1983-1989 Yamaha G1 Golf Cart Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

YAMAHA

SERVICE MANUAL

@YAMAHA

GOLF CAR

GI-AM3

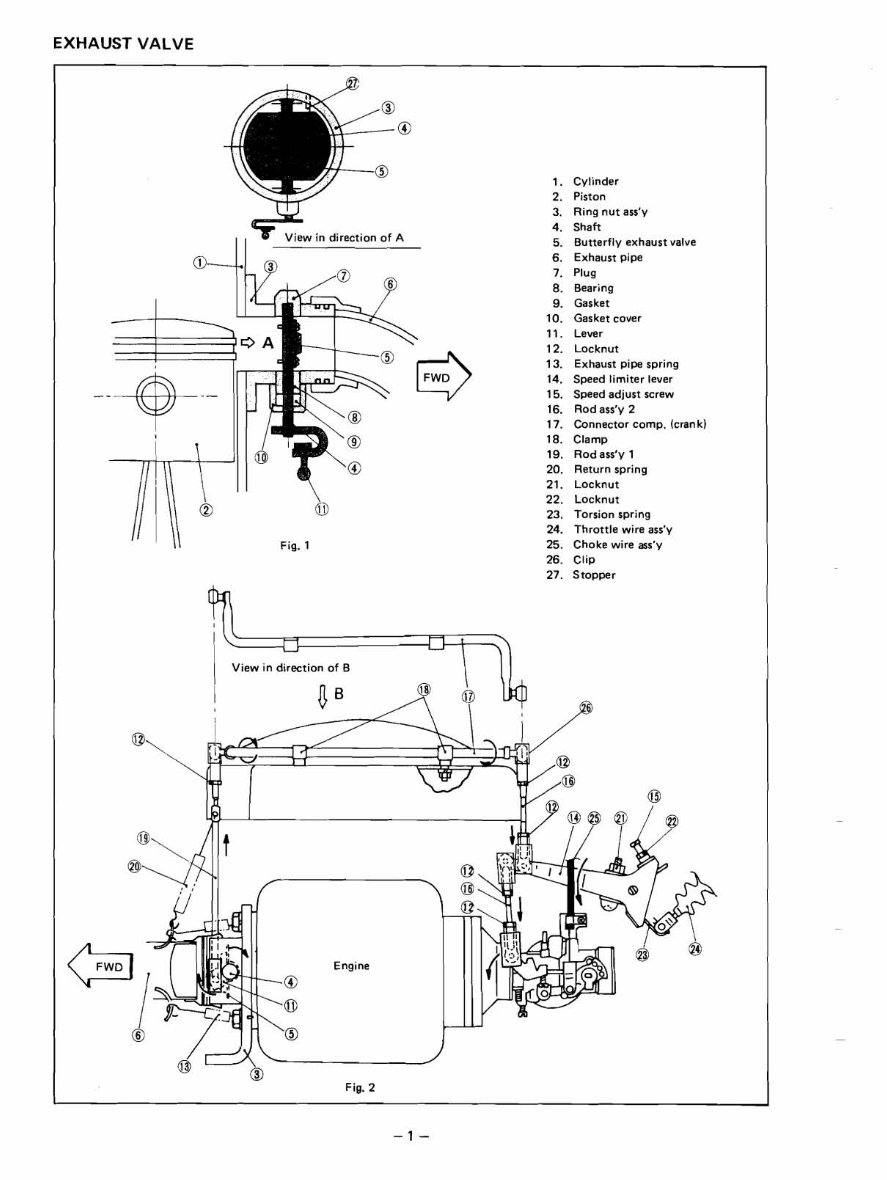

EXHAUST VALVE

Fig. 1

1. Cylinder

2. Piston

3. Ring nut ass'y

4. Shaft

View in direct~o of A

5. Butterfly exhaust valve

6. Exhaust plpe

7. Plug

8. Bear~n

9. Gasket

10. Gasket cover

11. Lever

12. Locknut

13. Exhaust pipe spring

14. Speed limiter lever

15. Speed adjust screw

16. Rod ass'y 2

17. Connector comp. (crank)

18. Clamp

19. Rod ass'y 1

20. Return spring

21. Locknut

22. Locknut

23. Torsion spring

24. Throttle wire ass'y

25. Choke wire ass'y

26. Cl~

27. Stopper

Fig. 2

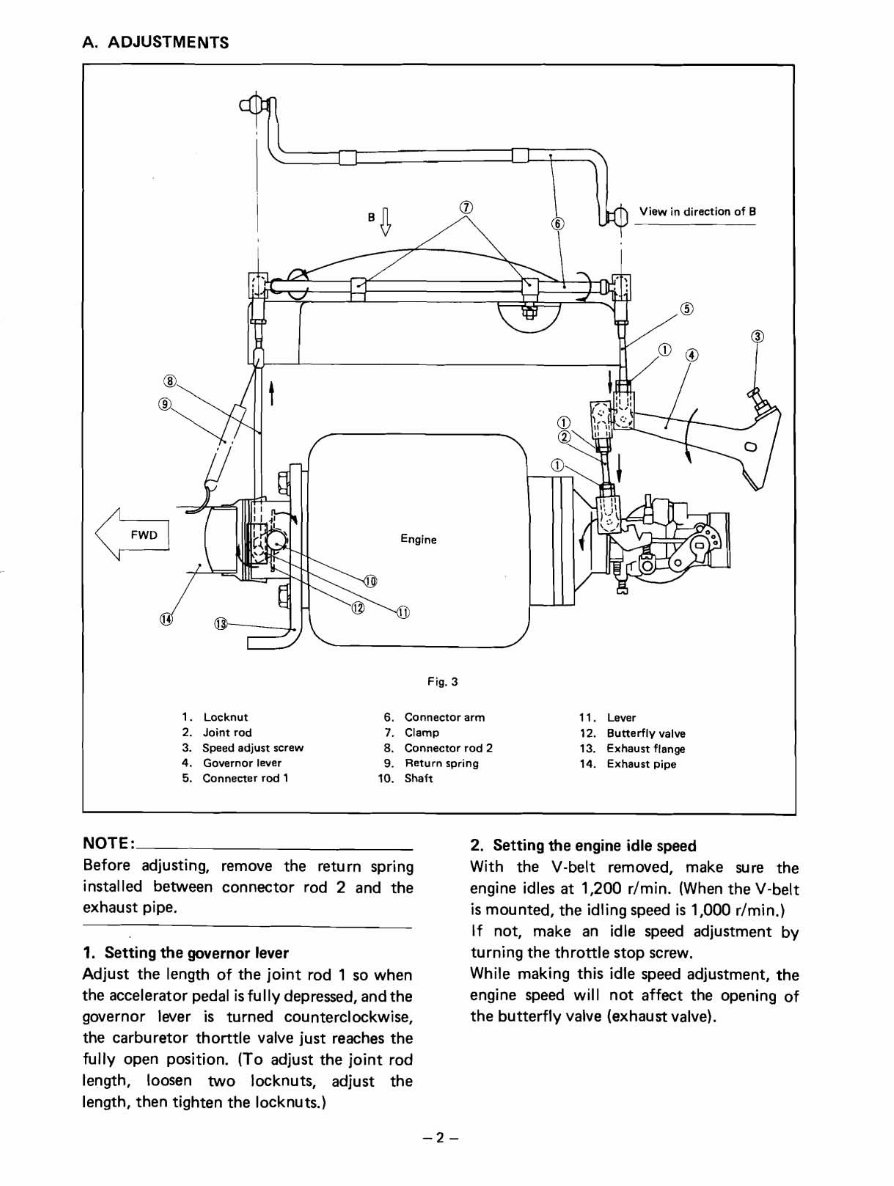

A. ADJUSTMENTS

View in direction of B

Fig. 3

1. Locknut 6. Connector arm 11. Lever

2. Joint rod 7. Clamp 12. Butterfly valve

3. Speed adjust screw 8. Connector rod 2 13. Exhaust flange

4. Governor lever 9. Return spring 14. Exhaust pipe

5. Connecter rod 1 10. Shaft

NOTE:

Before adjusting,

installed between

remove the return spring

connector rod 2 and the

exhaust pipe.

1. Setting the governor lever

Adjust the length of the joint rod 1 so when

the accelerator pedal is fully depressed, and the

governor lwer is turned counterclockwise,

the carburetor thorttle valve just reaches the

fully open position. (To adjust the joint rod

length, loosen two locknuts, adjust the

length, then tighten the locknuts.)

2. Setting the engine idle speed

With the V-belt removed, make sure the

engine idles at 1,200 rlmin. (When the V-belt

is mounted, the idling speed is 1,000 rlmin.)

If not, make an idle speed adjustment by

turning the throttle stop screw.

While making this idle speed adjustment, the

engine speed will not affect the opening of

the butterfly valve (exhaust valve).

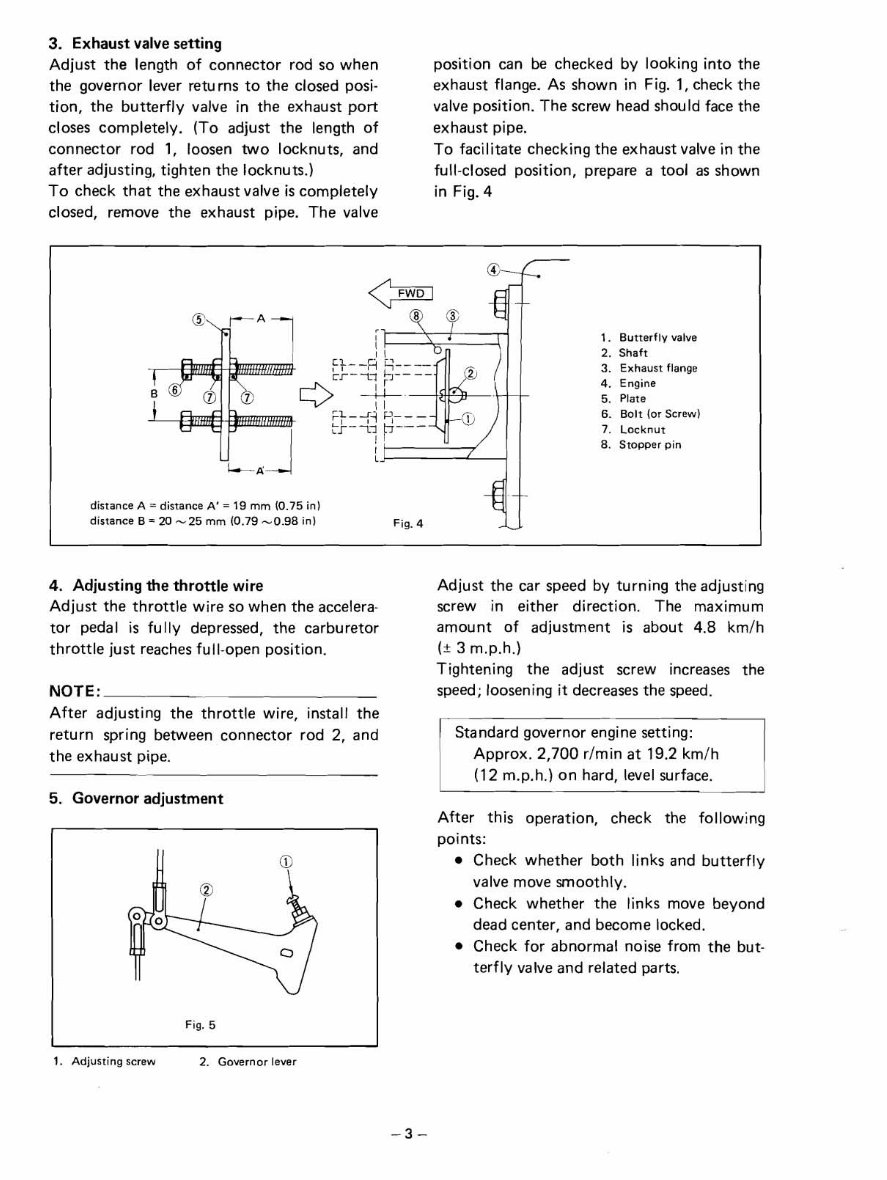

3. Exhaust valve setting

Adjust the length of connector rod so when

the governor lever returns t o the closed posi-

tion, the butterfly valve in the exhaust port

closes completely. (To adjust the length of

connector rod 1, loosen two locknuts, and

after adjusting, tighten the locknuts.)

To check that the exhaust valve is completely

closed, remove the exhaust pipe. The valve

position can be checked by looking into the

exhaust flange. As shown in Fig. 1, check the

valve position. The screw head should face the

exhaust pipe.

To facilitate checking the exhaust valve in the

full-closed position, prepare a tool as shown

in Fig. 4

1. Butterfly valve

2. Shaft

3. Exhaust flange

4. Engine

5. Plate

6. Bolt (or Screw)

7. Locknut

8. Stopper pin

distance A = distance A ' = 19 mm (0.75 in)

distance B = 20 - 25 mm (0.79 -0.98 in)

4. Adjusting the throttle wire

Adjust the throttle wire so when the accelera-

tor pedal is fully depressed, the carburetor

throttle just reaches fu II-open position.

NOTE:

After adjusting the throttle wire, install the

return spring between connector rod 2, and

the exhaust pipe.

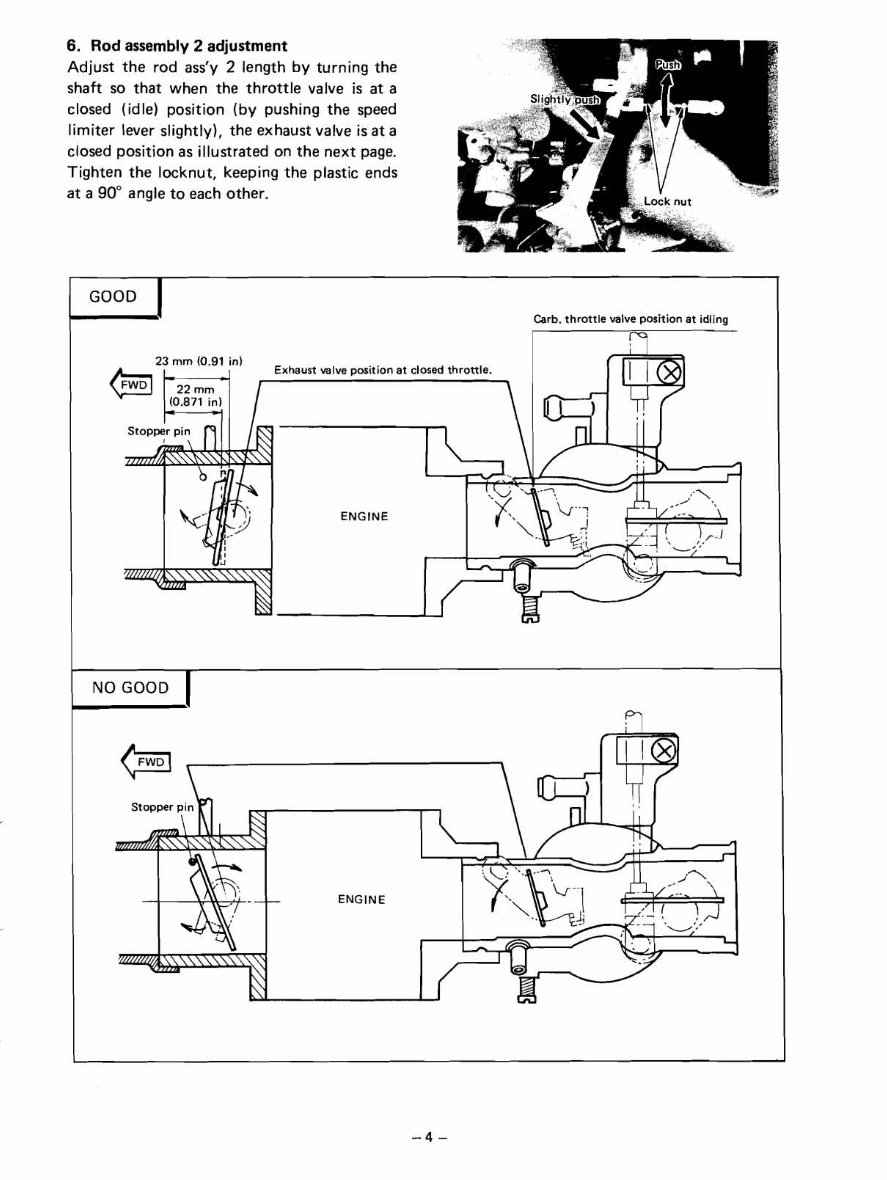

5. Governor adjustment

Fig. 5

Adjust the car speed by turning the adjusting

screw in either direction. The maximum

amount of adjustment is about 4.8 kmlh

(* 3 m.p.h.1

Tightening the adjust screw increases the

speed; loosening it decreases the speed.

Approx. 2,700 r/min at 19.2 kmlh

(12 m.p.h.) on hard, level surface.

After this operation, check the following

points:

Check whether both links and butterfly

valve move smoothly.

Check whether the links move beyond

dead center, and become locked.

Check for abnormal noise from the but-

terfly valve and related parts.

1. Adjusting screw 2. Governor lever

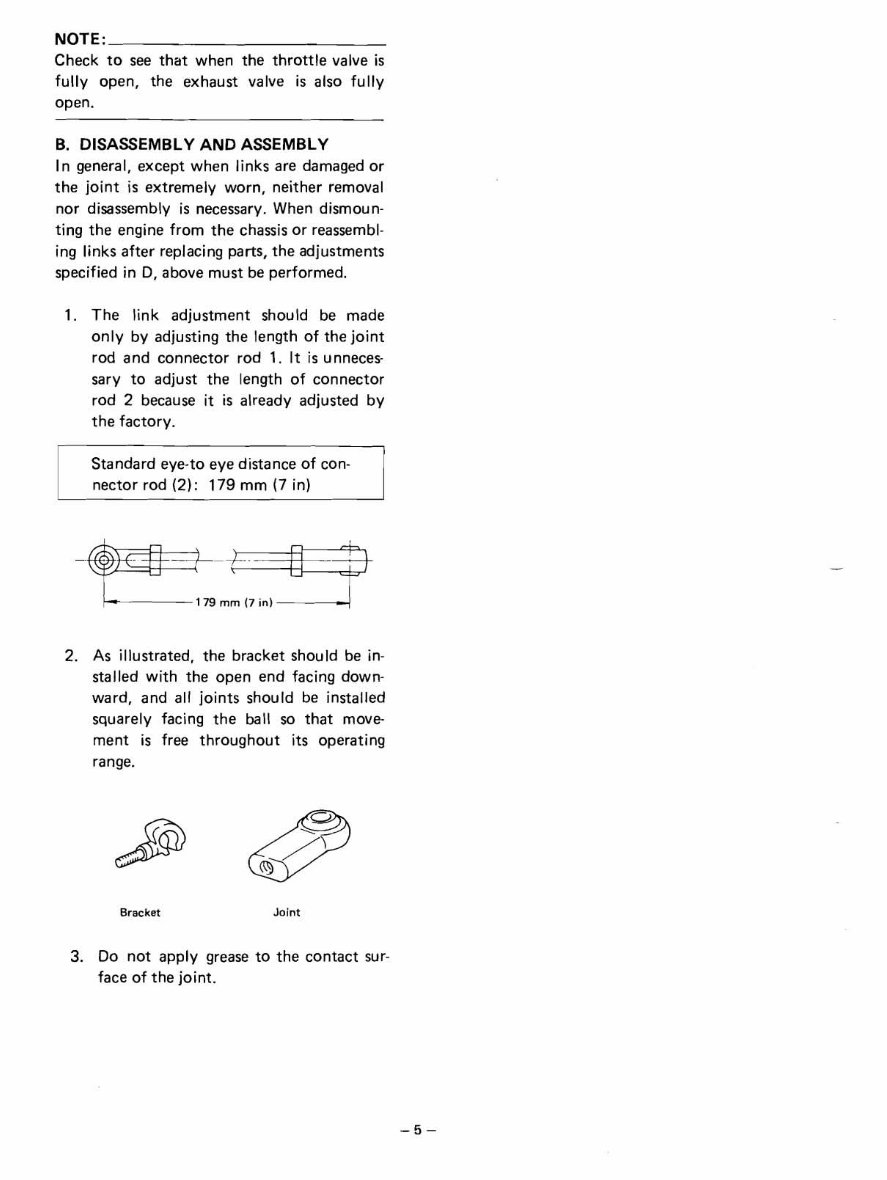

6. Rod assembly 2 adjustment

Adjust the rod ass'y 2 length by turning the

shaft so that when the throttle valve is at a

closed (idle) position (by pushing the speed

limiter lever slightly), the exhaust valve is at a

closed position as illustrated on the next page.

Tighten the locknut, keeping the plastic ends

at a 90" angle to each other.

GOOD

Carb. throttle valve position at idling

ENGINE

NOTE:

Check t o see that when the throttle valve is

fully open, the exhaust valve is also fully

open.

B. DISASSEMBLY AND ASSEMBLY

In general, except when links are damaged or

the joint is extremely worn, neither removal

nor disassembly is necessary. When dismoun-

ting the engine from the chassis or reassembl-

ing links after replacing parts, the adjustments

specified in D, above must be performed.

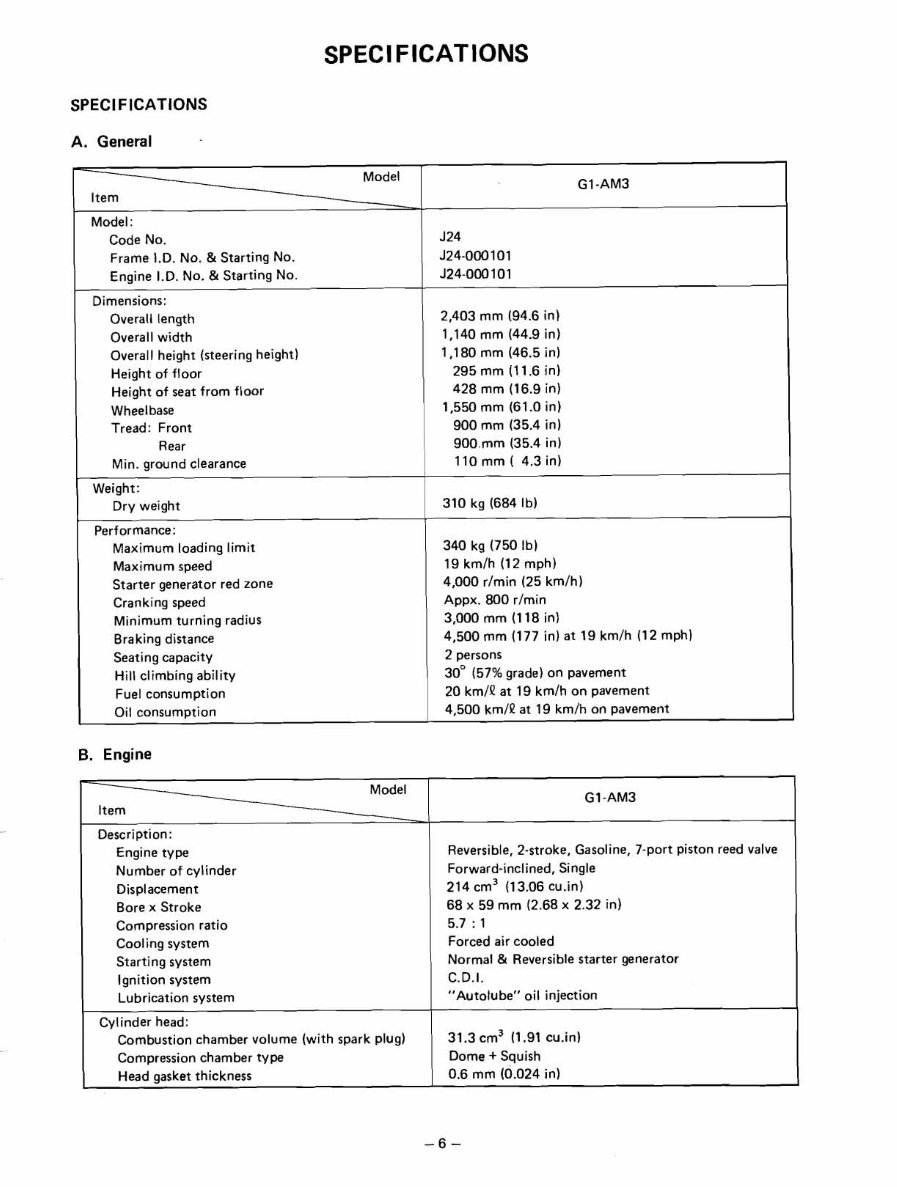

1. The link adjustment should be made

only by adjusting the length of the joint

rod and connector rod 1. It is unneces-

sary to adjust the length of connector

rod 2 because it is already adjusted by

the factory.

Standard eye-to eye distance of con-

nector rod (2): 179 mm (7 in)

2. As illustrated, the bracket should be in-

stalled with the open end facing down-

ward, and all joints should be installed

squarely facing the ball so that move-

ment is free throughout its operating

range.

Bracket Joint

3. Do not apply grease to the contact sur-

face of the joint.

SPECI FICATIONS

A. General

Weight:

Dry weight

Model

GI -AM3

Item

Performance:

Maximum loading limit

Maximum speed

Starter generator red zone

Cranking speed

Minimum turning radius

Braking distance

Seating capacity

Hill climbing ability

Fuel consumption

Oil consumption

Model:

Code No.

Frame I.D. No. & Starting NO.

Engine I.D. No. & Starting No.

Dimensions:

Overall length

Overall width

Overall height (steering height)

Height of floor

Height of seat from floor

Wheelbase

Tread: Front

Rear

340 kg (750 Ib)

19 kmlh (12 mph)

4,000 rlmin (25 kmlh)

Appx. 800 rlmin

3,000 mm (118 in)

4,500 mm (177 in) at 19 kmlh (12 mph)

2 persons

30" (57%grade) on pavement

20 kmlP at 19 km/h on pavement

4,500 km/P at 19 kmlh on pavement

J24

J24-000101

J24-000 101

2,403 mm (94.6 in)

1,140 mm (44.9 in)

1,180 mm (46.5 in)

295 mm (11.6 in)

428 mm (16.9 in)

1,550 mm (61.0 in)

900 mm (35.4 in)

900.mm (35.4 in)

6. Engine

Min. ground clearance 1 110 mm ( 4.3 in)

-

Model

-

.

Description:

Engine type

Number of cylinder

Displacement

Bore x Stroke

Compression ratio

Cooling system

Starting system

Ignition system

Lubrication system

Cylinder head:

Combustion chamber volume (with spark plug)

Compression chamber type

Head gasket thickness

G1 -AM3

Reversible, 2-stroke, Gasoline, 7-port piston reed valve

Forward-inclined, Single

214 cm3 (13.06 cu.in)

68 x 59 mm (2.68 x 2.32 in)

5.7 : 1

Forced air cooled

Normal & Reversible starter generator

C.D.I.

"Autolube" oil injection

31.3 cm3 (1.91 cu.in)

Dome + Squish

0.6 mm (0.024 in)

Material

Bore size

Taper limit

Out of round limit

Model

Item

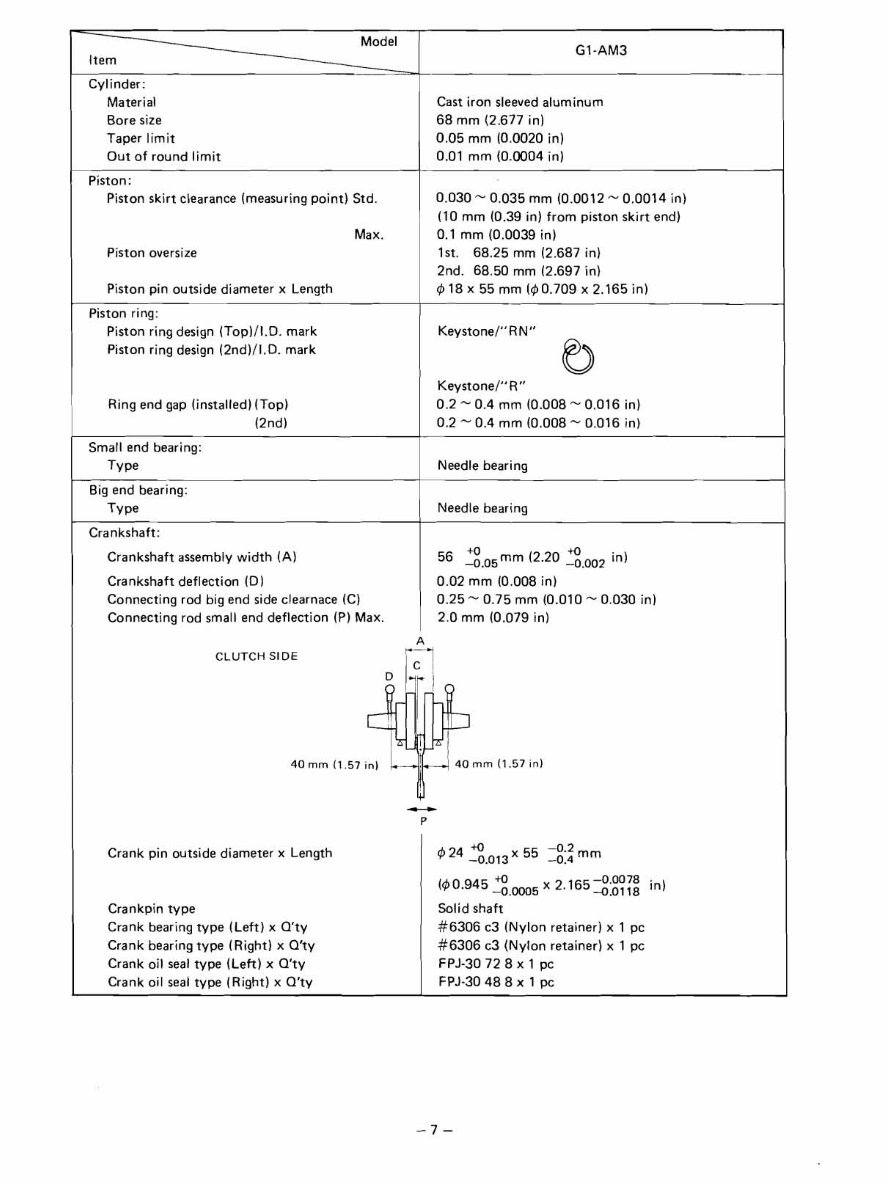

Cylinder:

Cast iron sleeved aluminum

68 mm (2.677 in)

0.05 mm (0.0020 in)

0.01 mm (0.0004 in)

GI-AM3

Piston:

Piston skirt clearance (measuringpoint) Std.

Max.

Piston oversize

Piston pin outside diameter x Length

Piston ring:

Piston ring design (Top)/l.D. mark

Piston ring design (2nd)ll.D. mark

Ring end gap (installed)(Top)

(2nd)

0.030 - 0.035 mm (0.0012 - 0.0014 in)

(10 mm (0.39 in) from piston skirt end)

0.1 mm (0.0039 in)

1st. 68.25 mm (2.687 in)

2nd. 68.50 mm (2.697 in)

418x 55 mm (40.709 x 2.165in)

Kevstonel" RN"

Keystone1"R"

0.2 - 0.4 rnrn (0.008 - 0.016 in)

0.2 - 0.4 mm (0.008 - 0.016 in)

I Type I Needle bearing

Small end bearing:

Big end bearing:

Crankshaft: I

Needle bearing

Crankshaft assembly width (A)

Crankshaft deflection (0

Connecting rod big end side clearnace (C)

Connecting rod small end deflection (P Max.

CLUTCH SIDE

40 rnrn

+O

56 TE.05mm (2.20 -0.002 in)

0.02 mm (0.008 in)

0.25- 0.75 rnm (0.010 - 0.030 in)

2.0 mm (0.079 in)

Crank pin outside diameter x Length

(1.57 in)

x 2.1652: in)

1 00'945-0.0005

Crankpin type

Crank bearing type (Left) x Q'ty

Crank bearing type (Right) x Q'ty

Crank oil seal type (Left) x Q'ty

Crank oil seal type (Right) x Q'ty

Solid shaft

#6306 c3 (Nylon retainer) x 1 pc

#6306 c3 (Nylon retainer) x 1 pc

FPJSO 72 8 x 1 PC

FPJ-30 48 8 x 1 PC

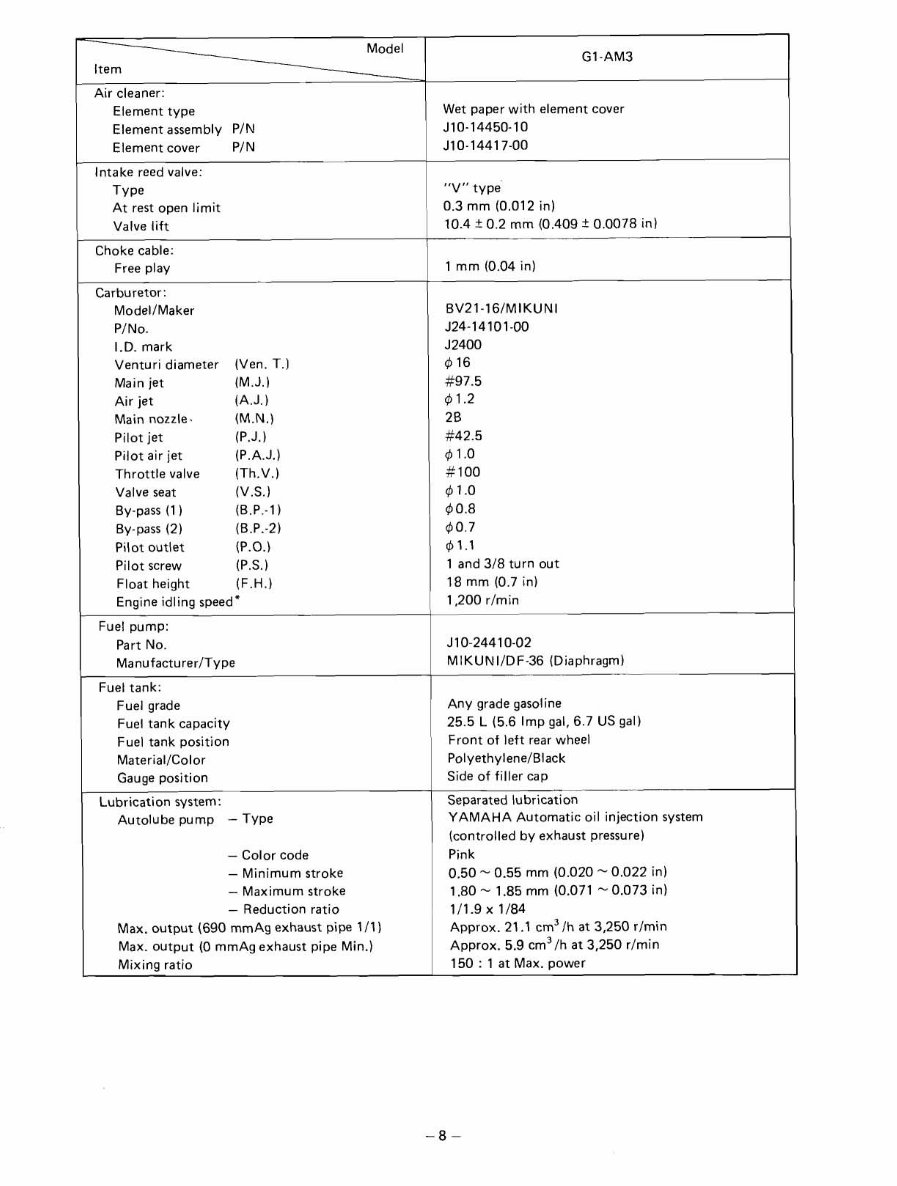

Air cleaner:

Model

-

Element type

Element assembly PIN

Element cover PIN

Intake reed valve:

GI -AM3

Type

At rest open limit

Valve lift

Choke cable:

Free play

Carburetor:

ModelIMaker

PINO

I.D. mark

Venturi diameter (Ven. T.)

Main jet (M.J.)

Air jet (A.J.)

Main nozzle. (M.N.)

Pilot jet (P.J.)

Pilot air jet (P.A.J.)

Throttle valve (Th.V.)

Valve seat (V.S.)

By-pass (1 ) (B.P.-1

By-pass (2) (B.P.-2)

Pilot outlet (P.O.)

Pilot screw (P.S.)

Float height (F.H.)

Engine idling speed"

Fuel pump:

Part No.

ManufacturerIType

Fuel tank:

Fuel grade

Fuel tank capacity

Fuel tank position

MaterialIColor

Gauge position 1

Lubrication system:

Autolube pump - Type

- Color code

- Minimum stroke

- Maximum stroke

- Reduction ratio

Max. output (690 mmAg exhaust pipe 111)

Max. output (0 mmAg exhaust pipe Min.)

Mixing ratio

Wet paper with element cover

J10-14450-10

J10-14417-00

"V" type

0.3 mm (0.012 in)

10.4 f 0.2 mm (0.409 f 0.0078 in)

1 mm (0.04 in)

BV21-161MIKUN

J24-14101-00

J2400

4 16

#97.5

41.2

2B

#42.5

4 1 .o

# 100

41.0

4 0.8

$0.7

41.1

1 and 318 turn out

18 mm (0.7 in)

1,200 rlmin

J10-24410-02

MIKUNIIDF-36 (Diaphragm)

Any grade gasoline

25.5 L (5.6 Imp gal, 6.7 US gal)

Front of left rear wheel

PolyethyleneIBlack

Side of filler cap

Separated lubrication

YAMAHA Automatic oil injection system

(controlled by exhaust pressure)

Pink

0.50 - 0.55 mm (0.020 - 0.022 in)

1.80 - 1.85 mm (0.071 - 0.073 in)

111.9 x 1/84

Approx. 21 . cm3/h at 3,250 rlmin

Approx. 5.9 cm3/h at 3,250 r/min

150 : 1 at Max. Dower

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

Viewed 73 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

Get the Yamaha G1 Golf Cart 1983-1989 Service Repair Manual for comprehensive factory service and owners manual. This manual provides fast access to essential technical information, allowing you to work on your golf cart yourself and save money. It is compatible with all Windows and Mac operating systems. Securely purchase using PayPal or credit card.