1996-1999 Polaris Xplorer 500 ATV Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

CONTENTS

QUICK REFERENCE DATA ........ •...•.• .............. • . IX

CHAPTER ONE .

GENERAL INFORMATION

Manual organization

Notes, cautions and warnings

Safety first

Cleaning parts

Handling gasoline saf ely

Service hints

Torque sped fications

Fasteners

Lubricants

Threadlocking compound

RTV gasket sealant

CHAPTER TWO .....

TROUBLESHOOTING

Operating requirements

Troubleshooting instruments

Starting the engine

Starting diffi culties

Engine is difficult to start

Engine starting system

Charging system

Ignition system

Electronic throttle control

.. .. .. .1

Expendable supplies

Serial numbers

Warning and information labels

Basic hand tools

Precision measuring tools

Special tools

Fabricating tools

Mechanic's tips

Beari ng replacement

Seals

Storage

.. 36

Fuel sys tem

Engine overheating

Engine

Engine noises

Cy linder leak down test

Powe r tra in

Steering

Frame noise

Brakes

CHAPTER THREE . .. .... .. .. •. •.. .

LUBRICATION, MAINTENANCE AND TUNE-UP

Pre- ride check list

Tire s and whee ls

Battery

Battery electrical cabl e connectors

Periodic lubrication

CHAPTER FOUR .

ENGINE TOP END

Eng ine prin cip les

Engine cooling

Eng ine lubrication

Servicing the engine in the frame

Exhaust system

Cylinder head cover

Rocker ann assembly

CHAPTER FIVE . . • .

ENGINE LOWER END

Engine

Flywheel and stator plate

Recoi l starter

Crankcase

Crankshaft inspection

Balancer shaft inspection

CHAPTER SIX • ....

FUEL SYSTEM

Carburetor operation

Carburetor

Carburetor cleaning and inspection

Carburetor tests and adjustments

Throttle cable replacement

CHAPTE R SEVEN. ........ •

COOLING SYSTE MS

Polaris variable transmission (PVT)

air cooling system

Eng ine cooling system

Safety precauti ons

Hoses and hose clamps

Engin e gaskets/sea ls

.... .. 53

Periodic main tenance

Unscheduled inspection

and maint enan ce

Engine tune-up

.. .. .. ...... 94

Camshaft

Cy linde r head

Valves and valve components

Cylinder block

Piston and piston rings

Camshaft chain and sprockets

Break-in procedure

. . . 137

Shan end float measurement

and shim selection

Oil pumr

Oil system one-way check valve

Break-in procedu re

175

Stall ing enrichment (choke) cab le

Fuel tank

Fuel shutoff valve

Air filter air box

Fu ~l pllm p

.... 198

Coo ling system inspection

Radiator

Coo ling fan

Coo lant pump

Thermostat

Temperature sensors

CHAPTER EIGHT .

CLUTCH/DRIVE BELT SYSTEM

Drive unit

Drive pulley

Specia l tools

Driven pulley

Drive belt

CHAPTER NINE .

TRANSMISSION

Tra nsmission

Tra nsmission inspection

Shift shafts

Front output shaft

CHAPTER TEN .......

FRONT DRIVE SYSTEM

Front hub and Hillard clutch

Front drive axle, boots and CV

(constant velocity) joints

CHAPTER ELEVEN ..

ELECTRICAL SYSTEM

Ba sic informat ion

Negative battery terminal

Charging system

Alterna tor stator

Voltage regulator/rectificr

Capacitordischarge ignition

Ignition coil

Ignition stator coils

CHAPTER TWELVE .

FRONT SUSPENSION AND STEERING

Front wheel

Front hub

Front strut cartridge and spring

Front strut/spindle

Control arm

CHAPTER THIRTEEN .

REAR SUSPENSION

Rear wheels

Tire changing and tire repairs

Shock absorber

Rear hub and bearing carrier

Rear axles

Upper control arm

. .. .. .. .... 213

Drive pulley

Driven pulley

Clutch outer and inner cover

(all models)

. . 249

Transmission gearcase oil seal

inspection andreplacement

Shift selector linkage

..... .... 290

Front drive shaft

Front drive unit

.. .. . 303

Electric starting system

Starter drive gears

Starter solenoid

Lighting system

Electrical components

Sw itches

Wi ring dia grams

. 337

Handlebar

Tie rods

Steerin g shaft

Tires and wheels

. 362

Lower control arm

Upper and lower control

arm inspection

Stabilizer linkage

Stabilizer support

CHAPTER FOURTEEN.

BRAKES

Disc brakes

Front brake padreplacement

Fro nt cal iper

Ou tput shaft brake pad replacement

(199 6-1997 models)

O utput shall brake cal iper

(] 996- 1997 models)

Outpu t shall brake pad replacement

(I998-on models)

Outp ut shaft brake caliper

(I 998-on models)

CHAPTER FIFTEEN

BODY

Seat

F ront rack and grille

Side pan els

Front fender

Front bumper (models so equipped)

SUPPLEMENT .

2001-2003 SERVICE INFORMATION

Starting the engine

Ignition system

Periodic maintenance

Engine tUIl C- Up

Cylinder block

Piston and piston rings

Engine

Fl ywhee l and stator plate

Carburetor (Sportsman 500 H.G. models)

Cleaning and inspection

Carburetor tests and adjustments

Drive belt

Driven pulley (2003 models bui lt

after 07/08102)

INDEX .

WIRING DIAGRAMS .

.. . .. . . 382

Fron t master cylinder

Rear master cylinder

Brake hose replacement

Rear brake pedal

Rem brake lever

(1996-1997 Sweden models)

Foot brak e

(1998-on Sweden model s)

Brake disc

Bleeding the system

... .. .. .. . 425

Radiator guard

Rear rack

Rear fender

Footv..'ells

Rear bumper (models so equipped)

... ... .... . 437

Tra nsmission

Lighting system

Electrical components

Steering shall (2002-on models)

Rear hub and bearing carrier (2003 models)

Rear brake pad replace men t

(2003 mode ls)

Rear calipers (2003 models)

Front master cylinder

Rear mast er cylinder (2003 models)

Rear brake disc (2003 models)

Brake hose replacemen t (2003 models)

.470

.476

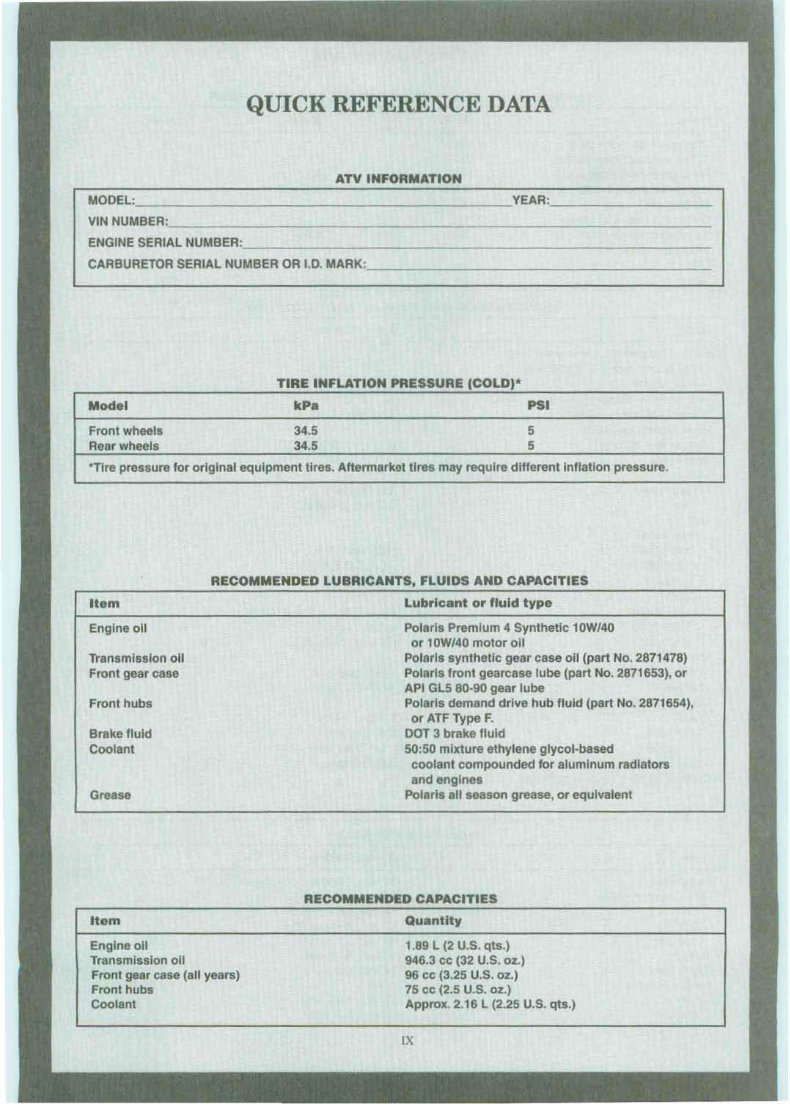

QUICK REFERENCE DATA

ATV INFORMATION

MODEL: YEAR: _

VIN NUMBER:, _

ENGINE SERIAL NUMBER : _

CARBURETOR SERIAL NUMBER OR 1 .0. MARK: _

TIRE INFLATION PRESSURE (COLD)'

Model kPa PSI

Front wheels 34.5 5

Rear wheels 34.5 5

"Tlre pressure for original equipment tires. Aftermarket tires may require different Inflation pressure.

RECOMMENDED LUBRICANTS, FLUIDS AND CAPACITIES

Item

Engine 011

Transmission all

Front gear case

Front hubs

Brake fluid

Coolant

Grease

Item

Engine all

Transmission all

Front gear case (all years)

Front hubs

Coolant

Lubricant or fluid type

Polaris Premium 4 Synthetic 10W/4Q

or 10W/40 motor all

Polaris synthetic gear case 011 (part No. 2871478)

Polaris front gearcase lube (part No. 2871653), or

API GL5 80·90 gear lube

Polaris demand drive hub fluid (part No. 2871654),

or ATF Type F.

DOT 3 brake fluid

50:50 mixture ethylene glycol·based

coolant compounded for aluminum radiators

and engines

Polaris all season grease, or equivalent

RECOMMENDED CAPACITIES

Quantity

1.89 L (2 U.S. qts.)

946.3 cc (32 U.S. oz.}

96 cc (3.25 U.S. oz.)

75 cc (2.5 U.S. oz.)

Approx. 2.16 L (2.25 U.S. qts.)

IX

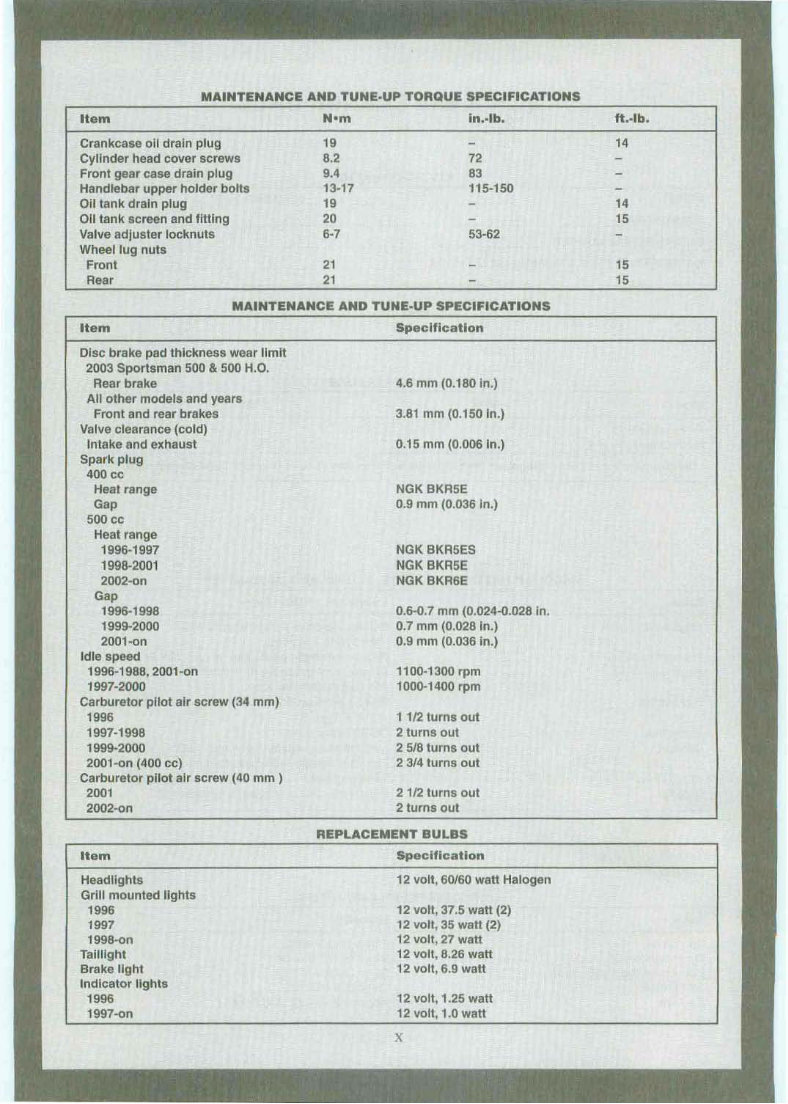

MAINTENANCE AND TUN E·UP TORQUE SPECIFICATIONS

Item N'm

in. .. lb.

Crankcase oil drain plug 19

Cylinder head cover screws 8.2 72

Front gear case drain plug 9.4 83

Handlebar up per holder bol ts 13·17 115-150

Oil tank drain plug 19

0 11 tank screen and fitting 20

Valve adjuster locknuts 6-7 53-62

Whee/lug nuts

Front 21

Rear 21

MAINTENANCEAND TUNE·UP SPECIFICATIONS

ft .·lb.

14

14

15

15

15

Item

Disc brake pad thickness wear limit

2003 Sportsman 500 & 500 H.O.

Rear brake

All other models and years

Front and rear brakes

Valve clearance (cold)

Intake and exhaust

Spark plug

400 cc

Heat range

Gap

500 ee

Heat r ange

1996-1997

1998-2001

2002·on

Gap

1996 · 1998

1999-2000

2001·on

Idle sp eed

1996-1988, 2001-on

1997·2000

Carburetor pilot air screw (34 mm)

1996

1997·1998

1999-2000

2001 -on (400 ee)

Carburetor pilot air screw (40 mm )

2001

2002-on

Item

Headlights

Grill mounted lights

1996

1997

1998-on

Tai lli g ht

Brake light

Indicator lights

1996

1997-on

Spec ificat ion

4.6 mm (0.180 In.)

3.81 mm (0.150 In.)

0.15 mm (0.006 In.)

NGK BKR5E

0.9 mm (0.036 in.)

NGK BKR5ES

NGK BKR5E

NGK BKR6E

0.6-0.7 mm (0.02 4-0.028 in .

0.7 mm (0.028 In.)

0.9 mm (0.036 in.)

1100-1300 rpm

1000-1400 rpm

1 1/2 turns out

2 turns out

2 5/8 turns out

23/4 turns out

2 1/2 turns out

2 turns out

REPLACE MENT BULBS

Spec ification

12 volt , 6 0/60 watt Halogen

12 volt, 37.5 watt (2)

12 volt, 35 watt (2)

12 volt, 27 watt

12 volt, 8.26 watt

12 volt, 6.9 watt

12 volt, 1.25 watt

12 volt ,l.0 watt

x

CHAPTER ONE

GENERAL INFORMATION

This detailed. comprehensive manual covers the

Polaris Sportsman 400, 500 and Xplorer 500 4 x 4

from I 996-on.

Keep this book handy in the toolbox. Reading

and using it will help to better understand how the

vehi cle runs, lower repair costs and generally im-

prove personal satisfaction with the vehicle.

The following tables are included at the end of

this chapter:

Tah le 1 lists model year and number.

Tahle 2 lists general dimensions.

Ta ble 3 lists vehicle weight (dry) .

Table 4 lists decimal and metric equivalents.

Tab le 5 lists general torque specifications.

Tab le 6 lists conversion tables .

Ta ble 7 lists technical abbreviations.

Table 8 lists metric tap and drill sizes.

Tables 1-8 are at the end of this chapter.

MANU AL OR GANIZATlO:'ll

All dimensions and capacities are expresse d in

English units familiar to U.S. mechanics. as well as

in metric units.

This chapter provides general information and

discusses equipment and too ls useful both for pre-

ventive maintenance and troubleshooting.

Chapter Two provides methods and suggestions

for the quick and accurate diagnosis and repair of

problems. Troubles hooting procedures discuss typ-

2

ica l sy mpto ms and logi cal method s to pinpoint the

t roub le.

Chap ter Th ree explains all periodic lubrication

and routine maintenance necessary to keep the veh i-

cle funning well. Cha pter Three also includes rec-

ommended t UIl C-Up proce du res , el imina ting the

need to constantly consult chapters on the various

ass e mb l ies .

S ubsequen tc hapters describe specific sys te ms

such as the engine, clutch/ drive belt system, trans-

mission, exhaust, cooling, suspension and brakes.

Eac hc hapter provides disass emb ly, repair and as-

sembly procedures in a simple step- by-step form .

Ifa repair is impract ica l for a ho me mechan ic . it is

so indicated. It is usually faster ami less expensive

to take such repairs to a dealer or competent repair

shop. Specifications concerning a particular system

arc i ncluded at the end of the appropriate chapter.

So me of the proc edures in this manual spec ify

s pec ial too ls. In most case s, the tool is illustrated ei-

ther in actual use or alone. Well-equi pped mec han-

ics may find they ca n substitute similar tools

alre ady on hand or can fabricate thei r own .

NOTES, CAUTIONS AND WARNI NGS

T he terms NOT E, CAUTION and WAR NING

have specific mean ings in this manual. A NOTE

pro vides add itio na l inform ation to mak e a step or

procedure easier or clearer . Di sregardi ng a NOTE

cou ld cause incon venience, but wou ld not cause

eq u ipment damage or personal injury.

A CAUTION emp hasize, areas where eq uipment

da mage co uld result. Di sregarding a CA UTION

co uld cause permane nt mechanical dama ge ; hO\\I-

eve r, personal inju ry is unlikely.

A WARNING emphasizes areas where pe rsona l

injury or eve n death could result from negligence.

Mechanical damage may also occ ur. WARNI NG S

are fa be taken seriously. In some cases, serious in-

jut)' or death has resulted from dis regar ding similar

w arn ings .

SA rETY FIRST

Professional mechan ics can work for years and

never sustain a serious injury. I f a few rul es of com-

mon sense and safe ty arc ob served. man y safe hours

can be enjo yed servicing the ATY. Ignoring these

CHAPTER ONE

rules can injure so meo ne working on the vehicle. or

damage the AT V.

I. Never lise gaso line or any t ype of low flash po int

solvent to clean parts, Sec Cleaning Parts and Han-

dling Gasoline Safety in this chapter for additional

informat ion on parts cleaning, gaso line usc and

safety.

NOTE

The flash point is the lowest tempera-

lur e at which the vapo rsfrom a com-

bustible liquid will ign ite when in

open ail: A lowjlash point solvent will

ignite at a lower temperature than a

higlzjlash point solvent.

2. Never smoke or usc a torch in the vicinity of

flammable liquids in open containers , such as gas o-

line or cleaning solvent.

3. lf wclding or brazing is req uir ed on the vehicle.

remove the fuel rank, c arbur etor, and fron t and rea r

shocks to a safe dist ance at leas t 50 feet (15 m)

away.

4. Use the proper sized wrenches to avo id damage

to fasteners.

5. When loosening a tight or stuck nut, be guided

by what would h app en if the wrench slips.

6. When rep lacing a fastener, make sure to usc one

with the same measurem ents and strength as the old

one. Incorrect or mismatched fasteners can result in

da mage to the vehicle and possibl e personal injury.

Beware of fastener kits that are filled with cheap

and p oor ly made nuts. bolts, was he rs and co tte r

pins. Ref er to Faste ne rs in this chapter for addi-

tional inform ation.

7. Keep all hand and power tool s in good condition.

Wipe greasy and oily tools after using them. Dirty

tools arc difficult to hold and can cause injury. Re-

place or repair worn or damaged tools.

8. Kee p the work area clean and uncl uttered.

9. Wear safety g ogglcs during all operation s in-

vo lving drillin g, grinding. the use of a cold chis el,

usin g chemicals, cleaning parts, when u sing com-

pressed air or anytim e the safety of eyes is in-

vo lved.

10 . Mak e sure to wear the correct typ e of clothes

for the jo b. Lon ghair should be tied up or covered

with a cap so thai it cannot be caught by a piece of

moving equipme nt or tool.

G ENE RAL INFO RMATION

11. Keep an approved fire extinguisher nearby. Be

sure it is rated fur gasoline (Class B) and electrical

(Cla ss C) fires.

12. When drying bearings or other rotating paris

with compressed air, never allow the air j et to rotate

the bearing or pari. The air jet is capab le of rotating

them at speeds tar in excess of those for which they

were designed . The bearing or rotating part is very

likely to disintegrate and cause serious injury and

damage. To prevent bearing damage when using

com pressed air, hold the inner bearing race by hand.

WARNING

The improper use ofcompressed air is

velJ' dangerous. Using compressed

air to tlUSI off clothes, the ATV or

workbench can cause jl ying particles

to be blown into eyes or skill. Neve r

direct or blow compress ed air in/a

skin or through any bod y openin g (in-

cluding cuts) as this can cause severe

injury or death. Compressed air must

be used care /id ly; never allow chil-

dren to lise or play with a ll)' com-

pressed air equipment or hoses.

13. Never work on the upper part of the vehicle

while someone is worki ng underneath it.

14. When putting the vehicle on a stand, make sure

the vehicle is secure before walking away from it.

15. Never carry sharp tools in clothing pockets.

16. There is always a right and wrong way to use

tools. Learn to use them the right way.

17. Do not start and run the ATV in an enclosed

area , The exhaust gases contain carbon monoxide, a

colorless, odorless, poisonous gas. Carbon monox-

ide levels build quickly in a small closed area and

can cause unconsciousness and death in a short

time. When it is necessary to start and run the vehi-

cle during a service procedure, always do so out-

side, or in a serv ice area equip ped with a ventilating

system.

CLEANING PARTS

Cleaning parts is one of the more tedious and dif-

ficu lt serv ice jo bs per formed in the home garage.

While there are a nnmber of chemical cleaners and

solvents available for home and shop lise, most arc

poisonous and extremely flammable. To prevent

chemical overexposure, vapor buildup, tire and sc-

3

rious injury. observe all manufact urer 's direct ions

and warn ings while noting the following,

I. Read the entire product label before using the

chem ical. Observe the precautions and warnings on

the label. Always know what type of chem ica l is be-

ing used.

2. If the chemical product must be mixed, measure

the proper amount according to the direction s.

3. Always provide sufficient ventilation when

working with solvents or other chemicals. If a

chemical can be smelled, there is some vapor in the

air. The stronger the smell, the stronger the vapor

con cent ration .

4. If a product is listed as combustible, flammable

or an extremely flammable Iiquid, the danger offi re

increases as the vapor collects and builds up in the

shop.

5. lf a product is listed as a poison, the vapor is poi-

sonous as well as the liquid.

o. To prevent skin exposure, wear protective

gloves when cleaning parts. Select a pair of chemi-

cal-resistant gloves suitable for the type of cherni-

cals that will be used. Replace the gloves whcn they

become thin, damaged, cha nge COIOf, or swe ll.

7. Wear safety goggles when using chemicals and

cleaning parts.

8. Do not lise more than one typ e of cleaning sol-

vent at a lime.

9. If a pan must be heated to remove a bearing,

clean it thoroughly to remove all oil, grease and

cleaner residue. Then wash with soapy water and

rinse with clear water,

10. Wear a respirator if the instruction label says to

do so.

II . Keep chemical products out of reach of chil-

dren and pets.

12. To prevent sparks, usc a nylon bristle brush

when cleaning paris.

13. When using a commercial paris washer, read

and follow the manufacturer's instructions lor se-

lecting the type of solvent to usc. Parts washers

must be equipped with a fusible link designed to

melt and drop the cover in the event of fire.

14. Wash both hands and arms thoroughly after

cleaning parts,

HANDLING GASOLINE SAFE LY

Gasoline, a vola tile flammable liquid, is one of

the most dan gerou s items in the shop, However, be-

a

cause gasoline is used so often, manypeople forget

that it is a dangerous product. Gasoline should be

used only as fuel for internal-combustion engines.

Never usc gas oline to clean part s, tools or to wash

hands. When working on an ATV. motorcycle or

any other type of gasoline engine. gasoline will al-

ways be present in tbe fuel tank, fuel line and carbu-

retor. To avoid a disa strous accident when working

around gasoline or on the fuel system, carefully ob-

serve the following precauti ons:

I. Never usc gasoline to clean part s. See Cleaning

Part s in this chapterfor additional information on

pans cleaning and safety.

2. Wh en working on the fuel sys tem, work outside

or in a well-ven tilated area.

3. Do not add fuel to the fuel tank or service the fuel

system while the ATV is in the vicinity of open

flames, sparksor where someoneissmoking. Gaso-

line vapors arc actually more dangerous than liquid

gasoline. Because these vapors are heavier than air.

they collect in low areas and are easily ignited.

4. Allow the engine to coo l completely bef ore

working on any fuel system component.

5. When draining the carburetor, catch the gasoline

in a plastic container and then pour it into a

safety-approved gas can.

6. Do not store gasoline in any type of glass con-

tainer. If the glass shoold break . a serious explosion

or fire could occur.

7. Wipe up spilled gasoline immediately with dry

rags. Store the rags in a metal container with a lid

ontil they can be properly disposed of . or put them

outside in a safe place to dry.

8. Do not po ur water onto a gasoline tire. Water

spreads the lire and makes it more difficult to put

oot. Use a Class B. BC. or AIlC fire extinguisher to

smother the names and put the fire out.

9. Always tum the engine off before refu eling. Usc

a wide-mouth funnel to prevent spilling gasoline

onto the engine. exhaust pipe or muffl er. Do not

overfill the fuel tank . Leave an airspace at the topof

the fuel tank to prevent fuel from spilling out when

installing the cap.

10. Always refuel the ATV while it is parked out-

side and away fro m all open flames and sparks.

II . When transporting the ATV in another vehicle.

keep it upright with the fuel valve turned oiT.

12. Do not perform a spark test (as described in

Chapter Two ) if there is any gasoline leaking from

the fuel tank , fuel line or carburetor.

CIIAI'TER O~E

FRONT

REAR

SERVICE HINTS

~..Iost of the service procedures covered are

straightfor wa rd and can be performed by anyone

reasonably handy with tools. It is suggested. how-

eve r. that the personal capabilities be carefully eon-

sidercd before attemp ting any operation involving

major disassembly of the engine.

Take time and do the job right. Do not forget that

a newly rebuilt engine must be broken in the same

wayas a new one. Refer to the Engine Br eak-In pro-

ccdure listed in Chapter Four and Chapter Five.

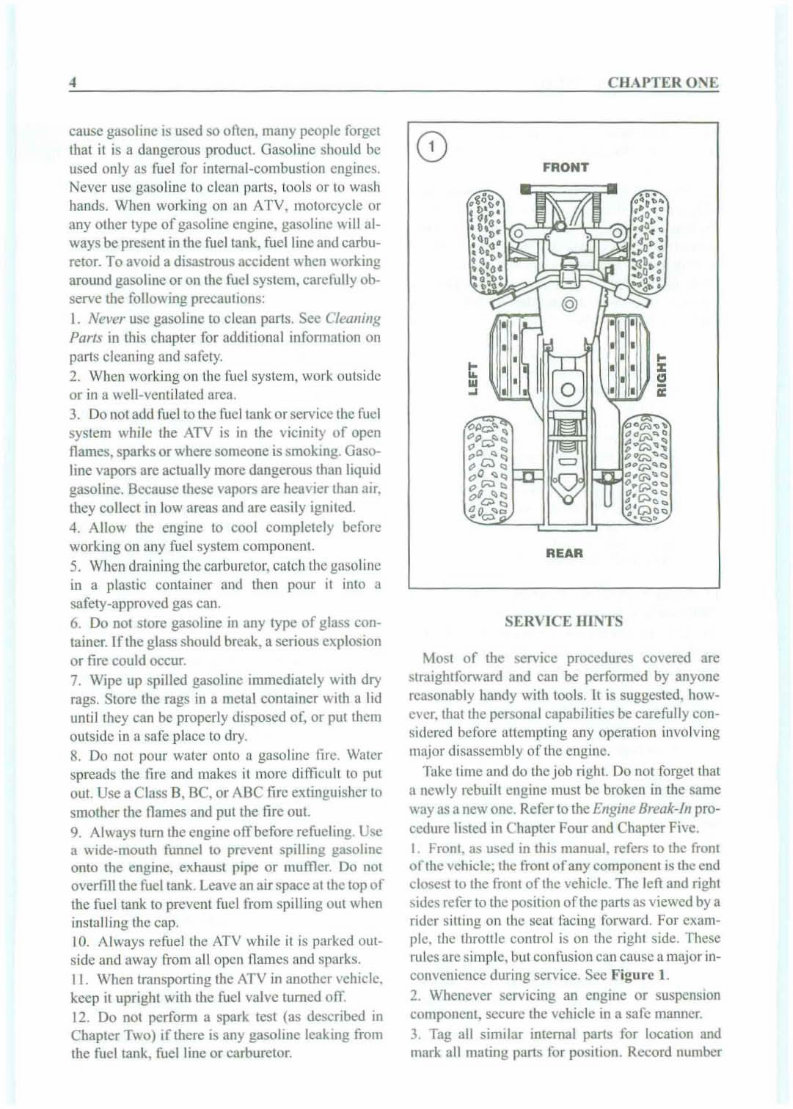

J. Fron t, as used in this manual, refersto the fro nt

ofthe vehicle; the front of any component is the end

closest to the front of the vehicle. The left and right

sides refer to the position afthe p art s as viewed by a

rider sitting 011 the seat rac ing forward. For exam-

ple, the throttle control is on the right side. The se

rules aresimple. but confusion can cause a major in-

convenience during service. Sec Figure 1.

2. Whenever servicing an engine or suspens ion

component, secure the vehicle in a safe manner.

3. Tag all similar internal part s for location and

mark all mating part s for position. Record number

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Viewed 13 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

This service manual for the Polaris ATV Xpress 300 from 1996 to 1998 is an essential resource for both professional mechanics and DIY enthusiasts. It contains detailed illustrations, diagrams, wiring schematics, and step-by-step instructions for a wide range of repair and maintenance tasks.

- General Information

- Maintenance

- Engine

- Fuel System/Carburetion

- Body

- Steering

- Suspension

- PVT System

- Final Drive

- Transmission

- Brakes

- Electrical

The manual is available in a printable PDF format and is compatible with both Windows and Mac operating systems. It can be viewed using Adobe Reader. With a wealth of pictures and diagrams, this manual provides comprehensive support for all your repair and maintenance needs. All pages are printable, allowing for easy access to the required information at home, in the office, or at the repair shop.