2016 Yamaha SR Viper 4-Stroke Snowmobile Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SERVICE MANUAL SERVICE MANUAL

p/n 8JR-F8197-70-E2 (LIT-12618-03-26)

FOREWORD

This Yamaha Service Manual contains service and maintenance information for the Model Year 2016 Yamaha SRV10

Snowmobile. The manual is designed to aid service personnel in service-oriented applications.

This manual is divided into sections. The sections cover specific snowmobile components or systems and, in addition to

the standard service procedures, includes assembling, disassembling, and inspecting instructions. When using this man-

ual as a guide, the technician should use discretion as to how much disassembly is needed to correct any given condition.

The service technician should become familiar with the operation and construction of the components or systems by

carefully studying the complete manual. This will assist the service technician in becoming more aware of and efficient

with servicing procedures. Such efficiency not only helps build consumer confidence but also saves time and labor.

All Yamaha publications and snowmobile decals display the words Warning, Caution, and Note to emphasize important

information. The symbol ! WARNING identifies personal safety-related information. Be sure to follow the direc-

tive because it deals with the possibility of severe personal injury or even death. A CAUTION identifies unsafe prac-

tices which may result in snowmobile-related damage. Follow the directive because it deals with the possibility of

damaging part or parts of the snowmobile. The symbol NOTE: identifies supplementary information worthy of partic-

ular attention.

At the time of publication, all information, photographs, and illustrations were technically correct. Some photographs

and illustrations used in this manual are used for clarity purposes only and are not designed to depict actual conditions.

Because Yamaha constantly refines and improves its products, no retroactive obligation is incurred.

All materials and specifications are subject to change without notice.

Keep this manual accessible in the shop area for reference.

©2016 by Yamaha Motor Corporation, U.S.A

January 2016

All Rights reserved.

Any reprinting or unauthorized use without the written permission of Yamaha Motor Corporation, U.SA. is

expressly prohibited.

TABLE OF CONTENTS

General Information ...................................................... 1

Special Tools ..................................................................... 1

Snowmobile Identification ................................................. 2

Recommended Gasoline and Oil ...................................... 2

Engine Break-In ................................................................ 2

Drive Belt Break-In ............................................................ 2

Genuine Parts ................................................................... 2

Varying Altitude Operation ................................................ 2

Preparation For Storage.................................................... 4

Preparation After Storage ................................................. 4

After Break-In Checkup/Checklist ..................................... 4

Engine Specifications ........................................................ 5

Electrical Specifications .................................................... 5

Drive System Specifications.............................................. 6

Track Specifications .......................................................... 8

Torque Conversions .......................................................... 9

Torque Conversions .......................................................... 9

Torque Specifications ........................................................ 9

Steering and Body ...................................................... 10

Steering Post................................................................... 10

Ski (Single Wear Bar) ..................................................... 13

Ski (SR10M).................................................................... 14

Ski (Dual Wear Bar) ........................................................ 15

Wear Bar (Single) ........................................................... 15

Wear Bar (Dual) .............................................................. 16

Spindle ............................................................................ 16

Spindle (SR10M) ............................................................. 17

Steering Tie Rod ............................................................. 18

Ski Alignment .................................................................. 19

A-Arms ............................................................................ 20

A-Arms (SR10M)............................................................. 21

Ski Shock Absorber ........................................................ 22

Sway Bar......................................................................... 23

Front Bumper .................................................................. 23

Seat Assembly ................................................................ 23

Seat Cushion .................................................................. 24

Taillight/Brakelight Assembly .......................................... 24

Rear Bumper/Snowflap ................................................... 25

Windshield/Console/Headlight ........................................ 25

Headlight Bulb................................................................. 26

Adjusting Headlight Aim ................................................. 26

Engine .......................................................................... 27

Removing ........................................................................ 27

Installing .......................................................................... 29

Servicing ......................................................................... 33

Troubleshooting Engine .................................................. 55

Engine-Related Items ................................................. 57

Water Pump .................................................................... 57

Pressure Testing Engine ................................................. 58

Checking Compression ................................................... 58

Changing Oil/Filter .......................................................... 59

Liquid Cooling System .................................................... 60

Cooling System Schematic ............................................. 61

Air Silencer ...................................................................... 61

Fuel Systems ............................................................... 62

Fuel System..................................................................... 62

Individual Components .................................................... 62

Self-Diagnostic System/Codes ........................................ 64

Fuel Pressure Regulator .................................................. 65

Throttle Body Assembly................................................... 65

Throttle Cable .................................................................. 66

Fuel Pump ....................................................................... 67

Gas Tank ......................................................................... 68

Troubleshooting ............................................................... 70

Electrical Systems ...................................................... 71

Ignition System ................................................................ 71

Throttle Position Sensor .................................................. 71

Electrical Resistance Tests .............................................. 73

Voltage Regulator Tests ................................................... 73

Testing Fuel Gauge Sender ............................................. 74

Emergency Stop Switch................................................... 74

Starter Relay Solenoid ..................................................... 74

Fuse................................................................................. 74

Ignition Switch ................................................................. 75

Starter Motor .................................................................... 75

Troubleshooting Electric Start .......................................... 76

Magneto........................................................................... 76

Brakelight Switch ............................................................. 78

Headlight Dimmer Switch ................................................ 78

Testing Handlebar Warmer Elements ............................. 79

Testing Thumb Warmer Element ..................................... 79

Testing Handlebar Warmer/Thumb Warmer Switch......... 79

Testing Seat Heater Switch ............................................. 80

Testing Speedometer Sensor .......................................... 80

Testing Gear Position Switch ........................................... 80

Testing Shift Switch ......................................................... 80

Testing Shift Actuator ....................................................... 81

Drive Train/Track/Brake Systems .............................. 82

Drive Belt ......................................................................... 82

Primary Sheave ............................................................... 83

Secondary Sheave .......................................................... 86

Primary Sheave/Stationary Sheave ................................. 88

Drive Train ....................................................................... 89

Drive Sprockets ............................................................... 94

Track Tension .................................................................. 96

Track Alignment ............................................................... 97

Brake System (Hydraulic) ................................................ 98

Brake Lever/Master Cylinder Assembly ........................ 103

Troubleshooting Track ................................................... 104

Troubleshooting Hydraulic Brake System...................... 104

Troubleshooting Primary Sheave/Secondary Sheave ...105

Suspension ................................................................ 106

Suspension Setup Basics .............................................. 106

Pressurizing Rebuildable Shocks .................................. 108

Servicing Suspension .................................................... 110

Wiring Harnesses ...................................................... 127

1

General Information

NOTE: Whenever a part is worn excessively, cracked,

or damaged in any way, replacement is necessary.

NOTE: Some illustrations and photographs used in

this manual are used for clarity purposes only and

are not designed to depict actual conditions.

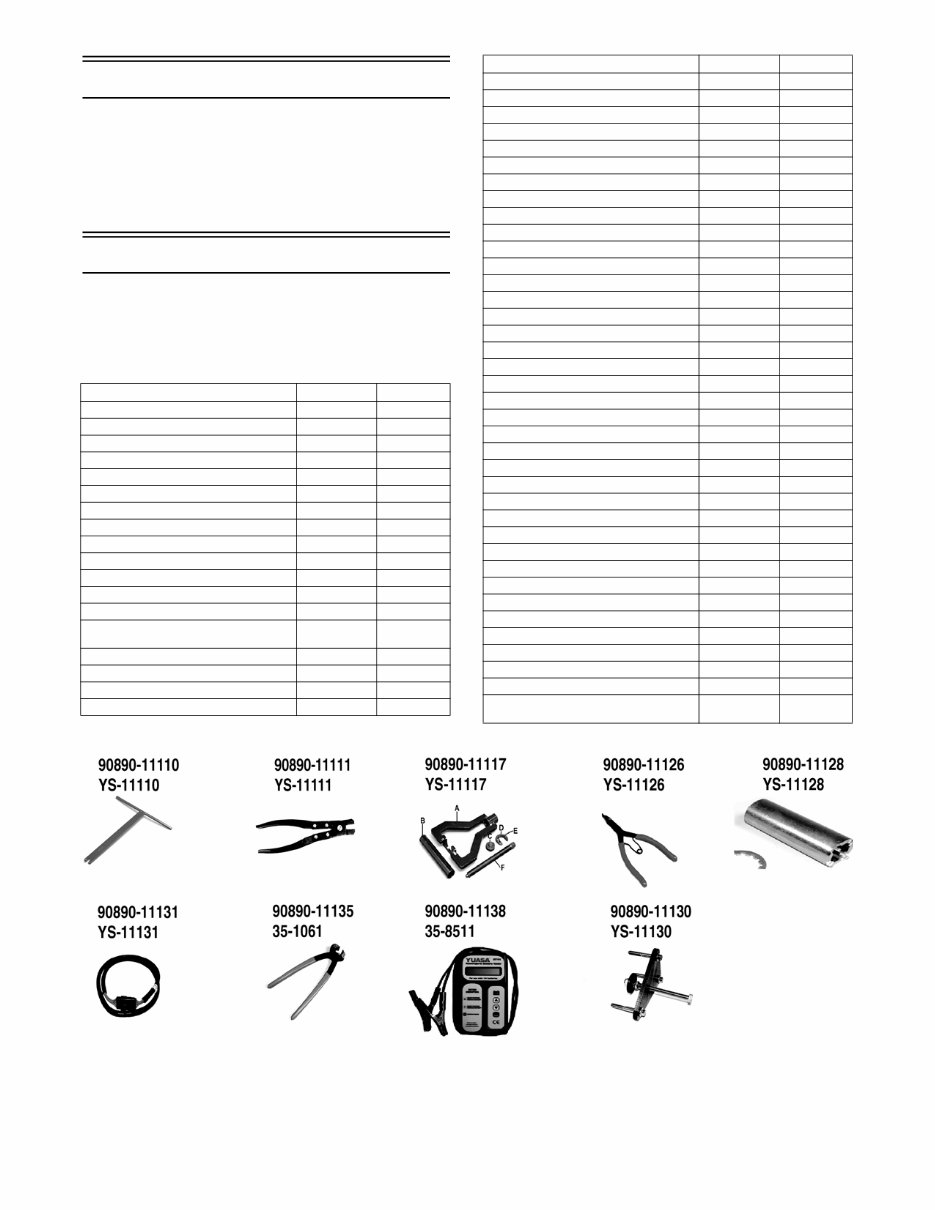

Special Tools

A number of special tools must be available to the techni-

cian when servicing snowmobile.

NOTE: Special tools are available from the Yamaha Ser-

vice Parts Department or K&L Tool Supply Company.

Snow_tool_2015A

Description Yamaha p/n K&L p/n

Engine Tachometer 90793-80009 YU-08036-C

Rotor Holder 90890-01235 YU-01235

Piston Pin Puller 90890-01304 YU-24460-01

Radiator Pressure Tester 90890-01325 YU-24460-01

Radiator Pressure Tester Adapter 90890-01352 YU-33984

Heavy Duty Puller 90890-01362 YU-33270-B

Oil Filter Wrench 90890-01469 YM-01469

YXR Clutch Bushing Jig Kit 90890-01528 YS-39752

Clutch Bushing Press 90890-01529 YS-42424

Primary Clutch Holder 90890-01701 YS-01880-A

Clutch Spider Separator 90890-01711 YS-28890-C

Track Clip Installation Tool 90890-01721 YS-91045-C

Clutch Separator Adapter 90890-01740 YS-34480

Clutch Puller 90890-01898 YS-01881-A

YS-1881-1

Engine Compression Tester 90890-03081 YU-33233

Carb Synchronizer 90890-03094 YU-44456

Dial Indicator 90890-03097 YU-A8428

Analog Pocket Tester 90890-03112 YU-03112-C

Fuel Pressure Gauge 90890-03153 YU-03153

Fuel Pressure Tester 90890-11143 YS-11143

Carb Angle Driver 2 90890-03173

Model 88 Multimeter 90890-03174 YU-A1927

Fuel Pressure Adapter 90890-03176 YM-03176

Kit, Diagnostics Tool (YSDT) 90890-03233

Valve Spring Compressor 90890-04019 YM-04019

Bearing Driver 40 mm 90890-04058 YM-04058

Crankshaft Protector 90890-04089 YM-33282

Valve Lapping Tool 90890-04101 YM-A8998

VSC Adapter 19.5mm 90890-04114 YM-04114

Valve Guide Remover (4.5mm) 90890-04116 YM-04116

Valve Guide Installer (4.5mm) 90890-04117 YM-04117

Valve Guide Reamer (4.5mm) 90890-04118 YM-04118

Mechanical Seal Installer 90890-04145

Piston Ring Compressor 90890-05158 YM-08037

Opama PET-4000 Spark Checker 90890-06754 YM-34487

Rear Spring Installer 90890-11110 YS-11110

Hose Clamp Installation Tool 90890-11111 YS-11111

Puller, Idler Wheel Kit (Includes * below) 90890-11117 YS-11117

* A Handle 90890-11118 YS-11118

* B Insertion Tool (1.0") 90890-11119 YS-11119

* B Insertion Tool (1.25") 90890-11120 YS-11120

* C Pivot Plate 90890-11121 YS-11121

* D Adapter Plate (1.0") 90890-11122 YS-11122

* D Adapter Plate (1.25") 90890-11123 YS-11123

* E Cap Screw 90890-11124 YS-11124

* F Puller Bolt 90890-11125 YS-11125

Snap Ring Pliers 90890-11126 YS-11126

Socket 90890-11128 YS-11128

Brake Caliper Bearing Puller 90890-11130 YS-11130

Hood Harness Extension 90890-11131 YS-11131

Fuel Hose Clamp Tool 90890-11135 35-1061

Battery Tester 90890-11138 35-8511

Shift Actuator Test Harness 90890-11141 YS-11141

Fuel Tank Filler Neck Nut Wrench 90890-11142 YS-11142

Yamaha Bond 1215 90890-85505

Angle Gauge Locally

Sourced

Description Yamaha p/n K&L p/n

2

Snowmobile Identification

The Yamaha Snowmobile has two important identifica-

tion numbers. The Vehicle Identification Number (VIN)

is stamped into the tunnel near the right-side footrest or

on top of the tunnel. The decal also displays pertinent

production information. The Engine Serial Number

(ESN) is stamped into the crankcase of the engine.

These numbers are required to complete warranty claims prop-

erly. No warranty will be allowed by Yamaha if the engine

serial number or VIN is removed or mutilated in any way.

Recommended Gasoline

and Oil

RECOMMENDED GASOLINE

The recommended gasoline to use in these snowmobiles

is 87 octane unleaded. In many areas, oxygenates are

added to the gasoline. Oxygenated gasolines containing

up to 10% ethanol are acceptable gasolines.

When using ethanol blended gasoline, it is not necessary

to add a gasoline antifreeze since ethanol will prevent the

accumulation of moisture in the fuel system.

RECOMMENDED OIL

The recommended oil to use is Semi-Synthetic YAMA-

LUBE 0W-30 oil.

The engine oil should be changed every 4000 km (2500

miles) before prolonged storage and the oil filter should

be changed every 20,000 km (12,500 miles).

Engine Break-In

The engine (when new or rebuilt) requires a short break-in

period before the engine is subjected to heavy load conditions.

This engine does not require any pre-mixed fuel during

the break-in period.

There is never a more important period in the life of the

engine than the first 500 km (300 miles). Since the

engine is brand new, do not put an excessive load on it

for the first 500 km (300 miles). The various parts in the

engine wear and polish themselves to the correct operat-

ing clearances. During this period, prolonged full throttle

operation or any condition that might result in engine

overheating must be avoided.

Operating your snowmobile for the first time: Start the

engine and let it idle for 15 minutes.

0-160 km (0–100 miles): Avoid prolonged operation

above 6000 RPM.

160-500 km (100–300 miles): Avoid prolonged operation

above 8000 RPM.

500 km (300 miles) and beyond: The snowmobile can

now be operated normally.

NOTE: After 800 km (500 miles) of operation, the

engine oil must be changed and the oil filter replaced.

If any engine trouble should occur during the engine

break-in period, immediately have a Yamaha dealer

check the snowmobile.

Drive Belt Break-In

Drive belts require a break-in period of approximately 40

km (25 miles). Drive the snowmobile for 40 km (25

miles) at 3/4 throttle or less. By revving the engine up

and down (but not exceeding 100 km/h [60 mph]), the

exposed cord on the side of a new belt will be worn

down. This will allow the drive belt to gain its optimum

flexibility and will extend drive belt life.

NOTE: Before starting the snowmobile in extremely

cold temperatures, the drive belt should be removed

and warmed up to room temperature. Once the drive

belt is at room temperature, install the drive belt.

Genuine Parts

When replacement of parts is necessary, use only genuine

Yamaha parts. They are precision-made to ensure high

quality and correct fit.

Varying Altitude Operation

Operating a snowmobile at varying altitudes requires recal-

ibration of drive system components.

Following are basic altitude theories for clutching,

engine, suspension, and track.

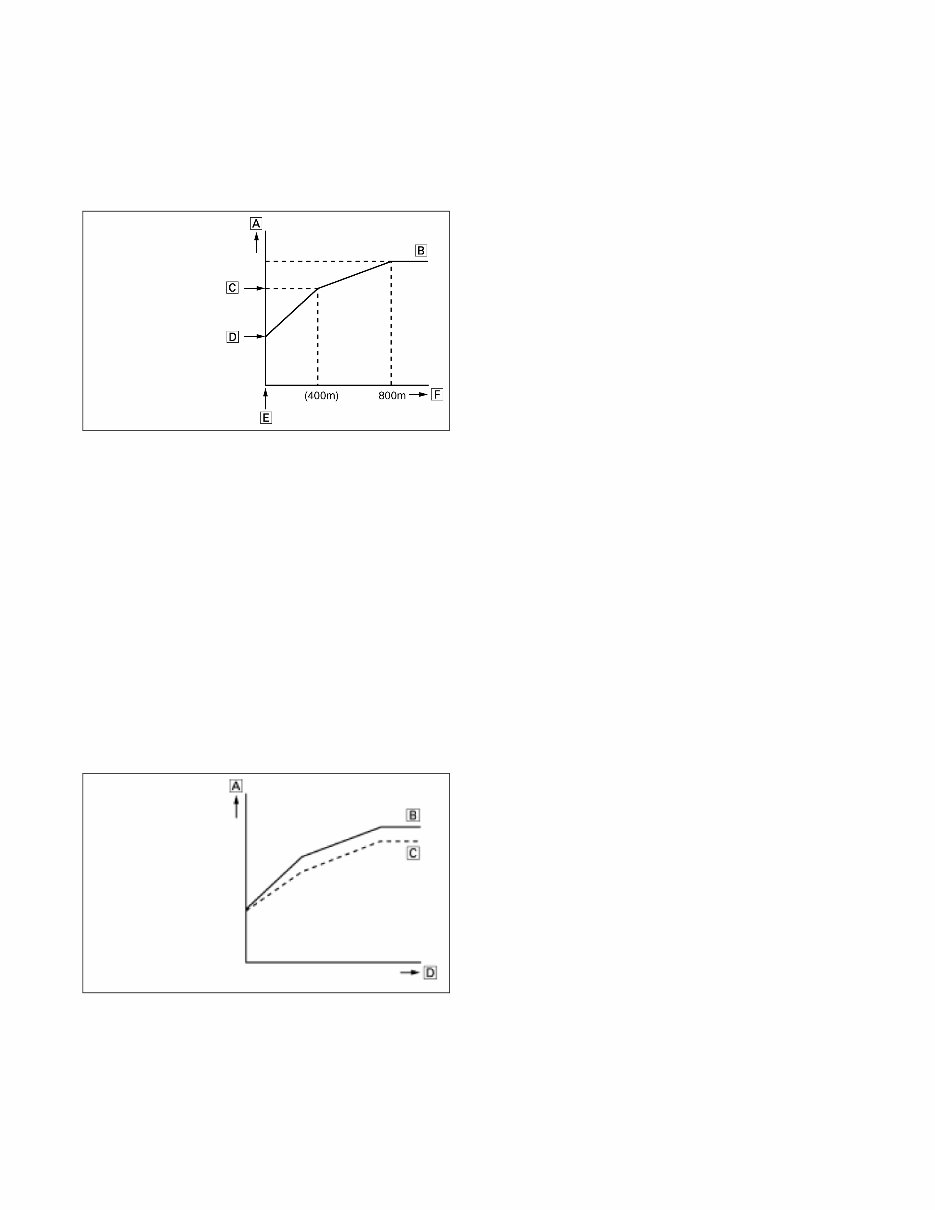

CLUTCHING

The clutch may require tuning depending upon where the

snowmobile will be operated and the desired handling

characteristics. The clutch can be tuned by changing the

engagement and shifting speeds.

Clutch engagement speed is defined as the engine speed

at which the snowmobile first begins to move from a

complete stop.

CAUTION

Do not use white gas or gasoline containing methanol. Only

Yamaha approved gasoline additives should be used.

CAUTION

Any oil used in place of the recommended oil may

cause serious damage.

CAUTION

Any oil used in place of the recommended oil could

cause serious engine damage.

CAUTION

Never run the engine with the drive belt removed. Exces-

sive revving of the engine could result in serious engine

damage and primary sheave failure.

3

Shifting speed is defined as the engine speed reached

when the snowmobile has travelled 800 m (2,500 ft) after

being started at full-throttle from a dead stop.

Normally, when a snowmobile reaches shifting speed, the

snowmobile speed increases but the engine speed remains

nearly constant. Under unfavorable conditions (wet snow,

icy snow, hills, or rough terrain), however, engine speed

may decrease after the shifting speed has been reached.

CLUTCHA

High altitude tuning

Atmospheric pressure decreases and engine output

becomes low at high altitude locations. Because of this,

clutch engagement speed and shifting speed also

decrease and unable to maximize the engine output

power. To maximize the engine output, tuning for

increasing clutch engagement speed and shifting speed is

necessary. This setting is called high altitude tuning. The

following changes are usually performed in high altitude

tuning.

• To increase the clutch engagement and shifting speed,

changing to a larger spring constant or using lighter

weights and rivets. (decreasing primary sheave thrust)

• Increasing the reduction ratio of the driven gear/drive

gear. (increasing the driving performance) Refer to

“HIGH ALTITUDE TUNING”.

CLUTCHB

ENGINE

A normally aspirated engine will generate more horse-

power at sea level than it does at higher altitudes. The

reason is that the higher you go, less oxygen is available

for the engine to use during its combustion process. Less

oxygen means it needs less fuel to obtain the correct air/

fuel ratio to operate properly.

This is why the fuel ratio has to be recalibrated. High alti-

tude engines operate as though they have a lower com-

pression ratio. This, along with less oxygen and less fuel,

means that the engine generates less horsepower. All of

these characteristics will become more evident the higher

the altitude.

SUSPENSION

Trail riding versus powder snow riding versus combina-

tion riding will all require different suspension settings.

The normal setting for front ski suspension is as little spring

pre-load tension as possible for powder snow riding allow-

ing the skis to float across the snow with the least amount

of resistance. Trail riding will require more spring tension

to carry the varying load more effectively. Many different

settings and spring tensions to consider exist when adjust-

ing for riding style and snow conditions.

The rear suspension has a number of spring settings that

produce different riding characteristics (see Suspension -

Suspension Setup Basics).

The front arm spring and shock will also affect the ride and

handling when either on a trail or in powder snow. A strong

spring setting on this shock will cause the snowmobile to

tend to “dig” more when riding in the powder snow rather

than climbing up on top of the snow. But, it will work more

effectively when riding on a trail. A softer spring setting

will allow the front of the rear suspension to collapse much

quicker and change the angle of the track to the snow. A

more gradual angle will tend to raise the snowmobile up on

the snow rather than digging into it.

Many possible variables and adjustments to the rear sus-

pension exist depending on snow conditions, riding style,

and type of terrain. These adjustments can be made to indi-

vidualize the snowmobile to the riding style of the operator.

Finally, track tension should be looked at to make sure that it

is within recommended specifications to affect the efficiency

of the snowmobile. On models with the torque sensing link,

the track is actually tightening as the suspension moves

through its range of motion causing the track to sag in the

middle and rub on the top part of the rear suspension arm.

TRACK

Carefully matching the riding requirements to the type of

track will ensure the maximum use of all available engine

power. Lug height and track durometer are the two main

concerns when selecting a track for various riding styles.

Tracks exist with lug heights from 31.75 - 75 mm (1.25 - 3.0

in.) to accommodate various snow conditions. Generally, the

deeper the snow, the taller the lug. It must be noted that the

installation of any deep-lug track may reduce top end speed

and promote premature wear strip wear in marginal snow

conditions.

Durometer is a measurement of how hard a rubber is. The

lugs on most tracks range between 60 and 80 durometer.

On the durometer scale, the higher the number, the harder

the lugs. For riding in deep powder snow, a softer durom-

eter track works best. The softer rubber allows the track

to “give” a little and pack the snow creating lift rather

than digging its way straight down. When hill-climbing,

the harder lug of an 80 durometer track works the best

due to penetrating the hard snow creating more bite.

A. Engine speed

B. Good

condition

C. Shifting speed

D. Clutch

engagement

speed

E. Starting

position

F. Distance

travelled

A. Engine speed

B. Speed at

maximum

output

C. Low speed

D. Distance

travelled

4

Some tracks come with a dual durometer rating, such as a

track with a 80/60 durometer rating. The lugs on this track

are 80% 80 durometer rubber, and the top 20% is made of

the softer 60 durometer rubber. This track is designed to be

a good all-around track for riding mostly in deep powder

snow but can climb the occasional hard snow hill.

Preparation For Storage

Prior to storing the snowmobile, it must be properly ser-

viced to prevent corrosion and component deterioration.

1. Clean the seat cushion with a damp cloth and a Vinyl

Protectant.

2. Clean the snowmobile thoroughly by hosing dirt, oil,

grass, and other foreign matter from the skid frame,

tunnel, hood, and belly pan. Allow the snowmobile

to dry thoroughly. DO NOT get water into any part

of the engine.

3. Change the engine oil.

4. Plug the exhaust system outlet with a clean cloth.

5. Fill the gas tank to its rated capacity; then add

Yamaha Fuel Stabilizer to the gas tank following

directions on the container for the stabilizer/gasoline

ratio. Tighten the gas tank cap securely.

6. With the snowmobile level, check the lubricant level

in the chain case. If low, add chain lube through the

fill plug hole.

7. Remove the drive belt from the primary sheave/sec-

ondary sheave. Lay the belt on a flat surface or slide

it into a cardboard sleeve to prevent warping or dis-

tortion during storage.

8. Clean and inspect the primary sheave and secondary

sheave.

9. Apply light oil to the upper steering post bushing and

shafts of the shock absorbers.

10. Lubricate the rear suspension with all-temperature

grease.

11. Tighten all nuts, bolts, and cap screws making sure

all nuts, bolts, and cap screws are tightened securely.

Make sure all rivets holding the components together

are tight. Replace all loose rivets.

12. Clean and polish the hood, console, and chassis. DO

NOT USE SOLVENTS. THE PROPELLANT WILL

DAMAGE THE FINISH.

NOTE: Disconnect the battery cables making sure

to disconnect the negative cable first; then clean the

battery posts and cables. Charge the battery.

13. If possible, store the snowmobile indoors. Raise the

track off the floor by blocking up the back end mak-

ing sure the snowmobile is secure. Loosen the track

adjusting bolts to reduce track tension. Cover the

snowmobile with a machine cover or a heavy tarpau-

lin to protect it from dirt and dust.

14. If the snowmobile must be stored outdoors, position

the snowmobile out of direct sunlight; then block the

entire snowmobile off the ground making sure the

snowmobile is secure. Loosen the track adjusting bolts

to reduce track tension. Cover with a machine cover or

a heavy tarpaulin to protect it from dirt, dust, and rain.

Preparation After Storage

Taking the snowmobile out of storage and correctly pre-

paring it for another season will assure many miles and

hours of trouble-free snowmobiling. Yamaha recom-

mends the following procedure:

1. Clean the snowmobile thoroughly. Polish the exterior

of the snowmobile.

2. Clean the engine. Remove the cloth from the exhaust

system. Check exhaust system and air-intake silencer

for obstructions.

3. Inspect all control wires and cables for signs of wear or

fraying. Replace if necessary. Use cable ties or tape to

route wires and cables away from hot or rotating parts.

4. Inspect the drive belt for cracks and tears. Check belt

specifications. Replace if damaged or worn. Install

the drive belt.

NOTE: If the old belt is worn but in reasonable con-

dition, retain it with the snowmobile as a spare in

case of an emergency.

5. Tighten all nuts, bolts, and cap screws making sure

all nuts, bolts, and cap screws are tightened securely.

6. If not done during preparation for storage, lubricate

the rear suspension with all-temperature grease.

7. Check the coolant level and all coolant hoses and

connections for deterioration or cracks. Add properly

mixed coolant as necessary.

8. Charge the battery until fully charged; then connect

the battery cables making sure to connect the posi-

tive cable first. Test the electric start system.

9. Inspect the entire brake system, all controls, head-

light, taillight, brakelight, ski wear bars, and head-

light aim; adjust or replace as necessary.

10. Adjust the track to the proper tension and alignment.

After Break-In Checkup/

Checklist

Certain areas require adjustment after the break-in period in

order to obtain peak performance and include the following.

DRIVE BELT POSITION — Drive belt length, condi-

tion, and position are all important for peak performance.

After the break-in period, drive belt deflection should be

checked according to the instructions given in the Drive

Train/Track/Brake Systems section of this manual.

CAUTION

Sealed batteries require charging if left for extended non-

start periods. Yamaha recommends trickle charging once a

month. Follow the manufacturer’s instructions and cautions.

CAUTION

Avoid storing in direct sunlight and using a plastic cover as

moisture may collect on the snowmobile causing corrosion.

5

PRIMARY SHEAVE/SECONDARY SHEAVE OFF-

SET — If premature drive belt wear is experienced or if

the drive belt turns over, offset must be checked. Also,

offset must be checked whenever either the primary

sheave or secondary sheave is serviced.

TRACK TENSION AND ALIGNMENT — A certain

amount of stretch occurs on all tracks during the first 800

km (500 miles). The track must be inspected/adjusted

after the first 80 to 160 km (50 to 100 miles) to the speci-

fications given in the Track Specifications sub-section of

this section and periodically thereafter. If these adjust-

ments aren’t performed, the track may “derail” which

leads to track and slide rail damage.

Along with these major areas, other areas should be

checked and adjusted. Below is a list of items to check after

the break-in period. The recommended mileage for this

inspection is between 160 and 500 km (100 and 300 miles).

Check drive belt position - primary sheave/secondary sheave

offset

Adjust track tension and alignment

Check throttle cable tension

Check engine idle

Check coolant level

Check chain case lubricant level

Check engine oil level

Check lights (high/low beam, brakelight)

Check safety switch operation

Check engine compartment for any rubbing components

Check steering hardware for tightness

Check skid frame and A-arm mounting hardware for tightness

Check brake lever travel and adjustment

Grease all lubrication points

Engine Specifications

Electrical Specifications

* See page 73 for test procedure

** Harness plugged in

The main harness connectors must be unplugged (except

on primary coil and regulator/rectifier tests) and tested by

pressing the starter button.

NOTE: Lighting coil output is unregulated voltage.

ITEM

Engine Model Number 8KH

Displacement 1049 cc

Compression Ratio 11:1

Bore x Stroke 82.0 x 66.2 mm (3.23 × 2.61”)

Cooling System Liquid

Spark Plug (NGK) CR9E

Spark Plug Gap 0.71-0.79 mm (0.028-0.031”)

Piston Skirt/Cylinder Clearance 0.036-0.061 mm (0.0014-0.0024”)

Piston Pin Diameter 18.991-19.000 mm (0.7477-0.7480”)

Piston Pin Bore Diameter 19.004-19.015 mm (0.7482-0.7486”)

Piston Pin to Piston Pin Bore Clearance 0.004-0.024 mm (0.0002-0.0009”)

Connecting Rod: Small End Diameter 19.005-19.027 mm (0.7482-0.7491”)

Crankshaft Pin/Connecting Rod Big

End Clearance

0.033-0.050 mm (0.0013-0.0020”)

Connecting rod: Big End Diameter 41.000-41.018 mm (1.6142-1.6149”)

Piston Ring End Gap (Top)

(2nd)

(Oil)

0.35-0.45 mm (0.014-0.018”)

0.70-0.80 mm (0.028-0.031”)

0.10-0.35 mm (0.004-0.014”)

Piston Ring/ (1st - Top)

Groove Clearance (2nd)

(Oil)

0.030-0.065 mm (0.0012-0.0026”)

0.020-0.055 mm (0.0008-0.0022”)

0.040-0.140 mm (0.0016-0.0055”)

Piston Diameter

(8 mm from bottom edge)

81.95-81.97 mm (3.2264-3.2270”)

Cam Lobe Height (Intake) 34.50 mm (1.3583”)

Cam Lobe Height (Exhaust) 34.00 mm (1.3356”)

Cam Lobe Width (Intake) 25.027 mm (0.9853”)

Cam Lobe Width (Exhaust) 25.000 mm (0.9843”)

Camshaft Journal Diameter 24.46-24.47 mm (0.9630-0.9635”)

Camshaft Journal Clearance 0.028-0.062 mm (0.0011-0.0024”)

Crank Pin Diameter 37.976-38.000 mm (1.4951-1.4961”)

Crankshaft Runout (max) 0.3 mm (0.012”)

Crankshaft Main Bearing Clearance 0.027-0.045 mm (0.0011-0.0018”)

Crankshaft/Rod Bearing Clearance 0.032-0.050 mm (0.0013-0.0020”)

Valve Stem Diameter (Intake) 4.475-4.490 mm (0.1762-0.1677”)

Valve Stem Diameter (Exhaust) 4.460-4.475 mm (0.1756-0.1762”)

Valve Guide Inside Diameter (Intake) 4.500-4.512 mm (0.1772-0.1776”)

Valve Guide Inside Diameter (Exhaust) 4.500-4.512 mm (0.1772-0.1776”)

Valve Guide/Stem Clearance (Intake) 0.010-0.037 mm (0.0004-0.0015”)

Valve Guide/Stem Clearance (Exhaust) 0.025-0.052 mm (0.0010-0.0020”)

Valve Face Width (Intake) 0.90-1.10 mm (0.035-0.043”)

Valve Face Width (Exhaust) 0.90-1.10 mm (0.035-0.043”)

Component Test Value + Test Connections -

(Normally Closed Ignition)

Magneto Coil (3 tests)* 0.15-0.23 ohm white white

Primary Ignition Coil* 1.19-1.61 ohms

Secondary Ignition Coil* 8.5k-11.5k ohms

Crankshaft Position Sensor 336-504 ohms blue/white green/white

Voltage Regulator/Rectifier** 12-14.5 DC Volts terminal terminal

Magneto Coil (no load) 36-44 AC Volts white white

Ignition Switch Less than 1 ohm

(key in OFF position)

terminal terminal

! WARNING

Most voltages generated by the ignition system are suf-

ficient to interrupt pacemakers! All technicians, espe-

cially those using pacemakers, must avoid contact with

all electrical connections when pressing the starter but-

ton or after the engine has been started.

ITEM

6

Drive System

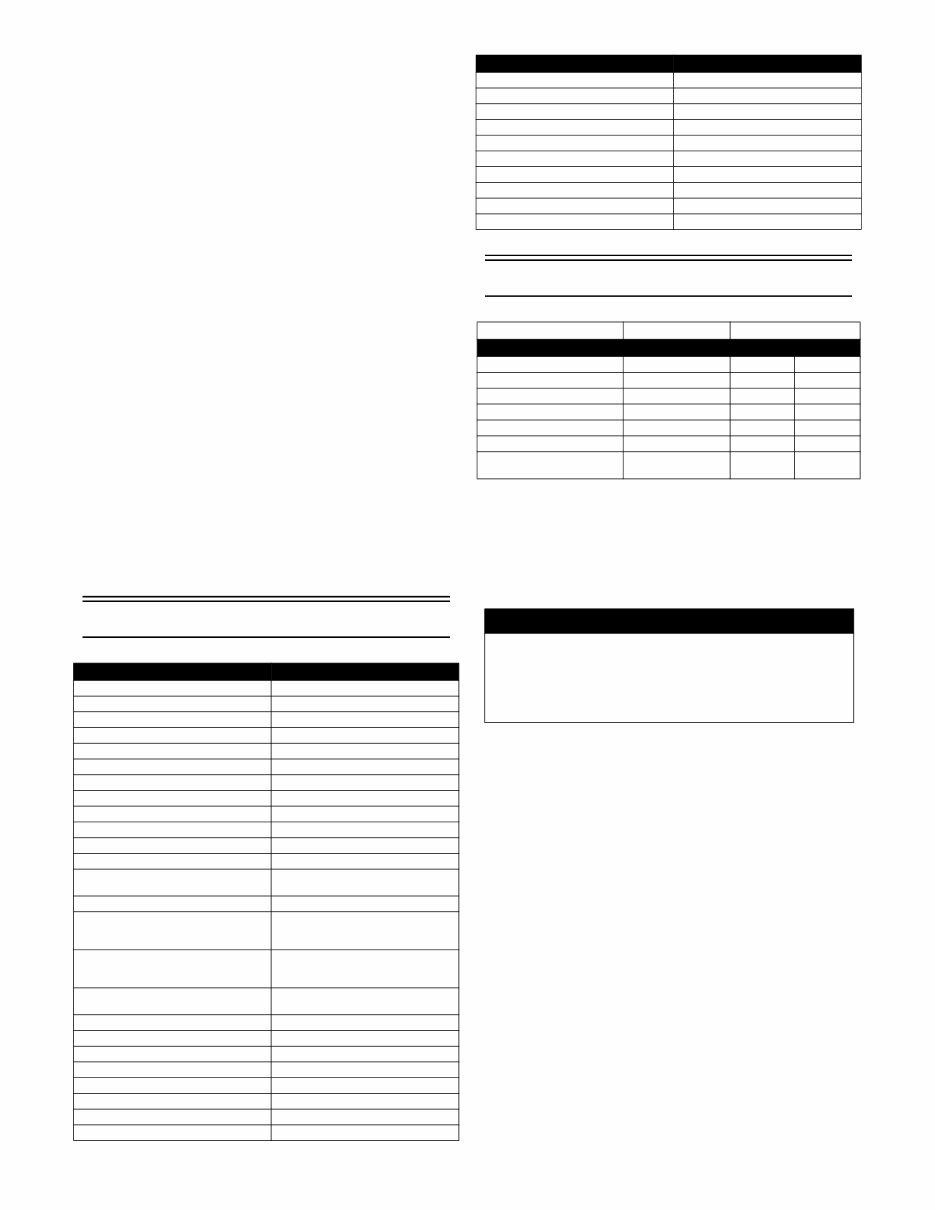

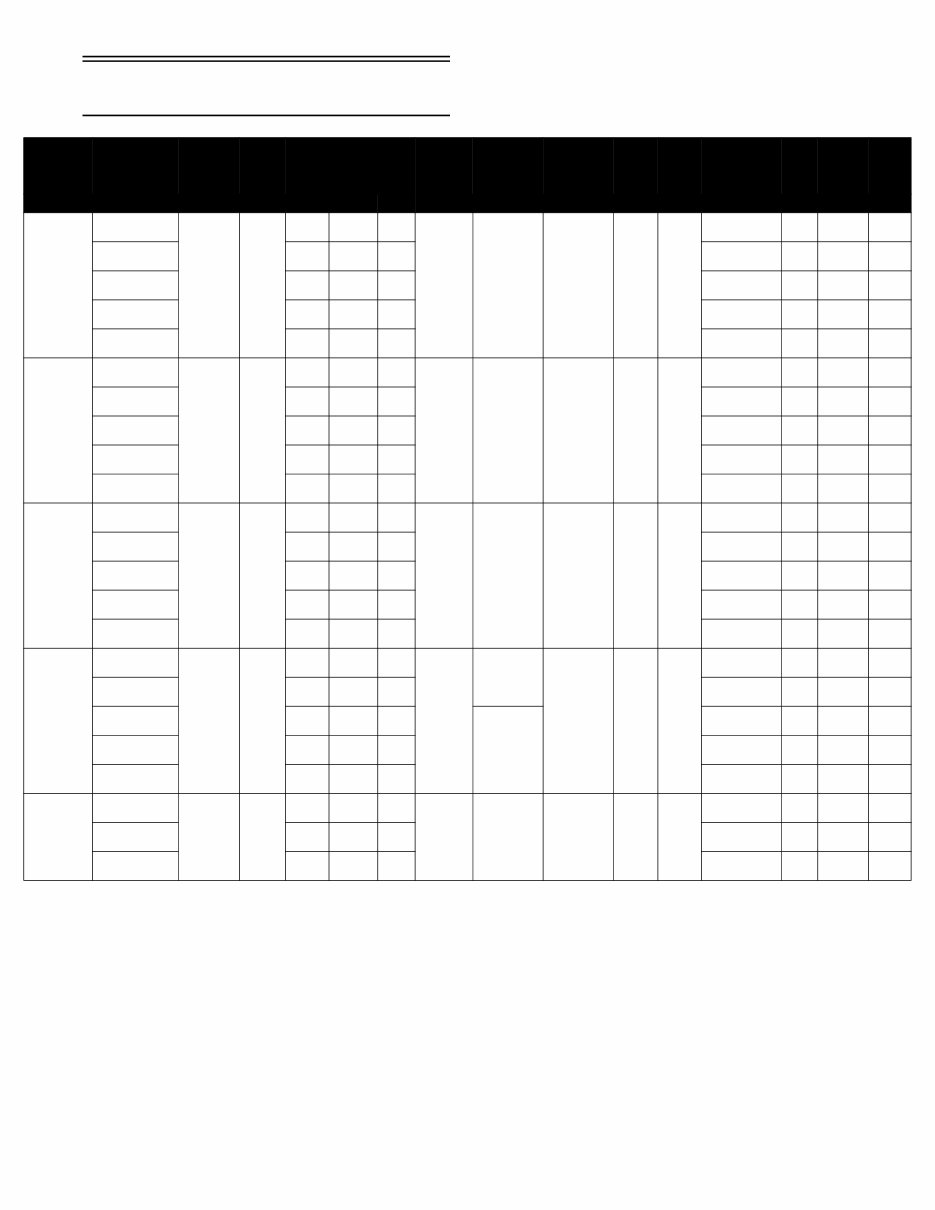

Specifications

Model Elevation

Primary

Clutch

Spring

Clutch

Weight

Clutch Rivets

Roller

Diameter

(mm)

Secondary

Clutch

Spring

Torque

Cam

(Degree)

Drive

Belt

Shift

RPM

(Appr

ox)

Engagement

RPM

(Approx)

Top

Gear

Bottom

Gear

Chain

Links

Outer Center Inner

139”, 137”

1.25" Track

SR10RD

SR10RS, RL

SR10LD, LS

SR10SD37

SR10SD46

~800m

(~2500 ft)

Blue

Silver

Blue

35Kgf

2.0Kgf/mm

8GL00

D C C

15.6

PINK

1211kgfmm/

rad

Preload 70

43° 8JP-00 8750

3800 24 50 92

600~1400m

(2000~4500 ft)

F D D 3800 24 50 92

1200~2000m

(4000~6500 ft)

G D D 3800 22 48 90

1800~2600m

(6000~8500 ft)

None D F 3900 21 49 90

2400~3000m

(8000~10000 ft)

None D None 3900 21 49 90

141”

NA

SR10XL, XS

141”

Europe

SR10XL

SR10M41

~800m

(~2500 ft)

Blue

Silver

Blue

35Kgf

2.0Kgf/mm

8GL00

D C C

15.6

PINK

1211kgfmm/

rad

Preload 70

43° 8JP-00 8750

3800 21 41 86

600~1400m

(2000~4500 ft)

F D D 3800 21 41 86

1200~2000m

(4000~6500 ft)

G D D 3800 21 50 92

1800~2600m

(6000~8500 ft)

None D F 3900 21 49 90

2400~3000m

(8000~10000 ft)

None D None 3900 21 49 90

129”, 137”

1.75” Track

Europe

SR10RL

SR10SD37

~800m

(~2500 ft)

Blue

Silver

Blue

35Kgf

2.0Kgf/mm

8GL00

D C C

15.6

PINK

1211kgfmm/

rad

Preload 70

43° 8JP-00 8750

3800 21 49 90

600~1400m

(2000~4500 ft)

F D D 3800 21 49 90

1200~2000m

(4000~6500 ft)

G D D 3800 24 49 90

1800~2600m

(6000~8500 ft)

None D F 3900 21 49 90

2400~3000m

(8000~10000 ft)

None D None 3900 21 49 90

MTX NA

SR10M41

SR10M53

SR10M62

~800m

(~2500 ft)

Green

Green

Green

40Kgf

2.75Kgf/

mm

8BU10

A N/A A

14.5

PINK

1211kgfmm/

rad

Preload 30

37° 8JP-00 8750

3700 21 49 90

600~1400m

(2000~4500 ft)

F N/A C 3750 21 49 90

1200~2000m

(4000~6500 ft)

G N/A D

PINK

1211kgfmm/

rad

Preload 40

3800 21 49 90

1800~2600m

(6000~8500 ft)

G N/A G 3850 21 49 90

2400~3000m

(8000~10000 ft)

None N/A None 3900 21 49 90

MTX

EUROPE

SR10M53

SR10M62

~800m

(~2500 ft) Blue

White

Blue

45Kgf

2.0Kgf/mm

8FN00

B N/A B

16.5

PINK

1211kgfmm/

rad

Preload 50

37° 8JP-00 8750

3000 24 50 92

600~1400m

(2000~4500 ft)

E N/A D 3000 24 50 92

1200~2000m

(4000~6500 ft)

H N/A D 3100 22 48 90

7

WEIGHT RIVETS

CLUTCH ROLLERS

CHAIN CASE COMPONENTS

DRIVE SYSTEM INFLUENCE

Components of the V-belt transmission having a direct

impact on the shifting function are described below.

Part

Number

Material Length Weight Effect

A 90261-06033 Steel 17.2 mm 4.5g Increase Force

B 90269-06006 Steel with hole 17.2 mm 3.6g

C 90261-06034 Steel 13.9 mm 3.6g

D 90261-06019 Steel 13.3 mm 3.1g

E 90266-06002 Steel with hole 13.3 mm 2.44g

F 90261-06015 Steel 10.3 mm 2.44g

G 90261-06028 Aluminum 10.3 mm 0.85g

H 90266-06001 Aluminum with hole 13.3 mm 0.85g Decrease Force

Part Number

Outside

Diameter

Identification Mark

(Width)

Effect

8FG-17624-00 14.5 mm

Groove and Machined

Increase Force

8FG-17624-10 15.0 mm

Groove

8FG-17624-20 15.6 mm

No Mark

8FG-17624-30 16.0 mm

Groove and Groove

8FG-17624-40 16.5 mm

Machined

Decrease Force

TOP GEAR BOTTOM GEAR CHAIN

Ratio

Teeth P/N Teeth P/N Links P/N

21 8JP-E769A-10 41 8JP-G7587-10 86 8JP-RAM01-20 1.952

24 8JP-E769A-40 50 8JP-G7587-00 92 8JP-RAM01-00 2.083

22 8JP-E769A-20 48 8JP-G7587-80 90 8JP-RAM01-10 2.182

21 8JP-E769A-10 49 8JP-G7587-90 90 8JP-RAM01-10 2.333

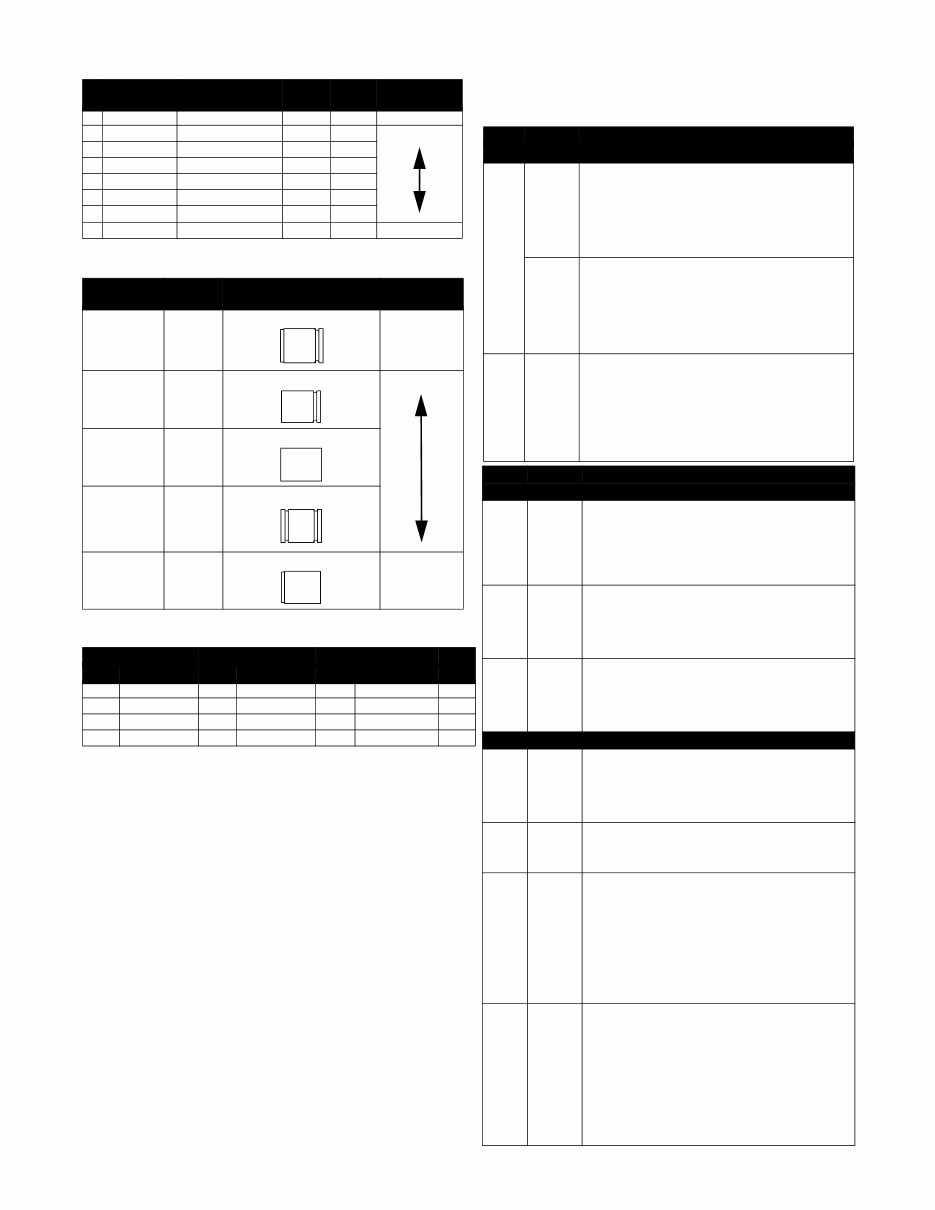

Part Element Impact on the shifting function

Primary sheave

Spring Preload • A larger preload increases the clutch engagement

speed, and the shifting speed tends to rise accord-

ingly. Shifting tends to become somewhat harder.

(increasing the spring reaction force)

• A smaller preload decreases the clutch engagement

speed, and the shifting speed tends to drop accord-

ingly. Shifting tends to become somewhat easier.

(decreasing the spring reaction force)

Spring

rate

• A larger spring rate increases the shifting speed. It

also slightly increases the clutch engagement speed.

Shifting tends to become somewhat harder. (increas-

ing the spring reaction force)

• A smaller spring rate decreases the shifting speed. It

also slightly decreases the clutch engagement speed.

Shifting tends to become somewhat easier. (decreas-

ing the spring reaction force)

Weight Shape,

weight

Shape and weight determine, the size of moment

about the center of the weight rotation when the

sheave is running.

• Heavier weight decreases the clutch engagement

and shifting speed. Shifting tends to become some-

what easier. (increasing the sheave thrust)

• Lighter weight increases the clutch engagement and

shifting speed. Shifting tends to become somewhat

harder. (decreasing the sheave thrust)

Part Element Impact on the shifting function

Primary sheave

Weight

rivet

Quantity

Material

(iron, alu-

minum)

Rivets are fastened through the hole in the weight.

• Using more rivets decreases the clutch engagement

and shifting speed. Shifting tends to become some-

what easier. (increasing the sheave thrust)

• Using less rivets increases the clutch engagement

and shifting speed. Shifting tends to become some-

what harder. (decreasing the sheave thrust)

Roller Outside

diameter

The outside diameter affects the contact angle with

the weight.

• A smaller diameter decreases the clutch engage-

ment speed. (increasing the sheave thrust)

• A larger diameter increases the clutch engagement

speed. (decreasing the sheave thrust)

Shim Quantity • Using more shims increases the preload and clutch

engagement speed. (increasing the spring reaction

force)

• Using less shim decreases the preload and clutch

engagement speed. (decreasing the spring reaction

force)

Secondary sheave

Spring Preload

Spring

rate (com-

pression,

torsion)

• A larger preload, spring rate or twist angle increases

the shifting speed and makes shifting somewhat

harder. (increasing the sheave thrust)

• A smaller preload, spring rate or twist angle

decreases the shifting speed and makes shifting

somewhat easier. (decreasing the sheave thrust)

Fixed

sheave

Spring

seat

Spring fit-

ting hole

One of the holes may be used selectively to change

the spring twist angle (preload). Refer to “ Spring”.

Torque

cam

Cam

angle

The cam angle determines the degree of sensitivity

(spring seat) of load torque detection.

• A smaller cam angle increases sensitivity, which in

turn increases the sheave thrust to make back shifting

easier. The shifting speed tends to increase and shift-

ing becomes somewhat harder. (increasing the

sheave thrust)

• A larger cam angle makes back shifting harder. The

shifting speed tends to decrease and shifting

becomes somewhat easier. (decreasing the sheave

thrust)

Shim Quantity Size of the secondary sheave clearance (between

fixed sheave and sliding sheave) can be adjusted by

the number of shims used.

Adjust the clearance when the V-belt wear deterio-

rates and belt width becomes smaller.

• Using more shims makes secondary sheave clear-

ance smaller.

• Using less shim makes secondary sheave clearance

larger.

When the V-belt width is smaller, wrap-around diame-

ter of the V-belt on the primary sheave is larger and

clutch engagement speed is slightly increased.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 88 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

- This manual covers all versions of the following machines:

- 2016 Yamaha SR Viper LTX DX 4-Stroke Snowmobiles

- 2016 Yamaha SR Viper LTX LE 4-Stroke Snowmobiles

- 2016 Yamaha SR Viper LTX SE 4-Stroke Snowmobiles

- 2016 Yamaha SR Viper MTX 153 4-Stroke Snowmobiles

- 2016 Yamaha SR Viper MTX 162 4-Stroke Snowmobiles

- 2016 Yamaha SR Viper MTX LE 153 4-Stroke Snowmobiles

- 2016 Yamaha SR Viper MTX LE 162 4-Stroke Snowmobiles

- 2016 Yamaha SR Viper MTX SE 141 4-Stroke Snowmobiles

- 2016 Yamaha SR Viper MTX SE 153 4-Stroke Snowmobiles

- 2016 Yamaha SR Viper MTX SE 162 4-Stroke Snowmobiles

- 2016 Yamaha SR Viper RTX DX 4-Stroke Snowmobiles

- 2016 Yamaha SR Viper RTX LE 4-Stroke Snowmobiles

- 2016 Yamaha SR Viper RTX SE 4-Stroke Snowmobiles

- 2016 Yamaha SR Viper STX DX 137 4-Stroke Snowmobiles

- 2016 Yamaha SR Viper STX DX 146 4-Stroke Snowmobiles

- 2016 Yamaha SR Viper XTX LE 4-Stroke Snowmobiles

- After payment, our informative repair manual, owners manuals, and parts catalogs contain all the information you'll need to perform repairs, look up parts, or do routine maintenance on your machine. You will have access to information regarding the following topics:

- General Information

- Routine Maintenance

- Engine Removal and Installation

- Fuel System

- Lubrication and Cooling System

- Engine Specifications

- Transmission, Drive Chain & Sprockets

- Steering System

- Shocks

- Body Work

- Intake & Exhaust

- Electrical System

- Advanced Troubleshooting

- With our repair manuals, find the page pertaining to your job, print it off, and get working on your machine. No more ruining your expensive paper shop manual with grease and dirt.

- Broke down on the trail or site and have a smartphone? What a cool way to find your problem and repair it on the trail, no downtime on the job site. With our repair manuals, you instantly have access to the material needed to get you running again. Kind of tough to do that with a paper manual.

- And did we mention the fact that you're saving the trees? All our repair manuals come with a lifetime protection policy. If lost or damaged, simply contact us and we'll replace it free of charge for life.

- We provide various repair service manuals, workshop manuals, repair manuals, owners manuals, parts catalogs, and other various manuals, all in an electronic format.

- UTVs, motorcycles, ATVs, quads, snowmobiles, Seadoo, equipment, small engines, inboards, outboards, and more.

- Instant download after payment. Thank you.