E-TON ATV RXL 50 / 70 / 90 Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

CONTENTS

1. INFORMATION…………………………………………………...2

2. MAINTENANCE………………………………………………….6

3. ENGINE REMOVAL AND INSTALLATION………………….12

4. ENGINE FUEL SYSTEM………………………………………14

5. ENGINE LUBRICATION AND COOLING SYSTEM….…….18

6. ENGINE COMBUSTION SYSTEM…………………………...20

7. TRANSMISSION SYSTEM……………………………………25

8. STEERING SYSTEM…………………………………………..31

9. FRONT WHEEL SYSTEM…………………………………….38

10. REAR WHEEL SYSTEM……..………………………………42

11. FENDERS AND EXHAUST PIPE..………………………….51

12. ELECTRICAL SYSTEM….…………………………….…….55

13. TROUBLE SHOOTING…..……………………………….….62

1

1. INFORMATION

1.1 SAFTY

1.2 NOTES

1.3 SPECIFICATION

1.4 SERIAL NUMBER

1.5 TORQUE VALVE

1.1 SAFETY

● Gasoline is extremely flammable and is explosive under certain condition.

Do not smoke or allow sparks or flames in your work area.

● Never run the engine in a closed area. The exhaust contains poisonous carbon

monoxide gas that may cause loss of consciousness and lead to death.

● The battery electrolyte contains sulfuric acid. Protect your eyes, skin and

clothing. If you contact it, flush thoroughly with water and call a doctor if electrolyte

gets in your eyes.

1.2 NOTES

All information, illustrations, directions and specifications included in this publication are base on the latest

product information available at the time of approval for printing.

JI-EE Dynamic Technology Industry Co., Ltd. reserves the right to make changes at any time without notice and

without incurring any obligation whatever.

No part of this publication may be reproduced without written permission.

2

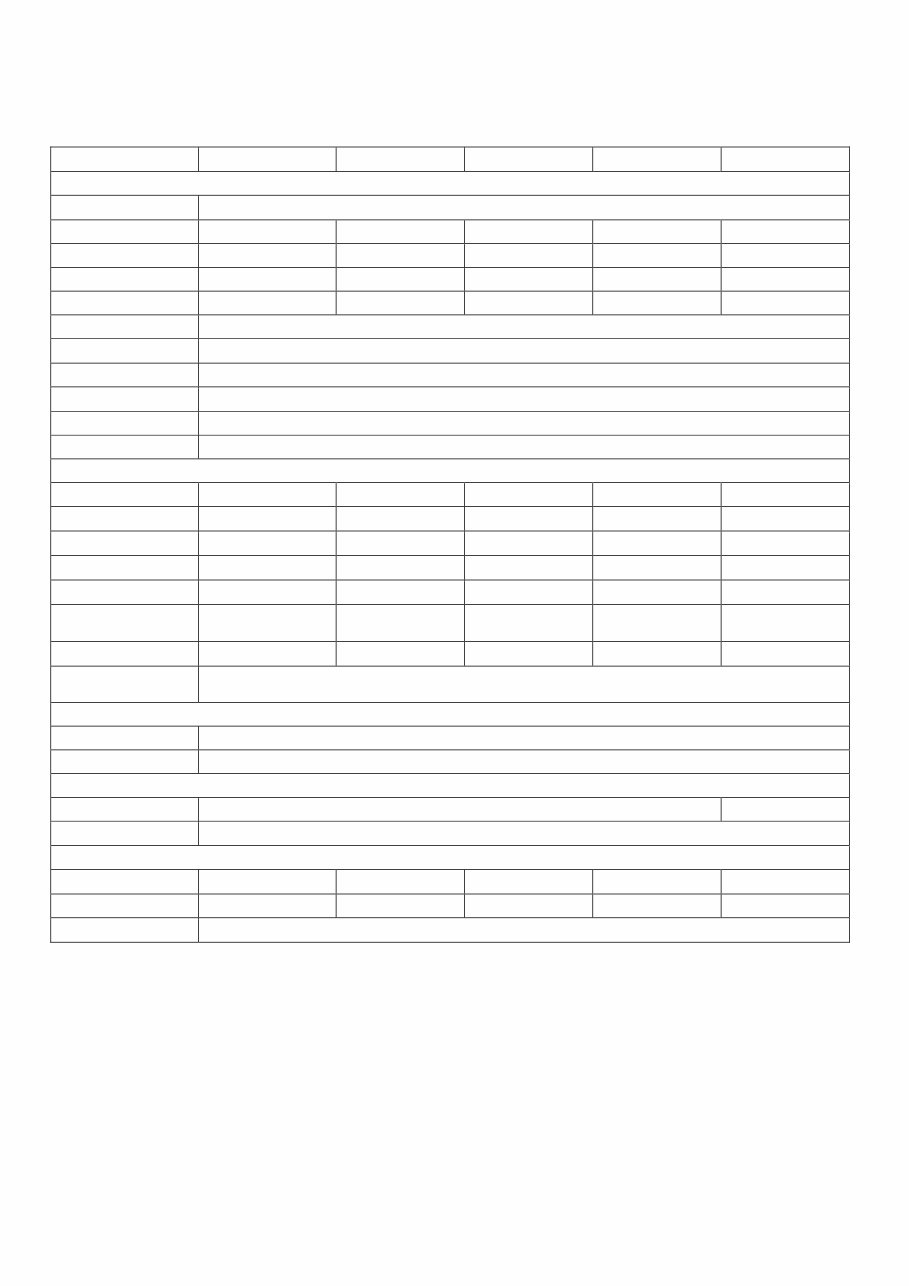

1.3 SPECIFICATION

RXL50 RXL70 RXL90 RXL90R RXL50M

ENGINE

TYPE AIR-COOLING TWO STROKE

DISPLACEMENT

49.3 ㏄ 68.0 ㏄ 82.5 ㏄ 82.5 ㏄

49.3

BORE & STROKE 40.0*39.2 mm 47.0*39.2 mm 50.0*42.0 mm 50.0*42.0 mm 40.0*39.2 mm

COMPRESSION

9.2:1 8.3:1 7.9:1 7.9:1 9.2:1

MAXIMUN TORQUE 5.2 N-m @ 7000rpm 6.3 N-m @ 6000rpm 7.0 N-m @ 7500rpm

CARBURETOR MIKUNI VM16 (for other country) / SW 18 mm-Manual Choke (for America)

IGNITION CAPACITOR DISCHARGE

STARTING ELECTRIC/KICK START

LUBRICATION AUTO OIL INJECTION

OIL CAPACITY 1.0 LITER

TRANSMISSION AUTOMATIC (C.V.T. V-Belt)

CHASSIS

OVERALL LENGTH 1470mm (57.9") 1470mm (57.9") 1500mm (59.0") 1500mm (59.0") 1430mm (56.3")

OVERALL WIDTH 850mm (33.5") 850mm (33.5") 850mm (33.5") 850mm (33.5") 820mm (32.3")

OVERALL HEIGHT 830mm (32.7") 830mm (32.7") 900mm (35.4") 900mm (35.4") 800mm (31.5")

SEAT HEIGHT 650mm (25.5") 650mm (25.5") 670mm (26.3") 670mm (26.3") 650mm (25.5")

WHEEL BASE 930mm (36.1") 930mm (36.1") 930mm (36.1") 930mm (36.1") 930mm (36.1")

GROUND

CLEARANCE 110mm (4.3") 95mm (3.7") 120mm (4.7") 130mm (5.1") 110mm (4.3")

DRY WEIGHT 108kg 108 kg 113 kg 113 kg 108kg

FUEL

TANK CAPACITY 4.5 LITERS

SUSPENSION

FRONT DUAL A-ARM

REAR SWING ARM

BRAKES

FRONT DUAL MECHANICAL DRUM N/A

REAR HYDRAULIC DISC

TIRES

FRONT 16" *8"-7 16" *8"-7 18" *7"-8 18" *7"-8 145/70-6

REAR 16" *8"-7 16" *8"-7 18" *9"-8 18" *9"-8 145/70-6

COLORING Red /Blue /Yellow /Black

7.0 N-m @ 7500rpm 5.2 N-m @ 7000rpm

Specifications subject to change without notice.

3

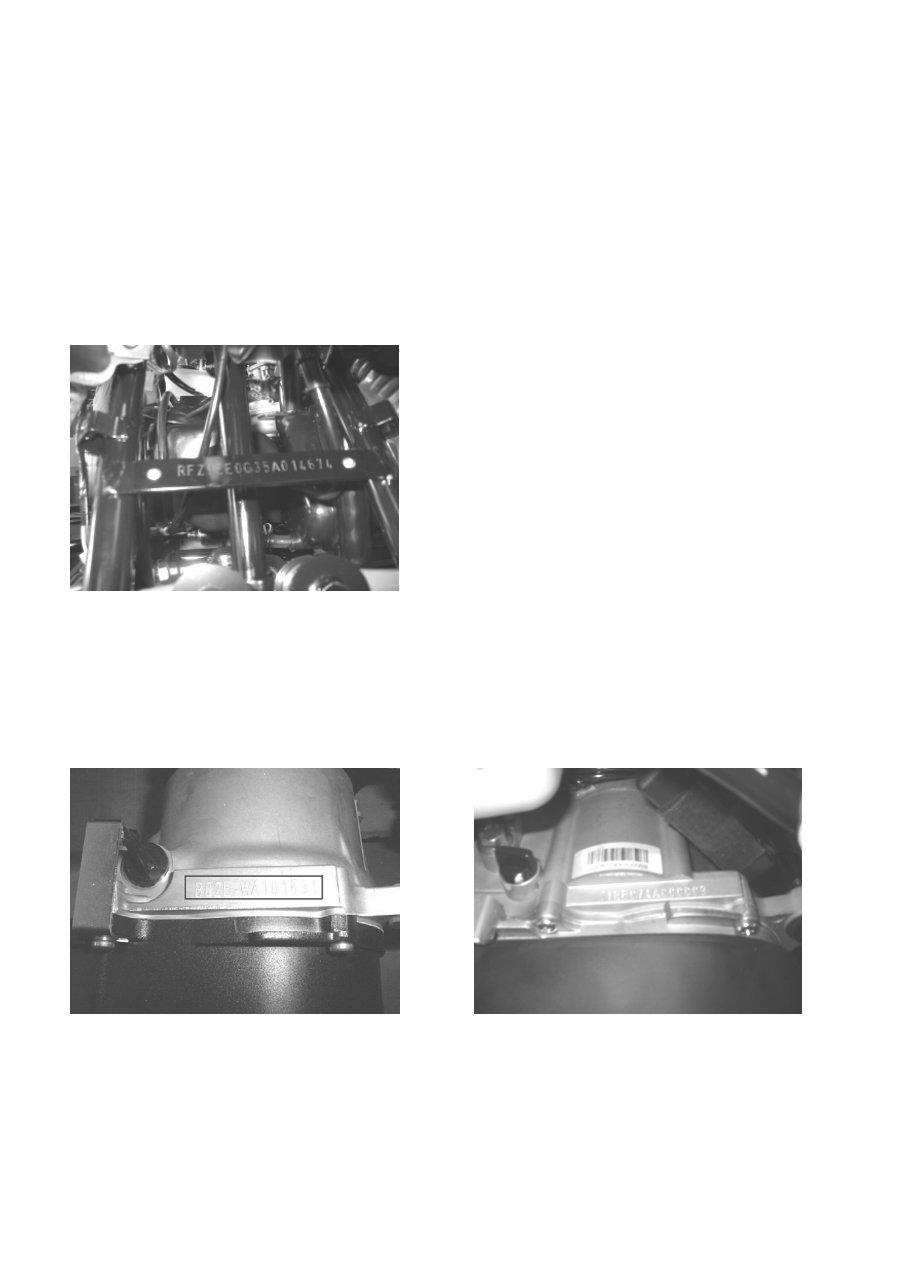

1.4 SERIAL NUMBER

For this ATV serial; the number of frame and engine are the same position, just like the picture below;

The frame serial number is stamped on the front of the frame.

The engine serial number is stamped on the left side of the crankcase.

Frame serial number

Engine serial number Engine serial number

For RXL 50/70/90/RXL50M For RXL 90R

4

1.5 TORQUE VALUES

For this ATV serial; the torque values of frame and engine are the same, just like the picture below;

ENGINE

● Cylinder head nut 28-30 N.m (20.7-22.1 lbf.ft)

● Spark plug 12-19 N.m (8.9-14.0 lbf.ft)

● Cylinder head bolt 20-30 N.m (14.8-22.1 lbf.ft)

● Alternator bolt 8-12 N.m (5.9- 8.9 lbf.ft)

FRAME

● Handlebar upper holder bolt 24-30 N.m (17.7-22.1 lbf.ft)

● Steering shaft nut 50-60 N.m (36.9-44.3 lbf.ft)

● Steering shaft bushing holder nut 24-30 N.m (17.7-22.1 lbf.ft)

● Wheel rim bolt 18-25 N.m (13.3-18.4 lbf.ft)

● Tie rod lock nut 35-43 N.m (25.8-31.7 lbf.ft)

● King pin nut 30-40 N.m (22.1-29.5 lbf.ft)

● Handlebar lower holder nut 40-48 N.m (29.5-35.4 lbf.ft)

● Front wheel bolt 24-30 N.m (17.7-22.1 lbf.ft)

● Front axle nut 55-65 N.m (40.6-47.9 lbf.ft)

● Front brake arm nut 4-7 N.m (3.0- 5.2 lbf.ft)

● Rear brake arm nut 7-12 N.m (5.2- 8.9 lbf.ft)

● Rear axle nut 40-60 N.m (30-45 lbf.ft)

● Rear wheel bolt 24-30 N.m (17.7-22.1 lbf.ft)

● Exhaust muffler mounting bolt 30-35 N.m (22.1-25.8 lbf.ft)

● Engine hanger bolt 24-30 N.m (17.7-22.1 lbf.ft)

5

2. MAINTENANCE

2.1 MAINTENANCE DATA 2.8 IDLE SPEED

2.2 MAINTENANCE SCHEDULE 2.9 DRIVE CHAIN

2.3 FUEL TUBE 2.10 BRAKE SYSTEM

2.4 THROTTLE OPERATION 2.11 WHEELS AND TIRES

2.5 THROTTLE CABLE ADJUSTMENT 2.12 STEERING SYSTEM

2.6 AIR CLEANER 2.13 TOE-IN

2.7 SPARK PLUG 2.14 GEAR OIL

2.1 MAINTENANCE DATA

SPECIFICATION

SPARK PLUG:

SPARK PLUG GAP: 0.6-0.7 mm

RECOMMENDED SPARK PLUGS: NGK BPR7HS

THROTTLE LEVER FREE PLAY: 5-10 mm

IDLE SPEED: 1800±100 rpm

BRAKE LEVER FREE PLAY: 15-25 mm

DRIVE CHAIN SLACK 10-25 mm

FRONT/REAR TIRE PRESSURE MIN 3.2 psi (0.23 kg/cm

2

)

MAX 4.0 psi (0.28 kg/cm

2

)

TOE-IN 5±10 mm

TORQUE VALUES

SPARK PLUG 12-19 N.m

TIE-ROD LOCK NUT 35-43 N.m

ENGINE OIL JASO FC Grade or same degree oil

GEAR LUBRICATION OIL SAE 90

2.2 MAINTENANCE SCHEDULE

The maintenance internals in the follow table is based upon average riding, conditions. Riding in

unusually

dusty areas, require more frequent servicing. (For ATV all serial in this service manual)

INITIAL SERVICE

(First week)

REGULAR SERVICE

(Every 30 operating days)

EVERY YEAR

FUEL LINE I

THROTTLE OPERATION I I

AIR CLEANER C

SPARK PLUG I

CARBURETOR IDLE SPEED I I

DRIVE CHAIN I, L I, L

BRAKE SHOE WEAR I

BRAKE SYSTEM I I

NUT, BOLT, FASTENER I I

WHEEL I I

STEERING SYSTEM I

SUSPENSION SYSTEM I

C.V.T. AIR FILTER C

GEAR OIL R

REVERSE GEAR OIL-RXL90R R

Note – I: Inspect and Clean, Adjust, Lubricate or Replace, if necessary

C: Clean L: Lubricate R: Replace

6

2.3 FUEL TUBE

Inspect the fuel lines for deterioration, damage or

leakage and replace if necessary. (For RXL50 / 90)

(For RXL70 / RXL90R / RXL50M)

2.4 THROTTLE OPERATION

Inspect for smooth throttle lever full opening and

automatic full closing in all steering positions.

Inspect if there is no deterioration, damage or kinking

in the throttle cable, replace it if necessary.

Check the throttle lever, free play is 5-10 mm at the tip

of the throttle lever.

Disconnect the throttle cable at the upper end.

Lubricate the cable with commercially lubricant to

prevent premature wear.

2.5 THROTTLE CABLE ADJUSTMENT

Slide the rubber cap of the adjuster off the throttle

Housing, loosen the lock nut and adjust the free play

of the throttle lever by turning the adjuster on the throttle

housing. Inspect the free play of the throttle lever.

7

2.6 AIR CLEANER

Unscrew the air cleaner cover screws.

Pull out the air filter element from the air cleaner case.

Wash the element in non-flammable solvent, squeeze

out the solvent thoroughly.

Let it dry.

Soak the filter element in gear oil and then squeeze

out the excess oil.

Install the element into air cleaner carefully.

2.7 SPARK PLUG

This spark plug located at the front of the engine.

Disconnect the spark plug cap and unscrew the spark plug.

Check the spark plug electrodes for wearness.

Change a new spark plug if the electrodes and insulator tip

appear unusually fouled or burned.

Discard the spark plug if there is apparent wear or if the

insulator is cracked or chipped.

The spark plug gap shall keep in 0.6-0.7mm.

With the sealing washer attached, thread the spark plug in

by hand to prevent cross threading.

Tighten the spark plug with 12-19 N.m

2.8 IDLE SPEED

Connect an engine speed meter.

Warm up the engine, 10 minutes are enough.

Turn the idle-speed adjust screw on the carburetor

to obtain the idle speed. “Turn in” (clockwise) will get higher

speed. “Turn out” (counter clockwise) will get lower speed.

IDLE SPEED: 1800±100 rpm

2.9 DRIVE CHAIN

Inspect the chain slack. The standard is 10-25mm.

8

Adjust the chain slack.

Loose the lock bolts (4 pcs) then adjust the drive chain

slack by turn the adjusting nut.

Tighten the four lock bolts.

When the drive chain becomes very dirty, it should be

removed, cleaned and lubricated by specify lubricator.

Using commercial chain lubricant to lubricate the drive

chain.

Clean the drive chain with kerosene and wipe it dry.

Inspect the drive chain for possible wear or damage.

Replace the chain, if it is worn excessively or damaged.

Inspect the sprocket teeth, if it is excessive wear

r damage, replace it. o

Inspect the chain-tensioned roller.

Replace it, if necessary.

2.10 BRAKE SYSTEM

Inspect the front brake lever and cable for excessive

play or other damage.

Replace or repair if necessary.

Measure the free play of the brake lever at the end of the

rake lever. The standard of free play is 15-25 mm. b

(For RXL50 / 90 / RXL90R, the ATV RXL50M doesn’t have

the front brake lever. )

9

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$28.99

Viewed 82 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$28.99

The E-TON ATV RXL 50 / 70 / 90 Service & Repair Manual is an indispensable resource designed specifically for servicing your E-TON ATV RXL 50, 70, and 90 models. This comprehensive manual offers detailed instructions and step-by-step procedures for maintenance and repairs, ensuring that both professional mechanics and DIY enthusiasts have the crucial insights they need.

- Detailed repair and maintenance procedures for E-TON ATV RXL 50, 70, and 90 models

- Comprehensive guidance for routine services and troubleshooting

- Step-by-step instructions to assist in complex repairs

- Accessible .PDF format for easy reference on any device