1986-2006 Kawasaki Bayou 300 (KLF300) Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

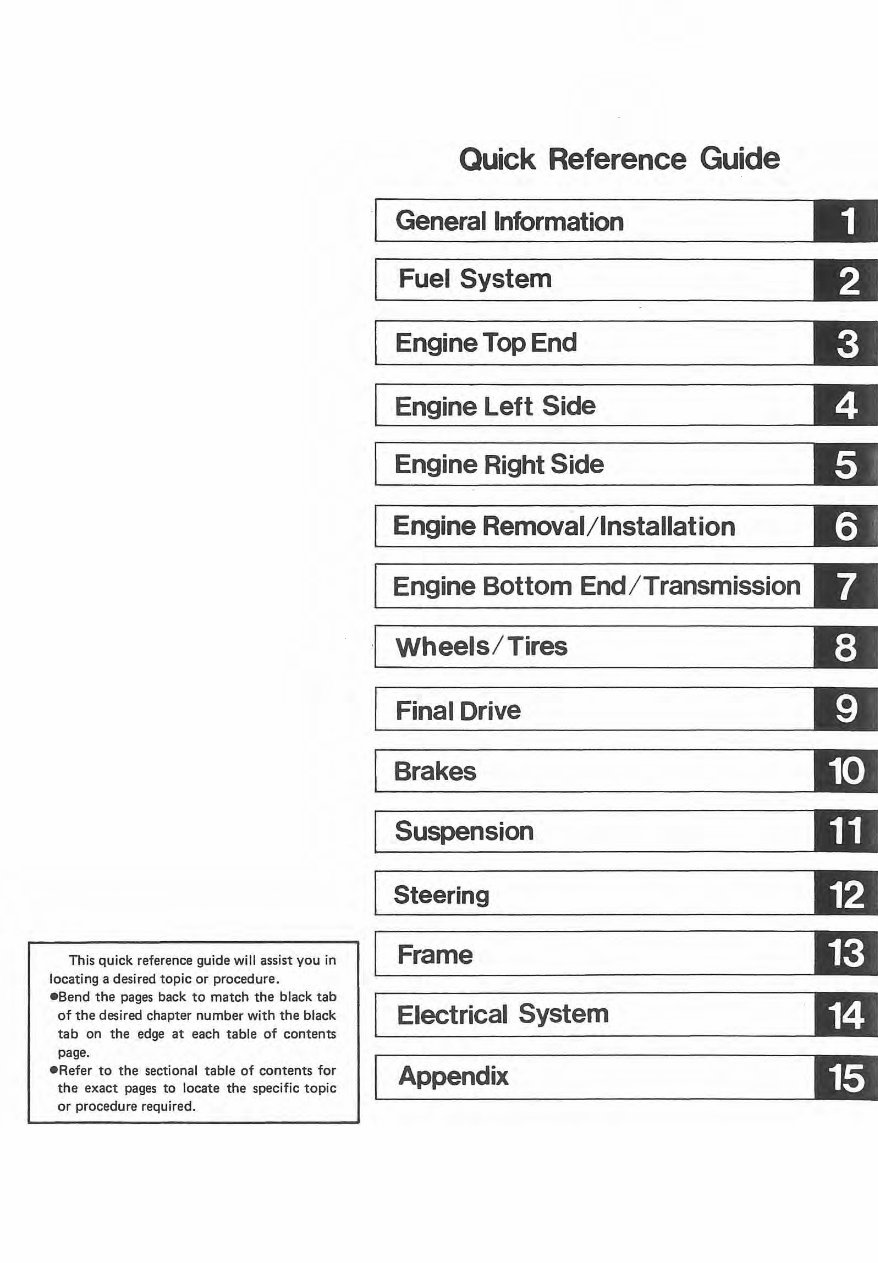

This quick reference guide will assist you in

locating a desired topic or procedure.

eSend the pages back to match the black tab

of the desired chapter number with the black

tab on the edge at each tab le of contents

page.

eRefer to the sectional table of contents for

the exact pages to locate the spec ific topic

or procedure requ ired.

Quick Reference Guide

·L J _G_e_n_e_r_ al _l_n_ fo_r_m_a_ t_ io_n _____ ----.J D

I

Fuel System .:w

L--. _____ K:iI

I

Engine Top End .:II

L- . ____ Ell

Engine Left Side

Engine Right Side

Engine Removal/Installation

Engine Bottom End/Transmission

Wheels/Tires

Final Drive

Brakes

Suspension

Steering

Frame

Electrical System

Appendix

Kawasaki KLF300

All Terrain Vehicle

Service Manual

~l:;~~%~~w;:~~:V:~;'~:~~:>"~~,~:&~~'!!~:}.~:>"~~'l:~{~C:~~:.'v.(;'fJ:-;~~~;t>.'~~V~~~

~~~n.~1ti~~~~~d;;l!!..'i\)~¢~~*~~{ui~~~¥~~~~r~~l!tJa.c~~d~~~~*,~

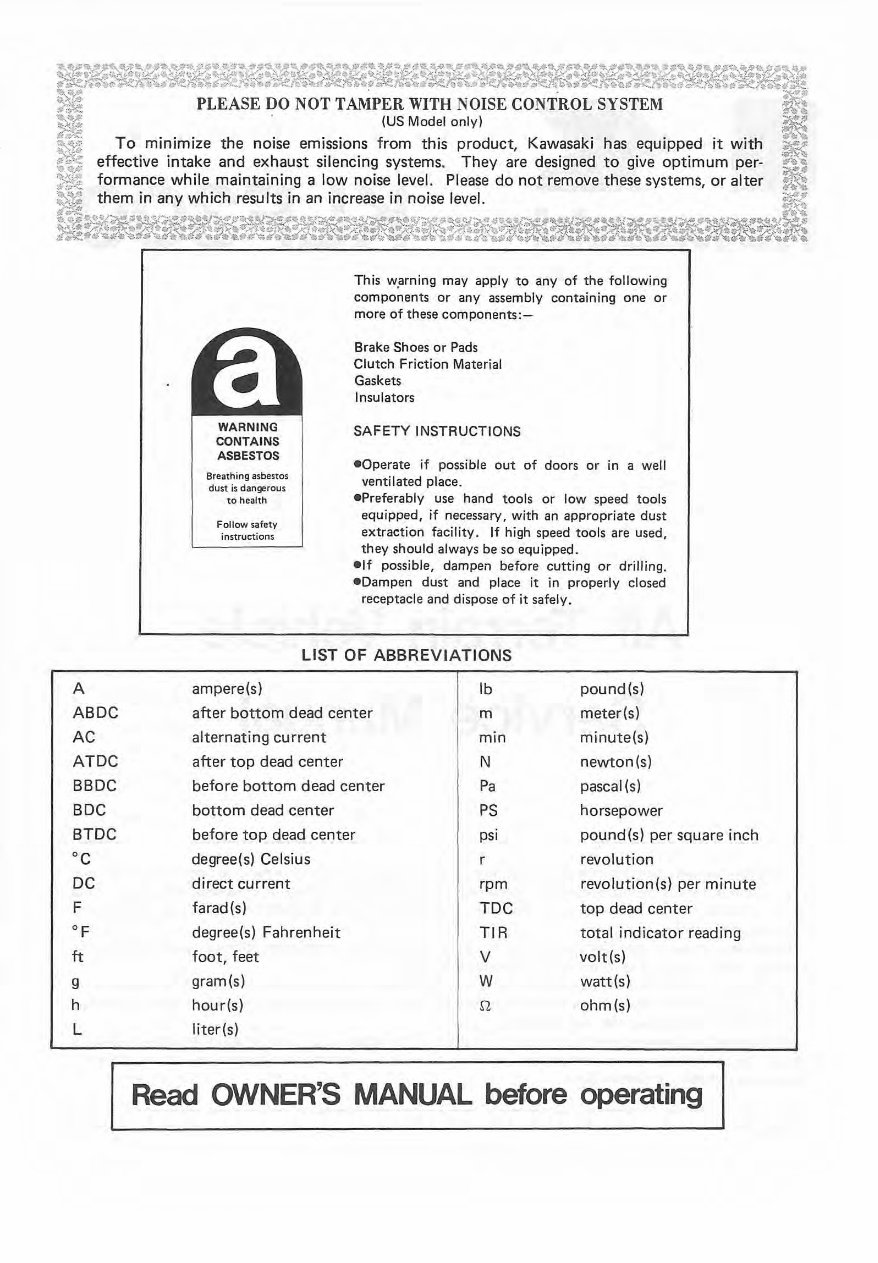

~ PLEASE DO NOT TAMPER WITH NOISE CONTROL SYSTEM ~

~ (US Model onlyl ~

~% To minimize the noise emissions from this product, Kawasaki has equipped it with ~

~ effective intake and exhaust silencing systems. They are designed to give optimum per- A ...

S~ formance while maintaining a low noise level. Please do not remove these systems, or alter ~

~ them in any which results in an increase in noise level. ~

"'~"~".~~"~~~' "''II~~'~~,,~~--~~qSl~."~ · . w:~~~~-~.m. ~~ .,,~ ~61!,~""$1 ~~ . , :tr(.~~li d";,. JI).xt't it .~-l<er~ .... r •. tI '! t~ 'It ~t,.

';;o¥'!. ""... ~;;<,; . ". ,..... ,," nA ...." ~'ii II ." .tf~" " ....... " "'" .. :?<''i. R if .....

A

ABDC

AC

ATDC

BBDC

BDC

BTDC

°C

DC

F

OF

ft

g

h

L

WARNING

CONTAINS

ASBESTOS

Breathing asbestos

dust is dangerous

to health

Fol low safety

instructions

This w,arning may apply to any of the following

components or any assembly containing one or

more of these components:-

Brake Shoes or Pads

Cl utch Friction Material

Gaskets

Insulators

SAFETY INSTRUCTIONS

-Operate if possible out of doors or in a well

ventilated place.

.Preferably use hand tools or low speed tools

equipped, if necessary, with an appropriate dust

extraction facility. If high speed tools are used,

they should always be so equipped .

• If possible, dampen before cutting or drilling .

• Dampen dust and place it in properly closed

receptacle and dispose of it safely.

LIST OF ABBREVIATIONS

ampere(s) Ib pound(s)

after bottom dead center m meter(s)

alternating current min minute(s)

after top dead center N newton(s)

before bottom dead center Pa pascal (s)

bottom dead center PS horsepower

before top dead center psi pound(s) per square inch

degree(s) Celsius r revolut ion

direct current rpm revolution(s) per minute

farad(s) TDC top dead center

degree(s) Fahrenheit TIR total indicator reading

foot, feet V volt(s)

gram(s) W watt(s)

hour(s) S1 ohm(s)

liter(s)

Read OWNER'S MANUAL before operating

Foreword

This manual is designed primarily for use by

trained mechanics in a properly equipped shop.

However, it contains enough detail and basic

information to make it useful to the owner who

desires to perform his own basic maintenance

and repair work. A basic knowledge of mechan-

ics, the proper use of tools, and workshop

procedures must be understood in order to carry

out maintenance and repair satisfactorily.

Whenever the owner has insufficient experience

or doubts his ability to do the work, all adjust-

ments, maintenance, and repair should be

carried out only by qualified mechanics.

In order to perform the work efficiently and

to avoid costly mistakes, read the text, thor-

oughly familiarize yourself with the procedures

before starting· work, and then do the work

carefully in a clean area. Whenever special tools

or equipment are specified, do not use makeshift

tools or equipment . Precision measurements can

only be made if the proper instruments are used,

and the use of substitute tools may adversely

affect safe operation.

For the duration of your warranty period,

especially, we recommend that all repairs and

scheduled maintenance be performed in accord-

ance with this service manual. Any owner

maintenance or repair procedure not performed

in accordance with this manual may void the

warranty.

To get the longest life out of your vehicle:

- Follow the Periodic Maintenance Chart in the

Service Manual.

-Be alert for problems and non-scheduled

maintenance.

-Use proper tools and genuine Kawasaki vehicle

parts. Special tools, gauges, and testers

that are necessary when servicing Kawasaki

vehicles are introduced by the Special Tool

Manual. Genuine parts provided as spare parts

are listed in t he Parts Catalog.

-Follow the procedures in this manual carefully.

Don't take shortcuts.

_ Remember to keep complete records of main-

tenance and repair with dates and any new

parts installed.

How to Use this Manual

In preparing this manual, we divided the

product into its major systems. These systems

became the manual's chapters. All information

for a particular system from adjustment

through disassembly and inspection is located in

a single chapter.

The Quick Reference Guide shows you all of

the product's systems and assists in locating

their chapters. Each chapter in turn has its own

comprehensive Table of Contents.

The Periodic Maintenance Chart is located in

the General Information chapter. The chart

gives a time schedule for required maintenance

operations.

If you want spark plug information, for

example, go to the Periodic Maintenance Chart

first. The chart tells you how frequently to

clean and gap the plug. Next, use the Quick

Reference Guide to locate the Electrical System

chapter. Then, use the Table of Contents on the

first page of the chapter to find the Spark Plug

section.

Whenever you see these WARNING and

CAUTION symbols, heed their instructions!

Always follow safe operating and maintenance

practices.

I WARNING.

oThis warning symbol identifies special instruc-

tions or procedures which, if not correctly

followed, could result in personal injury, or

loss of life.

oThis caution symbol identifies special instruc-

tions or procedures which, if not strictly

observed, could result in damage to or destruc-

tion of equipment.

This manual contains five more symbols (in

addition to WARNING and CAUTION) which

will help you distinguish different types of

information.

NOTE

o This note symbol indicates points of particular

interest for more efficient and convenient

operation.

elndicates a procedural step or work to be done.

o lndicates a procedural sub-step or how to do

the work of the procedural step it follows.

It also precedes the text of a WARNING,

CAUTION, or NOTE.

*Indicates a conditional step or what action to

take based on the results of the test or inspec-

tion in the procedural step or sub-step it

follows.

<r Indicates a conditional sub-step or what action

to take based upon the results of the condi-

tional step it follows.

In most chapters an exploded view illustration

of the system components follows the Table of

Contents. In these illustrations you will find

the instructions indicating which parts require

specified tightening torque, oil, grease or a

locking agent during assembly.

GENERAL INFORMATION 1-1

10

General Information

Table of Contents

Before Servicing . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . . . . . . . . . . . . • . 1·2

Model Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

General Specifications .............................. •. . . . . . . 1·6

Torque and Locking Agent. . . . . . . . . . . . . ... . . . .. .. .. . . . . . .. . .. 1·8

Periodic Maintenance Chart. . . . . . . • . . . . . . . . . . . . . . . . . . . . . . . . . . 1·10

'-2 GENERAL INFORMATION

Before Servicing

Before starting to service a vehicle, careful reading of the applicable section is recommended to

eliminate unnecessary work. Photographs, diagrams, notes, cautions, warnings, and detailed des-

criptions have been included wherever necessary. Nevertheless, even a detailed account has limi-

tations, a certain amount of basic knowledge is also required for successful work.

Especially note the following:

(1) Dirt

Before removal and disassembly, clean the vehicle. Any dirt entering the engine or - other

parts will work as an abrasive and shorten the life of the vehicle. For the same reason, before

installing a new part, clean off any dust or metal filings.

(2) Battery Ground

Remove the ground (-) lead from the battery before performing any disassembly operations

on the vehicle. This prevents:

(a) the possibility of accidentally turning the engine over while partially disassembled.

(b) sparks at electrical connections which will occur when they are disconnected.

(c) damage to electrical parts.

(3) Tighten ing Sequence

Generally, when installing a part with several bolts, nuts, or screws, start them all in their holes

and tighten them to a snug fit. Then tighten them evenly in a cross pattern. This is to avoid

distortion of the part and/or causing gas or oil leakage. Conversely when .loosening the bolts,

nuts, or screws, first loosen all of them by about a quarter of turn and then remove them.

Where there is a tightening sequence indication in this Service Manual, the bolts, nuts, or

screws must be tightened in the order and method indicated.

(4) Torque

When torque values are given in this Service Manual, use them. Either too little or too much

torque may lead to serious damage. Use a good quality, reliable torque wrench.

(5) Force

Common sense should dictate how much force is necessary in assembly and disassembly. If a

part seems especially difficult to remove or install, stop and examine what may be causing the

problem. Whenever tapping is necessary, tap lightly using a wooden or plastic-faced mallet. Use

an impact driver for screws (particularly for the removal of screws held by a locking agent) in

order to avoid damaging the screw heads.

(6) Edges

Watch for sharp edges, especially during major engine disassembly and assembly. Protect your

hands with gloves or a piece of thick cloth when lifting the engine or turning it over.

(7) High-Flash Point Solvent

A high-flash point solvent is recommended to reduce fire danger. A commercial solvent com-

monly available in North America is Stoddard solvent (generic name). Always follow manufac-

turer and container directions regarding the use of any solvent.

(B) Gasket, O-Ring

Do not reuse a gasket or O-ring once it has been in service. The mating surfaces around the

gasket should be free of foreign matter and perfectly smooth to avoid oil or compression leaks.

(9) Liquid Gasket, Non-Permanent Locking Agent

Follow manufacturer's directions for cleaning and preparing surfaces where these compounds

will be used. Apply sparingly. Excessive amounts may block engine oil passages and cause

serious damage. An example of a non-permanent locking agent commonly available in North

America is Loctite Lock'n Seal (Blue) .

(10) Press

A part installed using a press or driver, such as a wheel bearing, should first be coated with oil

on its outer or inner circumference so that it w ill go into place smoothly .

(11) Ball Bearing

When installing a ball bearing, the bearing race which is affected by friction should be pushed

by a su itable driver. This prevents severe stress on the balls and races, and prevents races and

balls from being dented . Press a ball bearing until it stops at the stop in the hole or on the shaft.

GENERAL INFORMATION 1-3

(12) Oil Seal and Grease Seal

Replace any oil or grease seals that were removed with new ones, as removal generally damages

seals.

When pressing in a seal which has manufacturer's marks, press it in with the marks facing out.

Seals should be pressed into place using a suitable driver, which contacts evenly with the side of

seal, until the face of the seal is even with the end of the hole.

(13) Seal Guide

A seal guide is required for certain oil or grease seals during installation to avoid damage to the

seal lips. Before a shaft passes through a seal, apply a little high temperature grease on the lips to

reduce rubber to metal friction.

(14) Circlip, Retaining Ring

Replace any circlips and retaining rings that were removed with new ones, as removal weakens

and deforms them. When installing circlips and retaining rings, take care to compress or expand

them only enough to install them and no more.

(15) Lubrication

Engine wear is generally at its maximum wh il e the engine is warming up and before all the

rubbing surfaces have an adequate lubricative film. During assembly, oil or grease (whichever is

more suitable) should be applied to any rubbing surface which has lost its lubricative film. Old

grease and dirty oil should be cleaned off . Deteriorated grease has lost its lubricative quality and

may contain abrasive foreign particles.

Don't use just any oil or grease. Some oils and greases in particular should be used only in

certain applications and may be harmful if used in an application for which they are not intended.

This manual makes reference to molybdenum disulfide grease (MoS,) in the assembly of certain

engine and chassis parts. Always check manufacturer recommendations before using such special

lubricants.

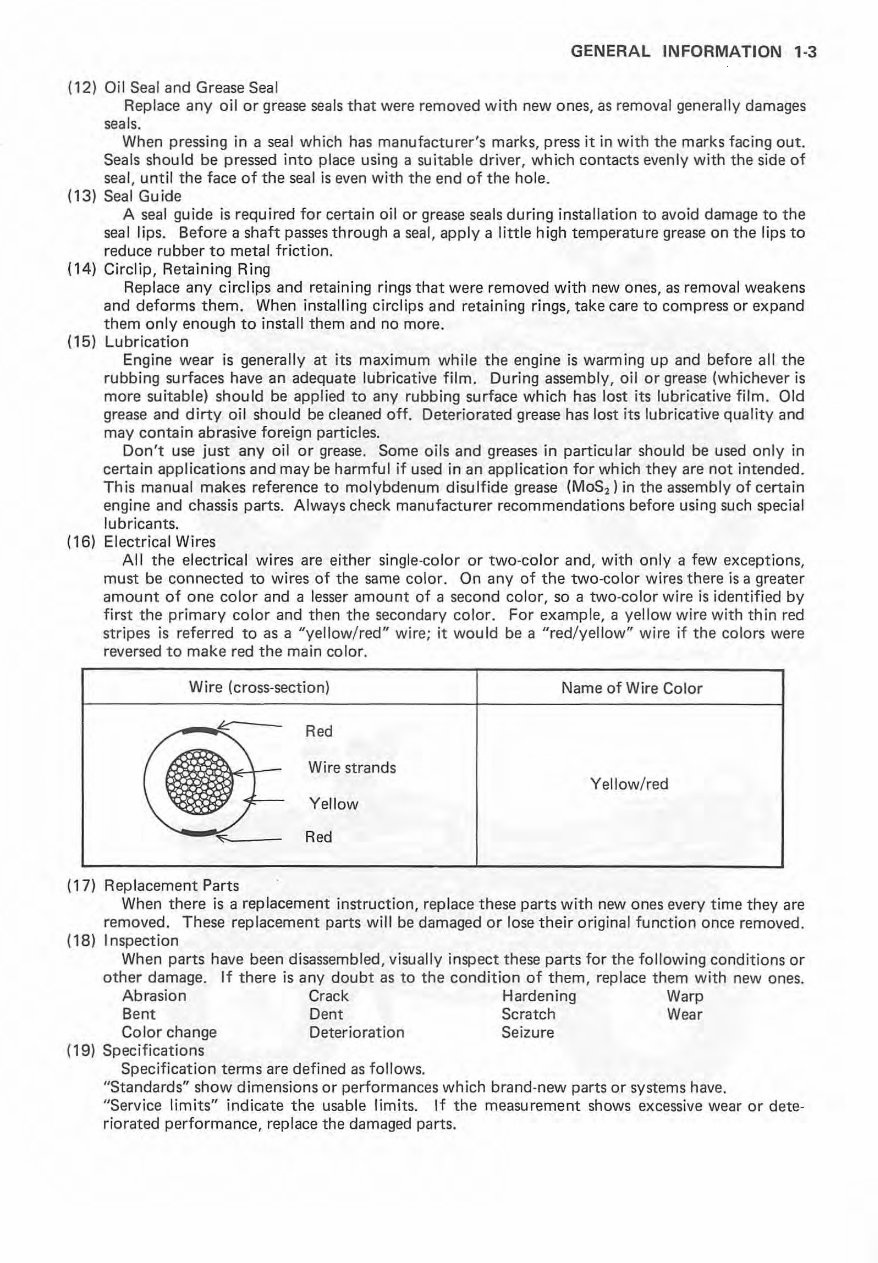

(16) Electrical Wires

All the electrical wires are either single- color or two-color and, with only a few exceptions,

must be connected to wires of the same color. On any of the two - color wires there is a greater

amount of one color and a lesser amount of a second color, so a two·color wire is identified by

first the primary color and then the secondary color. For example, a yellow wire with thin red

stripes is referred to as a "yellow/red" wire; it would be a "red/yellow" wire if the colors were

reversed to make red the main color.

Wire (cross-section) Name of Wire Color

e:

Red

~~

Wire strands

r

Yellow/ red

f--

Yellow

....

'"

Red

(17) Replacement Parts

When there is a replacement instruction, replace these parts with new ones every time they are

removed. These replacement parts will be damaged or lose their original function once removed.

(18) Inspection

When parts have been disassembled, visually inspect these parts for the following conditions or

other damage. If there is any doubt as to the condition of them, replace them with new ones.

Abrasion Crack Hardening Warp

Bent Dent Scratch Wear

Color change Deterioration Seizure

(19) Specifications

Specification terms are defined as follows.

"Standards" show dimensions or performances which brand-new parts or systems have.

"Service limits" indicate the usable limits. If the measurement shows excessive wear or dete-

riorated performance, replace the damaged parts.

14 GENERAL INFORMATION

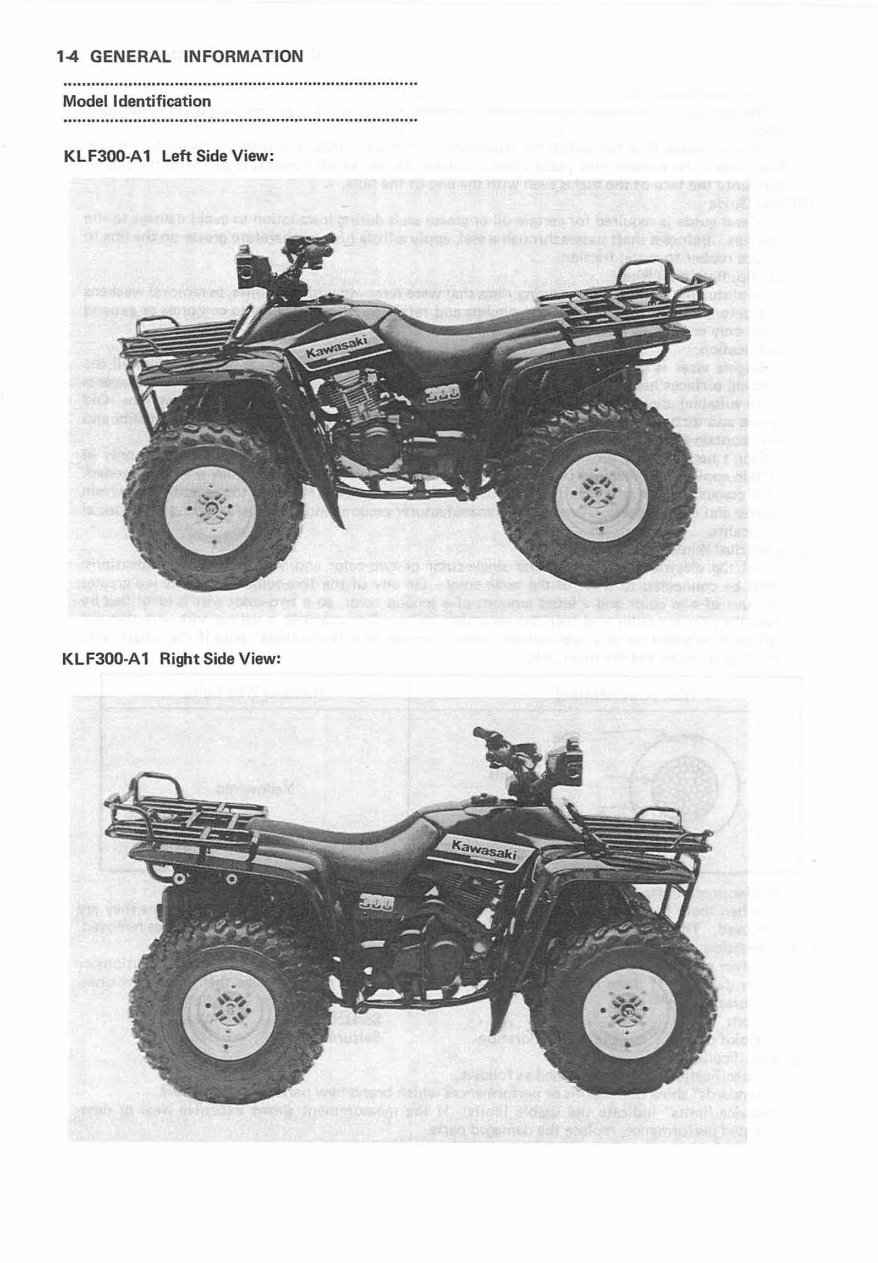

Model Identification

KLF300-A 1 Left Side View:

KLF300-A 1 Right Side View:

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 83 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get the comprehensive service and repair manual for the 1986-2006 Kawasaki Bayou 300 (KLF300) ATV. This manual equips you with all the necessary troubleshooting and replacement procedures, complete with step-by-step instructions, clear images, and exploded-view illustrations.

Whether you're a professional mechanic or a DIY enthusiast, regular maintenance is essential for your ATV's longevity. Over time, certain parts will wear out, necessitating replacements. This manual provides the manufacturer's recommended troubleshooting charts and procedures, enabling you to save on repairs, enhance your ATV's reliability, and minimize visits to the repair shop.

Please note:

- This is not a generic repair manual but the essential resource used by professional technicians for servicing and maintaining your ATV.

- No need to sift through numerous pages or worry about damaged or lost pages. This digital manual offers easy accessibility, search functionality, and the option to print a physical copy if desired.

Specifications:

- Format: PDF

- Printable: Yes

- Language: English

- Compatibility: Compatible with various electronic devices, including PC, Mac, Android, and Apple devices

- Requirements: Adobe Reader (free)