1986 Yamaha Moto-4 60 (4-Zinger) Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

_YAMAHA

LIT -11616-04-87

1HN-28197-10

NOTICE

This manual was written by the Yamaha Motor Company primarily for use by Yamaha dealers and

their qualified mechanics. It is not possible to put an entire mechanic's education into one manual,

so it is assumed that persons using this book to perform maintenance and repairs on Yamaha motor-

cycles have a basic understanding of the mechanical concepts and procedures inherent in motorcycle

repair technology. Without such knowledge, attempted repairs or service to this model may render

it unfit to use and/or unsafe.

Yamaha Motor Company, Ltd. is continually striving to improve all models manufactured by Yamaha.

Modifications and significant changes in specifications or procedures will be forwarded to all Authorized

Yamaha dealers and will, where applicable, appear in future editions of this manual.

TECHNICAL PUBLICATIONS

SERVICE DIVISION

MOTORCYCLE OPERATIONS

YAMAHA MOTOR CO., LTD

HOW TO USE THIS MANUAL

PARTICULARLY IMPORTANT INFORMATION

This material is distinguished by the following notation.

NOTE:

WARNING:

A NOTE provides key information to make procedures easier or clearer.

A CAUTION indicates special procedures that must be followed to avoid damage

to the motorcycle.

A WARNING indicates special procedures that must be followed to avoid injury

to a motorcycle operator or person inspecting or repairing the motorcycle.

MANUAL FORMAT

All of the procedures in this manual are organized in a sequential, step-by-step format. The informa-

tion has been compiled to provide the mechanic with an easy to read, handy reference that contains

comprehensive explanations of all disassembly, repair, assembly, and inspection operations.

In this revised format, the condition of a faulty component will precede an arrow symbol and the course

of action required will follow the symbol, e.g.,

-Bearings

Pitting/ Damage--+ Replace.

EXPLODED DIAGRAM

Each chapter provides exploded diagrams before each disassembly section for ease in identifying cor-

rect disassembly and assembly procedures.

CD ®

I=I~I

l~g~1 §tl

® ®

IENGI~I

lcooy ~I

@

®

~ARBI.I ~HASI~I

(j)

®

IELEel §I

~pp~6"1

®

~

@

~

QD

~

@

~

@

[0J

(3)

~

@

1

@

1

@

1

m m a

@ @

®

~~ ~sn ~

@

A

B

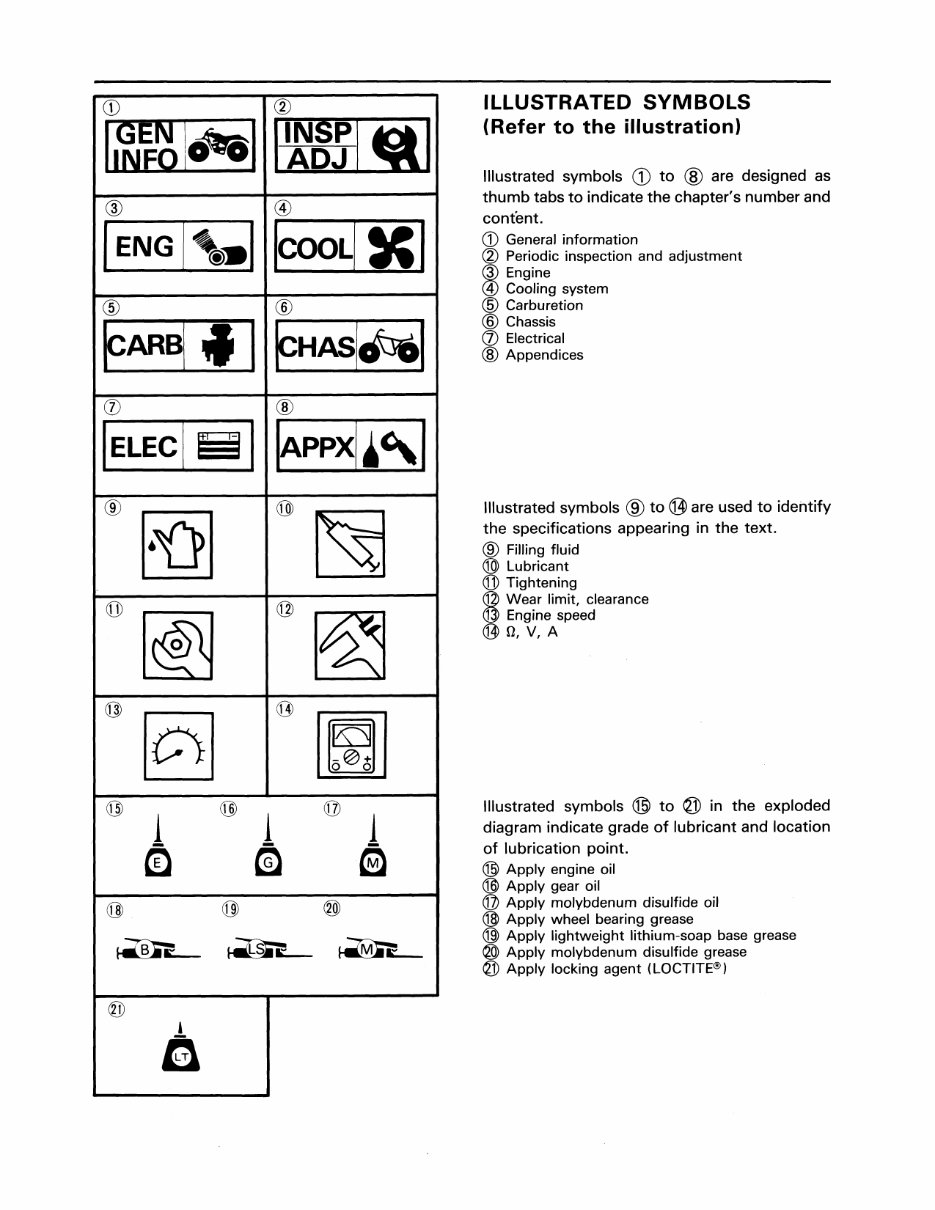

ILLUSTRATED SYMBOLS

(Refer to the illustration)

Illustrated symbols CD to ® are designed as

thumb tabs to indicate the chapter's number and

content.

CD General information

(2) Periodic inspection and adjustment

@ Engine

@ Cooling system

@ Carburetion

® Chassis

(J) Electrical

@ Appendices

Illustrated symbols ® to @ are used to identify

the specifications appearing in the text.

® Filling fluid

® Lubricant

@ Tightening

© Wear limit, clearance

@ Engine speed

@O,V,A

Illustrated symbols @ to @ in the exploded

diagram indicate grade of lubricant and location

of lubrication point.

® Apply engine oil

® Apply gear oil

@ Apply molybdenum disulfide oil

@ Apply wheel bearing grease

@l Apply lightweight lithium-soap base grease

@ Apply molybdenum disulfide grease

@ Apply locking agent (LOCTITE®)

INDEX

GENERAL INFORMATION

fItti;

GEN

INFO

____________________ I~~~I~I

CHAPTER 1.

GENERAL INFORMATION

MACHINE IDENTIFICATION . ...................................... 1-1

VEHICLE IDENTIFICATION NUMBER .............................. 1-1

ENGINE SERIAL NUMBER ....................................... 1-1

IMPORTANT INFORMATION . ..................................... 1-2

ALL REPLACEMENT PARTS ..................................... 1-2

GASKETS, OIL SEALS, AND O-RINGS ............................ 1-2

LOCK WASHERS/PLATES AND COTTER PINS .................... 1-2

BEARINGS AND OIL SEALS ..................................... 1-2

CIRCLIPS ...................................................... 1-3

SPECIAL TOOLS .................................................. 1-3

FOR TUNE-UP .................................................. 1-3

FOR ENGINE SERVICE .......................................... 1-3

FOR CHASSIS SERViCE ......................................... 1-5

FOR ELECTRICAL COMPONENTS ................................ 1-5

I ~~ IAI MACHINE IDENTIFICATION

1-1

GENERAL

INFORMATION

MACHINE IDENTIFICATION

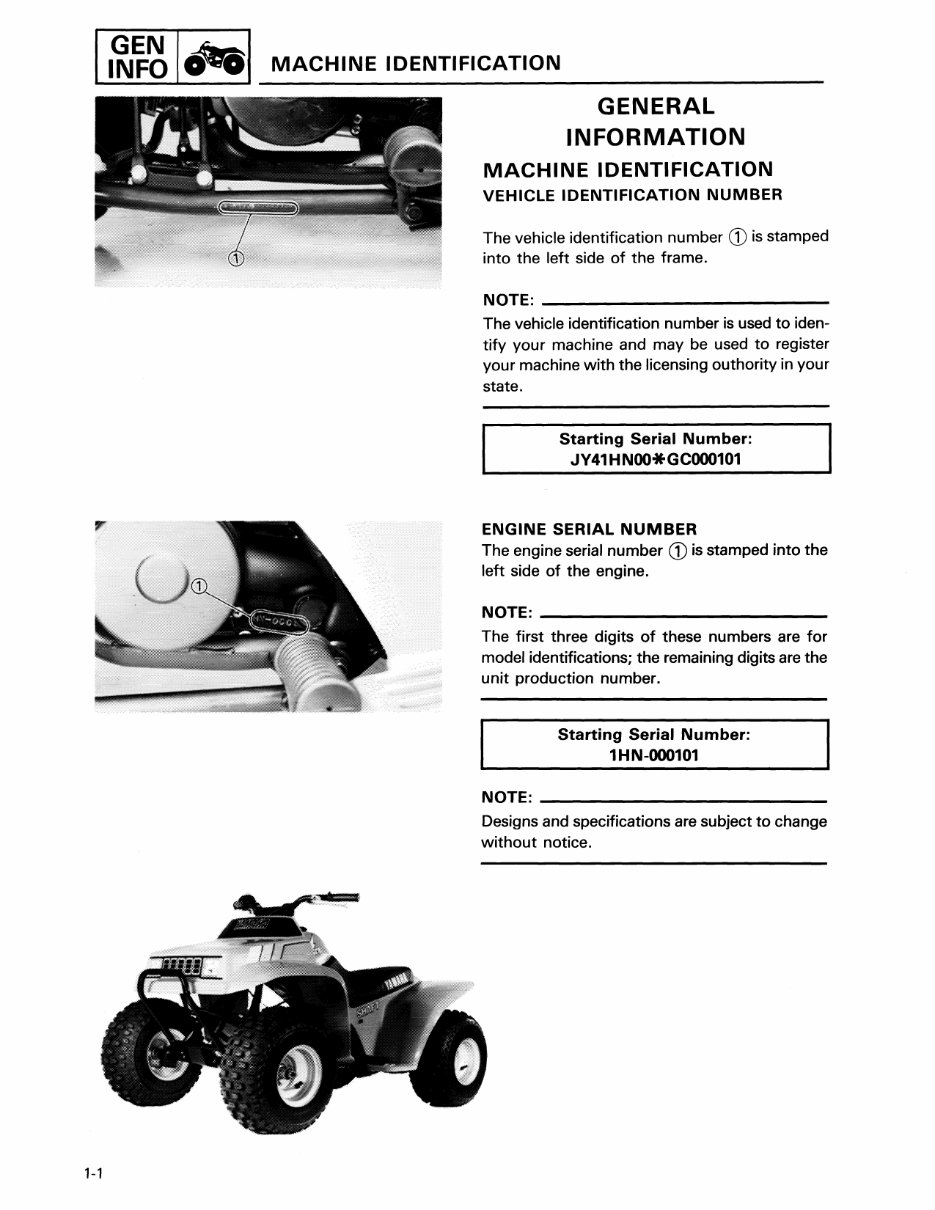

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number CD is stamped

into the left side of the frame.

NOTE: ________________________ _

The vehicle identification number is used to iden-

tify your machine and may be used to register

your machine with the licensing outhority in your

state.

Starting Serial Number:

JY41HNOO*GCOOO101

ENGINE SERIAL NUMBER

The engine serial number CD is stamped into the

left side of the engine.

NOTE: ______________________ __

The first three digits of these numbers are for

model identifications; the remaining digits are the

unit production number.

Starting Serial Number:

1HN-000101

NOTE: ________________________ _

Designs and specifications are subject to change

without notice.

IMPORTANT INFORMATION I,~~ Icteal

IMPORTANT INFORMATION

300-000

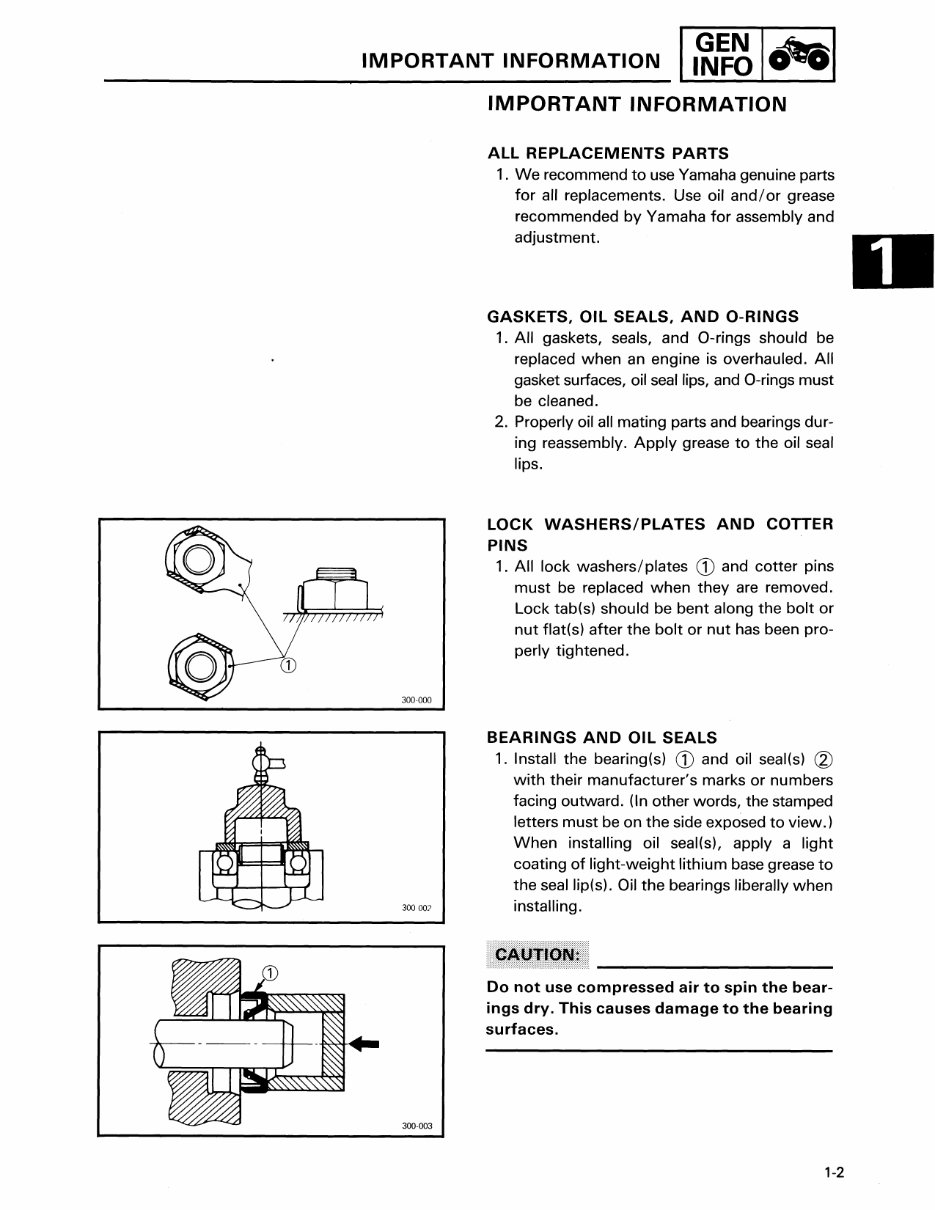

ALL REPLACEMENTS PARTS

1. We recommend to use Yamaha genuine parts

for all replacements. Use oil and/or grease

recommended by Yamaha for assembly and

adjustment.

GASKETS, OIL SEALS, AND a-RINGS

1. All gaskets, seals, and a-rings should be

replaced when an engine is overhauled. All

gasket surfaces, oil seal lips, and a-rings must

be cleaned.

2. Properly oil all mating parts and bearings dur-

ing reassembly. Apply grease to the oil seal

lips.

LOCK WASHERS/PLATES AND COTTER

PINS

1. All lock washers/plates CD and cotter pins

must be replaced when they are removed.

Lock tab(s) should be bent along the bolt or

nut flat(s) after the bolt or nut has been pro-

perly tightened.

BEARINGS AND OIL SEALS

1. Install the bearing(s) CD and oil seal(s) CV

with their manufacturer's marks or numbers

facing outward. (In other words, the stamped

letters must be on the side exposed to view.)

When installing oil seal(s), apply a light

coating of light-weight lithium base grease to

the seallip(s). Oil the bearings liberally when

300 OO? installing.

300-003

Do not use compressed air to spin the bear-

ings dry. This causes damage to the bearing

surfaces.

1-2

I,~~~ I AI SPECIAL TOOLS

1-3

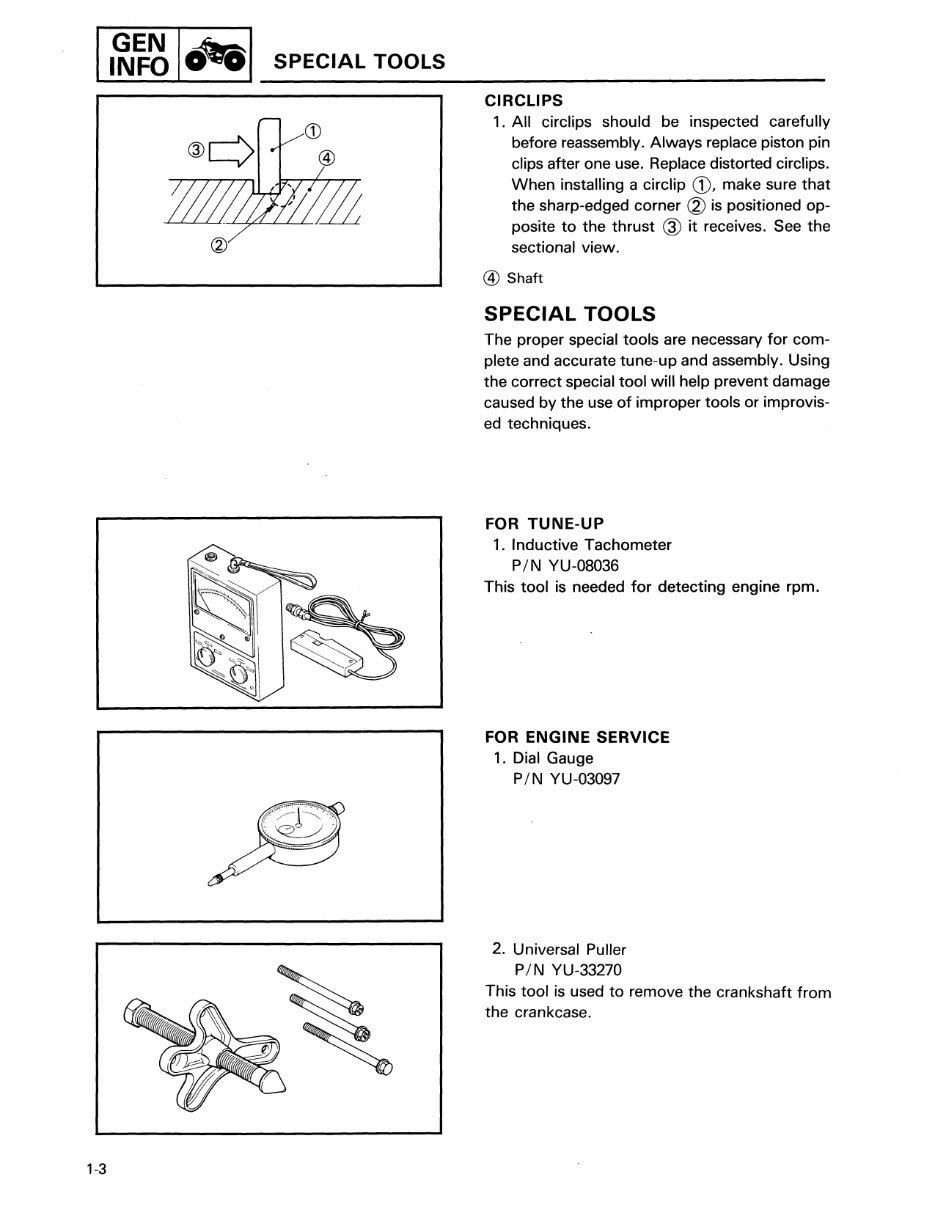

CIRCLIPS

1. All circlips should be inspected carefully

before reassembly. Always replace piston pin

clips after one use. Replace distorted circlips.

When installing a circlip CD, make sure that

the sharp-edged corner (2) is positioned op-

posite to the thrust ® it receives. See the

sectional view.

@ Shaft

SPECIAL TOOLS

The proper special tools are necessary for com-

plete and accurate tune-up and assembly. Using

the correct special tool will help prevent damage

caused by the use of improper tools or improvis-

ed techniques.

FOR TUNE-UP

1. Inductive Tachometer

P/ N YU-08036

This tool is needed for detecting engine rpm.

FOR ENGINE SERVICE

1. Dial Gauge

P/ N YU-03097

2. Universal Puller

P/ N YU-33270

This tool is used to remove the crankshaft from

the crankcase.

SPECIAL TOOLS I ~~ I ~I

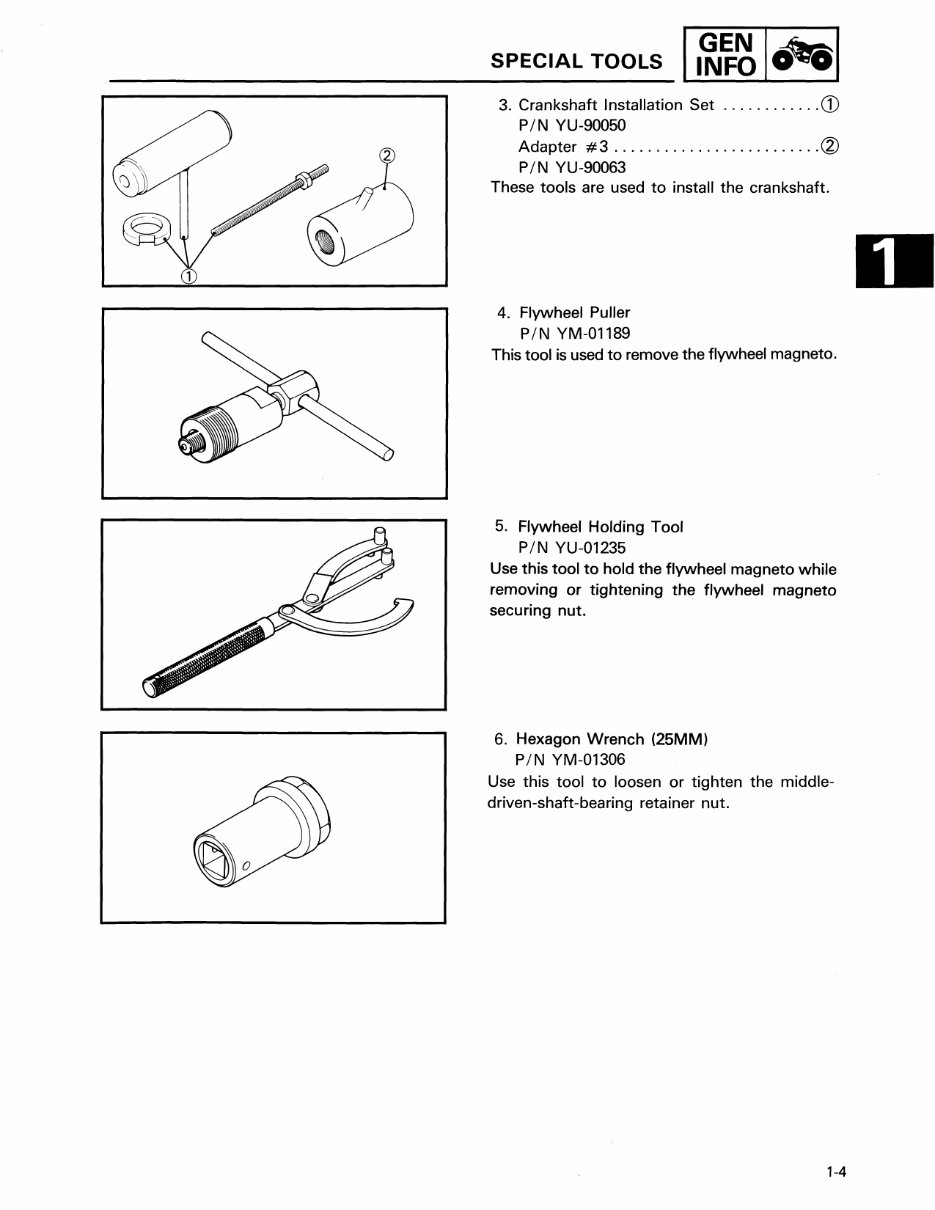

3. Crankshaft Installation Set ............ CD

PIN YU-90050

Adapter # 3 ......................... <bl

PIN YU-90063

These tools are used to install the crankshaft.

4. Flywheel Puller

PIN YM-01189

This tool is used to remove the flywheel magneto.

5. Flywheel Holding Tool

PIN YU-01235

Use this tool to hold the flywheel magneto while

removing or tightening the flywheel magneto

securing nut.

6. Hexagon Wrench (25MM)

PIN YM-01306

Use this tool to loosen or tighten the middle-

driven-shaft-bearing retainer nut.

1-4

II~~ 1cJe81 SPECIAL TOOLS

'II __ -~I

L-. -- __ II

I

1-5

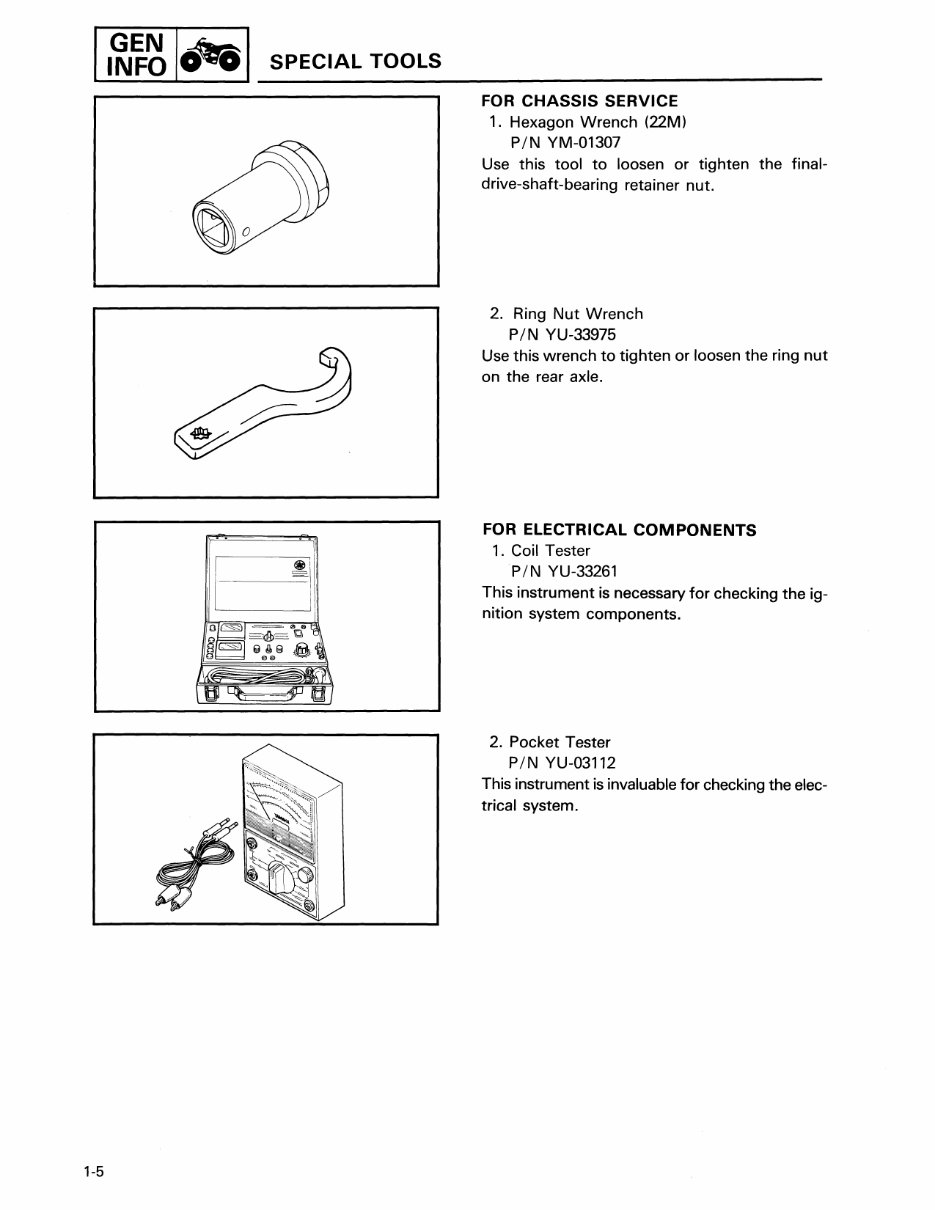

FOR CHASSIS SERVICE

1. Hexagon Wrench (22M)

PIN YM-01307

Use this tool to loosen or tighten the final-

drive-shaft-bearing retainer nut.

2. Ring Nut Wrench

PIN YU-33975

Use this wrench to tighten or loosen the ring nut

on the rear axle.

FOR ELECTRICAL COMPONENTS

1. Coil Tester

PIN YU-33261

This instrument is necessary for checking the ig-

nition system components.

2. Pocket Tester

PIN YU-03112

This instrument is invaluable for checking the elec-

trical system.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$24.99

Viewed 53 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$24.99

Yamaha Moto-4 60 (4-Zinger) Service and Repair Manual

Covers: 1986

Instant access to the factory repair manual for the 1986 Yamaha Moto-4 60 youth ATV, also known as the 4-Zinger. This manual covers complete tear down and rebuild, including pictures and part diagrams, torque specs, maintenance, troubleshooting, and more. It consists of 151 pages and features clickable chapters, making it searchable for easy navigation. There are no restrictions on printing or saving/burning to disc.