TGB TARGET 400 425 ATV Full Service & Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Home page Contents

17. ELECTRICAL SYSTEM

Mechanism Diagram ·························· 17-1

Maintenance Data ······························· 17-2

Technical Specification······················17-2

Trouble Diagnosis ······························ 17-3

Battery ················································· 17-4

Charging System ································ 17-5

Ignition System··································· 17-8

Starting System ·································· 17-10

Meters ················································· 17-12

Light / Bulb········································· 17-13

Switch / Horn······································ 17-16

Fuel Unit ············································· 17-19

Cooling Fan Thermo Switch ············· 17-20

Thermo unit········································ 17-21

Water Temperature Indicator Light ·· 17-21

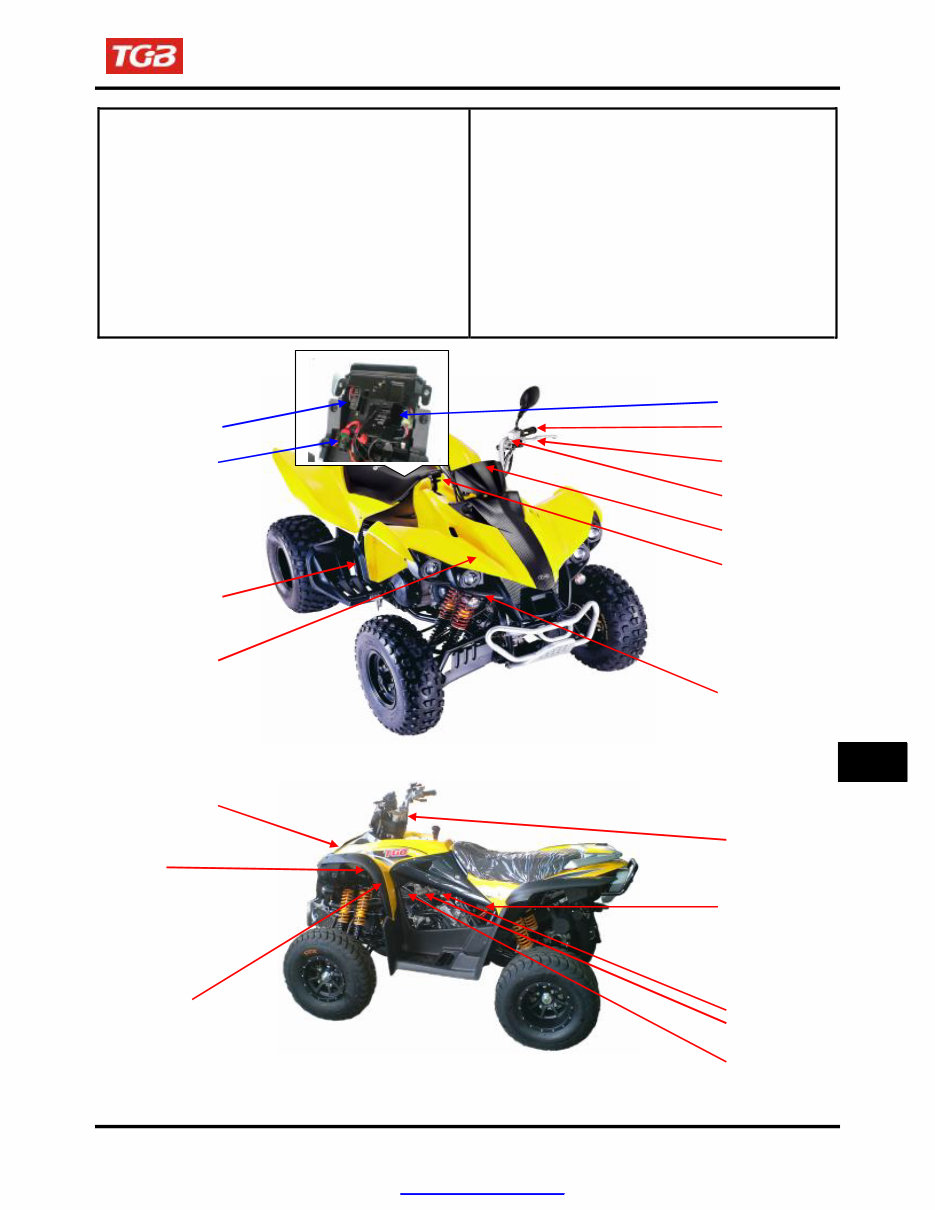

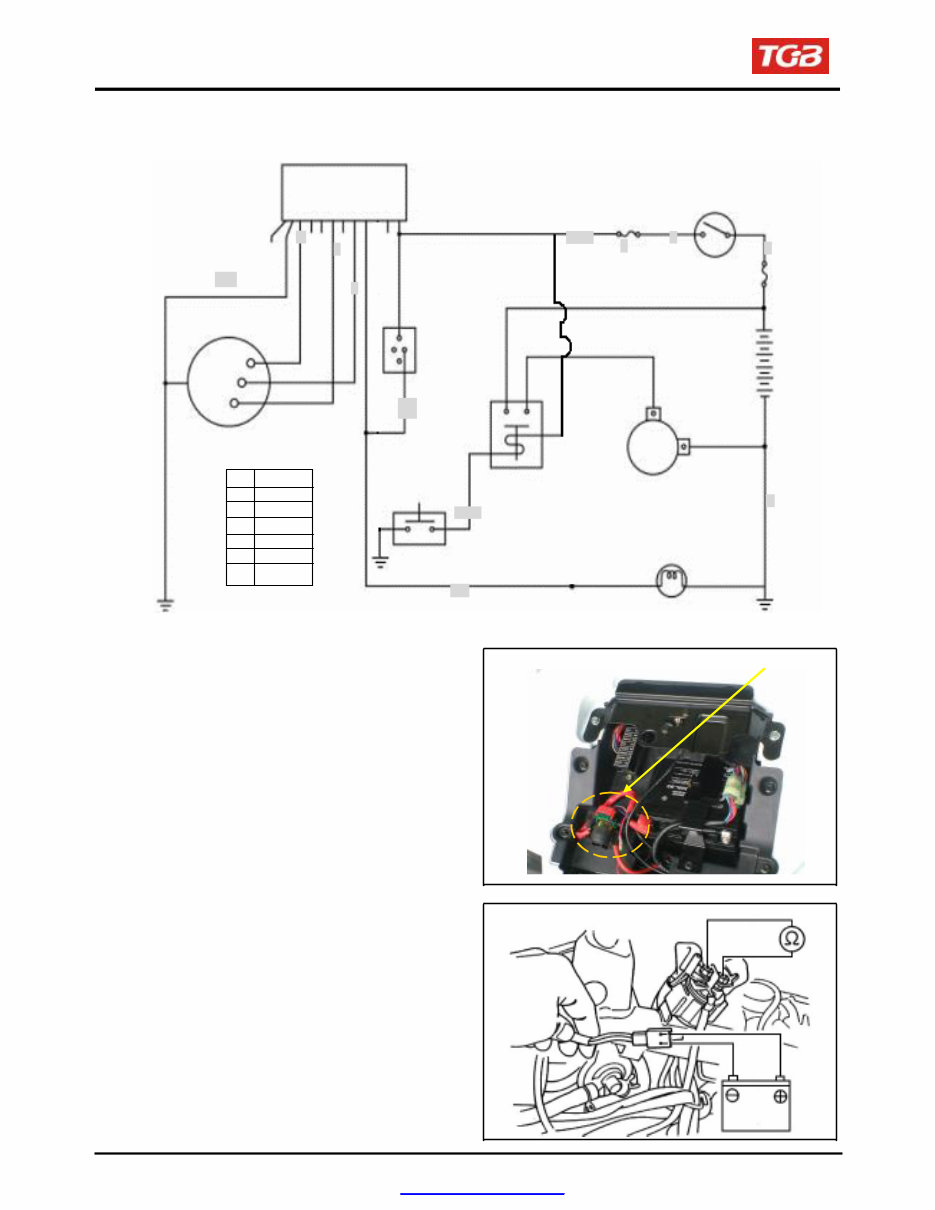

Mechanism Diagram

Battery

Fuse box Front brake switch

Starter relay

Hazard

control unit

Winker relay

Main switch

Shift gear

control unity

Rear brake switch

C.D.I. Unitx

Thermo unit

Headlight relay

Start & light &

winker & horn &

brake switch

Horn

Rectifier

Ignition coil

AC.Generator

Spark plug

Change switch

17-1

17

PDF created with pdfFactory Pro trial version www.pdffactory.com

To this chapter contents

17. ELECTRICAL SYSTEM

Maintenance Data

Operational precaution

● When remove the battery, the disconnection sequence of cable terminals shall be strictly observed.

(First disconnect the negative cable terminal, next, the positive cable terminal.)

● The model of the spark plug and the tightening torque.

● The ignition timing.

● Adjustment of headlight.

● Removal and installation of AC generator.

● The maintenance free battery requires no inspection of electrolyte level and refilling of distilled water.

● To recharge the battery, remove the battery from rack without removing ventilation caps.

● Unless in emergency, never rapid charge the battery.

● The voltage must be checked with the voltmeter while charging the battery.

● As C.D.I assembly does not require an ignition timing check. In case ignition timing is incorrect, check

C.D.I and AC generator. Verify with an ignition timing light after replacement if necessary.

Technical Specification

Charging system

Description Specification

Battery

Capacity 12V18Ah

Charging rate 1.4A / 5 ~ 10 hours (standard)

14A / 0.5 hour (fast charging)

Leak current < 1mA

Charging current 1.2 A / 1500rpm

Control voltage in charging 14.5 + 0.5 V / 1500rpm

Ignition system

Description Specification

Spark plug

Ignition coil and

Model NGK CR7E (Recommended)

Gap 0.8mm

Primary winding 2.9 ± 10%Ω

Without cap: 15. ± 10KΩ

resistance

Secondary winding

Ignition timing “F” mark

With cap:20 ± 10KΩ

15° TDC / 1700rpm

46°TDC / 4200rpm

17-2

PDF created with pdfFactory Pro trial version www.pdffactory.com

To this chapter contents

17. ELECTRICAL SYSTEM

Trouble Diagnosis

No voltage

● Battery discharged

● The cable disconnected

● The fuse is blown

● Improper operation of the main switch

Low voltage

● The battery is not fully charged

● Poor contact

● Poor charging system

● Poor voltage regulator

No spark produced by spark plug

● The spark plug is out of work

● The cable is poorly connected, open or

short-circuited

- Between AC.G. and C.D.I.

● Poor connection between C.D.I. and ignition

coil

- Poor connection between C.D.I. and the

main switch

● Poor main switch

● Poor C.D.I.

● AC.G. is out of work

Starter motor does not work

● The fuse is blown

● The battery is not fully charge

● Poor main switch

● Poor starter switch

● The front and rear brake switches do not

operate correctly

● Starter relay is out of work

● The ignition coil is poorly connected, open or

short-circuited

● The starter motor is out of work

Intermittent power supply

● The connector of the charging system becomes

loose

● Poor connection of the battery cable

● Poor connection or short-circuit of the

discharging system

● Poor connection or short-circuit of the power

generation system

Charging system does not operate

properly

● Burnt fuse

● Poor contact, open or short circuit

● Poor regulator

● Poor ACG

Engine does not crank smoothly

● Primary winding circuit

- Poor ignition coil

- Poor connection of cable and connectors

- Poor main switch

● Secondary winding circuit

- Poor ignition coil

- Poor spark plug

- Poor ignition coil cable

- Current leakage in the spark plug

● Incorrect ignition timing

- Poor AC.G.

- Improper installation of the pulse sensor

- Poor C.D.I.

Weak starter motor

● Poor charging system

● The battery is not fully charged

● Poor connection in the windings

● The motor gear is jammed by foreign material

Starter motor is working, but engine does

not crank

● Poor starter motor pinion

● The starter motor run in reverse direction

● Poor battery

17-3

PDF created with pdfFactory Pro trial version www.pdffactory.com

To this chapter contents

17. ELECTRICAL SYSTEM

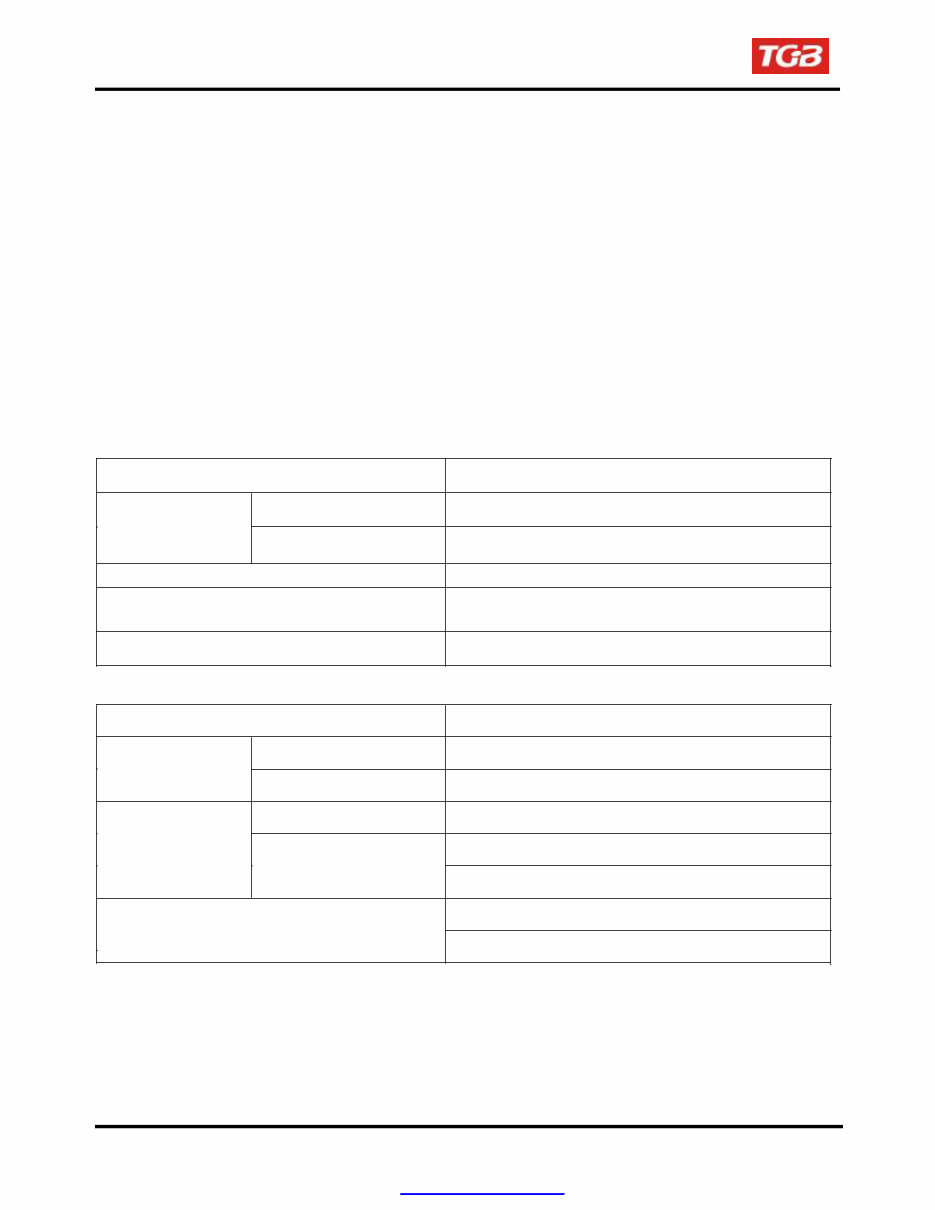

Battery

Removal

Remove the seat, and then you can see the

battery.

Disconnect the negative cable terminal first, then

the positive cable terminal.

Remove the battery clamp, and then remove

battery.

Clamp

Voltage Check

Use the digital voltmeter to check the voltage of

the battery.

Voltage:

Fully charged: 13.0~13.2 V at 20℃

Undercharged: Below 12.3 V at 20℃

Charging

Connect the positive terminal (+) of the charger to

the battery positive terminal (+).

Connect the negative terminal (-) of the charger to

the battery negative terminal (-).

Standard Maximum

Charging current 1.8A 18.0A

Charging time 5H 0.5H

Warning

● Keep flames away while recharging.

● Charging is completely controlled by the

ON/OFF switch on the charger, not by

battery cables.

Caution

● Never rapid charge the battery unless in

emergency.

● Verify the battery is recharged with current

and duration prescribed above.

● Large current and fast time to charge will

render damage to the battery.

When installing the battery, coat the cable terminal

with grease.

17-4

PDF created with pdfFactory Pro trial version www.pdffactory.com

To this chapter contents

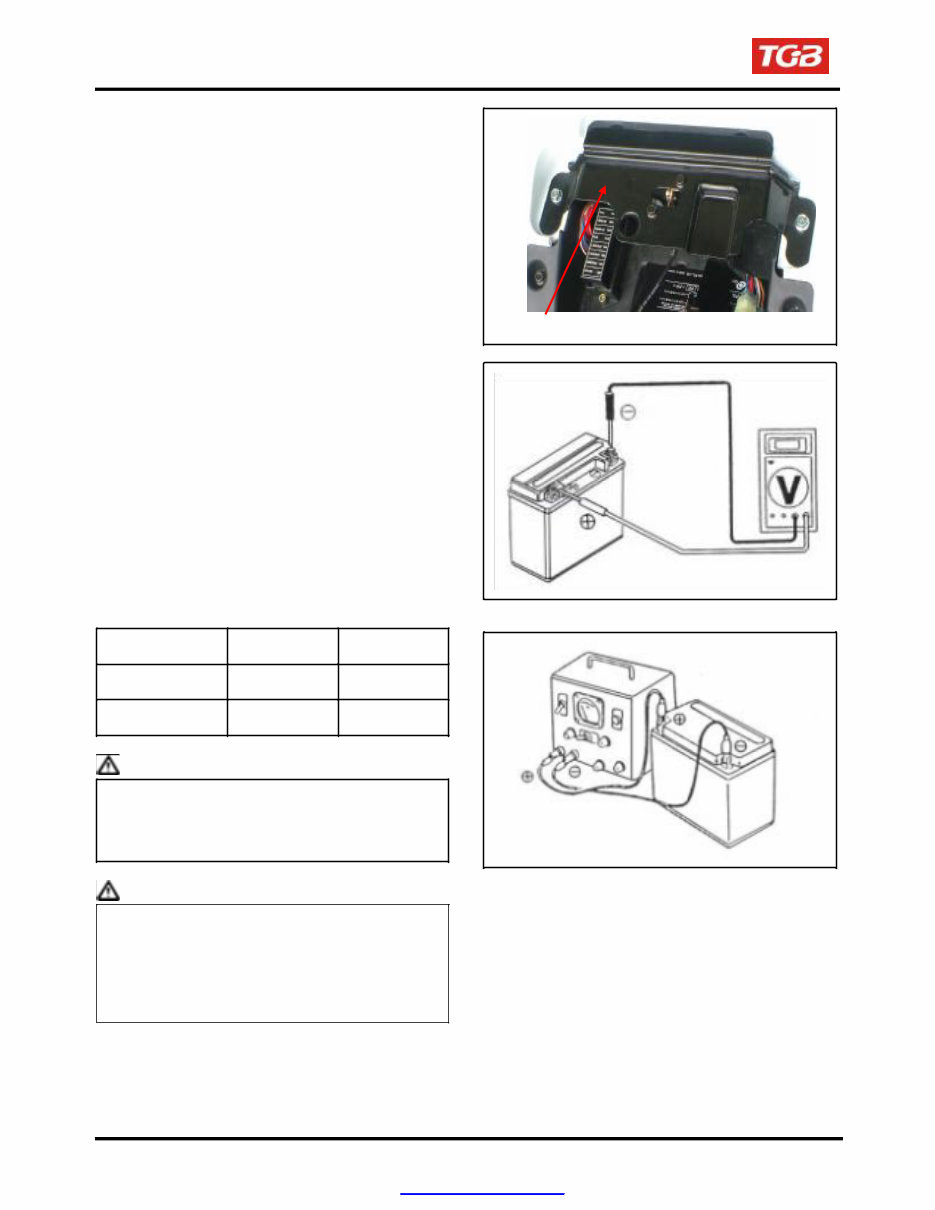

17. ELECTRICAL SYSTEM

Charging System

Charging circuit

Main switch

Black Blue

B/R Yellow Yellow

Yellow

Battery

Regulator rectifier

AC. Generator

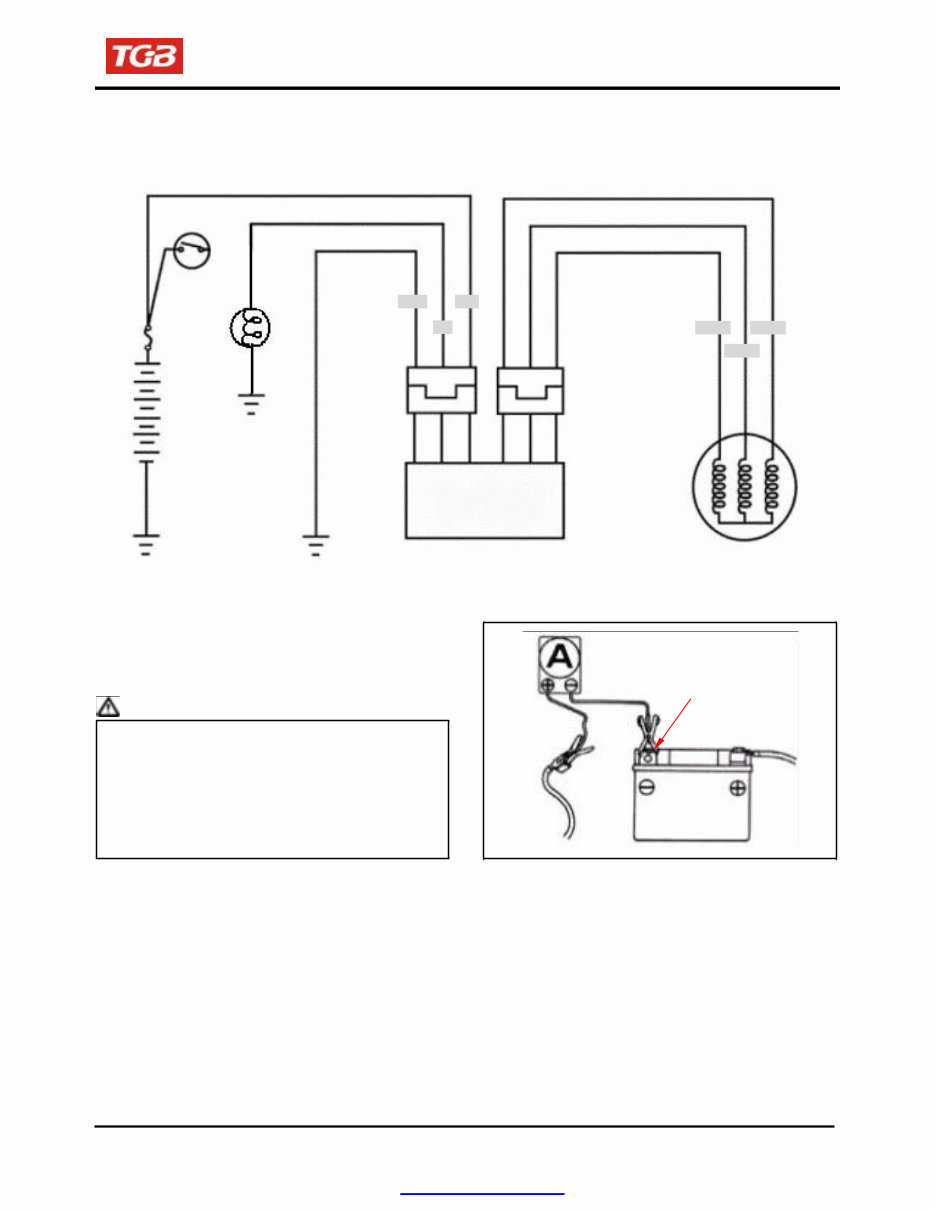

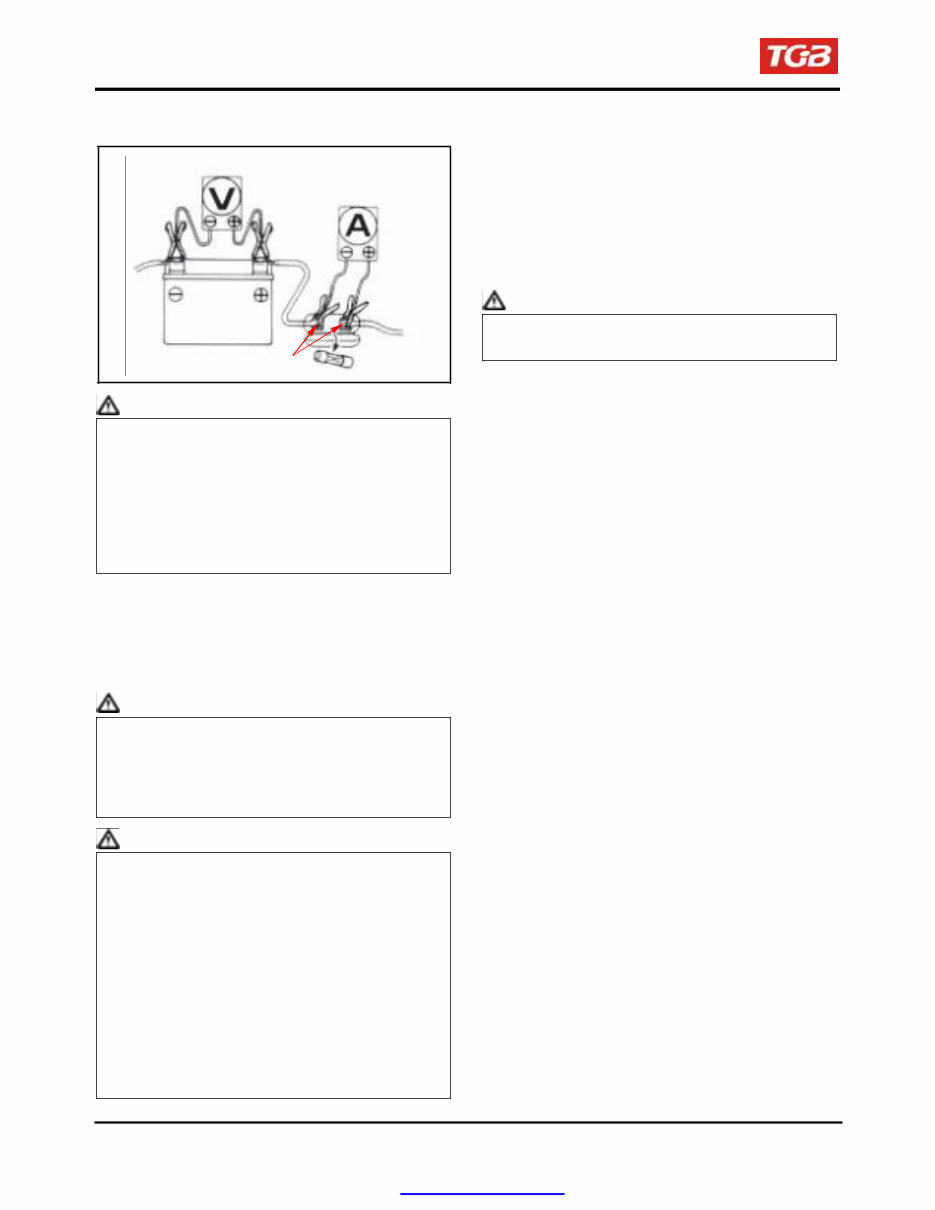

Current Leakage Inspection

Turn the main switch to OFF position, and remove

the negative cable terminal (-) from the battery.

Connect an ammeter between the negative cable

terminal and the battery negative terminal.

Caution

● In the current leakage test, set the current

range at the largest scale, then gradually

decrease to the lower scale as the test

process goes to avoid possible damage to

the ammeter and the fuse.

● Do not turn the main switch to ON position

during test.

If the leaked current exceeds the specified value, it

may indicate a short circuit.

Allowable current leakage: Less than 1mA

Disconnect each cable one by one and take

measurement of the current of each cable to

locate the short circuit.

Battery negative terminal

17-5

Fuse 20A

PDF created with pdfFactory Pro trial version www.pdffactory.com

To this chapter contents

17. ELECTRICAL SYSTEM

Inspection on Charging Voltage

Voltmeter

Ammeter

Connect a tachometer.

Turn on the headlight to high beam and start the

engine.

Accelerate the engine to the specified revolution

per minute and measure the charging voltage.

Specified Charging Current:

1.2 A / 6000 rpm

Control Charging Voltage:

14.5 + 0.5 V / 2000 rpm

Fuse connector

Caution

To replace the old battery, use a new battery with

the same current and voltage.

Caution

● Before conducting the inspection, be sure that

the battery is fully charged. If undercharged, the

current changes dramatically.

● Use a fully charged battery having a voltage

larger than 13.0 V

● While starting the engine, the starter motor

draws large amount of current from the

battery.

After the engine is warmed up, replace original

battery with a fully charged battery.

Connect a digital voltmeter to the battery

terminals.

Connect an ammeter between both ends of the

main fuse.

Caution

When the probe is reversibly connected, use a

voltmeter having an indication that the current

flows from the positive or the negative direction

and the measurement should be at zero,

ammeter at one direction only.

Caution

● Does not use short-circuit cable.

● It is possible to measure the current by

connecting an ammeter between the battery

positive terminal and the cable position

terminal, however, while the starter motor is

activated, the surge current the motor draws

from the battery may damage the ammeter.

Use the kick starter to start the engine.

● The main switch shall be turned to OFF position

during the process of inspection. Never tamper

with the ammeter and the cable while there is

current flowing through. It may damage the

ammeter.

The following problems are related to the charging

system; follow the instructions provided in the

checking list to correct it if any one of the problems

takes place.

(1) The charging voltage can not exceed the

voltage between two battery terminals and

the charging current is in the discharging

direction.

(2) The charging voltage and current are too

much higher than the standard values.

The following problems are not related to the

charging system; correct it if any by following

steps indicate in the checking list.

(1) The standard charging voltage and current

can only reach when the revolution of the

engine exceeds the specified rpm.

- Bulbs used exceed their rate and

consume too much power.

- The replacement battery is aged and

does not have enough capacity.

(2) The charging voltage is normal, but the

current is not.

- The replacement battery is aged and

does not have enough capacity.

- Battery used does not have enough

electricity or is over charged.

- The fuse of the ammeter is blown.

- The ammeter is improperly connected.

(3) The charging current is normal, but the

voltage is not.

- The fuse of the voltmeter is blown.

17-6

PDF created with pdfFactory Pro trial version www.pdffactory.com

To this chapter contents

17. ELECTRICAL SYSTEM

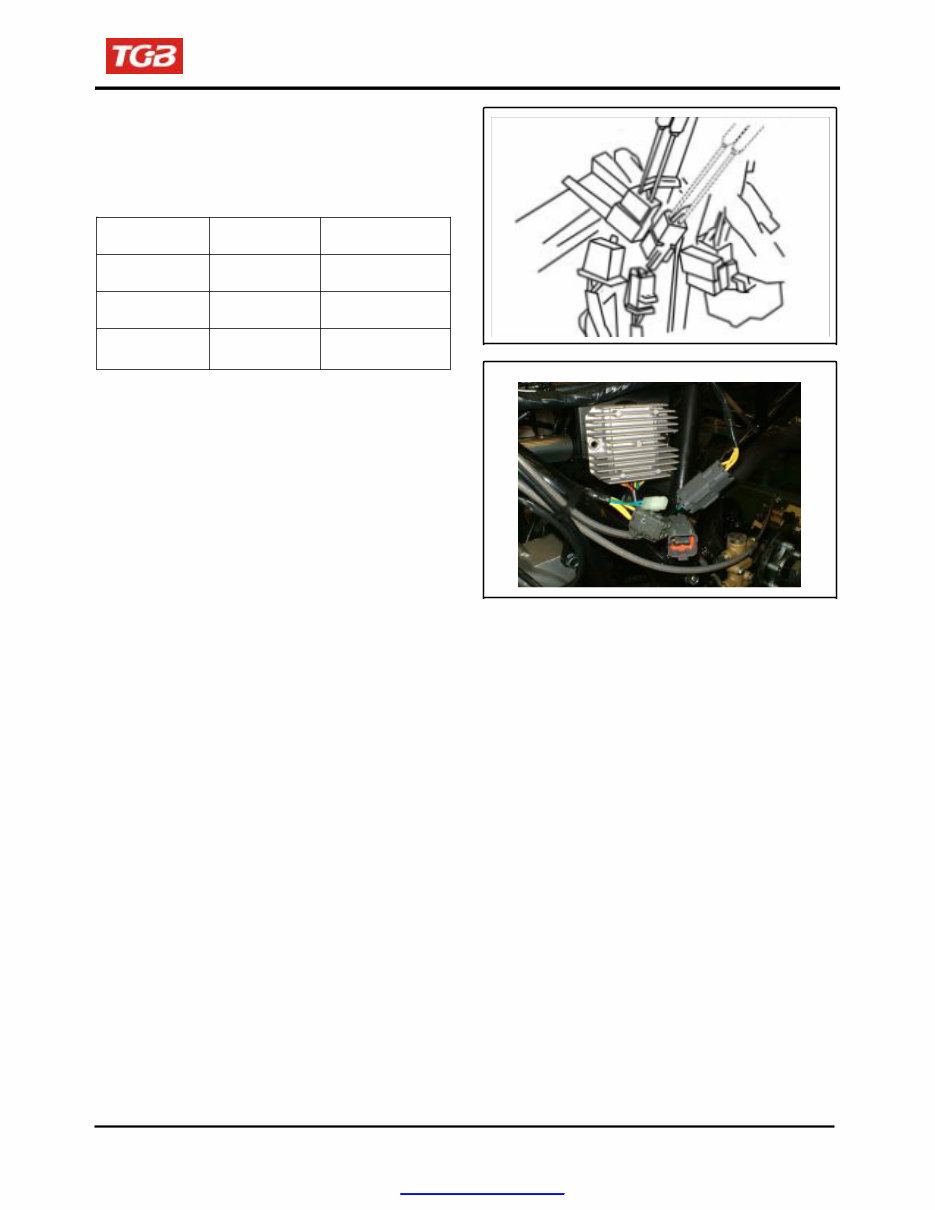

Inspection on regulator rectifier

Remove the seat, rear carrier and rear fender.

Disconnect two 3 pin couplers of the regulator

rectifier.

Inspection the rectifier coupler to the wire harness

passes the condition.

Item Check Points Standard Value

Main switch

connection Bl – B

Battery

Battery voltage

(ON)

connection Bl – B Battery voltage

Charging coil B – B 0.1 ~ 0.5Ω

If the readings measured are not normal, check

parts in the circuit.

If the parts are normal, then trouble is in the wiring. If

there is nothing wrong with parts and wiring, replace

the regulator rectifier.

17-7

PDF created with pdfFactory Pro trial version www.pdffactory.com

To this chapter contents

17. ELECTRICAL SYSTEM

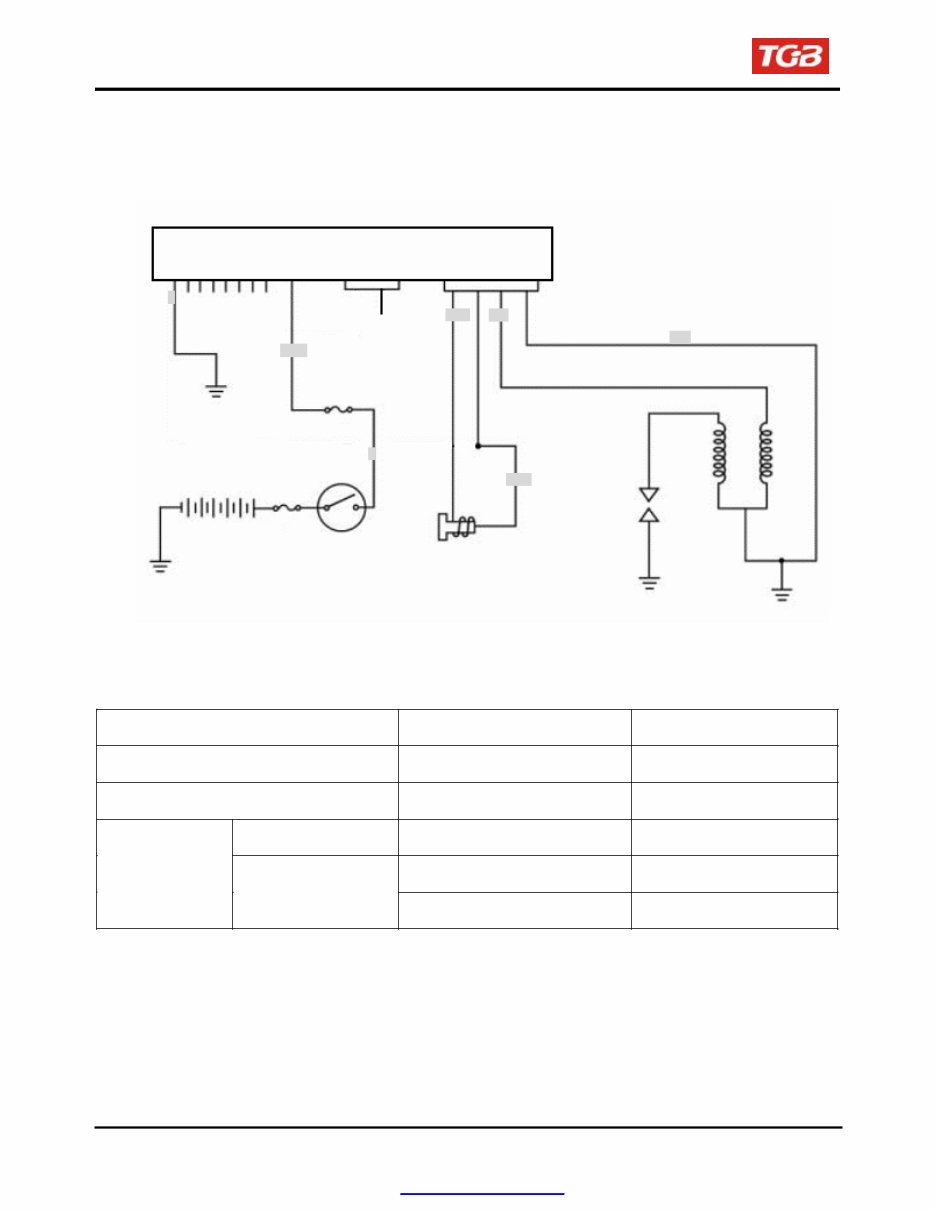

Ignition System

Ignition circuit diagram

C D I Unit

B

B Black

R Red

G Green

W White

Y Yellow

L Blue

BR/B

Fuse 10A

Main fuse

20A

Spark plug

Ignition

coil

Battery

Main switch

G

Pulse generator

C.D.I unit

Disconnect connectors of the C.D.I unit.

Check the following connectors as indicated in the table at the harness side.

Item Points to check Result

Main switch turn to “ON” position Br/Bl ~ B Battery voltage

Pulse generator Bl/Y ~ G/R 50~170Ω

Primary circuit G/R ~ B 2.9±10%Ω

Ignition coil

Secondary circuit

TERMINAL-B ~ with no cap 15.0±10%Ω

TERMINAL-B ~ with cap 20.0±10%KΩ

17-8

C D I Unit

G/R B1/Y

LG/R

B

B/W

PDF created with pdfFactory Pro trial version www.pdffactory.com

To this chapter contents

17. ELECTRICAL SYSTEM

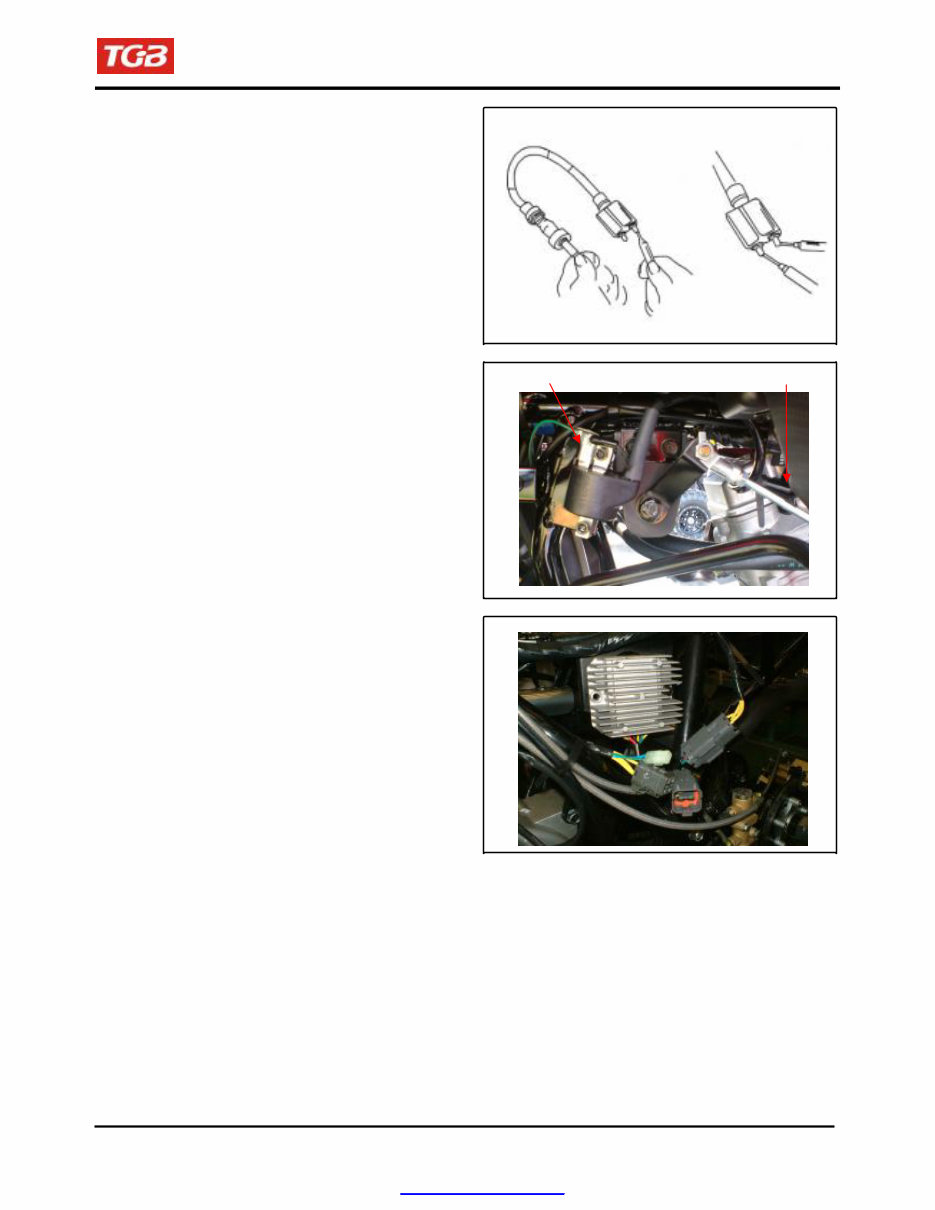

Inspection on Ignition Coil

Disengage the connector of the ignition coil and

the spark plug cap.

Measure the resistance between the terminals of

the primary winding.

Standard resistance: 2.9Ω ± 10%

Remove the cap from the spark plug and measure

the resistance between the spark plug and the

primary winding.

Standard resistance:

With no cap: 15.0Ω ± 10%

With cap: 20.0±10%KΩ

Ignition Coil Replacement

Loosen the lock bolt and replace the ignition coil if

necessary.

Inspection of Pulse Generator

Disconnect the coupler of the pulse generator and

measure the resistance between the terminals of

green/white and blue/yellow.

Standard resistance: 50~170Ω

Ignition coil

Spark plug

17-9

PDF created with pdfFactory Pro trial version www.pdffactory.com

To this chapter contents

17. ELECTRICAL SYSTEM

Starting System

Starting circuit diagram

C.D.I

W

B/W

Fuse 15A

B

Main switch

R

Main fuse

30A

F

N

R

G/Y

Brake

switch

Battery

Change switch

B1 Blue

B Black

R Red

G Green

W White

Y Yellow

BR Brown

Starter switch

Starter relay

Starter motor

G

G/Y

Brake light

Inspection on starter relay

Open the main switch.

Press the brake.

Push down the starter switch.

If a sound of “ Looh Looh” is heard, it indicates the

relay function normally.

Remove the seat.

Disconnect the negative cable terminal of the

battery.

Disconnect the cable positive terminal from the

relay.

Disconnect the positive cable of the starter motor.

Disconnect the coupler of the relay.

Connect an ohmmeter to the large terminal end.

Connect the yellow/red cable to the battery positive

terminal and the black / blue cable to the battery

negative terminal.

Check the continuity of the large terminal end. If

there is no continuity, replace the relay.

17-10

Starter relay

BR/B

B1/W

R

B

B

PDF created with pdfFactory Pro trial version www.pdffactory.com

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 17 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get instant access to the Complete Factory Service Repair Workshop Manual without any extra fees or expiry dates. This Professional Manual is suitable for both professional Mechanics and Technicians, as well as DIY enthusiasts. It covers all repairs, servicing, and troubleshooting procedures with detailed photos, diagrams, step-by-step instructions, and highly detailed exploded diagrams & pictures to ensure every job is completed correctly.

Print out a single page or the entire manual as per your choice. This Manual can be used on multiple computers without any limitations or trial periods, and it does not expire or require any renewal fees. It is fully compatible with all Windows & MAC Computers.