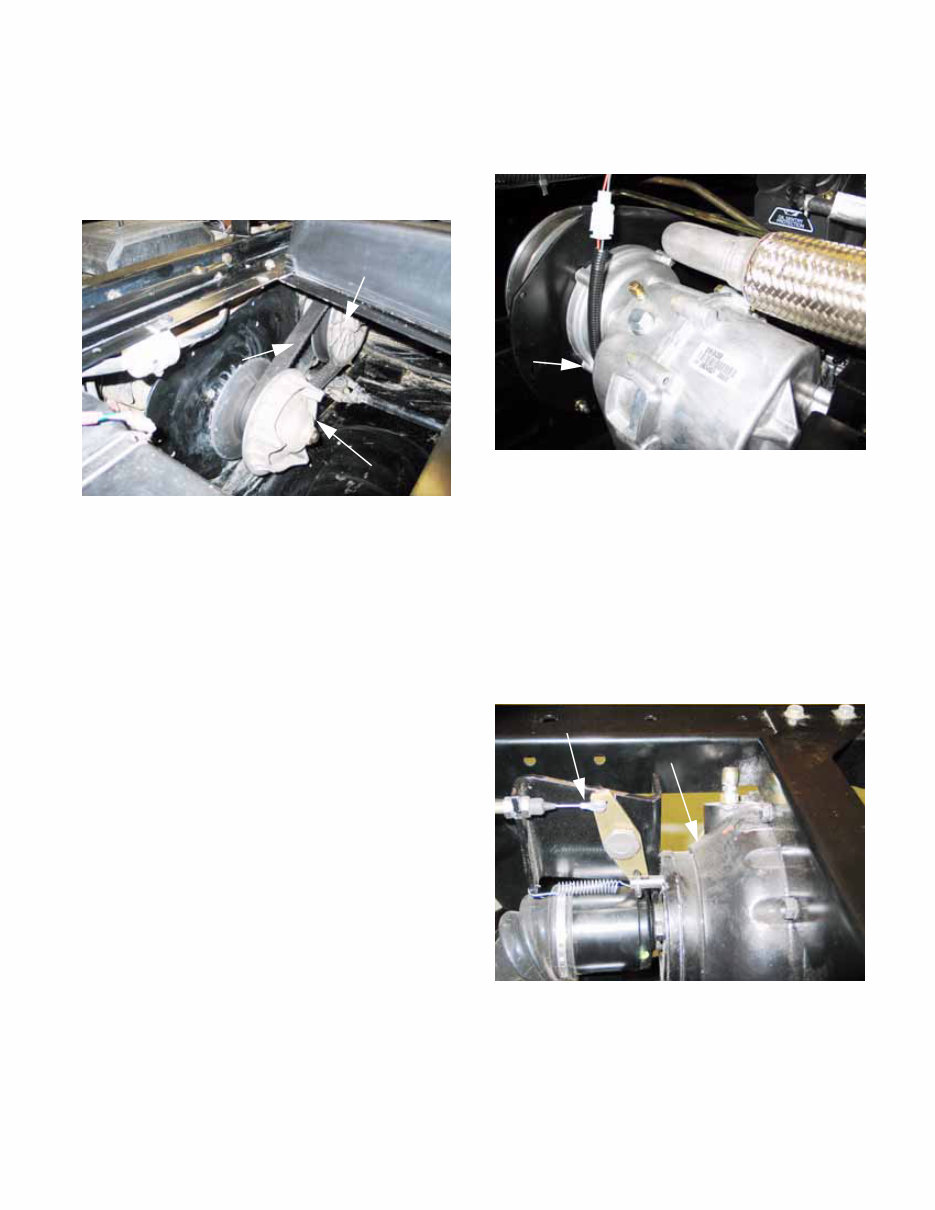

• The transfer case is mounted adjacent to the

engine, with the input shaft running fore-and-aft

in the frame. See Figure 1.11.

• The transfer case contains two forward ratios,

neutral, and reveres.

• Gear selection is controlled by rods and a selec-

tor lever sourced from Hurst®.

Drive shafts with Hooke/Spicer type universal joints

extend fore and aft from the output shafts of the trans-

fer case to drive the front and rear differentials.

The rear differential has a cast iron housing and a

cable-actuated locking feature. See Figure 1.12.

Figure 1.11

Transfer

case

Figure 1.12

Differential lock

actuator

Rear differential

Chapter 1: Introduction

6

The front differential has an aluminum housing, and

an electronically controlled, slip sensing Auto-Lok®

feature. See Figure 1.13.

• The front differential is engaged or disengaged

using a rocker switch on the dashboard.

Each differential transfers power to the drive hubs

through a drive shaft with Rzeppa-type constant veloc-

ity joints at each end.

6. SERVICE INTENT

The transfer case is manufactured by Cub Cadet. If it

fails during the first year , it should be removed and

replaced as a complete unit.

• In the event of a failure, the transfer case will be

called back for engineering analysis.

• If the failure is warrantable, Cub Cadet will cover

the cost of replacement.

• If the failure is not warrantable, replacement will

be at the customer’s expense.

• Beyond the first year, but within the first two

years, the decision whether to repair or replace

the transfer case will be based on economic fea-

sibility and the availability of parts and assem-

blies.

• Beyond the warranty period, the dealer can

repair or replace the transfer case at their own

discretion.

The remainder of the drive system (CVT, drive shafts,

axles, differentials) is purchased from outside ven-

dors.

• If any of these items fail in the first two years,

they should be removed and replaced with a

complete unit. The only exception to this may be

the axles. Rzeppa (Constant Velocity) joints

may be available to repair rather than replace

axles. Service intent has not been decided as

this manual goes to print.

• In the event of a failure, the component will be

called back for engineering analysis and vendor

recovery.

• If the failure is warrantable, Cub Cadet will cover

the cost of replacement.

• If the failure is not warrantable, replacement will

be at the customer’s expense.

• Beyond the warranty period, internal parts for

the differentials will be made available so that

the dealer can repair or replace them at their

own discretion.

Kohler Engines will be serviced as they are in the rest

of the Cub Cadet product Line. They are seen as an

integral part of the Cub cadet product, with parts and

warranty coverage provided through Cub Cadet.

Caterpillar Engines in Cub cadet equipment will con-

tinue to be serviced exclusively by CAT dealers.

Figure 1.13

Front differential

Electrical connection for

Auto-Lok® feature

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 76 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

- Get the comprehensive repair manual for the 2006 Cub Cadet 4x4 Utility Vehicle (w/ Kohler Engine) to troubleshoot and replace parts with ease.

- Whether you're a professional mechanic or a DIY enthusiast, this manual provides step-by-step instructions, clear images, and exploded-view illustrations.

- Regular maintenance is essential for the durability of your UTV, and this manual offers the manufacturer's recommended troubleshooting charts and replacement procedures.

- Save on repairs, increase your UTV's reliability, and avoid frequent visits to the repair shop with the help of this repair manual.

- It's not a generic manual; it's the same OEM manual used by professional technicians, ensuring accuracy and reliability.

- No need to search through numerous pages; carry, search, screenshot, and bookmark the manual on any electronic device.

- It's printable and compatible with various electronic devices, including PC, Mac, Android, and Apple devices, requiring only Adobe Reader (free).