2000-2003 Honda TRX350FM TRX350FE Rancher 4x4 Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

-

-

-

Honda Motor Co., Ltd.

SERVICE PUBLICATION OFFICE

ALL INFORMATION, ILLUSTRATIONS, DIREC-

TIONS AND SPECIFICATIONS INCLUDED IN

THIS PUBLICATION ARE BASED ON THE LATEST

PRODUCT INFORMATION AVAILABLE AT THE

TIME OF APPROVAL FOR PRINTING. Honda

Motor Co., Ltd. RESERVES THE RIGHT TO MAKE

CHANGES AT ANY TIME WITHOUT NOTICE AND

WITHOUT INCURRING ANY OBLIGATION

WHATSOEVER. NO PART OF THIS PUBLICATION

MAY BE REPRODUCED WITHOUT WRITTEN

PERMISSION. THIS MANUAL IS WRITTEN FOR

PERSONS WHO HAVE ACQUIRED BASIC

KNOWLEDGE OF MAINTENANCE ON Honda

MOTORCYCLES, MOTOR SCOOTERS OR ATVS.

HOW TO USE THIS MANUAL CONTENTS

GENERAL INFORMATION

MAINTENANCE

LUBRICATION SYSTEM

FUEL SYSTEM

ALTERNATOR/STARTER CLUTCH

BATTERY/CHARGING SYSTEM

IGNITION SYSTEM

ELECTRIC STARTER

LIGHTS/METERS/SWITCHES

FRAME/BODY PANELS/EXHAUST

SYSTEM

CLUTCH/GEARSHIFT LINKAGE

REAR WHEEL/SUSPENSION

TROUBLESHOOTING

ENGINE REMOVAL/INSTALLATION

TECHNICAL FEATURES

FRONT WHEEL/SUSPENSION/

STEERING

REAR DRIVING MECHANISM

CHASSIS ELECTRICAL

INDEX

CYLINDER/PISTON

CRANKCASE/TRANSMISSION/

CRANKSHAFT

BRAKE SYSTEM

WIRING DIAGRAM

ENGINE

CYLINDER HEAD/VALVE

•

•

•

FRONT DRIVING MECHANISM (FM/FE models)

ELECTRIC SHIFT PROGRAM

(ESP: TE/FE models)

Date of Issue:

Honda Motor Co., Ltd.

May, 2002

Your safety, and the safety of others, is very important. To help

you make informed decisions we have provided safety

messages and other information throughout this manual. Of

course, it is not practical or possible to warn you about all the

hazards associated with servicing this vehicle. You must use

your own good judgement.

You will find important safety information in a variety of forms

including:

Instructions how to service this vehicle correctly and safety.

This service manual describes the service procedures for the TRX350

TM/TE and TRX350 FM/FE.

Follow the Maintenance Schedule (Section 3) recommendations to

ensure that the vehicle is in peak operating condition and the

emission levels are within the standards set by the California Air

Resources Board.

Performing the first scheduled maintenance is very important. It

compensates for the initial wear that occurs during the break-in

period.

Sections 1 and 3 apply to the whole motorcycle. Section 2 illustrates

procedures for removal/installation of components that may be

required to perform service described in the following sections.

Sections 4 through 21 describe parts of the vehicle, grouped

according to location.

Find the section you want on this page, then turn to the table of

contents on the first page of the section.

Most sections start with an assembly or system illustration, service

information and troubleshooting for the section. The subsequent

pages give detailed procedures.

If you don’t know the source of the trouble, go to Section 24,

Troubleshooting.

Safety Labels on the vehicle

Safety Messages preceded by a safety alert symbol and

one of three signal words, DANGER, WARNING, or CAUTION.

These signal words mean:

You WILL be KILLED or SERIOUSLY

HURT if you don’t follow instructions.

You CAN be KILLED or SERIOUSLY HURT

if you don’t follow instructions.

You CAN be HURT if you don’t follow

instructions.

As you read this manual, you will find information that is preceded by

a symbol. The purpose of this message is to help prevent

damage to your vehicle, other property, or the environment.

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

1

23

24

25

-

-

-

-

SERVICE RULES 1-1

MODEL IDENTIFICATION 1-1

SPECIFICATIONS 1-3

TORQUE VALUES 1-13

TOOLS 1-16

LUBRICATION & SEAL POINTS 1-18

CABLE & HARNESS ROUTING 1-22

EMISSION CONTROL SYSTEMS 1-33

EMISSION CONTROL INFORMATION

LABEL (U.S.A only) 1-34

SERVICE RULES

MODEL IDENTIFICATION

1

1-1

1. GENERAL INFORMATION

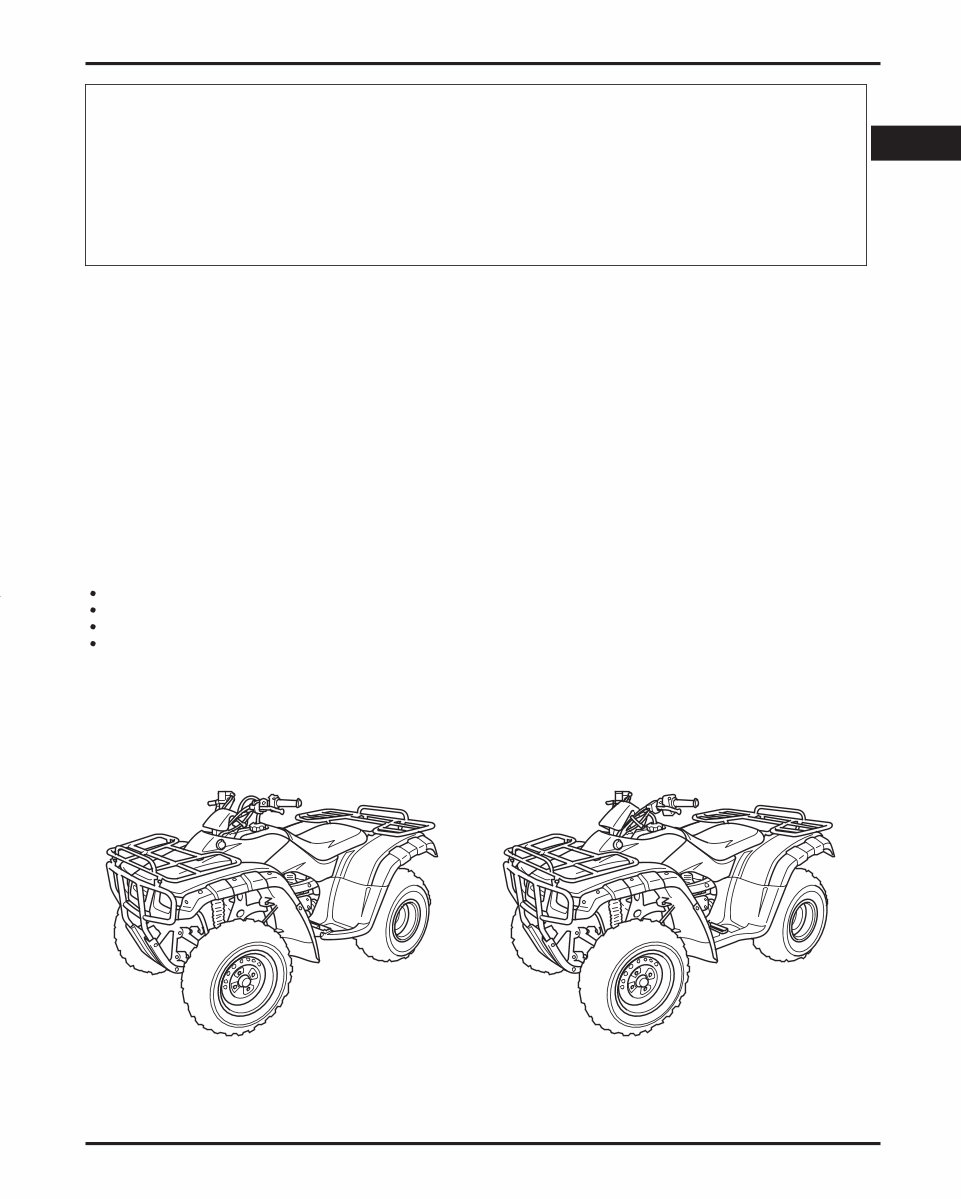

This manual covers 4 types of TRX350 models:

TM 2WD/Left foot operated gearshift

TE 2WD/Electric shift program (ESP)

FM 4WD/Left foot operated gearshift

FE 4WD/Electric shift program (ESP)

Be sure to refer to the procedure that pertains to the appropriate version of the TRX350.

Use genuine HONDA or HONDA-recommended parts and lubricants or their equivalents. Parts that don’t meet HONDA’s

design specifications may cause damage to the motorcycle.

Use the special tools designed for this product to avoid damage and incorrect assembly.

Use only metric tools when servicing the motorcycle. Metric bolts, nuts and screws are not interchangeable with English

fasteners.

Install new gaskets, O-rings, cotter pins, and lock plates when reassembling.

When tightening bolts or nuts, begin with the larger diameter or inner bolt first. Then tighten to the specified torque

diagonally in incremental steps unless a particular sequence is specified.

Clean parts in cleaning solvent upon disassembly. Lubricate any sliding surfaces before reassembly.

After reassembly, check all parts for proper installation and operation.

Route all electrical wires as shown on pages 1-22 through 1-32, Cable & Harness routing.

1.

2.

3.

4.

5.

6.

7.

8.

TRX350 TM/FM:

(U.S.A. type shown)

TRX350 TE/FE:

GENERAL INFORMATION

1-2

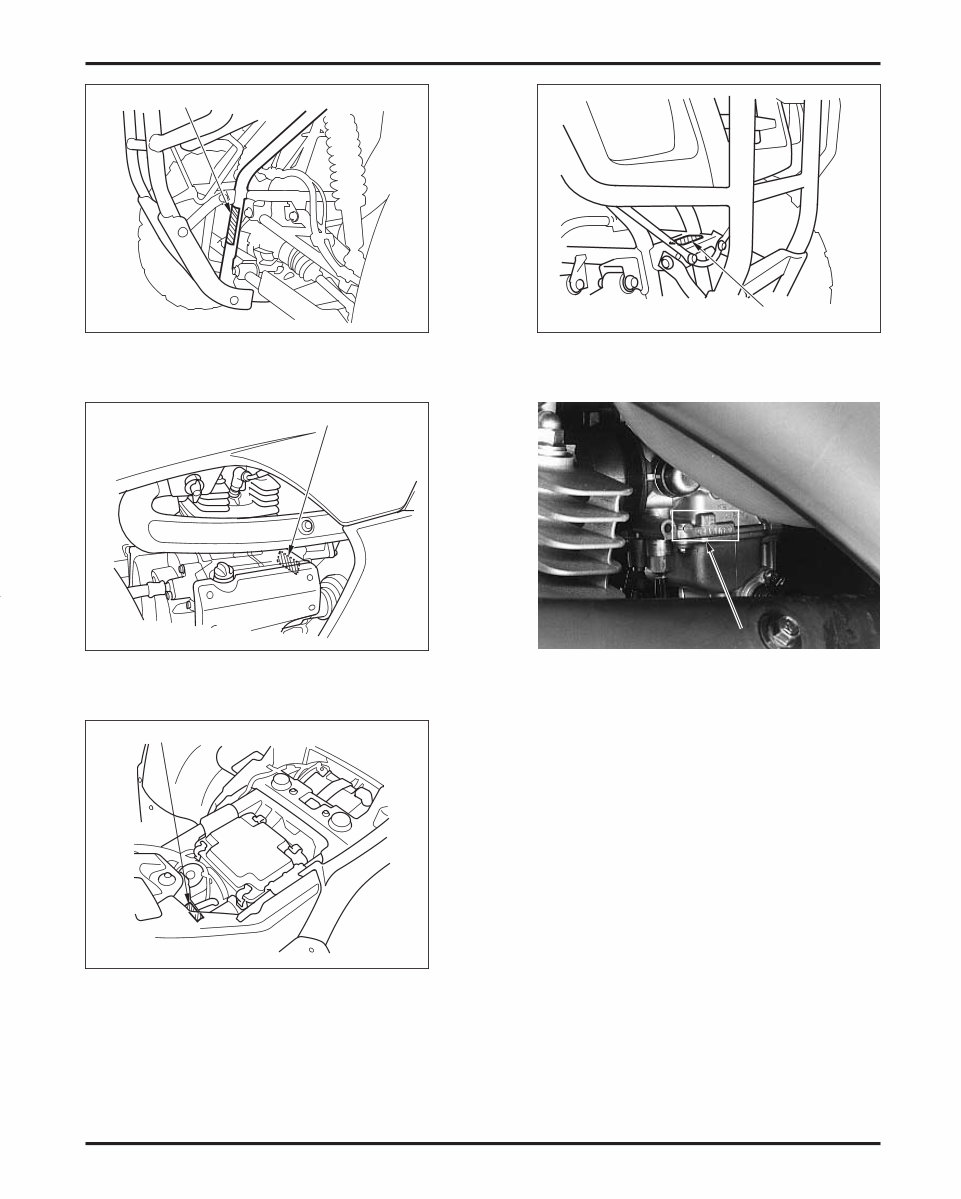

The frame serial number is stamped on the front side

of the frame.

The engine serial number is stamped on the left side

of the rear crankcase.

The carburetor identification number is stamped on

the left side of the carburetor body.

The Vehicle Identification Number (VIN) is located on

the left side frame down tube.

The color label is attached on the frame

crossmember under the seat. When ordering color-

coded parts, always specify the designated color

code.

E EN NG GI IN NE E S SE ER RI IA AL L N NU UM MB BE ER R

C CO OL LO OR R L LA AB BE EL L

F FR RA AM ME E S SE ER RI IA AL L N NU UM MB BE ER R

V VE EH HI IC CL LE E I ID DE EN NT TI IF FI IC CA AT TI IO ON N N NU UM MB BE ER R

C CA AR RB BU UR RE ET TO OR R I ID DE EN NT TI IF FI IC CA AT TI IO ON N N NU UM MB BE ER R

× ×

°

×

×

× ★★

× ★★

-

-

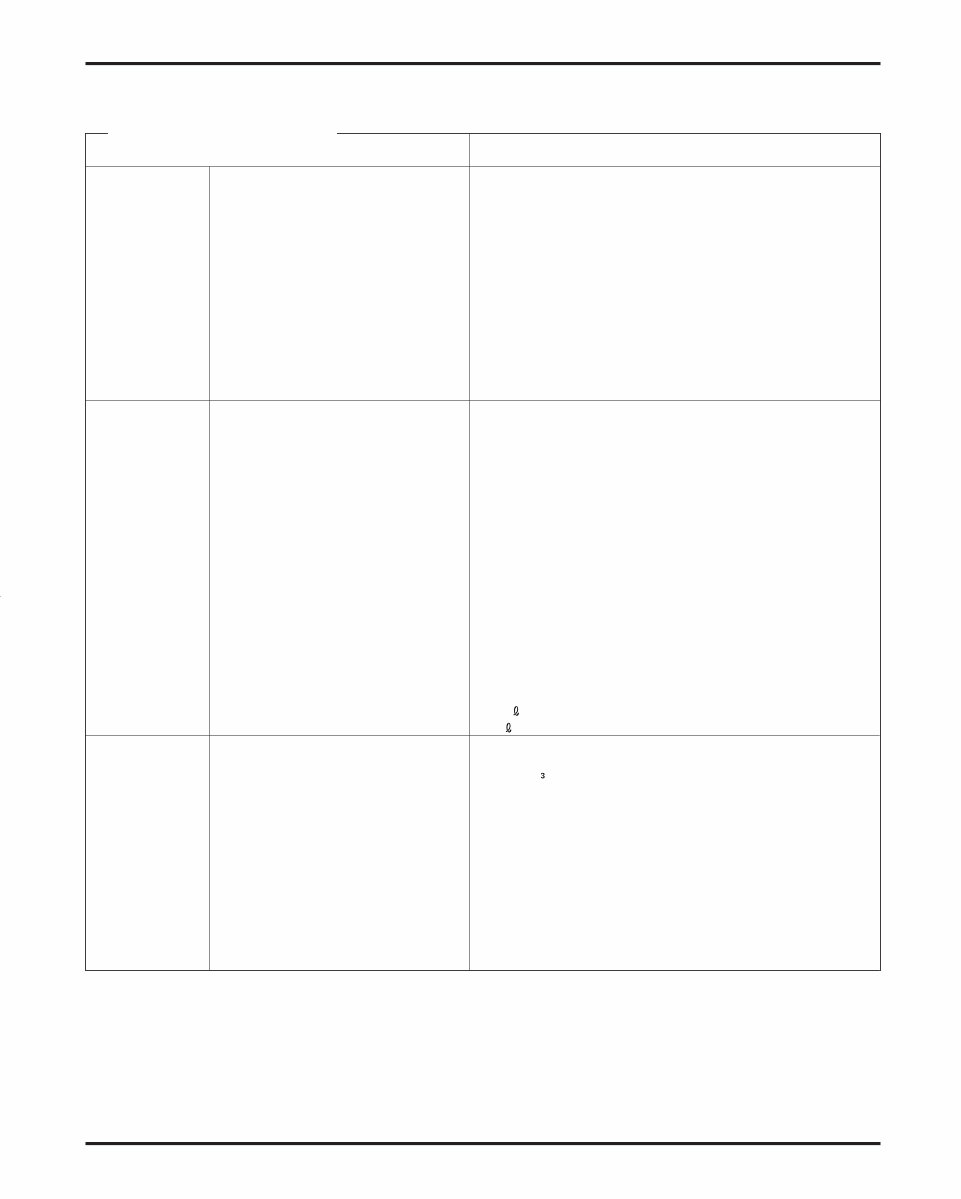

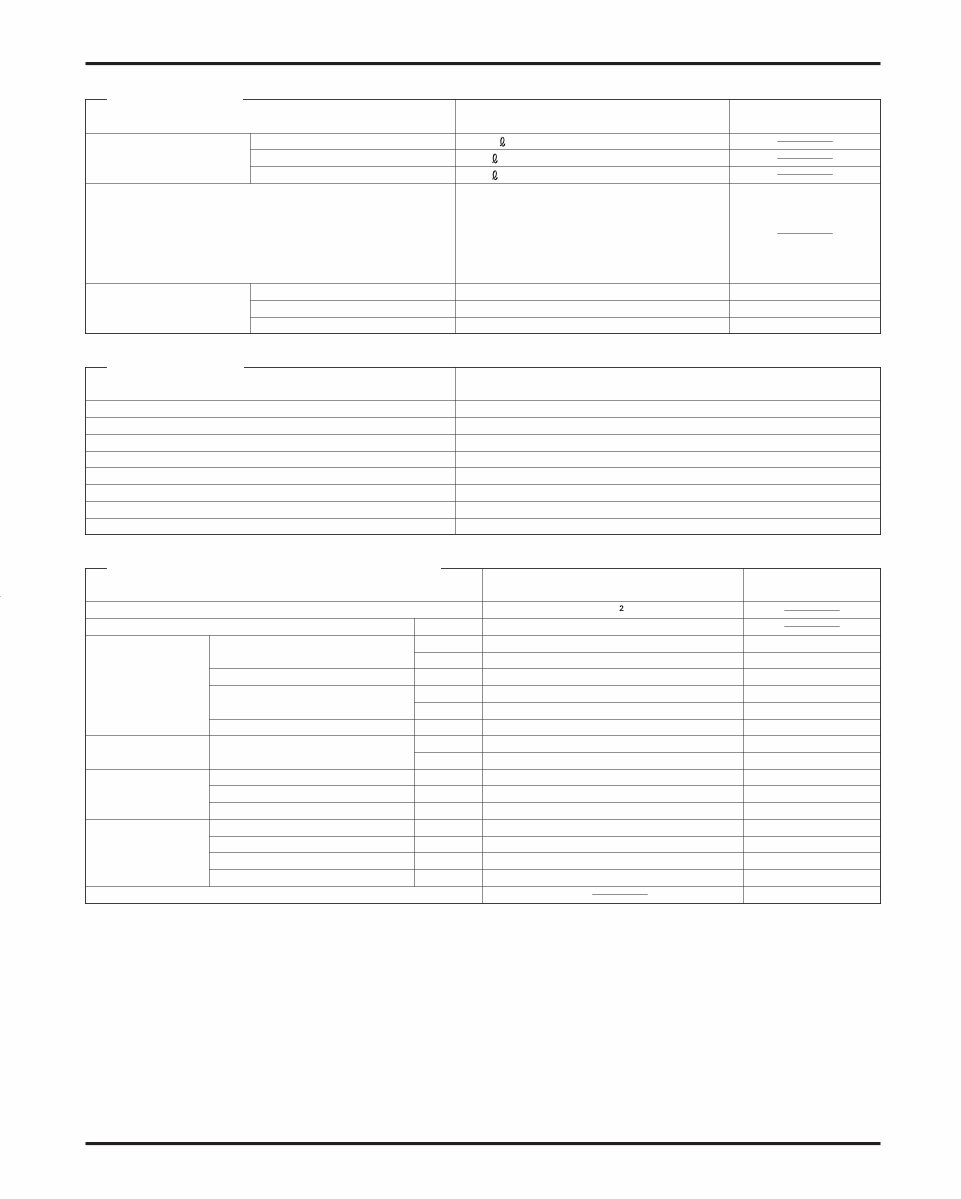

SPECIFICATIONS

ITEM SPECIFICATIONS

GENERAL INFORMATION

GENERAL: TRX350TM/TE

1-3

1,983 mm (78.1 in)

1,143 mm (45.0 in)

1,119 mm (44.1 in)

1,253 mm (49.3 in)

851 mm (33.5 in)

840 mm (33.1 in)

812 mm (32.0 in)

186 mm (7.3 in)

318 mm (12.5 in)

226 kg (498 lbs)

323 mm (12.7 in)

43.4 kg (95.7 lbs) 44.9 kg (99.0 lbs)

Oiled urethane foam

Air cooled (with cooling fan [TE only] and oil cooler)

Trochoid

Forced pressure (dry sump)

7°ATDC (at 1 mm lift)

40°BBDC (at 1 mm lift)

38°ABDC (at 1 mm lift)

8°BTDC (at 1 mm lift)

OHV

8.8 : 1

329.1 cm (20.08 cu-in)

78.5 68.0 mm (3.09 2.68 in)

Single cylinder, longitudinally installed

3.2 (0.85 US gal , 0.70 Imp gal)

13.0 (3.43 US gal , 2.86 Imp gal)

0°

31 mm (1.2 in)

7

Mechanical drum brake (Leading-trailing)

Hydraulic drum brake (Dual leading)

TRACKER CL (Goodyear)

TRACKER CL (Goodyear)

10 8.5 AT

12 6.0 AT

AT25 11-10

AT24 8-12

Double tube

150 mm (5.9 in)

Swingarm

Double tube

150 mm (5.9 in)

Double wish-bone

Double cradle

DIMENSIONS

FRAME

ENGINE

210 kg (463 lbs)

237 kg (522 lbs)

Overall length

Overall width

Overall height

Wheelbase

Front tread

Rear tread

Seat height

Footpeg height

Ground clearance

Dry weight

Curb weight

Maximum weight capacity

Frame type

Front suspension

Front wheel travel

Front damper

Rear suspension

Rear wheel travel

Rear damper

Front tire size

Rear tire size

Front rim size

Rear rim size

Front tire brand

Rear tire brand

Front brake

Rear brake

Caster angle

Trail length

Camber angle

Fuel tank capacity

Fuel tank reserve capacity

Cylinder arrangement

Bore and stroke

Displacement

Compression ratio

Valve train

Intake valve opens

closes

Exhaust valve opens

closes

Lubrication system

Oil pump type

Cooling system

Air filtration

Engine dry weight

226.5 kg (499.3 lbs)

232 kg (511 lbs)

243 kg (536 lbs)

232.5 kg (512.6 lbs)

243.5 kg (536.8 lbs) 237.5 kg (523.6 lbs)

TM: /TE:

TM: /TE:

TM: /TE:

TM: /TE:

TM: /TE:

TM: /TE:

2000 2001:

After 2001:

2000 2001:

After 2001:

- -----

×

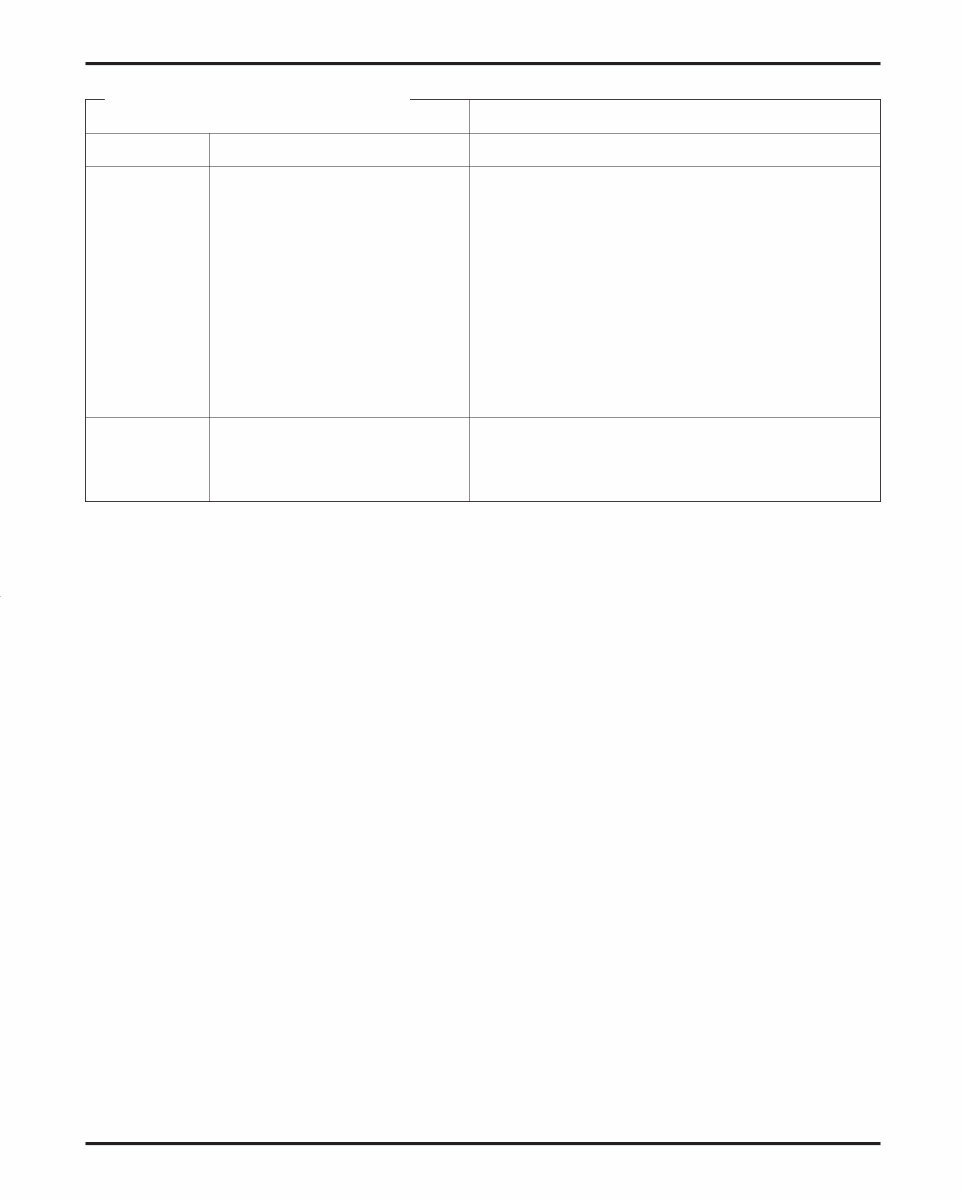

ITEM SPECIFICATIONS

GENERAL INFORMATION

GENERAL: TRX350TM/TE (Cont’d)

1-4

CARBURETOR

DRIVE TRAIN

ELECTRICAL

Constant Vacuum (VE type)

32 mm (1.3 in)

Centrifugal and Multi-plate, wet

Automatic

Constant mesh, 5-speeds with reverse

2.188

1.933

3.692

3.455

1.933

1.333

0.966

0.720

4.600

R N 1 2 3 4 5

DC-CDI

Electric starter motor and emergency recoil starter

Triple phase output alternator

SCR shorted, triple phase full wave rectification

Battery

Carburetor type

Throttle bore

Clutch system

Clutch operation system

Transmission

Primary reduction

Secondary reduction

Final reduction

Gear ratio 1st

2nd

3rd

4th

5th

Reverse

Gearshift pattern

Ignition system

Starting system

Charging system

Regulator/rectifier

Lighting system

(70/32)

(29/15)

(48/13)

(38/11)

(29/15)

(28/21)

(28/29)

(18/25)

(39/13 23/15)

Left foot operated return system (TM)

Electric shift (left hand operated) return system (TE)

× ×

°

×

×

× ★★

× ★★

-

-

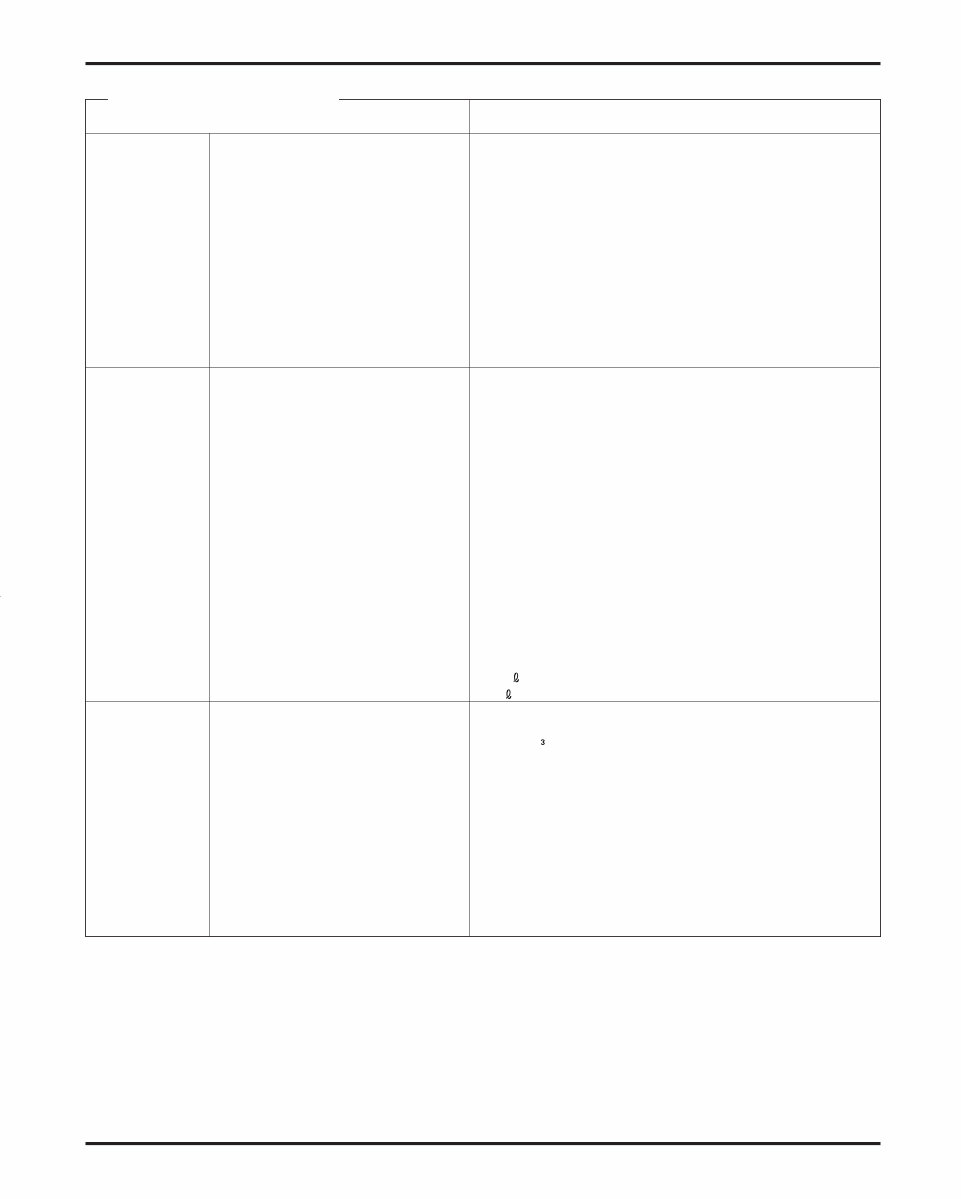

ITEM SPECIFICATIONS

GENERAL INFORMATION

GENERAL: TRX350FM/FE

1-5

1,983 mm (78.1 in)

1,143 mm (45.0 in)

1,130 mm (44.5 in)

1,246 mm (49.1 in)

844 mm (33.2 in)

860 mm (33.9 in)

824 mm (32.4 in)

334 mm (13.1 in) 330 mm (13.0 in)

184 mm (7.2 in)

242.5 kg (534.6 lbs)

Overall length

Overall width

Overall height

Wheelbase

Front tread

Rear tread

Seat height

Footpeg height

Ground clearance

Dry weight

Curb weight

Maximum weight capacity

Frame type

Front suspension

Front wheel travel

Front damper

Rear suspension

Rear wheel travel

Rear damper

Front tire size

Rear tire size

Front rim size

Rear rim size

Front tire brand

Rear tire brand

Front brake

Rear brake

Caster angle

Trail length

Camber angle

Fuel tank capacity

Fuel tank reserve capacity

Cylinder arrangement

Bore and stroke

Displacement

Compression ratio

Valve train

Intake valve

Exhaust valve

Lubrication system

Oil pump type

Cooling system

Air filtration

Engine dry weight

DIMENSIONS

FRAME

ENGINE

43.8 kg (96.6 lbs) 45.3 kg (99.9 lbs)

Oiled urethane foam

Air cooled (with cooling fan and oil cooler)

Trochoid

Forced pressure (dry sump)

7°ATDC (at 1 mm lift)

40°BBDC (at 1 mm lift)

38°ABDC (at 1 mm lift)

8°BTDC (at 1 mm lift)

OHV

8.8 : 1

329.1 cm (20.08 cu-in)

78.5 68.0 mm (3.09 2.68 in)

Single cylinder, longitudinally installed

3.2 (0.85 US gal , 0.70 Imp gal)

13.0 (3.43 US gal , 2.86 Imp gal)

0° 06’

17 mm (0.7 in)

4

Mechanical drum brake (Leading-trailing)

Hydraulic drum brake (Dual leading)

DIRT HOOKS 14 (Bridgestone)

DIRT HOOKS 15 (Bridgestone)

11 7.0 AT

12 6.0 AT

AT24 9-11

AT24 8-12

Double tube

150 mm (5.9 in)

Swingarm

Double tube

150 mm (5.9 in)

Double wish-bone

Double cradle

220 kg (485 lbs)

248.5 kg (547.8 lbs) 253.5 kg (558.9 lbs)

237.5 kg (523.6 lbs)

238 kg (525 lbs) 243 kg (536 lbs)

249 kg (549 lbs) 254 kg (560 lbs)

opens

closes

opens

closes

FM: /FE:

FM: /FE:

FM: /FE:

FM: /FE:

FM: /FE:

FM: /FE:

2000 2001:

After 2001:

2000 2001:

After 2001:

- -----

×

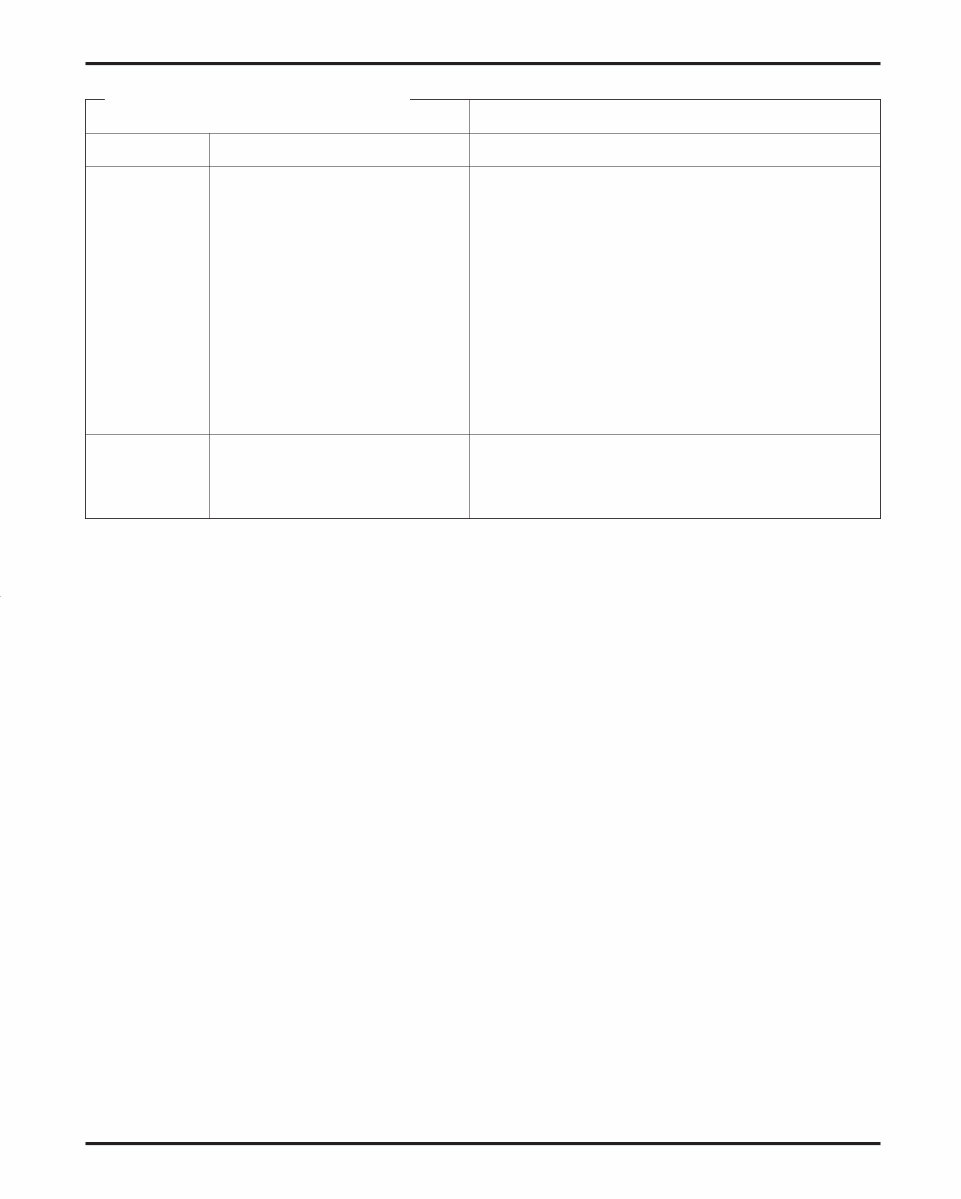

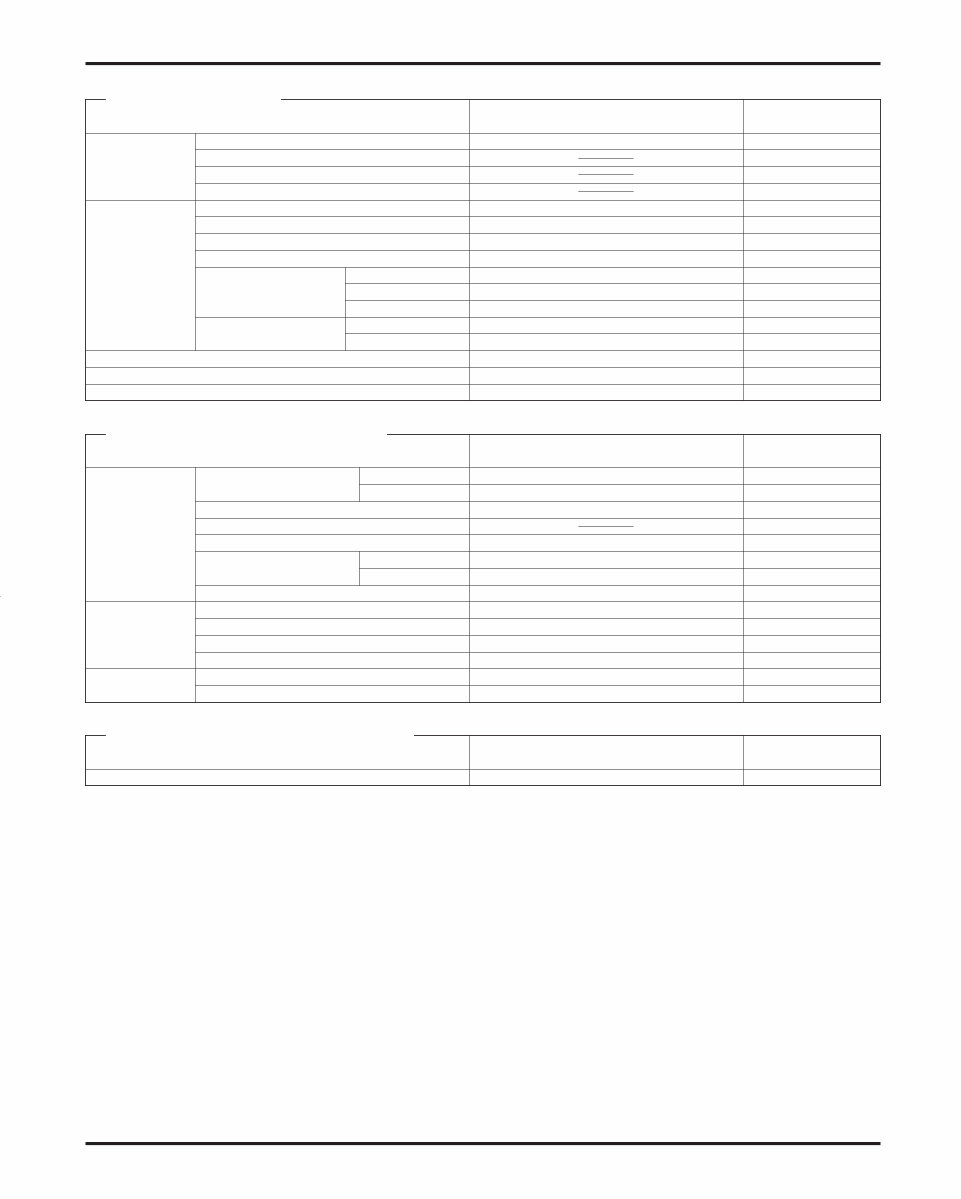

ITEM SPECIFICATIONS

GENERAL INFORMATION

GENERAL: TRX350FM/FE (Cont’d)

1-6

CARBURETOR

DRIVE TRAIN

ELECTRICAL

Constant Vacuum (VE type)

32 mm (1.3 in)

Centrifugal and Multi-plate, wet

Automatic

Constant mesh, 5-speeds with reverse

2.188

1.933

3.692

3.455

1.933

1.333

0.966

0.720

4.600

R N 1 2 3 4 5

DC-CDI

Electric starter motor and emergency recoil starter

Triple phase output alternator

SCR shorted, triple phase full wave rectification

Battery

3.769

Carburetor type

Throttle bore

Clutch system

Clutch operation system

Transmission

Primary reduction

Secondary reduction

Final reduction Front

Rear

Gear ratio 1st

2nd

3rd

4th

5th

Reverse

Gearshift pattern

Ignition system

Starting system

Charging system

Regulator/rectifier

Lighting system

Left foot operated return system (FM)

Electric shift (left hand operated) return system (FE)

(70/32)

(29/15)

(49/13)

(48/13)

(38/11)

(29/15)

(28/21)

(28/29)

(18/25)

(39/13 23/15)

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

±

#

#

- -

- -

STANDARD ITEM

ITEM SPECIFICATIONS

ITEM

SERVICE LIMIT

SERVICE LIMIT STANDARD

FUEL SYSTEM

GENERAL INFORMATION

LUBRICATION

CYLINDER HEAD/VALVE/CAMSHAFT

1-7

Recommended engine oil

Engine oil capacity After draining

After draining/filter change

After disassembly

1.95 (2.06 US qt , 1.72 Imp qt)

2.0 (2.1 US qt , 1.8 Imp qt)

2.5 (2.6 US qt , 2.2 Imp qt)

Cylinder head warpage

Valve,

valve guide

Valve spring

Rocker arm

Camshaft and

cam follower

Valve clearance

Cylinder compression at 450 rpm

Valve stem O.D.

Valve guide I.D.

Stem-to-guide clearance

Valve seat width

Free length

Arm I.D.

Shaft O.D.

Arm-to-shaft clearance

Cam lobe height

Cam follower O.D.

Follower bore I.D.

Follower-to-bore clearance

IN/EX

IN

EX

IN/EX

IN

EX

IN/EX

Inner

Outer

IN/EX

IN/EX

IN/EX

IN/EX

IN/EX

IN/EX

IN/EX 0.028 0.059 (0.0011 0.0023)

22.510 22.526 (0.8862 0.8868)

22.467 22.482 (0.8845 0.8851)

35.2995 35.4595 (1.38974 1.39604)

0.016 0.052 (0.0006 0.0020)

11.966 11.984 (0.4711 0.4718)

12.000 12.018 (0.4724 0.4731)

41.67 (1.641)

36.95 (1.455)

1.2 (0.05)

0.030 0.057 (0.0012 0.0022)

0.010 0.037 (0.0004 0.0015)

5.500 5.512 (0.2165 0.2170)

5.455 5.470 (0.2148 0.2154)

5.475 5.490 (0.2156 0.2161)

0.15 (0.006)

667 kPa (6.8 kgf/cm , 97 psi)

0.10 (0.004)

0.07 (0.003)

22.54 (0.887)

22.46 (0.884)

35.13 (1.383)

0.08 (0.003)

11.92 (0.469)

12.05 (0.474)

40.42 (1.591)

36.94 (1.454)

1.5 (0.06)

0.14 (0.006)

0.12 (0.005)

5.52 (0.217)

5.43 (0.214)

5.45 (0.215)

Carburetor identification number

Main jet

Slow jet

Jet needle clip position

Pilot screw opening

Float level

Idle speed

Throttle lever free play 3 8 mm (1/8 5/16 in)

1,400 100 rpm

18.5 mm (0.73 in)

3rd groove from top

42

130

VE94A

Tip clearance

Body clearance

Side clearance

Oil pump

0.02 0.09 (0.001 0.004)

0.15 0.22 (0.006 0.009)

0.15 (0.006)

0.12 (0.005)

0.25 (0.010)

0.20 (0.008)

Pro Honda GN4 or HP4 (without

molybdenum additives) 4-stroke oil or

equivalent motor oil

API service classification: SG or higher

JASO T 903 standard: MA

Viscosity: SAE 10W-40

Unit: mm (in)

Unit: mm (in)

See page 5-15

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

ITEM

ITEM SERVICE LIMIT STANDARD

SERVICE LIMIT

ITEM STANDARD SERVICE LIMIT

STANDARD

1-8

GENERAL INFORMATION

CYLINDER/PISTON

ALTERNATOR/STARTER CLUTCH

CLUTCH/GEARSHIFT LINKAGE

Cylinder

Piston,

Piston pin,

piston ring

Cylinder-to-piston clearance

Connecting rod small end I.D.

Connecting rod-to-piston pin clearance

Piston ring end gap

Piston ring-to-ring

groove clearance

Top

Second

Oil (side rail)

Top

Second

Change

clutch

Centrifugal

clutch

Primary

drive gear

Spring free length

Disc thickness

Plate warpage

Outer I.D.

Outer guide

Mainshaft O.D. at clutch outer guide

Drum I.D.

Weight lining thickness

Clutch spring height

Clutch weight spring free length

Gear I.D.

Crankshaft O.D. at drive gear

TM/FM

TE/FE

I.D.

O.D.

Starter driven gear boss O.D.

78.500 78.510 (3.0905 3.0909)

78.465 78.485 (3.0892 3.0900)

17.002 17.008 (0.6694 0.6696)

16.994 17.000 (0.6691 0.6693)

0.002 0.014 (0.0001 0.0006)

0.15 0.30 (0.006 0.012)

0.30 0.45 (0.012 0.018)

0.20 0.70 (0.008 0.028)

0.030 0.060 (0.0012 0.0024)

0.015 0.045 (0.0006 0.0018)

0.015 0.045 (0.0006 0.0018)

17.016 17.034 (0.6699 0.6706)

0.016 0.040 (0.0006 0.0016)

0.10 (0.004)

0.10 (0.004)

17.04 (0.671)

16.96 (0.668)

0.02 (0.001)

0.5 (0.02)

0.6 (0.02)

0.9 (0.04)

0.09 (0.004)

0.09 (0.004)

0.10 (0.004)

17.10 (0.673)

0.06 (0.002)

28.0 (1.10)

2.62 2.78 (0.103 0.109)

28.000 28.021 (1.1024 1.1032)

22.000 22.021 (0.8661 0.8670)

27.959 27.980 (1.1007 1.1016)

21.967 21.980 (0.8648 0.8654)

126.0 126.2 (4.96 4.97)

2.0 (0.08)

2.87 (0.113)

25.8 (1.02)

26.959 26.980 (1.0614 1.0622)

45.660 45.673 (1.7976 1.7981)

2.3 (0.09)

0.20 (0.008)

28.04 (1.104)

22.05 (0.868)

27.92 (1.099)

27.05 (1.065)

26.93 (1.060)

0.10 (0.004)

31.3 (1.23)

27.000 27.021 (1.0630 1.0638)

78.60 (3.094)

78.43 (3.088)

27.0 (1.06)

30.2 (1.19)

21.93 (0.863)

126.4 (4.98)

1.3 (0.05)

2.73 (0.107)

26.9 (1.06)

45.65 (1.797)

I.D.

Out-of-round

Taper

Warpage

Piston O.D. at 15 (0.6) from bottom

Piston pin hole I.D.

Piston pin O.D.

Piston-to-piston pin clearance

Unit: mm (in)

Unit: mm (in)

Unit: mm (in)

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 15 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get instant access to the Complete Factory Service Repair Workshop Manual without any extra fees or expiry dates. This Professional Manual is suitable for both professional Mechanics and Technicians, as well as DIY enthusiasts. It covers all repairs, servicing, and troubleshooting procedures with highly detailed step-by-step instructions, exploded diagrams, and pictures. You can easily print out a single page or the entire manual as per your requirement. The Manual can be used on multiple computers without any limitations or trial periods, and it does not expire or require any renewal fees. It is fully compatible with Windows and MAC computers.

- Comprehensive manual covering all repairs, servicing, and troubleshooting procedures

- Contains detailed photos, diagrams, and highly detailed exploded diagrams

- Can be printed out as per the user's choice

- No limitations or trial periods, can be used for life

- Compatible with Windows & MAC computers

For instant access to this invaluable resource, click the button below.