2002 Bombardier DS90 2-Stroke ATV Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

2002

Shop Manual

DS50

DS90

DS90 (4-STROKE)

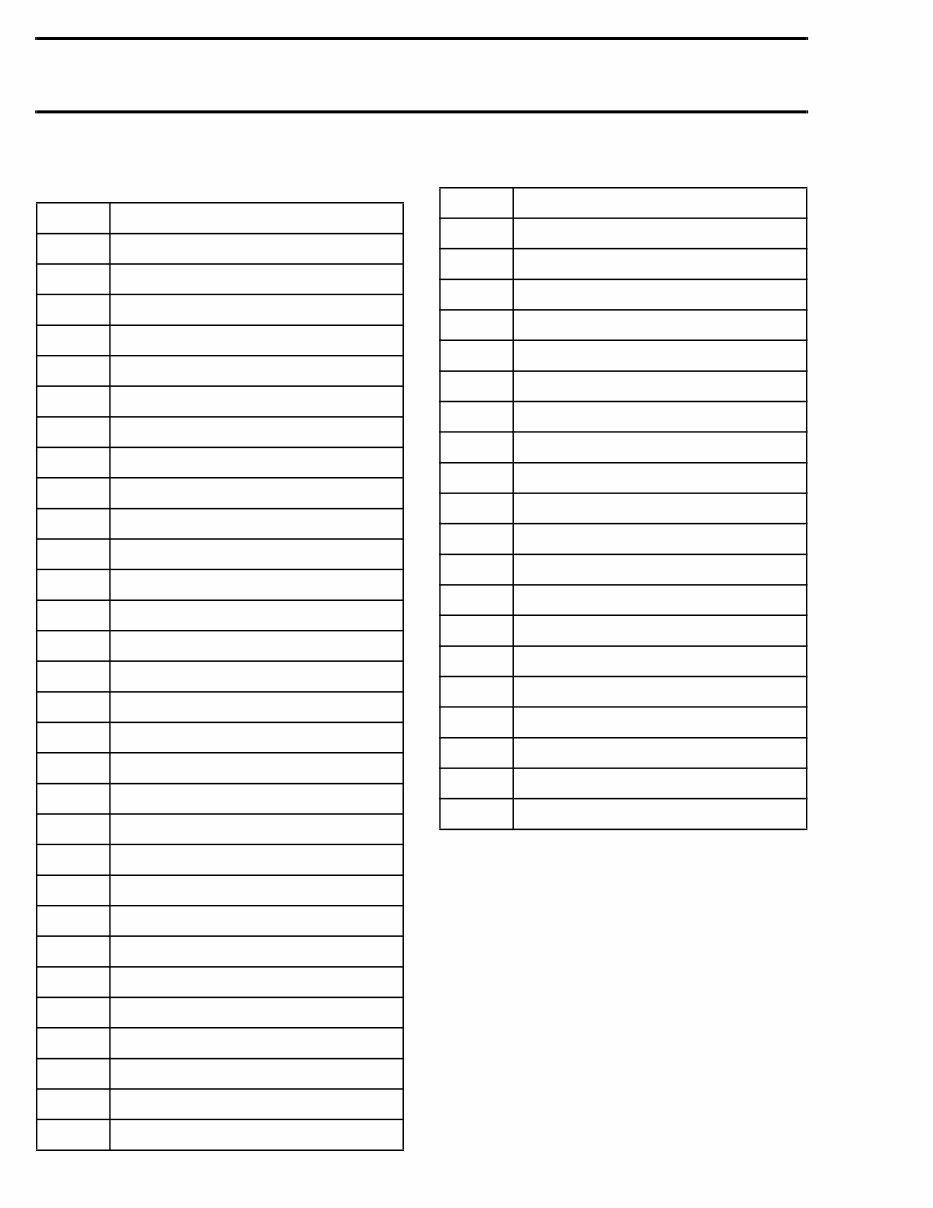

SECTION SUBSECTION PAGE

TABLE OF CONTENTS .......................................................................................................... I

SAFETY NOTICE .................................................................................................................... III

INTRODUCTION ................................................................................................................... V

01 SERVICE TOOLS AND

SERVICE PRODUCTS

01 – Table of contents .................................................................... 01-01-1

02 – Service tools ........................................................................... 01-02-1

03 – Service products ..................................................................... 01-03-1

02 MAINTENANCE 01 – Table of contents .................................................................... 02-01-1

02 – Maintenance chart .................................................................. 02-02-1

03 ENGINE 01 – Table of contents .................................................................... 03-01-1

02 – Removal and installation ....................................................... 03-02-1

03 – Generator, starter motor ........................................................ 03-03-1

04 – Cylinder and head .................................................................. 03-04-1

05 – Crankcase/crankshaft ............................................................. 03-05-1

06 – Lubrication system ................................................................. 03-06-1

07 – Transmission/kick start .......................................................... 03-07-1

08 – Clutch....................................................................................... 03-08-1

09 – Exhaust system....................................................................... 03-09-1

04 FUEL SYSTEM 01 – Table of contents .................................................................... 04-01-1

02 – Fuel circuit ............................................................................... 04-02-1

03 – Carburetor and air cleaner ..................................................... 04-03-1

05 ELECTRICAL 01 – Table of contents .................................................................... 05-01-1

02 – Charging system..................................................................... 05-02-1

03 – Starting system....................................................................... 05-03-1

04 – Ignition system ....................................................................... 05-04-1

06 DRIVE TRAIN 01 – Table of contents .................................................................... 06-01-1

02 – Chain drive system................................................................. 06-02-1

07 STEERING/CONTROL

SYSTEMS

01 – Table of contents .................................................................... 07-01-1

02 – Steering/control systems ....................................................... 07-02-1

08 SUSPENSION 01 – Table of contents .................................................................... 08-01-1

02 – Front suspension .................................................................... 08-02-1

03 – Rear suspension ..................................................................... 08-03-1

09 BRAKES 01 – Table of contents .................................................................... 09-01-1

02 – Brakes ...................................................................................... 09-02-1

10 TECHNICAL DATA 01 – SI metric information guide................................................... 10-01-1

02 – Engine and vehicle ................................................................. 10-02-1

11 WIRING DIAGRAMS 01 – Wiring diagrams ..................................................................... 11-01-1

TABLE OF CONTENTS

VMR2002_105_00_02AB.FM III

SAFETY NOTICE 0

This manual has been prepared as a guide to correctly service and repair 2002 ATVs.

This edition was primarily published to be used by ATV mechanical technicians who are already familiar

with all service procedures relating to Bombardier made vehicles. Mechanical technicians should attend

continuous training courses given by Bombardier Training Department.

Please note that the instructions will apply only if proper hand tools and special service tools are used.

This shop manual uses technical terms which may be slightly different from the ones used in parts catalog.

It is understood that this manual may be translated into another language. In the event of any discrepancy,

the English version shall prevail.

The content depicts parts and/or procedures applicable to the particular product at time of writing. Service

and Warranty Bulletins may be published to update the content of this manual. Make sure to read and

understand these. It does not include dealer modifications, whether authorized or not by Bombardier,

after manufacturing the product.

In addition, the sole purpose of the illustrations throughout the manual, is to assist identification of the

general configuration of the parts. They are not to be interpreted as technical drawings or exact replicas

of the parts.

The use of Bombardier parts is most strongly recommended when considering replacement of any com-

ponent. Dealer and/or distributor assistance should be sought in case of doubt.

The engines and the corresponding components identified in this document should not be utilized on

product(s) other than those mentioned in this document.

This manual emphasizes particular information denoted by the wording and symbols:

CAUTION: Denotes an instruction which, if not followed, could severely damage vehicle compo-

nents.

NOTE: Indicates supplementary information needed to fully complete an instruction.

Although the mere reading of such information does not eliminate the hazard, your understanding of the

information will promote its correct use. Always use common shop safety practice.

This information relates to the preparation and use of Bombardier ATV and has been utilized safely and

effectively by Bombardier Inc. However, Bombardier Inc. disclaims liability for all damages and/or injuries

resulting from the improper use of the contents. We strongly recommend that any services be carried

out and/or verified by a highly skilled professional mechanic. It is understood that certain modifications

may render use of the vehicle illegal under existing federal, provincial and state regulations.

WARNING

Identifies an instruction which, if not followed, could cause serious personal injury including

possibility of death.

SAFETY NOTICE

INTRODUCTION

VMR2002_105_00_02AC.FM V

INTRODUCTION 0

This Shop Manual covers the following Bombardier

made 2002 ATV:

Models

VEHICLE IDENTIFICATION

NUMBER LOCATION

1. V.I.N.

ENGINE IDENTIFICATION

NUMBER LOCATION

2-stroke engine

On 2-stroke engines, the engine identification

number is located on the top side of engine.

4-stroke engine

On 4-stroke engines, the engine identification

number is located on the clutch cover near trans-

mission shifter.

ARRANGEMENT OF THE MANUAL

The manual is divided into 11 major sections:

01 SERVICE TOOLS AND SERVICE PRODUCTS

02 MAINTENANCE

03 ENGINE

04 FUEL SYSTEM

05 ELECTRICAL

06 DRIVE TRAIN

07 STEERING/CONTROL SYSTEMS

08 SUSPENSION

09 BRAKES

10 TECHNICAL DATA

11 WIRING DIAGRAMS

Each section is divided in various subsections, and

again, each subsection has one or more division.

DS50

TM

..................................................... 7557

DS90

TM

..................................................... 7558

DS90 4-stroke .......................................... 7559

VI VMR2002_105_00_02AC.FM

LIST OF ABBREVIATIONS USED IN THIS MANUAL

A ampere

amp ampere

A•h ampere-hour

AC alternate current

BDC bottom dead center

BTDC before top dead center

°C degree Celsius

cm centimeter

DC direct current

°F degree Fahrenheit

fl. oz fluid ounce

ft foot

GRD ground

hal. halogen

I.D. inside diameter

IDI induction discharge ignition

imp. oz imperial ounce

in inch

k kilo (thousand)

kg kilogram

km/h kilometer per hour

kPa kilo pascal

L liter

LH left hand

lb pound

lbf pound (force)

m meter

MAG magneto

Max. maximum

Min. minimum

mL milliliter

mm millimeter

MPH mile per hour

N newton

N.A. not applicable

no. number

00.0 continuity

0.L overload (open circuit)

O.D. outside diameter

OHC Over head camshaft

OPT optional

oz ounce

P/N part number

PSI pound per square inch

PTO power take off

RH Right hand

RPM revolution per minute

TDC top dead center

U.S. oz ounce (United States)

USFD U.S. Forest Service

V volt

Vac volt (alternative current)

INTRODUCTION

VMR2002_105_00_02AC.FM VII

GENERAL INFORMATION

The information and component/system descrip-

tions contained in this manual are correct at time

of publication. Bombardier Inc. however, main-

tains a policy of continuous improvement of its

products without imposing upon itself any obliga-

tion to install them on products previously manu-

factured.

Due to late changes, it may have some differences

between the manufactured product and the de-

scription and/or specifications in this document.

Bombardier Inc. reserves the right at any time to

discontinue or change specifications, designs,

features, models or equipment without incurring

obligation.

ILLUSTRATIONS AND

PROCEDURES

Illustrations and photos show the typical construc-

tion of the different assemblies and, in all cases,

may not reproduce the full detail or exact shape of

the parts shown, however, they represent parts

which have the same or a similar function.

CAUTION: Most components of those vehicles

are built with parts dimensioned in the metric

system. Most fasteners are metric and must

not be replaced by customary fasteners or vice-

versa. Mismatched or incorrect fasteners could

cause damage to the vehicle or possible per-

sonal injury.

As many of the procedures in this manual are in-

terrelated, we suggest, that before undertaking

any task, you read and thoroughly understand the

entire section or subsection in which the proce-

dure is contained.

A number of procedures throughout the book re-

quire the use of special tools. Before commencing

any procedure, be sure that you have on hand all

the tools required, or approved equivalents.

The use of RIGHT and LEFT indications in the text,

always refers to driving position (when sitting on

vehicle).

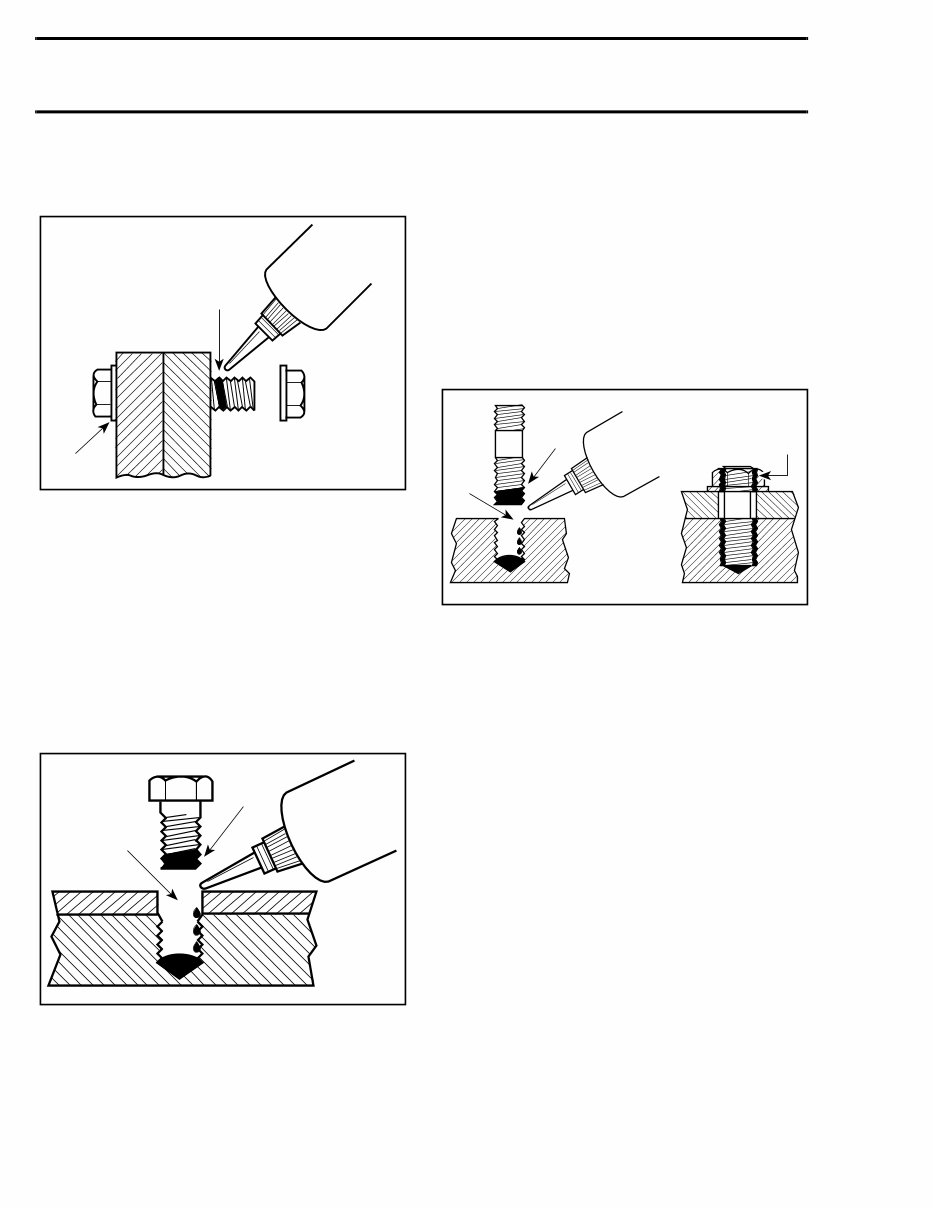

SELF-LOCKING FASTENERS

PROCEDURE

The following describes the most common appli-

cation procedures when working with self-locking

fasteners.

Use a metal brush or a screwtap to clean the hole

properly then use a solvent (Methyl-Chloride), let

act during 30 minutes and wipe off. The solvent

utilization is to ensure the adhesive works properly.

LOCTITE APPLICATION

PROCEDURE

The following describes the most common appli-

cation procedures when working with Loctite

products.

NOTE: Always use proper strength Loctite prod-

uct as recommended in this Shop Manual.

INTRODUCTION

VIII VMR2002_105_00_02AC.FM

Threadlocker

Uncovered Holes (bolts and nuts)

1. Apply here

2. Do not apply

1. Clean threads (bolt and nut) with solvent.

2. Apply Loctite Primer N (P/N 293 800 041) on

threads and allow to dry.

3. Choose proper strength Loctite threadlocker.

4. Fit bolt in the hole.

5. Apply a few drops of threadlocker at proposed

tightened nut engagement area.

6. Position nut and tighten as required.

Blind Holes

1. On threads

2. On threads and at the bottom of hole

1. Clean threads (bolt and hole) with solvent.

2. Apply Loctite Primer N (P/N 293 800 041) on

threads (bolt and nut) and allow to dry for 30 sec-

onds.

3. Choose proper strength Loctite threadlocker.

4. Apply several drops along the threaded hole and

at the bottom of the hole.

5. Apply several drops on bolt threads.

6. Tighten as required.

Stud in Blind Holes

1. On threads

2. On threads and in the hole

3. Onto nut threads

1. Clean threads (stud and hole) with solvent.

2. Apply Loctite Primer N (P/N 293 800 041) on

threads and allow to dry.

3. Put several drops of proper strength Loctite

threadlocker on female threads and in hole.

4. Apply several drops of proper strength Loctite

on stud threads.

5. Install stud.

6. Install cover, etc.

7. Apply drops of proper strength Loctite on un-

covered threads.

8. Tighten nuts as required.

A00A3LA

1

2

INTRODUCTION

VMR2002_105_00_02AC.FM IX

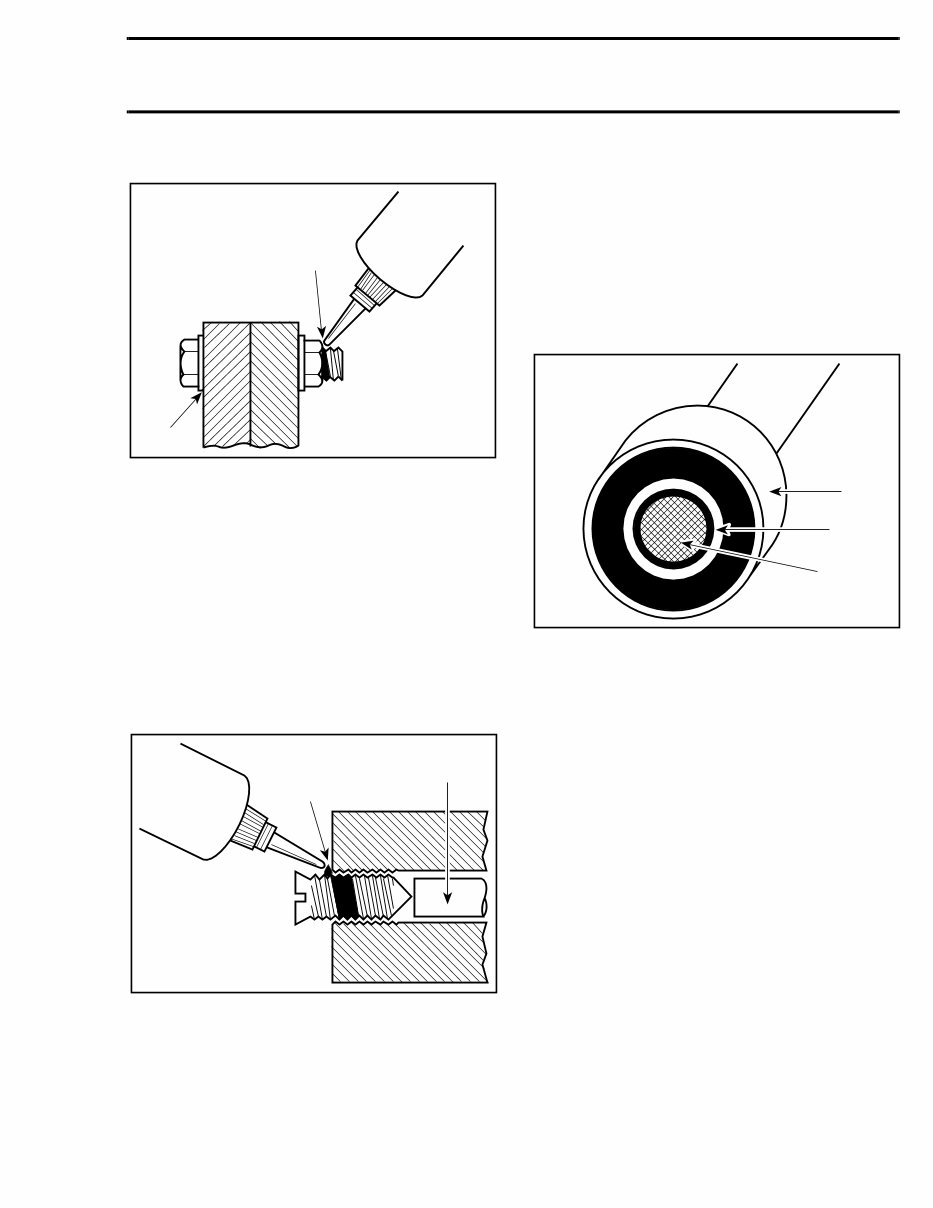

Preassembled Parts

1. Apply here

2. Do not apply

1. Clean bolts and nuts with solvent.

2. Assemble components.

3. Tighten nuts.

4. Apply drops of proper strength Loctite on bolt/nut

contact surfaces.

5. Avoid touching metal with tip of flask.

NOTE: For preventive maintenance on existing

equipment, retighten nuts and apply proper

strength Loctite on bolt/nut contact surfaces.

Adjusting Screw

1. Apply here

2. Plunger

1. Adjust screw to proper setting.

2. Apply drops of proper strength Loctite thread-

locker on screw/body contact surfaces.

3. Avoid touching metal with tip of flask.

NOTE: If it is difficult to readjust, heat screw with

a soldering iron (232°C (450°F)).

Mounting on Shaft

Mounting with a Press

1. Bearing

2. Proper strength Loctite

3. Shaft

Standard

1. Clean shaft external part and element internal

part.

2. Apply a strip of proper strength Loctite on shaft

circumference at insert or engagement point.

NOTE: Retaining compound is always forced out

when applied on shaft.

3. DO NOT use anti-seize Loctite or any similar

product.

4. No curing period is required.

Mounting in Tandem

1. Apply retaining compound on internal element

bore.

2. Continue to assemble as shown above.

A00A3OA

1

2

A00A3UA

1

2

3

INTRODUCTION

X VMR2002_105_00_02AC.FM

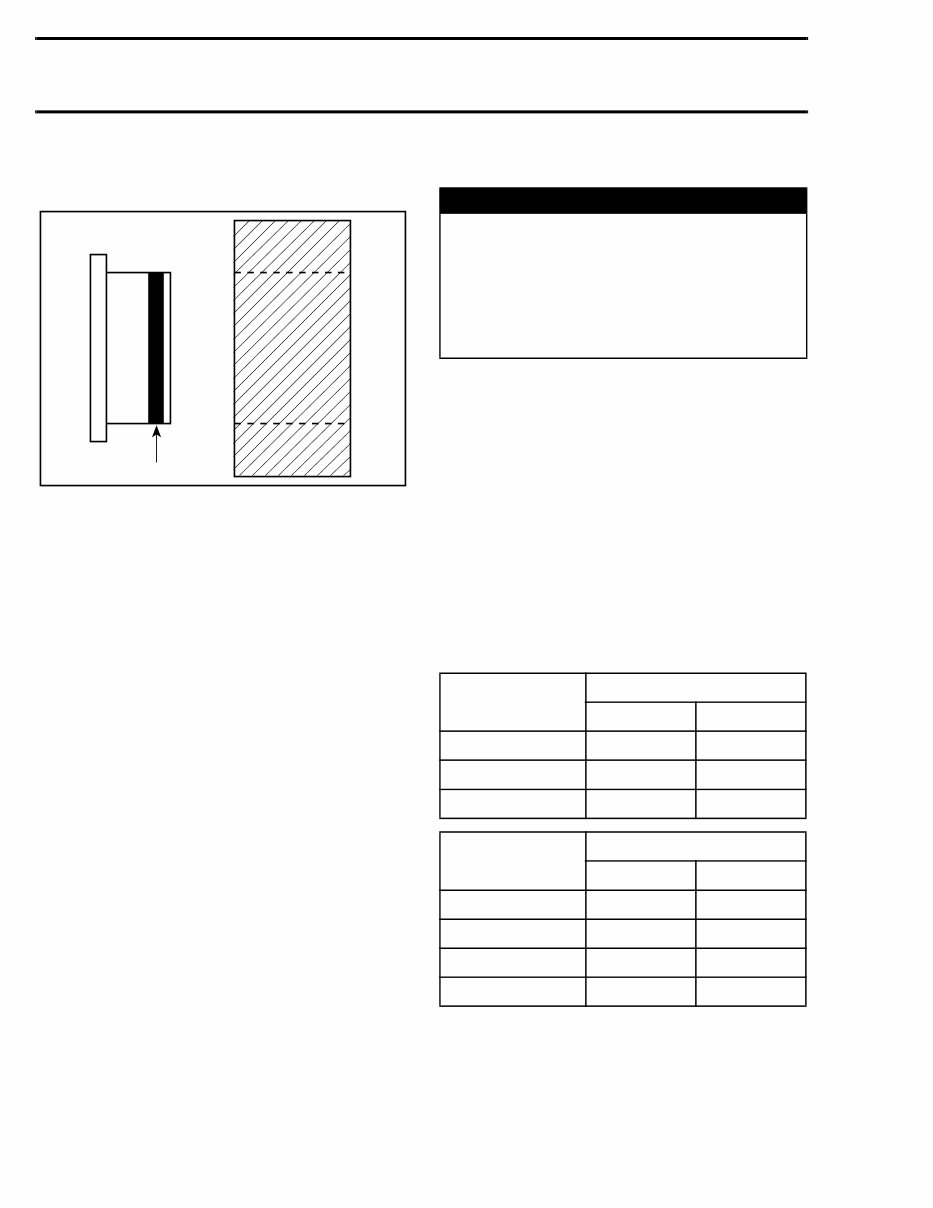

Case-In Components

Metallic Gaskets

1. Proper strength Loctite

1. Clean inner housing diameter and outer gasket

diameter.

2. Spray housing and gasket with Loctite Primer N

(P/N 293 800 041).

3. Apply a strip of proper strength Loctite on lead-

ing edge of outer metallic gasket diameter.

NOTE: Any Loctite product can be used here. A

low strength liquid is recommended as normal

strength and gap are required.

4. Install according to standard procedure.

5. Wipe off surplus.

6. Allow it to cure for 30 minutes.

NOTE: Normally used on worn-out housings to

prevent leaking or sliding.

It is generally not necessary to remove gasket

compound applied on outer gasket diameter.

TIGHTENING TORQUES

Tighten fasteners to torque mentioned in explod-

ed views and text. When they are not specified

refer to following table.The table also gives the

metric conversion.

In order to avoid a poor assembling, tighten

screws and bolts in accordance with the following

procedure:

1. Manually screw all screws, bolts and/or nuts.

2. Apply the half of the recommended torque value.

NOTE: When possible, always apply the torque

on nut.

3. Torque at the recommended torque value.

NOTE: Always torque screws, bolts and/or nuts in

a criss-cross sequence.

* TIGHTENING TORQUES FOR 8.8 GRADE BOLTS AND NUTS

A00A3VA 1

WARNING

Torque wrench tightening specifications

must strictly be adhered to.

Locking devices (ex.: locking tabs, elastic

stop nuts, self-locking fasteners, etc.) must

be installed or replaced with new ones where

specified. If the efficiency of a locking device

is impaired, it must be renewed.

BOLT OR NUT

SIZE

TIGHTENING TORQUE*

N•m lbf•in

M4 2 18

M5 4 35

M6 10 89

BOLT OR NUT

SIZE

TIGHTENING TORQUE*

N•m lbf•ft

M8 23 17

M10 48 35

M12 80 59

M14 135 100

INTRODUCTION

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 27 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

- Get comprehensive guidance for maintaining and repairing your 2002 Bombardier DS90 2-Stroke ATV with this detailed Service & Repair Manual.

- Includes in-depth instructions for maintenance, troubleshooting, and repairs, along with clear illustrations and exploded-view diagrams.

- Recommended for professional mechanics and DIY enthusiasts to ensure optimal performance and longevity of the ATV.

- Covers a wide range of tasks including engine servicing, carburetor adjustments, electrical system diagnostics, and chassis maintenance.

- Accessible in digital format for easy retrieval and efficient navigation on various devices such as PCs, tablets, and smartphones.

- Essential for keeping your 2002 Bombardier DS90 2-Stroke ATV in top condition for off-road adventures.

- Printable: Yes

- Language: English

- Compatibility: Compatible across a wide range of devices including PCs, Macs, smartphones, and tablets.

- Requirements: A PDF reader like Adobe Reader (free)