2004-2005 Honda TRX450R Service Repair Manual ( 04 05 )

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

A Few Words About Safety

Service Information

The service and repair information contained in this manual is intended for use by qualified, professional technicians.

Attempting service or repairs without the proper training, tools, and equipment could cause injury to you or others. It could also

damage the vehicle or create an unsafe condition.

This manual describes the proper methods and procedures for performing service, maintenance, and repairs. Some procedures

require the use of specially designed tools and dedicated equipment. Any person who intends to use a replacement part, service

procedure or a tool that is not recommended by Honda, must determine the risks to their personal safety and the safe operation of

the vehicle.

If you need to replace a part, use genuine Honda parts with the correct part number or an equivalent part. We strongly recommend

that you do not use replacement parts of inferior quality.

For Your Customer's Safety

Proper service and maintenance are essential to the customer's safety and

the reliability of the vehicle. Any error or oversight while servicing a vehicle

can result in faulty operation, damage to the vehicle, or injury to others.

AWARIMING

Improper service or repairs can create an

unsafe condition that can cause your customer

or others to be seriously hurt or killed.

Follow the procedures and precautions in this

manual and other service materials carefully.

AWARNING

Failure to properly follow instructions and

precautions can cause you to be seriously hurt

or killed.

Follow the procedures and precautions in this

manual carefully.

For Your Safety

Because this manual is intended for the professional service technician, we

do not provide warnings about many basic shop safety practices (e.g., Hot

parts-wear gloves). If you have not received shop safety training or do not

feel confident about your knowledge of safe servicing practice, we

recommended that you do not attempt to perform the procedures described

in this manual.

Some of the most important general service safety precautions are given

below. However, we cannot warn you of every conceivable hazard that can

arise in performing service and repair procedures. Only you can decide

whether or not you should perform a given task.

Important Safety Precautions

Make sure you have a clear understanding of all basic shop safety practices and that you are wearing appropriate clothing and

using safety equipment. When performing any service task, be especially careful of the following:

• Read all of the instructions before you begin, and make sure you have the tools, the replacement or repair parts, and the skills

required to perform the tasks safely and completely.

• Protect your eyes by using proper safety glasses, goggles or face shields any time you hammer, drill, grind, pry or work around

pressurized air or liquids, and springs or other stored-energy components. If there is any doubt, put on eye protection.

• Use other protective wear when necessary, for example gloves or safety shoes. Handling hot or sharp parts can cause severe

burns or cuts. Before you grab something that looks like it can hurt you, stop and put on gloves.

• Protect yourself and others whenever you have the vehicle up in the air. Any time you lift the vehicle, either with a hoist or a jack,

make sure that it is always securely supported. Use jack stands.

Make sure the engine is off before you begin any servicing procedures, unless the instruction tells you to do otherwise.

This will help eliminate several potential hazards:

• Carbon monoxide poisoning from engine exhaust. Be sure there is adequate ventilation whenever you run the engine.

• Burns from hot parts or coolant. Let the engine and exhaust system cool before working in those areas.

• Injury from moving parts. If the instruction tells you to run the engine, be sure your hands, fingers and clothing are out of the way.

Gasoline vapors and hydrogen gases from batteries are explosive. To reduce the possibility of a fire or explosion, be careful when

working around gasoline or batteries.

• Use only a nonflammable solvent, not gasoline, to clean parts.

• Never drain or store gasoline in an open container.

• Keep all cigarettes, sparks and flames away from the battery and all fuel-related parts.

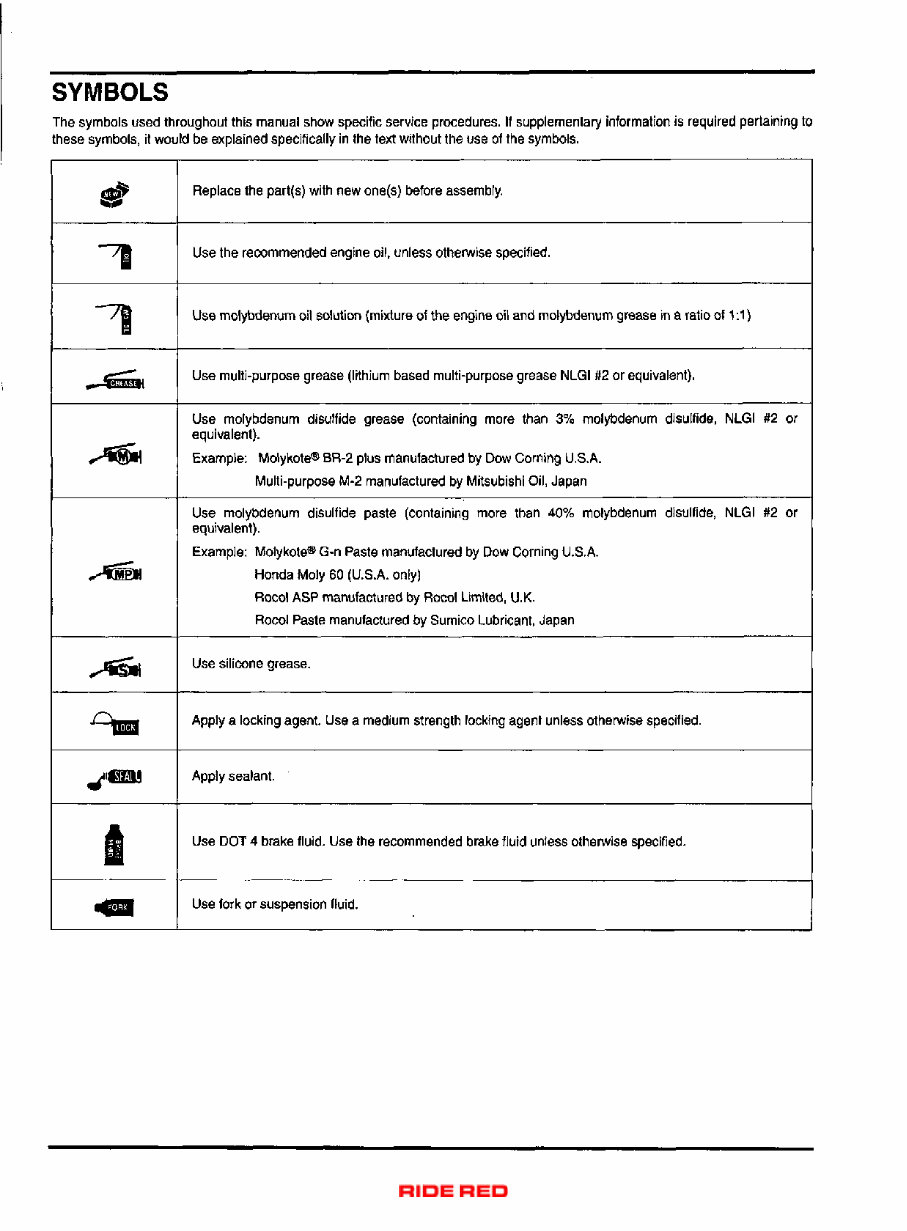

SYMBOLS

The symbols used throughout this manual show specific service procedures. If supplementary information is required pertaining to

these symbols, it would be explained specifically in the text without the use of the symbols.

Replace the part(s) with new one(s) before assembly.

Use the recommended engine oil, unless otherwise specified.

Use molybdenum oil solution (mixture of the engine oil and molybdenum grease in a ratio of 1:1)

Use multi-purpose grease (lithium based multi-purpose grease NLGI #2 or equivalent).

Use molybdenum disulfide grease (containing more than 3% molybdenum disulfide, NLGI #2 or

equivalent).

Example: Molykote® BR-2 plus manufactured by Dow Corning U.S.A.

Multi-purpose M-2 manufactured by Mitsubishi Oil, Japan

Use molybdenum disulfide paste (containing more than 40% molybdenum disulfide, NLGI #2 or

equivalent).

Example: Molykote® G-n Paste manufactured by Dow Corning U.S.A.

Honda Moly 60 (U.S.A. only)

Rocol ASP manufactured by Rocol Limited, U.K.

Rocol Paste manufactured by Sumico Lubricant, Japan

Use silicone grease.

Apply a locking agent. Use a medium strength locking agent unless otherwise specified.

Apply sealant.

Use DOT 4 brake fluid. Use the recommended brake fluid unless otherwise specified.

Use fork or suspension fluid.

1. GENERAL INFORMATION

SERVICE RULES 1-2

MODEL IDENTIFICATION 1-2

GENERAL SPECIFICATIONS ('04 - '05) 1-5

GENERAL SPECIFICATIONS (After '05) 1-6

LUBRICATION SYSTEM

SPECIFICATIONS 1-8

FUEL SYSTEM

SPECIFICATIONS ('04-'05) 1-8

FUEL SYSTEM

SPECIFICATIONS (After '05) 1-8

COOLING SYSTEM SPECIFICATIONS 1-9

CYLINDER HEAD/VALVE/CAMSHAFT

SPECIFICATIONS ( ' 0 4 - ' 0 5 ) - 1-9

CYLINDER HEAD/VALVE/CAMSHAFT

SPECIFICATIONS (After '05) 1-10

CYLINDER/PISTON

SPECIFICATIONS ('04-'05) 1-10

CYLINDER/PISTON

SPECIFICATIONS (After '05) 1-11

CLUTCH/KICKSTARTER/GEARSHIFT

LINKAGE SPECIFICATIONS ('04- '05) 1-11

CLUTCH/STARTER CLUTCH/KICKSTARTER/

GEARSHIFT LINKAGE

SPECIFICATIONS (After '05) 1-11

CRANKCASE/TRANSMISSION/CRANKSHAFT

SPECIFICATIONS ('04 - '05) 1-12

CRANKCASE/TRANSMISSION/CRANKSHAFT

SPECIFICATIONS (After '05) 1-13

FRONT WHEEL/SUSPENSION/STEERING

SPECIFICATIONS 1-13

REAR WHEEL/SUSPENSION

SPECIFICATIONS 1-14

HYDRAULIC BRAKE SPECIFICATIONS 1-14

ELECTRICAL SPECIFICATIONS ('04 - '05) -1-14

BATTERY/CHARGING SYSTEM

SPECIFICATIONS (TRX450ER) 1-15

IGNITION SYSTEM SPECIFICATIONS

(After'05) • 1-15

ELECTRIC STARTER SPECIFICATIONS

(TRX450ER) 1-15

LIGHTS/SWITCH SPECIFICATIONS

(After'05) 1-15

STANDARD TORQUE VALUES 1-16

ENGINE & FRAME TORQUE VALUES 1-16

LUBRICATION & SEAL POINTS 1-21

CABLE & HARNESS ROUTING 1-24

EMISSION CONTROL SYSTEMS 1-43

1-1

GENERAL INFORMATION

SERVICE RULES

1. Use genuine Honda or Honda-recommended parts and lubricants or their equivalents. Parts that do not meet Honda's

design specifications may cause damage to the vehicle.

2. Use the special tools designed for this product to avoid damage and incorrect assembly.

3. Use only metric tools when servicing the vehicle. Metric bolts, nuts and screws are not interchangeable with English

fasteners.

4. Install new gaskets, O-rings, cotter pins, and lock plates when reassembling.

5. When tightening bolts or nuts, begin with the larger diameter or inner bolt first. Then tighten to the specified torque

diagonally in incremental steps unless a particular sequence is specified.

6. Clean parts in cleaning solvent upon disassembly. Lubricate any sliding surfaces before reassembly.

7. After reassembly, check all parts for proper installation and operation.

8. Route all electrical wires as shown in the Cable and Harness Routing (page 1-24).

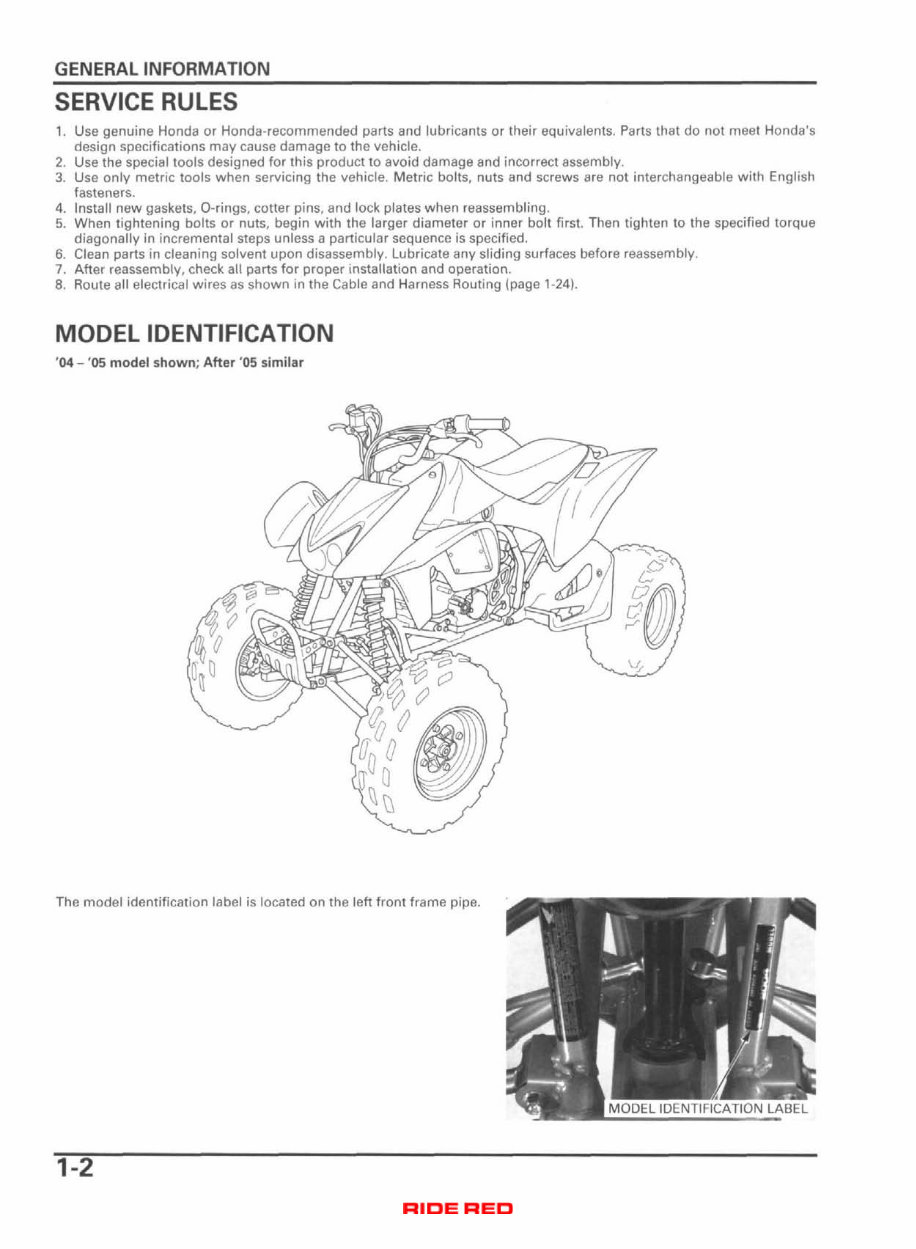

MODEL IDENTIFICATION

'04 - '05 model shown; After '05 similar

The model identification label is located on the left front frame pipe.

MODEL IDENTIFICATION LABEL

1-2

GENERAL INFORMATION

The vehicle identification number (VIN) is stamped on the front side of

the frame.

The engine serial number is stamped on the left side of the crankcase. --

•T? jLi ENGINE SERIAL NUMBER

The carburetor identification number is stamped on the left side of the BTT.r,,,,

l

nrTn^

carburetor bodv ^ LAnount i un

'04 - '05; The Vehicle Emission Control Information Label is attached

on the right front frame pipe (U.S.A. only).

EMISSION CONTROL INFORMATION LABEL

1-3

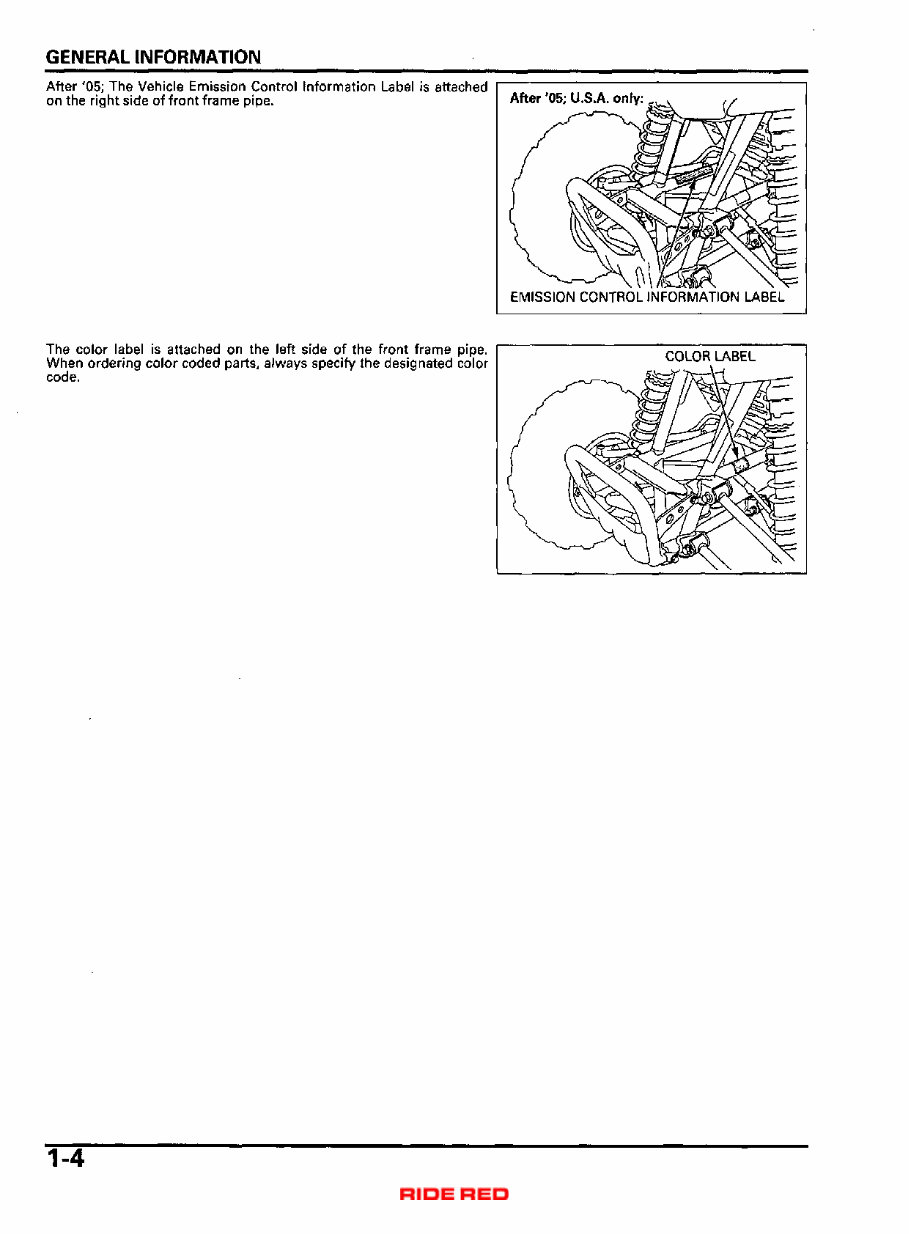

GENERAL INFORMATION

After '05; The Vehicle Emission Control Information Label is attached

on the right side of front frame pipe.

After '05; U.S.A. only

EMISSION CONTROL INFORMATION LABEL

The color label is attached on the left side of the front frame pipe.

When ordering color coded parts, always specify the designated color

code.

1-4

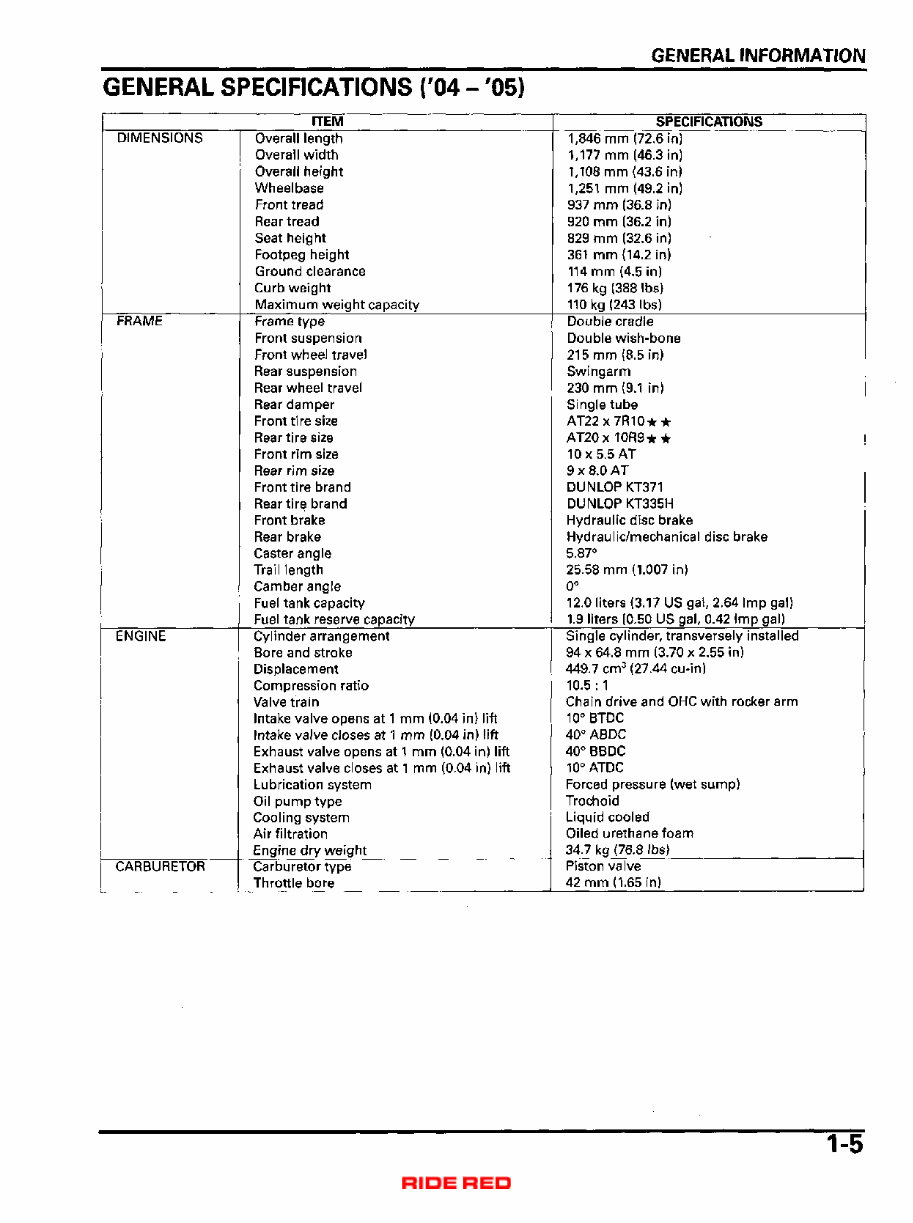

GENERAL INFORMATION

GENERAL SPECIFICATIONS ('04 - '05)

ITEM

DIMENSIONS

FRAME

ENGINE

CARBURETOR

Overall length

Overall width

Overall height

Wheelbase

Front tread

Rear tread

Seat height

Footpeg height

Ground clearance

Curb weight

Maximum weight capacity

Frame type

Front suspension

Front wheel travel

Rear suspension

Rear wheel travel

Rear damper

Front tire size

Rear tire size

Front rim size

Rear rim size

Front tire brand

Rear tire brand

Front brake

Rear brake

Caster angle

Trail length

Camber angle

Fuel tank capacity

Fuel tank reserve capacity

Cylinder arrangement

Bore and stroke

Displacement

Compression ratio

Valve train

Intake valve opens at 1 mm (0.04 in) lift

Intake valve closes at 1 mm (0.04 in) lift

Exhaust valve opens at 1 mm (0.04 in) lift

Exhaust valve closes at 1 mm (0.04 in) lift

Lubrication system

Oil pump type

Cooling system

Air filtration

Engine dry weight

Carburetor type

Throttle bore

SPECIFICATIONS

1,846 mm (72.6 in)

1,177 mm (46.3 in)

1,108 mm (43.6 in)

1,251 mm (49.2 in)

937 mm (36.8 in)

920 mm (36.2 in)

829 mm (32.6 in)

361 mm (14.2 in)

114 mm (4.5 in)

176 kg (388 lbs)

110 kg (243 lbs)

Double cradle

Double wish-bone

215 mm (8.5 in)

Swingarm

230 mm (9.1 in)

Single tube

AT22x7R10**

AT20x10R9**

10x5.5 AT

9 x 8.0 AT

DUN LOP KT371

DUN LOP KT335H

Hydraulic disc brake

Hydraulic/mechanical disc brake

5.87°

25.58 mm (1.007 in)

0°

12.0 liters (3.17 US gal, 2.64 Imp gal)

1.9 liters (0.50 US gal, 0.42 Imp gal)

Single cylinder, transversely installed

94x64.8 mm (3.70x2.55 in)

449.7 cm

3

(27.44 cu-in)

10.5 : 1

Chain drive and OHC with rocker arm

10° BTDC

40° ABDC

40° BBDC

10° ATDC

Forced pressure (wet sump)

Trochoid

Liquid cooled

Oiled urethanefoam

34.7 kg (76.8 lbs)

Piston valve

42 mm (1.65 in)

1-5

GENERAL INFORMATION

ITEM

DRIVE TRAIN

ELECTRICAL

Clutch system

Clutch operation system

Transmission

Primary reduction

Final reduction

Gearratio 1st

2nd

3rd

4th

5th

Gearshift pattern

Ignition system

Charging system

Regulator/rectifier

Lighting system

SPECIFICATIONS

Multi-plate, wet

Cable operated

Constant mesh, 5-speed

2.739 (63/23)

2.714(38/14)

2.071 (29/14)

1.625(26/16)

1.333(24/18)

1.120(28/25)

0.963 (26/27)

Left foot operated return system, 1-N-2-3-4-5

AC-CDI

Triple phase output alternator

Triple phase full wave rectification

12 V DC output

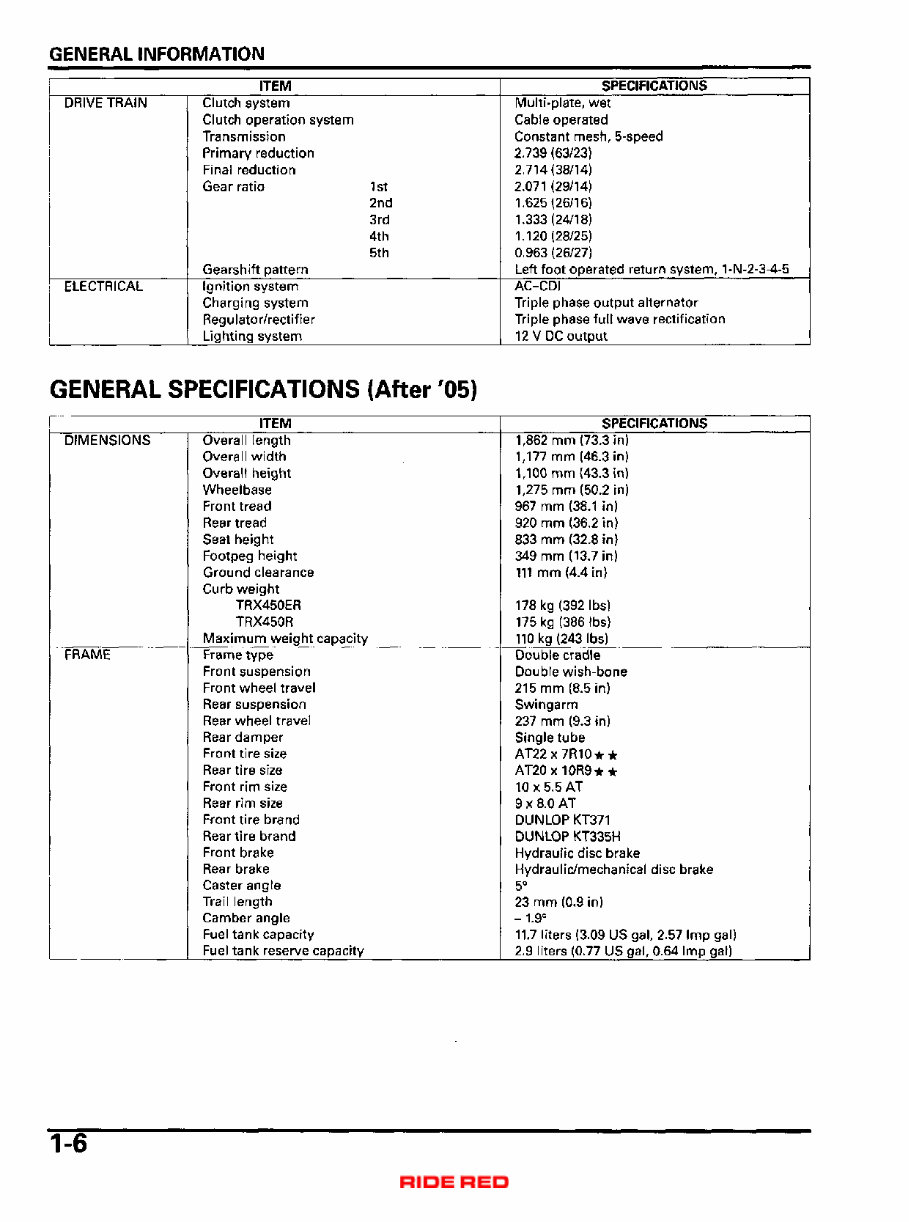

GENERAL SPECIFICATIONS (After '05)

ITEM

DIMENSIONS

FRAME

Overall length

Overall width

Overall height

Wheelbase

Front tread

Rear tread

Seat height

Footpeg height

Ground clearance

Curb weight

TRX450ER

TRX450R

Maximum weight capacity

Frame type

Front suspension

Front wheel travel

Rear suspension

Rear wheel travel

Rear damper

Front tire size

Rear tire size

Front rim size

Rear rim size

Front tire brand

Rear tire brand

Front brake

Rear brake

Caster angle

Trail length

Camber angle

Fuel tank capacity

Fuel tank reserve capacity

SPECIFICATIONS

1,862 mm (73.3 in)

1,177 mm (46.3 in)

1,100 mm (43.3 in)

1,275 mm (50.2 in)

967 mm (38.1 in)

920 mm (36.2 in)

833 mm (32.8 in)

349 mm (13.7 in)

111 mm (4.4 in)

178 kg (392 lbs)

175 kg (386 lbs)

110 kg (243 lbs)

Double cradle

Double wish-bone

215 mm (8.5 in)

Swingarm

237 mm (9.3 in)

Single tube

AT22x7R10**

AT20x10R9**

10x5.5 AT

9 x 8.0 AT

DUNLOP KT371

DUNLOP KT335H

Hydraulic disc brake

Hydraulic/mechanical disc brake

5°

23 mm (0.9 in)

-1.9°

11.7 liters (3.09 US gal, 2.57 Imp gal)

2.9 liters (0.77 US gal, 0.64 Imp gal)

1-6

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

Viewed 39 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

This Service Repair Manual is the ultimate guide for maintaining and repairing your 2004 2005 Honda TRX450R. It is packed with high-quality diagrams and instructions covering everything from the front bumper to the rear, making it essential for both professional mechanics and DIY enthusiasts.

- General Information

- Technical features

- Frame / Body Panels / Exhaust System

- Maintenance

- Lubrication System

- Fuel System

- Cooling system

- Engine Removal / Installation

- Cylinder Head / Valve

- Cylinder / Piston

- Clutch / kickstarter / Gearshift Linkage

- Crankcase / Transmission / crankshaft / balancer

- Front Wheel / Suspension / Steering

- Rear Wheel / Suspension

- Hydraulic Brake

- Electrical

- Wiring Diagram

- Troubleshooting

- Index

This Service Repair Manual is available in a printable file format, compatible with all versions of Windows & Mac. It is in English and requires Adobe Reader for access. Whether you are a professional mechanic or a DIY enthusiast, this manual is an indispensable resource that will save you time and money on maintenance and repairs.