753-704 Piper navajo PA31 service manual PA31-300 / 325

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

PIPER

AIRPLANE

SERVICE MANUAL

CARD 1 OF 5

PA-31

PA-31-300

PA-31-325

PIPER AIRCRAFT CORPORATION

(PART NUMBER 753 704)

lAl

PIPER NAVAJO SERVICE MANUAL

AEROFICHE EXPLANATION AND REVISION STATUS

Service manualinformation incorporated in this set of Aerofichecards is arranged in accordance with

general specifications of Aeroficheadoptedby GeneralAviation Manufacturer'sAssociation. Information

compiled in this Aerofiche service manual is kept current by revisions distributed periodically. These

revisions supersede all previous revisions and are complete Aerofichecard replacements and supersede

Aerofichecards of samenumberin set, exceptas notedbelow.

Identification of revised material: Revised text and illustrations are indicatedby a black vertical line

along the left-hand margin of the frame, opposite revised,or added material.Revision lines indicate only

current revisions with changes and additionsto existingtext and illustrations.Changesin capitalization,

spelling, punctuation, indexing.physicallocation of materialor completepage additionsare not identified

by revisionlines.

Revisions to service manual 753 704 issued October 1, 1966 are as follows:

Revisions Publication Date Aerofiche CardEffectivity

ORG661001

CR720707

CR791012

PR800923

PR810311

P R8 10924

PR820129

PR821115

PR831012

PR840302

PR840503

IR860429

IR860921

IR870505

IR871009

IR900313

PR940218

IR941202

October 1, 1966

July 7, 1972

October 12, 1979

September 23, 1980

March 11. 1981

September 24, 1981

January 29, 1982

November 15,1982

October 12, 1983

March 2, 1984

May 3,1984

April 29,1986

September 21, 1986

June 12, 1987

June 15, 1988

Marchl3, 1990

February 18, 1994

December 2, 1994

1, 2, 3,4 and5

1, 2, 3,4 and 5

1, 2, 3,4 and5

1, 2, 3,4 and5

1,2, 3,4 and5

1,2, 3,4and5

1,2, 3,4and5

1,2, 3,4 and5

1

1

1

1

2

1

1, 2, 3,4 and 5

1

INTERIM REVISION

REVISIONS APPEAR IN THE INTRODUCTION AND

SECTION III OF CARD 1. PLEASE DISPOSE OF YOUR

CURRENT CARD 1, AND REPLACE IT WITH THE

REVISED CARD.

Consult the Customer Service Information Aerofiche for current revision dates for this manual.

Revised: February18, 1994

Interim Revision: December 2, 1994

1A2

TABLE OF CONTENTS

AEROFICHE CARD NO. 1 GRID NO.

I

III

IV

V

INTRODUCTION ........................

HANDLING AND SERVICING ...........

INSPECTION ............................

STRUCTURES ...........................

SURFACE CONTROLS ..................

...........

...........

...........

...........

...........

1A17

1A20

1D9

1E11

1H20

AEROFICHE CARD NO. 2

VI

VII

VIII

VIIIA

VIIIB

HYDRAULIC SYSTEM...................

LANDING GEAR AND BRAKE SYSTEM .

POWER PLANT (PA-31 Turbo)...........

POWER PLANT (PA-31-300) ............

POWER PLANT (PA-31-325) ............

...........

...........

...........

...........

...........

2A9

2E4

2H6

2K8

2K18

AEROFICHE CARD NO. 3

IX

X

FUEL SYSTEM ..........................

INSTRUMENTS .........................

...........

...........

3A8

3C21

XI

AEROFICHE CARD NO. 4

ELECTRICAL SYSTEM ..................

AEROFICHE CARD NO. 5

ELECTRONICS ..........................

HEATING AND VENTILATING...........

ACCESSORIES AND UTILITIES .........

4A7

XII

XIII

XIV

5A9

5B3

5E1

1A3

INTENTIONALLY

LEFT BLANK

PIPER NAVAJO SERVICE MANUAL

LIST OF ILLUSTRATIONS

Figure

Aerofiche

Grid No.

2-1. Three-View of Navajo .................. ......... ... ................ 1A23

2-2. Station Reference Lines ..................... .......... ................. . B4

2-3. Access Plates and Panels, Fuselage Interior ................................. 1B7

2-4. Access Plates and Panels. Fuselage and Empennage ................ ............ 1B8

2-5. Access Plates and Panels. Wings ............................................. B9

2-5a. Torque Wrench Formula ........................... ..... .......... ..... 1B13

2-6. Jacking Arrangements ...................................................... 1B14

2-7. Weighing the Airplane ................................................... 1

2-8. Leveling Longitudinally .............................................. IB15

2-9. Leveling Laterally ........................................ ................. 1

2-10. Tow Turn Limits Indicator ........................................ ......... B17

2-11. Service Points ............................................................ 1B19

2-12. Servicing Landing Gear Shock Struts ........................................ IB22

2-12a. Tire Balancer ............................................................. 1C1

2-13. Lubrication Chart (Landing Gear. Main) ............. ........................ 1C10

2-13a. Lubrication Chart (Landing Gear, Nose) .................................... ICII

2-13b. Lubrication Chart (Control System) ..... ......... ................ ............ 1C12

2-13c. Lubrication Chart (Control System) (cont.) ................................... 1C13

2-13d. Lubrication Chart (Power Plant. Propeller and Cowl Flap) ..................... IC14

2-13e. Lubrication Chart (Doors and Seats) ........................................ IC15

2-14. Fabricated Jack Stand for Piper Jack, Part No. 18338-00 ....................... 1C19

2-15. Fabricated Tail Stand ......................... ............................. 1C20

2-16. Removal of Cherrylock Rivets ............................................... IDI

2-17. Identification of Aircraft Fluid Lines .......................................... 1D2

3-1. Wing Flap Transmission Inspection .................... ....................... ID12

3-2. Wing Flap Actuator Cable - 100 Hour Inspection .............................. ID13

3-2a. Wing Flap Actuator Cable - 500 Hour Inspection ............................. ID14

3-3. Friction Reduction in Wing Flap System ................................... ............... 1D18

3-4. Wing Flap Motor.......................................................... 1D19

3-5. Fuel Selector and Crossfeed Valve Control Cables ................... .......... ID21

3-6. Inspection of Aileron Sprocket and Chain .................................... 1D22

4-1. Landing Light ............... .................................... .......... IE16

4-2. Aileron and Flap Installation ................................................ 1

4-3. Methods of Blocking Trim Cables ...........................................

1

4-4. Fuselage Cradle ...........................................................

1

4-5. Wing Installation .......................................................... 1

4-6. Empennage Installation .....................................................

1F3

4-7 Windshield Installation (Standard) ........................................... IFII

4-8. Windshield Installation (Heated) ............................................. 1

4-9. Windshield Wiper ........................................................

IF15

4-10. Side Window Installation (Typical) ......................................... IF17

4-11. Cabin Entrance Door Latch Assembly ....................................... 1

4-12. Nacelle Wing Lockers ...................................................... 1F23

Revised: 3/2/84

1A5

PIPER NAVAJO SERVICE MANUAL

LIST OF ILLUSTRATIONS

(cont.)

Figure

Aerofiche

Grid No

4-13 Cargo Door.................................................

IGI

4-14. Pilot Door.......... ...............................................

1G

4-15. Aileron Balancing.1G7

4-15. Aileron Balancing ......................................................... IG7

4-16. Elevator Balancing .... ............................................

1G8

4-17 Elevator Trim Weight Installation ............................................

IG10

4-18. Elevator Trim Weight Installation (Without Wing Lockers) .................. .. .. 1G11

4-19. Elevator Trim Weight Installation

(With Wing Lockers) .........................

IGII

4-20. Elevator Friction Measurement.........................................

1G

4-21. Rudder Balancing.1G14

4-1. Rudder Balancing .........................................................

1G14

4-22. Balancing Rudder ..........................................................

1G15

4-23. Balancing Rudder .......................................................

IG16

4-24. Empennage

and Nacelle Skin Material and Thickness ...........................

1G17

4-25

Fuselage and Wing Skin Material and Thickness ...............................

1G19

4-26. Typical Access Holes .........

1G

4-27 Installation of Balance Weight Anchor Nut. Elevators P N 40140-00

and P N 40140-01

1G22 and P N 40140-01 ........................................................

1G22

4-28. Installation of Balance Weight Anchor Nut. Elevators P N 43757-00

and P N 43757-01 ..........................................

1G24

4-29 Installation of Rudder

Balance Weight Anchor Nut .............................

1H1

4-30.

Ballast Weight Lifting Handle (PA-31-300) .....................................

1H2

4-31 Surface Scratches Abrasions or Ground-In-Dirt ...................... .... 1H7

4-32. Deep Scratches. Shallow

Nicks and Small Holes ...............

1H

4-33.

Mixing of Epoxy Patching Compound .......................................

1H8

4-34. Welding Repair Method..............................

1H8

4-35 Repairing of Cracks.... ..... .. 1H10.. ...........

1

4-36. Various Repairs ................ 1H11

4-37 Repair of Stress Lines ................

1

4-38. Repair of Impacted Damage .................................................

1

4-39 Installation of Radome Erosion Shield .......................

H 17

4-40 Wing,Front Spar Attachment Bulkhead Repair ................................

1H

5-1 Control Column Installation .......................................

114

5-1a. Correct Method of Installing Rod End Bearings ................................

5-2. Ailcron and Aileron Trim Controls ...........

5-3. Installation of Bellcrank R in Tool.......................................

1114

5-4. Installation of Aileron Rigging Tool ..................................

. . 111

5-5 Elevator and Eleator Trim Contols...........................................

1121

5-6. Installation of Elevator Rigging Tool .......................................

5-7 Elevator Travel Stops .......................................

.

11

5-

7

a. Safety Wiring Control Surface Stops ...................................

. 1124

5-8. Methods

of Blocking Trim Cables ..............

1

5-8a. Cable Routing on Elevator Trim Sero ...............................

1J4

5-9 Rudder Pedal Installation ...............................................

....

5-10.

Rudder and Rudder Trim Controls ........................................

1

5-11 Clamping Rudder Pedals in Neutral Position ...................................

1J13

5-12. Installation of Rudder Rigging Tool

5-12. Installation of Rudder Rigging Tool .......................................... 1G13

5-13. Trim Screw Assembly 5-13. Trim Screw Assembly .......................................................

1J13

5-14. Control Pedestal.............

1J18

Revised: 3/2/84

1A6

PIPER NAVAJO SERVICE MANUAL

LIST OF ILLUSTRATIONS (cont.)

Figure Aerofiche

Grid No.

5-15.

5-16.

5-17

5-18.

5-19.

5-20.

5-21

5-23.

5-24.

5-25.

5-26.

5-26a.

5-26b

5-27.

5-28.

5-29

6-1

6-2.

6-3.

6-4.

6-5.

6-6.

6-7

6-8.

6-9.

6-10.

6- 11

6-12.

6-13.

6-14.

6-15.

6-16.

6-17

6-18.

6-19

6-20.

6-21.

6-22.

6-23.

6-24.

6-25.

6-26.

6-27.

Flap Controls (Piper System) ................................................

Flap Circuit Schematic (Dukes System)........................................

Flap Rigging Check ........................................................

Flap System Diagram (Calco) ................................................

Motor Assembly. Exploded View .............................................

Flap Controls (Calco System) ................................................

Deleted ...................................................................

Deleted ...................................................................

Deleted . . . ...........................................

Deleted ...................................................... ............

Flap Rigging Adjustments ...................................................

Use of Flap Rigging Tool ....................................................

Amplifier - Electrical Schematic (Calco) P N 8482 .............................

Amplifier - Electrical Schematic (Calco) P N 8502M I ..........................

IJ20

IJ24

IKI

IK3

IK5

IK8

IK16

1K16

1KI8

1K21

1L 15

Fabricated Bellcrank Rigging Tool ..........................

Fabricated Aileron - Elevator Rigging Tool ..................

Fabricated Rudder Rigging Tool ...........................

Schematic Diagram of Hydraulic System (Ozone 2930-1) ......

Schematic Diagram of Hydraulic System (Ozone 2930-3) ......

Schematic Diagram of Hydraulic System (Ozone 2930-5 and -7)

or (Wiebel 2135-1 and -3)................................

Schematic of Power Pack Electrical S\stem ..................

Power Pack Installation (Ozone 2930-1) .....................

Power Pack Installation (Ozone 2930-3) .....................

Power Pack Installation (Ozone 2930-5 and -7) or (Wiebel 2135-

Identification of Power Pack ...............................

Location of Power Pack Components (Ozone) ................

Hydraulic Power Pack (Ozone 2930-1) ......................

Hydraulic Power Pack (Ozone 2930-3. -5 and -7) .............

Power Pack Manifold (Ozone) .............................

Power Pack Handle Release (Ozone) ....... ................

Safetying Control Arms (Ozone) ............................

Timing of Selector Spool (Ozone). ..........................

Handle Release Adjustment (Ozone) ........................

Location of Power Pack Components (Wiebel Tool) ..........

Hydraulic Power Pack (Wiebel Tool). .................

Power Pack Manifold (Wiebel Tool) ........................

Power Pack Handle-Release Mechanism (Wiebel Tool) ........

Safetying Control Arm (Wiebel Tool) ......................

Indexing of Selector Spool (Wiebel Tool) ....................

Handle Release Adjustment (Wiebel Tool) ...................

Landing Gear Selector Mechanism. Serial Nos. 31-5 thru 31-511

Landing Gear Selector Mechanism. Serial Nos. 31-512 and up..

Hand Pump (Ozone)......................................

Hand Pump (Wiebel Tool) .................................

.................

. . .. .. ...

. . . . . . . .

. . .. .. ...

. . .. .. ...

..........

..................

. . . . . . . . . . . . . . . . .

...................

..............

...................

. . . . . . . . . . . . . . . . . .

...................

...................

..................

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

11.16

1l.17

2A17

2A18

2A19

2A20

2A21

2A22

2A23

2B13

2B16

2B21

2B22

2Cl

2C1

2C4

2C9

2C I

2C14

2C15

2C17

2C21

2C 24

2D2

2D5

Revised: 3/2/84

1A7

PIPER NAVAJO SERVICE MANUAL

LIST OF ILLUSTRATIONS

(cont.)

Aerofiche

Figure

Grid No.

6-28.

Hydraulic System Installation ........ ......................................................

2D6

6-29.

Gear Actuating Cylinder (Ozone) ........................................................................................

2D8

6-3 0.

Gear Actuating Cylinder (Wiebel Tool)...............................................................2D10

6-31.

Gear Door Actuating Cylinder (Ozone) ....... ..........................................

2D12

6-32.

Gear Door Actuating Cylinder (Wiebel Tool)......................................................15

6-33. Hydraulic Filter .......................................................................................

2D16

6-34. Hydraulic Pum p..............................................................................................................

2D19

6-35.

Power Pack Test Harness Schematic.....................................................................................

2D23

7-1.

Nose Gear Oleo Strut Assembly ........ ...........................................................

E8

7-2. Nose Landing Gear Installation...........................................

................................ 2E17

7-3.

Clamping Rudder Pedals in Neutral Position.............................................................................2E22

7-4.

Rudder Pedals Neutral Angle ....................................................................................

2E22

7-5. Aligning Nose Gear. .............................................

2E22

7-6.

Main Gear Oleo Strut Assembly ................................................................................................

2F

7-6a.

Correct Method of installing Rod End Bearings............ ...............................................

2F4

7-7.

Main Landing Gear Installation (Left) ............................................................................

2F7

7-8.

Actuator Cylinder Lock Installation...........................................................................................

2F

7-9. Aligning Main Gear .......... ...............................................................................................

2F12

7-10.

Landing Gear Circuit Diagram (S/N 31-2 to 31-184 Inc.) ...........................................

2F16

7-10a.

Landing Gear Circuit Diagram (S/N 31-185 and up) .............................................

2F17

7-11.

Adjusting Main Gear Down Light Switch ............................................................................

2F18

7-12.

Gear Warning Switches Installation...........................................

................. 2F20

7-13. Nose W heel Assembly ................................................................

7-14. Main W heel Asse m bly.....................................................................................2F24

7-15. Brake Installation ..................................................................................................

2G

7-16.

W heel Brake Assembly (30-68 and 30-68A)...........................................

........ ... 2G3

7-16a.

Removal and Installation of Anchor Bolts...............................................................................2G4

7-16b. Wheel Brake Assembly (30-95 and 30-95A ......................................

2G5

7-17.

Brake Master Cylinder Assembly ..............................................................................................

2G8

7-18.

Parking Brake Valve Assembly ...........................................................................................

2G10

7-19. Bleeding Brake ................... ...........................................................................

2G I

7-19a. Nose Gear Wear Limits .. . ......................................................................

2G12

7-19b. Main Gear Wear Limits ............................................................................................

2G16

7-20.

Fabricated Tool, Checking Nose Wheel Alignment ...............................................

2H2

7-21.

Fabricated Tool, Checking Nose Gear Drag Link Travel .............................................. 2H3

7-22.

Fabricated Tool, Checking Main Gear Side Brace Link Travel ...............................................

2H4

7-23.

Fabricated Tool, Checking Main Gear Toe-in Adjustment ...............................................

2H5

8-1. Engine Cowling ........................................................................................................

12

8-2.

Cowl Flap Transmission and Sender Assembly.....................................................................

2H14

8-3. Propeller Installation .........................................................................................................

2H17

8-4.

Typical Nicks and Removal Method ...........................................................................

2H18

8-5. Propeller Governor ...................................................................................................

2H22

8-6. Engine Installation.......................................................................................211

8-7.

Schematic Diagram of Turbocharger System...............................................

................. 217

8-7a.

Turbocharger Installation (PA-310-325) ....... .............................................

218

8-7b. Exhaust W tegate....................................................................................................................2I11

8-8. Fuel Injector ...............................................................................................................................

2117

Revised: 2/18/94

LANDING GEAR AND BRAKE SYSTEM

1A8

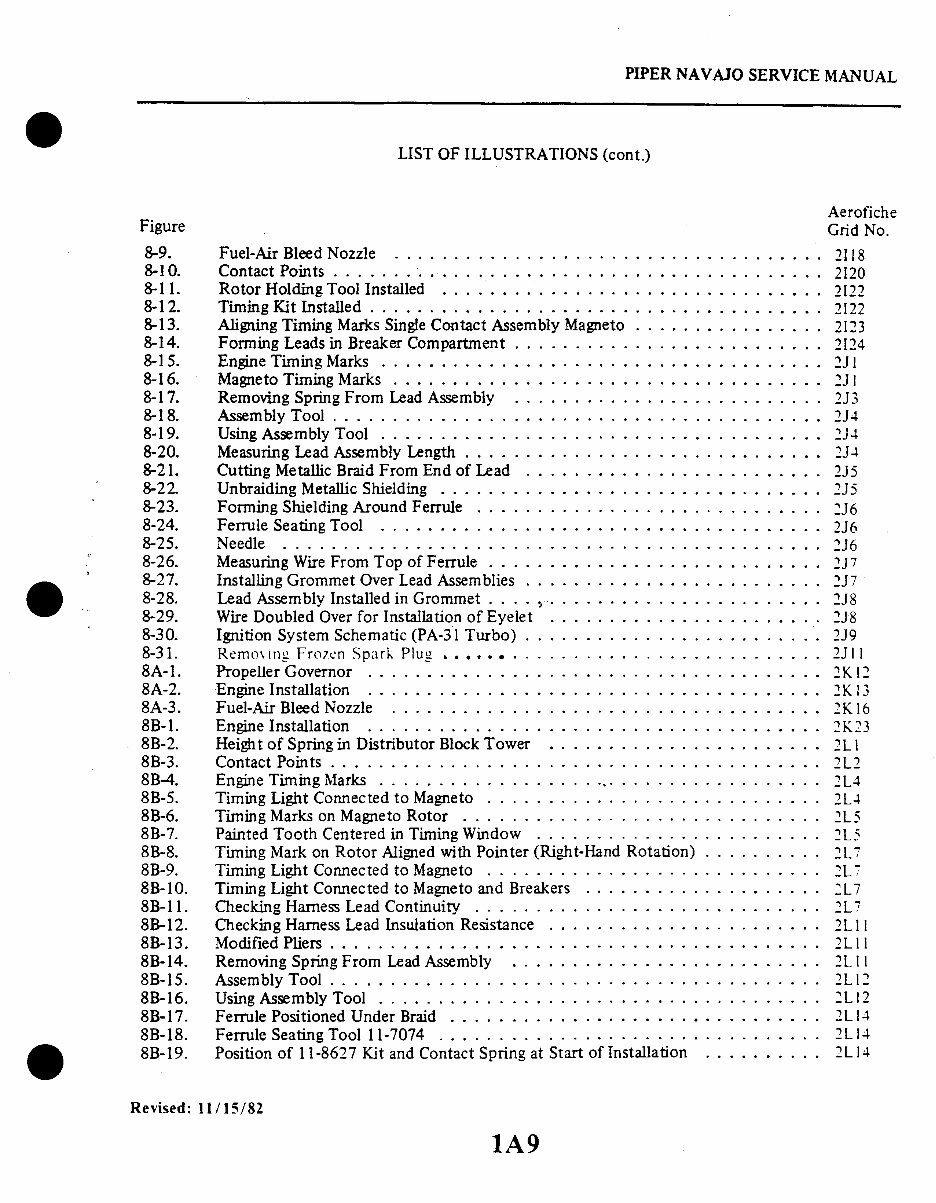

PIPER NAVAJO SERVICE MANUAL

LIST OF ILLUSTRATIONS (cont.)

Figure

8-9.

8-10.

8-11.

8-12.

8-13.

8-14.

8-15.

8-16.

8-17.

8-18.

8-19.

8-20.

8-21.

8-22.

8-23.

8-24.

8-25.

8-26.

8-27.

8-28.

8-29.

8-30.

8-31.

8A-1.

8A-2.

8A-3.

8B-1.

8B-2.

8B-3.

8B-4.

8B-5.

8B-6.

8B-7.

8B-8.

8B-9.

8B-10.

8B-11.

8B-12.

8B-13.

8B-14.

8B-15.

8B-16.

8B-17.

8B-18.

Fuel-Air Bleed Nozzle ....................

Contact Points .........................

Rotor Holding Tool Installed ................

Timing Kit Installed ......................

Aligning Timing Marks Single Contact Assembly Magneto

Forming Leads in Breaker Compartment ..........

Engine Timing Marks .....................

Magneto Timing Marks ....................

Removing Spring From Lead Assembly ..........

Assembly Tool .........................

Using Assembly Tool .....................

Measuring Lead Assembly Length ..............

Cutting Metallic Braid From End of Lead .........

Unbraiding Metallic Shielding ................

Forming Shielding Around Ferrule .............

Ferrule Seating Tool .....................

Needle . .. ... . .............. . ......

Measuring Wire From Top of Ferrule ............

Installing Grommet Over Lead Assemblies .........

Lead Assembly Installed in Grommet ..... ......

Wire Doubled Over for Installation of Eyelet .......

Ignition System Schematic (PA-31 Turbo) .........

Removing Frozen Spark Plug ................

Propeller Governor ......................

Engine Installation ......................

Fuel-Air Bleed Nozzle ....................

Engine Installation ......................

Height of Spring in Distributor Block Tower .......

Contact Points .........................

Engine Timing Marks ......................

Timing Light Connected to Magneto ............

Timing Marks on Magneto Rotor .......

Painted Tooth Centered in Timing Window ........

Timing Mark on Rotor Aligned with Pointer (Right-Hand Rotation)

Timing Light Connected to Magneto ............

Timing Light Connected to Magneto and Breakers ....

Checking Harness Lead Continuity .............

Checking Harness Lead Insulation Resistance .......

Modified Pliers .........................

Removing Spring From Lead Assembly ..........

Assembly Tool .........................

Using Assembly Tool .....................

Ferrule Positioned Under Braid ...............

Ferrule Seating Tool 11-7074 ................

Rotation)

Aerofiche

Grid No.

......... ...... 2118

............... 2120

............... 2122

.......... ..... 2122

.......... .... . 2I23

. ...... ... .. . .. 2124

. ... .. . .. . . . . .. 2Jl

. ..... . ... ... .. 2J1

... ............ 2J3

. ... .. . .. . . . . .. 2J4

. ..... . ... .. . . .2J4

............... 2J4

. ... ... ... ... .. 2J5

............... 2J5

. .. . ... ... .. . . . 2J6

............... 2 J6

. .. . . . . .. . . . . . . 2J6

. .. . ... ... .. . . . 2J7

. .. . ... ... .. . . .2J7

. .. . ... .. . . . . . . 2J8

. .. . ... . .. .. . . . 2J8

.... ........... 2J9

............... 2J1l

. ............ .. 2K12

. ...... ... ..... 2K 13

. ......... ..... 2K 16

............... 2K23

.......... . . ... 2L1

............... 2L2

...... ....... . . 2L4

...... ......... 2L4

. .. . . . . .. . . . . . . 2L5

. . . . .. . .. . . . . . . 2L5

otation) .......... 2L7

............... 2L7

. . . .. .. . ..... . . 2L7

... ... ......... 2L7

............... 2L11

............... 2L II

. .. ... ......... 2L11

. ... ... ... ... . . .2L12

............... 2L14

. .. . ... ... ..... 2L 14

8B-19. Position of 11-8627 Kit and Contact Spring at Start of Installation .. 2L14

Revised: 11/15/82

1A9

PIPER NAVAJO SERVICE MANUAL

LIST OF ILLUSTRATIONS (cont.)

Figure

Aerofiche

Grid No.

8B-20.

Position of 11-8627 Kit and Contact Spring After Installation ................... 2L14

8B-21. Lubricating Sleeve .......................... ............................... 2L15

8B-22. Lubricating Ferrule Shoulder . ..............................................

2L15

8B-23.

Ignition System Schematic (PA-31-325) .......................................

2L17

9-1. Fuel System Schematic (PA-31-310) .. .......................................

3A11

9-la. Fuel System Schematic (PA-31-300) . ........................................

3A12

9-lb. Fuel System Schematic (PA-31-325) ...................... ................... 3A13

9-1c.

Fuel Boost Pump Installation (PA-31-325) .................. ............................... 3A15

9-1d.

Fuel Cell Installation (Nacelle Optional) PA-31-325 only ........ ............ 3A16

9-2.

Fuel Cell Installation (Main Inboard) ........................................

3A21

9-3.

Fuel Cell Installation (Auxiliary Outboard) ..............................

3A22

9-4.

Installation of Fuel Valve Drain Plate ........................................

3A24

9-5. Fuel Gauge Adjustment Wires ...............................................

3B3

9-6. Scott Fuel Selector Valve ...................................................

3B12

9-7. Crossfeed Valve ...........................................................

3B13

9-8. Emergency Shut-Off Valve ..................................................

3B15

9-9.

Fuel System Installation (PA-31 Turbo) ............................. ......... 3B16

9-9a.

Fuel System Installation (PA-31-300) ........................... ................. 3B18

9-10.

Adjustment of Crossfeed %alve ..............................................

3B20

9-1 1. Fuel Filter ................................................................

3B22

9-12.

Electric Fuel Pump (PA-31-310 and -325) ......... .................. 3C2

9-12a. Electric Fuel Pump (PA-31-300) .............................................

3C6

9-13. Fuel Cell Tie Detail ........................................................

3C11

9-14.

Low Fuel Warning Sender Sealing ...........................................

3C12

10-1. Instrument Panel (Typical) ..................................................

3C23

10-2.

Instrument Air System Installation (Typical) .............. ................ 3D2

10-2a.

Single Attitude and Directional Gyro Installation .............................. 3D7

10-3.

Dual Attitude and Directional Gyro Installation ....................... ........ 3D8

10-4.

Single or Dual Attitude and Directional Gyro Installation with

Deicer Boots ............................................................

3D10

10-5. Test Take-Off .............................................................

3D 14

10-6.

Single or Dual Attitude and Directional Gyro Installation with

H-14 Autopilot ..........................................................

3D15

10-7 Pneumatic Relay ..........................................................

3D17

10-8.

Single or Dual Attitude and Directional Gyro Installation with

Deicer Boots and H-14 Autopilot ..........................................

3D19

10-9. Digital Clock .............................................................

3D22

11-1. Overhead Switch Panel .....................................................

4A17

11-2.

Switch and Circuit Breaker Control Panel ....................................

4A18

11-3.

Dual Alternator Wiring System (Delco-Remy) .................................

4A23

11-4.

Cross-Sectional View of Alternator ..........................................

4B2

Revised: 9/24/81

lA10

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

Viewed 90 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

The Piper Navajo PA31 service manual for PA31-300/325 is a comprehensive resource spanning over 1100 pages. It provides detailed instructions for maintenance, repair, and troubleshooting of the aircraft. The manual is designed to be easily navigable, with bookmarked and indexed sections, making it convenient for both professional mechanics and DIY enthusiasts to locate specific information. Whether you prefer to print the entire manual or select sections as needed, this resource offers valuable support for maintaining and servicing the Piper Navajo PA31 aircraft.