2008-2014 Suzuki KingQuad 750 LT-A750 Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

FOREWORD

This manual contains an introductory description on the SUZUKI LT-A750X/P and procedures for its inspection/

service and overhaul of its main components.

Other information considered as generally known is not included.

Read the GENERAL INFORMATION section to familiarize yourself with the vehicle and its maintenance. Use this

section as well as other sections to use as a guide for proper inspection and service.

This manual will help you know the vehicle better so that you can assure your customers of fast and reliable ser-

vice.

* This manual has been prepared on the basis of the latest specifications at the time of publication. If modifi-

cations have been made since then, differences may exist between the content of this manual and the

actual vehicle.

* Illustrations in this manual are used to show the basic principles of operation and work procedures. They

may not represent the actual vehicle exactly in detail.

* This manual is written for persons who have enough knowledge, skills and tools, including special tools, for

servicing SUZUKI vehicles. If you do not have the proper knowledge and tools, ask your authorized

SUZUKI motorcycle dealer to help you.

WARNING !

Inexperienced mechanics or mechanics without the proper tools and equipment may not be able to

properly perform the services described in this manual.

Improper repair may result in injury to the mechanic and may render the vehicle unsafe for the rider

and passenger.

00

0

1

2

3

4

5

6

9

Precautions............................................................... 00-i

Precautions ............................................................ 00-1

General Information ................................................... 0-i

General Information ............................................... 0A-1

Maintenance and Lubrication ................................. 0B-1

Service Data........................................................... 0C-1

Engine ......................................................................... 1-i

Precautions .............................................................. 1-1

Engine General Information and Diagnosis ........... 1A-1

Emission Control Devices ...................................... 1B-1

Engine Electrical Devices....................................... 1C-1

Engine Mechanical ................................................. 1D-1

Engine Lubrication System .................................... 1E-1

Engine Cooling System.......................................... 1F-1

Fuel System ...........................................................1G-1

Ignition System....................................................... 1H-1

Starting System....................................................... 1I-1

Charging System.....................................................1J-1

Exhaust System ..................................................... 1K-1

Suspension ................................................................. 2-i

Precautions .............................................................. 2-1

Suspension General Diagnosis .............................. 2A-1

Front Suspension ................................................... 2B-1

Rear Suspension.................................................... 2C-1

Wheels and Tires ................................................... 2D-1

Driveline / Axle ........................................................... 3-i

Precautions .............................................................. 3-1

Drive Chain / Drive Train / Drive Shaft ................... 3A-1

Differential .............................................................. 3B-1

Transfer .................................................................. 3C-1

Propeller Shafts...................................................... 3D-1

Brake ........................................................................... 4-i

Precautions .............................................................. 4-1

Brake Control System and Diagnosis .................... 4A-1

Front Brakes........................................................... 4B-1

Rear Brakes ........................................................... 4C-1

Parking Brake......................................................... 4D-1

Transmission / Transaxle .......................................... 5-i

Precautions .............................................................. 5-1

Automatic Transmission ......................................... 5A-1

Steering ....................................................................... 6-i

Precautions .............................................................. 6-1

Steering General Diagnosis ................................... 6A-1

Steering / Handlebar .............................................. 6B-1

Body and Accessories ............................................... 9-i

Precautions .............................................................. 9-1

Wiring Systems ...................................................... 9A-1

Lighting Systems .................................................... 9B-1

Combination Meter / Fuel Meter / Horn .................. 9C-1

Exterior Parts ......................................................... 9D-1

Body Structure ....................................................... 9E-1

TABLE OF CONTENTS

SUPPLEMENTS L

LT-A750XK9 (’09 MODEL) 10

LT-A750XPK9 (’09 MODEL) 11

Table of Contents 00- i

00

Section 00

CONTENTS

Precautions

Precautions ............................................... 00-1

Precautions........................................................... 00-1

Warning / Caution / Note..................................... 00-1

General Precautions ........................................... 00-1

Precautions for Electrical Circuit Service ............ 00-2

00-1 Precautions:

Precautions

Precautions

Precautions

Warning / Caution / Note

B831G20000001

Please read this manual and follow its instructions

carefully. To emphasize special information, the symbol

and the words WARNING, CAUTION and NOTE have

special meanings. Pay special attention to the messages

highlighted by these signal words.

WARNING !

Indicates a potential hazard that could result

in death or injury.

CAUTION !

Indicates a potential hazard that could result

in vehicle damage.

NOTE

Indicates special information to make

maintenance easier or instructions clearer.

Please note, however, that the warnings and cautions

contained in this manual cannot possibly cover all

potential hazards relating to the servicing, or lack of

servicing, of the vehicle. In addition to the WARNINGS

and CAUTIONS stated, you must use good judgement

and basic mechanical safety principles. If you are unsure

about how to perform a particular service operation, ask

a more experienced mechanic for advice.

General Precautions

B831G20000002

WARNING !

• Proper service and repair procedures are

important for the safety of the service

mechanic and the safety and reliability of

the vehicle.

• When 2 or more persons work together,

pay attention to the safety of each other.

• When it is necessary to run the engine

indoors, make sure that exhaust gas is

forced outdoors.

• When working with toxic or flammable

materials, make sure that the area you

work in is well ventilated and that you

follow all of the material manufacturer’s

instructions.

• Never use gasoline as a cleaning solvent.

• To avoid getting burned, do not touch the

engine, engine oil, radiator and exhaust

system until they have cooled.

• After servicing the fuel, oil, water, exhaust

or brake systems, check all lines and

fittings related to the system for leaks.

CAUTION !

• If parts replacement is necessary, replace

the parts with Suzuki Genuine Parts or

their equivalent.

• When removing parts that are to be reused,

keep them arranged in an orderly manner

so that they may be reinstalled in the

proper order and orientation.

• Be sure to use special tools when

instructed.

• Make sure that all parts used in

reassembly are clean. Lubricate them

when specified.

• Use the specified lubricant, bond, or

sealant.

• When removing the battery, disconnect the

negative (–) cable first and then the

positive (+) cable.

• When reconnecting the battery, connect

the positive (+) cable first and then the

negative (–) cable, and replace the terminal

cover on the positive (+) terminal.

• When performing service to electrical

parts, if the service procedures do not

require use of battery power, disconnect

the negative (–) cable the battery.

• When tightening the cylinder head or case

bolts and nuts, tighten the larger sizes

first. Always tighten the bolts and nuts

diagonally from the inside toward outside

and to the specified tightening torque.

• Whenever you remove oil seals, gaskets,

packing, O-rings, locking washers, self-

locking nuts, cotter pins, circlips and

certain other parts as specified, be sure to

replace them with new ones. Also, before

installing these new parts, be sure to

remove any left over material from the

mating surfaces.

Precautions: 00-2

• Never reuse a circlip. When installing a

new circlip, take care not to expand the

end gap larger than required to slip the

circlip over the shaft. After installing a

circlip, always ensure that it is completely

seated in its groove and securely fitted.

• Use a torque wrench to tighten fasteners

to the specified torque. Wipe off grease

and oil if a thread is smeared with them.

• After reassembling, check parts for

tightness and proper operation.

• To protect the environment, do not

unlawfully dispose of used motor oil,

engine coolant and other fluids: batteries,

and tires.

• To protect Earth’s natural resources,

properly dispose of used vehicle and parts.

Precautions for Electrical Circuit Service

B831G20000003

When handling the electrical parts or servicing the FI

systems, observe the following points for the safety of

the systems.

Electrical Parts

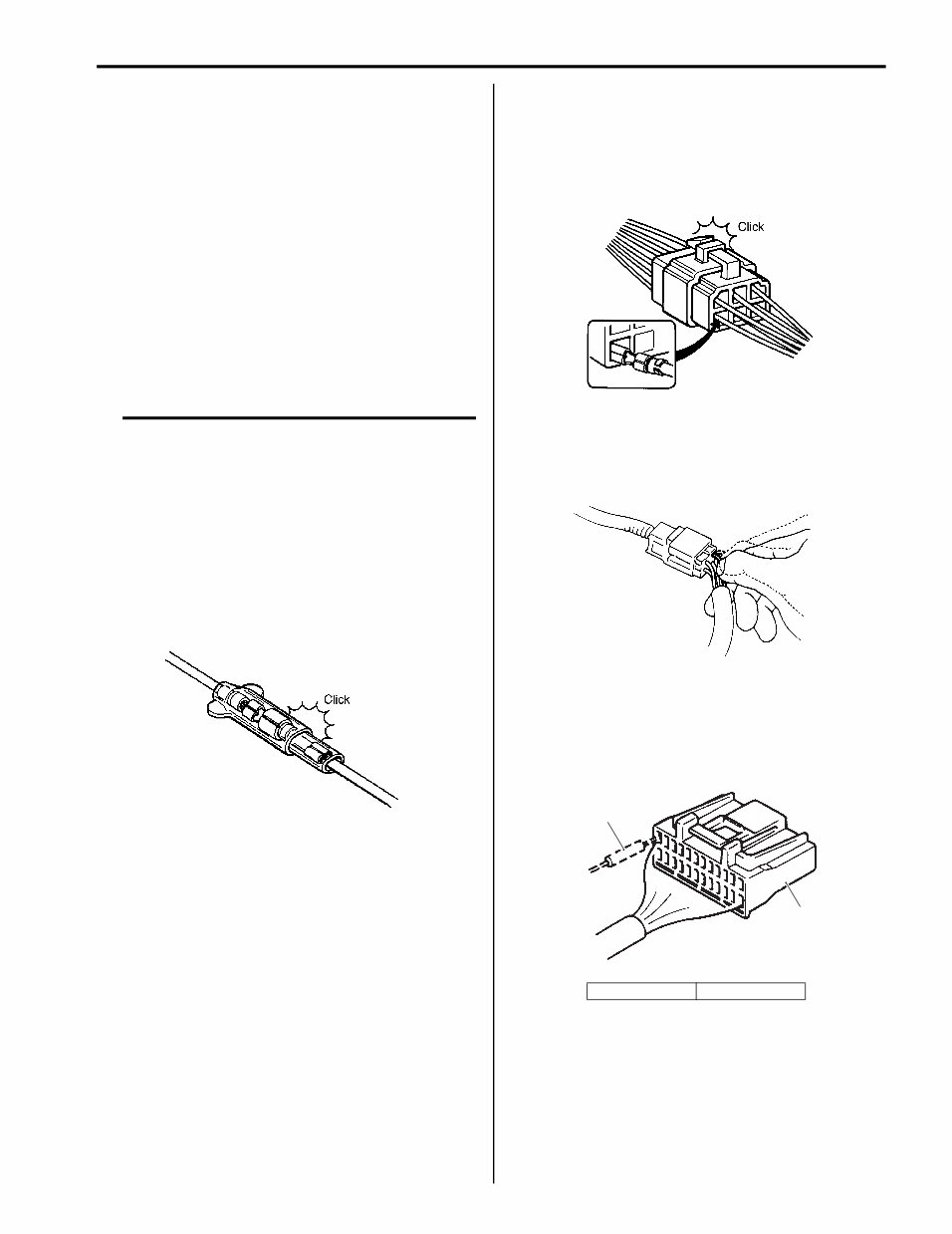

Connector / Coupler

• When connecting a connector, be sure to push it in

until a click is felt.

• With a lock type coupler, be sure to release the lock

when disconnecting, and push it in fully to engage the

lock when connecting.

• When disconnecting the coupler, be sure to hold the

coupler body and do not pull the lead wires.

• Inspect each terminal on the connector/coupler for

looseness or bending.

• Push in the coupler straightly. An angled or skewed

insertion may cause the terminal to be deformed,

possibly resulting in poor electrical contact.

• Inspect each terminal for corrosion and

contamination. The terminals must be clean and free

of any foreign material which could impede proper

terminal contact.

• Before refitting the sealed coupler, make sure its seal

rubber is positioned properly. The seal rubber may

possibly come off the position during disconnecting

work and if the coupler is refitted with the seal rubber

improperly positioned, it may result in poor water

sealing.

• Inspect each lead wire circuit for poor connection by

shaking it by hand lightly. If any abnormal condition is

found, repair or replace.

• When taking measurements at electrical connectors

using a tester probe, be sure to insert the probe from

the wire harness side (backside) of the connector/

coupler.

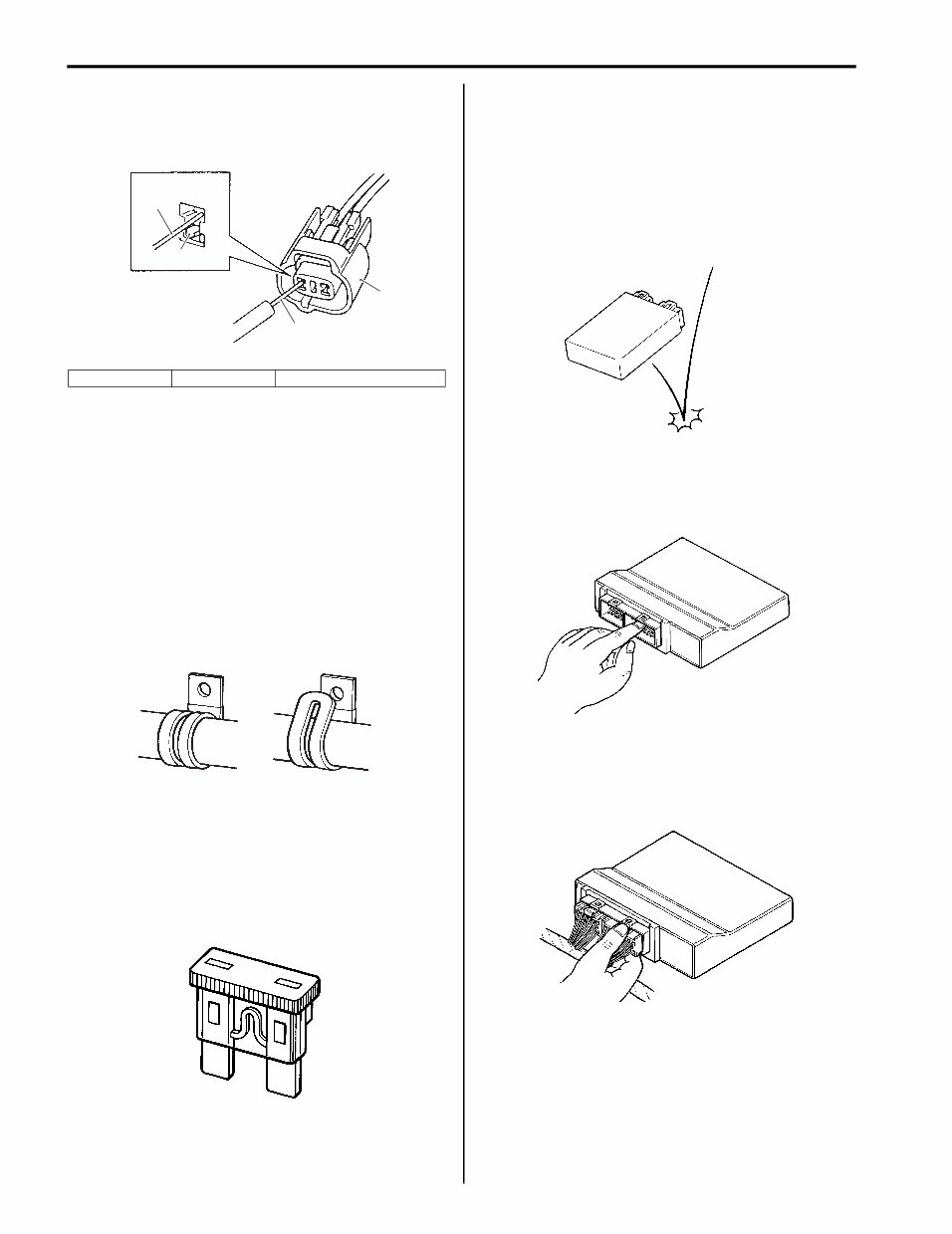

• When connecting meter probe from the terminal side

of the coupler (where connection from harness side

not being possible), use extra care not to force and

cause the male terminal to bend or the female

terminal to open. Connect the probe as shown to

avoid opening of female terminal. Never push in the

probe where male terminal is supposed to fit.

I310G1000001-01

1. Coupler 2. Probe

I310G1000002-01

I310G1000003-02

2

1

I649G1000013-02

00-3 Precautions:

• Check the male connector for bend and female

connector for excessive opening. Also check the

coupler for locking (looseness), corrosion, dust, etc.

Clamp

• Clamp the wire harness at such positions as indicated

in “Wiring Harness Routing Diagram in Section 9A

(Page 9A-4)”.

• Bend the clamp properly so that the wire harness is

clamped securely.

• In clamping the wire harness, use care not to allow it

to hang down.

• Do not use wire or any other substitute for the band

type clamp.

Fuse

• When a fuse blows, always investigate the cause to

correct it and then replace the fuse.

• Do not use a fuse of different capacity.

• Do not use wire or any other substitute for the fuse.

Switch

Never apply grease material to switch contact points to

prevent damage.

ECM / Various sensors

• Since each component is a high-precision part, great

care should be taken not to apply any severe impacts

during removal and installation.

• Be careful not to touch the electrical terminals of the

electronic parts (ECM, etc.). The static electricity from

your body may damage these.

• When disconnecting and connecting the coupler,

make sure to turn OFF the ignition switch, or

electronic parts may get damaged.

3. Coupler 4. Probe “A”: Where male terminal fits

3

4

4

“A”

I649G1000030-02

CORRECT INCORRECT

I718H1000001-02

I649G1000001-02

I310G1000007-01

I310G1000008-01

I831G1000001-01

Precautions: 00-4

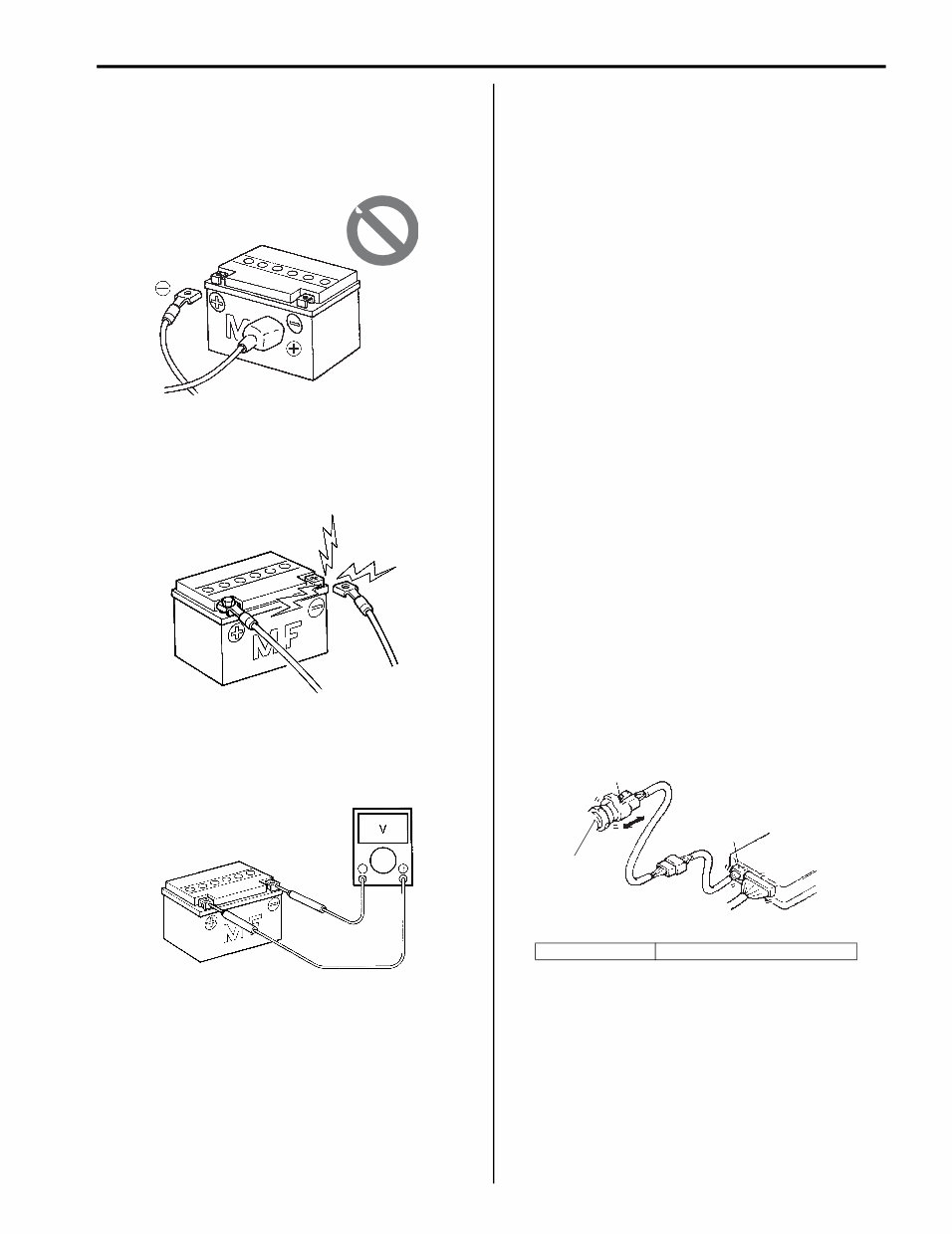

Battery

• Battery connection in reverse polarity is strictly

prohibited. Such a wrong connection will damage the

components of the FI systems instantly when reverse

power is applied.

• Removing any battery terminal of a running engine is

strictly prohibited. The moment such removal is made,

damaging counter electromotive force will be applied

to the ECM which may result in serious damage.

• Before measuring voltage at each terminal, check to

make sure that battery voltage is 11 V or higher.

Terminal voltage check with a low battery voltage will

lead to erroneous diagnosis.

• Never connect any tester (voltmeter, ohmmeter, or

whatever) to the electronic unit when its coupler is

disconnected. Otherwise, damage to electronic unit

may result.

• Never connect an ohmmeter to the ECM with its

coupler connected. If attempted, damage to ECM or

sensors may result.

• Be sure to use a specified voltmeter/ohmmeter.

Otherwise, accurate measurements may not be

obtained and personal injury may result.

Electrical Circuit Inspection Procedure

While there are various methods for electrical circuit

inspection, described here is a general method to check

for open and short circuit using an ohmmeter and a

voltmeter.

Open circuit check

Possible causes for the open circuit are as follows. As

the cause can exist in the connector/coupler or terminal,

they need to be checked carefully.

• Loose connection of connector/coupler

• Poor contact of terminal (due to dirt, corrosion or rust,

poor contact tension, entry of foreign object etc.)

• Wire harness being open.

• Poor terminal-to-wire connection.

When checking system circuits including an electronic

control unit such as ECM, etc., it is important to perform

careful check, starting with items which are easier to

check.

1) Disconnect the negative (–) cable from the battery.

2) Check each connector/coupler at both ends of the

circuit being checked for loose connection. Also

check for condition of the coupler lock if equipped.

I718H1000004-01

I310G1000011-01

I310G1000012-02

1. Sensor “A”: Check for loose connection

ECM

“A”

1

“A”

I718H1000005-02

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 42 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get the factory repair manual for the 2008-2014 Suzuki KingQuad 750 ATV. This manual is specifically for 2008-2009 models but can also be used for 2010-2014 models as there were only minor updates. It covers all model variations and includes complete tear down and rebuild, pictures and part diagrams, torque specs, maintenance, troubleshooting, and more. With 711 pages, it has clickable chapters and is searchable, making it easy to find what you're looking for. There are no restrictions on printing or saving/burning to disc.

For all available Suzuki KingQuad manuals, copy/paste this link into your browser: Suzuki KingQuad Manuals