2001 Bombardier Traxter XT XL ATV Repair Manual

The manual covers the following models:

- 2001 BOMBARDIER TRAXTER 500 4x4

- 2001 BOMBARDIER TRAXTER 500 4x4 Manual Shift

- 2001 BOMBARDIER TRAXTER 500 4x4 Semi-Auto Shift

- 2001 BOMBARDIER TRAXTER XL 4x4

- 2001 BOMBARDIER TRAXTER XT 4x4

Our informative shop, service, repair manual, owner's manuals, and parts catalogs contain all the information you'll need to perform repairs, look up parts, or do routine maintenance on your machine. They include topics such as:

- General Information

- Routine Maintenance

- Engine Removal and Installation

- Fuel System

- Lubrication and Cooling System

- Engine Specifications

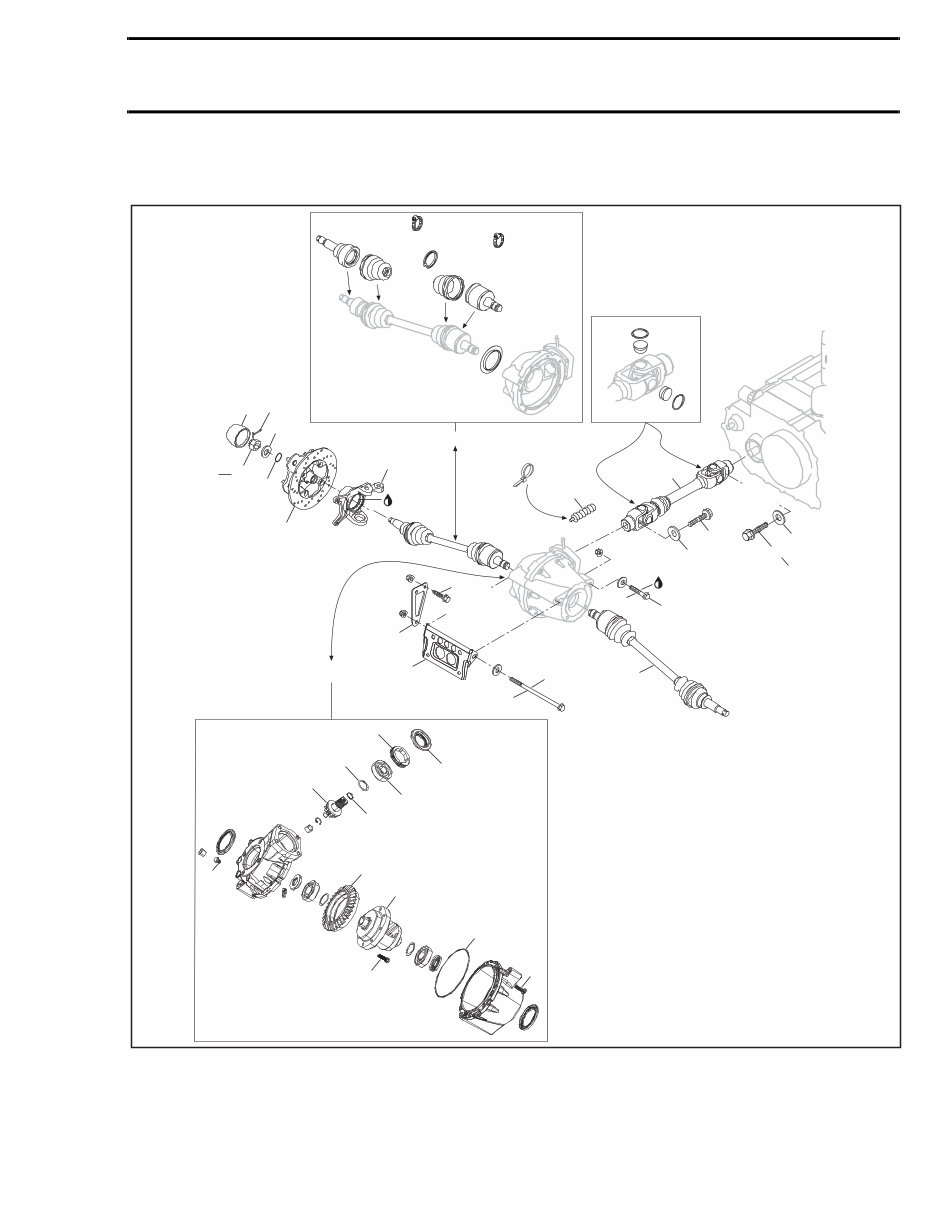

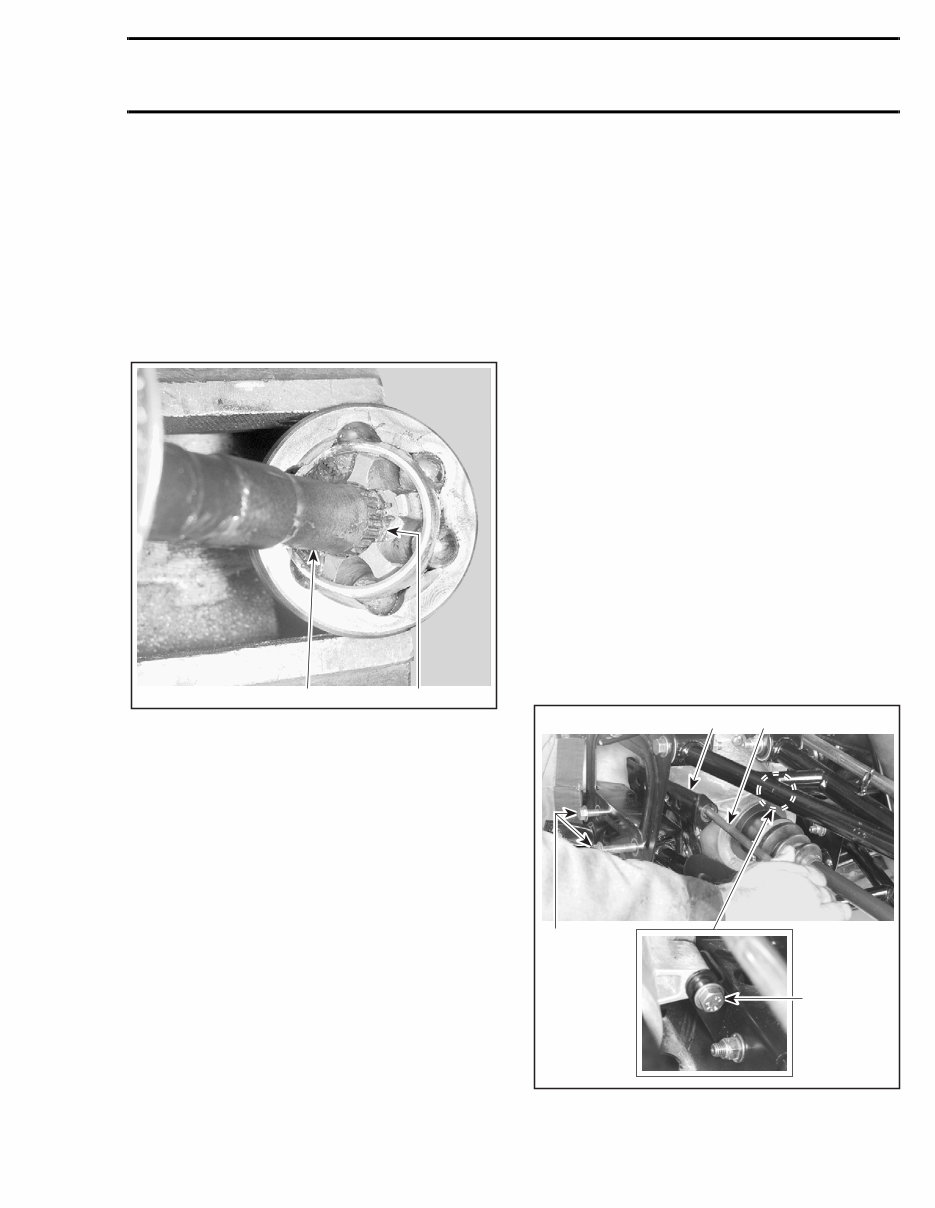

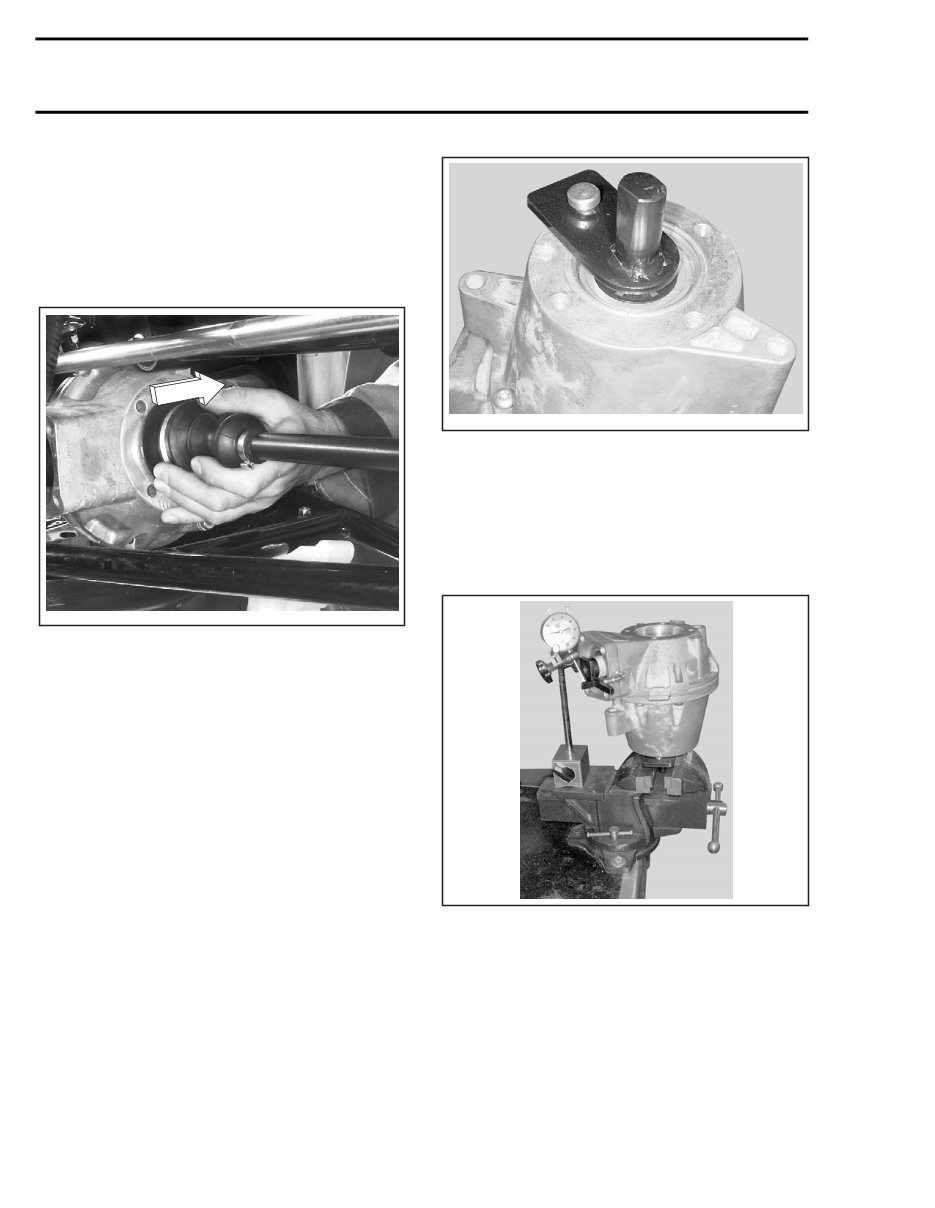

- Transmission, Drive Chain & Sprockets

- Steering System

- Shocks

- Body Work

- Intake & Exhaust

- Electrical System

- Advanced Troubleshooting

With our manuals, find the page pertaining to your job, print it off, and get working on your project. No more ruining your expensive paper shop manual with grease and dirt.

Broken down on the trail or site and have a smartphone? What a cool way to find your problem and fix it, no downtime on the job site. With our manuals, you instantly have access to the material needed to get you running again.

Our entire manual collection comes with a lifetime protection policy. If lost or damaged, simply contact us, and we'll replace it free of charge for life.

We provide various service manuals, workshop manuals, repair manuals, owner's manuals, parts catalogs, and other various manuals, all in an electronic format.

UTVs, motorcycles, ATVs, quads, snowmobiles, Seadoo, equipment, small engines, inboards, outboards, and more.

Instant access with no shipping cost. Get a manual now and repair it without waiting.

If you are looking for a specific manual and cannot find it or do not see it listed, then contact our customer support team via the contact us link above with details of the required manual, and we will do our absolute best to find and list it for you.

Instant access after payment. Thank you.