Cessna 185 Skywagon POH owners manual aircraft

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

www.powersportsupply.co

performance - s

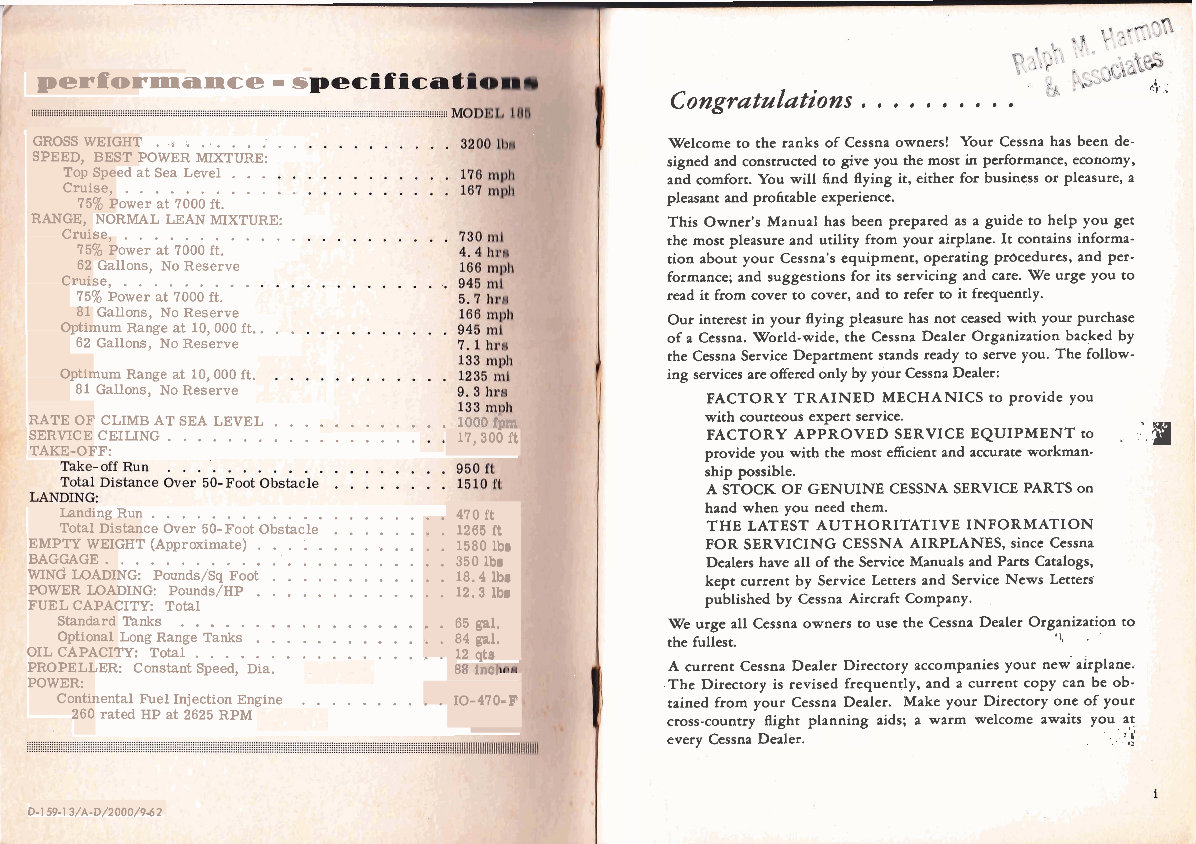

.. . ...... GROSS WEIGHT .* .'

SPEED, BEST POWER MIXTURE:

Top Speed at Sea Level ...

Cruise, ............

75% Power at 7000 ft.

RANGE, NORMAL LEAN MIXTURE:

Cruise, ............

75% Power at 7000 ft.

62 Gallons, No Reserve

Cruise, .........

75% Power at 7000 ft.

81 Gallons, No Reserve

..

Optimum Range at 10,000 ft..

62 Gallons, No Reserve

Optimum Range at 10,000 ft.

81 Gallons, No Reserve

RATE OF CLIMB AT SEA LEVEL ...

SERVICE CEILJNG ................. , 17,300 it

TAKE-OFF:

Landing Run .................... 470 ft

Total Distance Over 50-Foot Obstacle ........ 1265 ft

EMPTY WEIGHT (Approximate) ............. 1580 lbr

BAGGAGE ........................ 350 1bm

WING LOADING: ~ o u n d s / ~ q Foot ............ 18.4 lbr

POWER LOADING: Pounds/HP ............. 12.3 lbr

FUEL CAPACITY: Total

Standard Tanks 65 gal.

..................

Optional Long Range Tanks ............. 84 gal,

OIL CAPACITY: Total ................. 12 qtm

PROPELLER: Constant Speed, Dia.

POWER:

Continental Fuel Injection Engine .......... 10-470- F

260 rated HP at 2625 RPM

D-159-13/A-D/2000/942

4.

Congratulations. .........

Welcome to the ranks of Cessna owners! Your Cessna has been de-

signed and constructed to give you the most in performance, economy,

and comfort. You will find flying it, either for business or pleasure, a

pleasant and profitable experience.

This Owner's Manual has been prepared as a guide to help you get

the most pleasure and utility from your airplane. It contains informa-

tion about your Cessna's equipment, operating procedures, and per-

formance; and suggestions for its servicing and care. We urge you to

read it from cover to cover, and to refer to it frequently.

Our interest in your flying pleasure has not ceased with your purchase

of a Cessna. World-wide, the Cessna Dealer Organization backed by

the Cessna Service Department stands ready to serve you. The follbw-

ing services are offered only by your Cessna Dealer:

FACTORY TRAINED MECHANICS to provide you

with courteous expert service.

FACTORY APPROVED SERVICE EQUIPMENT to . .

a

provide you with the most efficient and accurate workman-

ship possible.

A STOCK OF GENUINE CESSNA SERVICE PARTS on

hand when you need them.

THE LATEST AUTHORITATIVE INFORMATION

FOR SERVICING CESSNA AIRPLANES, since Cessna

Dealers have all of the Service Manuals and Parts Catalogs,

kept current by Service Letters and Service News Letters

published by Cessna Aircraft Company.

We urge all Cessna owners to use the Cessna Dealer Organization to

the fullest. 'I, .

A current Cessna Dealer Directory accompanies your new airplane.

.The Directory is revised frequently, and a current copy can be ob-

tained from your Cessna Dealer. Make your Directory one of your

cross-country flight planning aids; a warm welcome awaits you at

every Cessna Dealer.

www.powersportsupply.co

XAELE of CONTENXS

. . . . . . . . . . .... I ........ I.. . . ... . . .. . . . .. . . . . . , , . , , . . . , , , . . . , . . , . , . . , , . . . .. . . . . . . . . . . . . .. . . . . . . . . . . . . . .. . . ... . . . . .. . . . . . . . .. . . . .. . . .. . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . ,, . . . . ,... . ... . . ... . . . .. . . . . ...

..................................................................................................................................................................................................

. ... . . ... . .

::::::: i:iii:iiit:iii Page iiiiiiiijii

SECTION I - DESCRIPTION ------------------ 1-1

SECTION II - OPERATING CHECK LIST---- 2-1

SECTION Ill - OPERATING DETAILS -------- 3-1

SECTION IV - OPERATING LIMITATIONS --- 4-1

SECTION V - CARE OF THE AIRPLANE --- 5-1

DEALER FOLLOW-UP SYSTEM --,-,,,,--- 5-1 2

SECTION VI - OPERATIONAL DATA ,,,,----- 6-1

SECTION VII - OPTIONAL SYSTEMS ------,-- 7-1

RADIO SELECTOR SWITCHES ----------,, 7-1

OXYGEN SYSTEM -------------- - ------------ 7-3

ALPHABETICAL INDEX ....................... Index-1

iii

.,I\,

www.powersportsupply.co

I

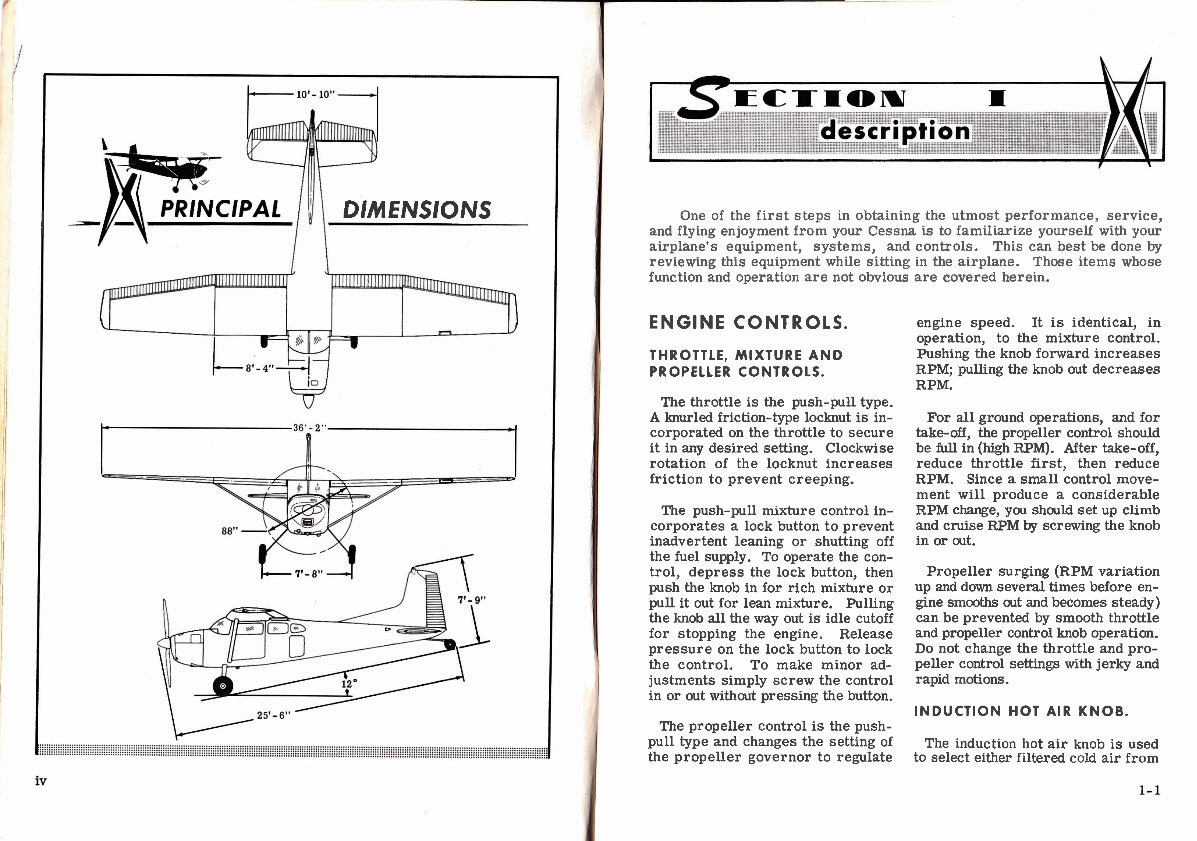

DIMENSIONS

One of the first steps in obtaining the utmost performance, service,

and flying enjoyment from your Cessna is to familiarize yourself with your

airplane's equipment, systems, and controls. This can best be done by

reviewing this equipment while sitting in the airplane. Those items whose

function and operation are not obvious are covered herein.

ENGINE CONTROLS. engine speed. ~t is identical, in

operation, to the mixture control.

THROTTLE, MIXTURE AND Pushing the knob forward increases

PROPELLER CONTROLS. RPM, pulling the knob out decreases

RPM.

The throttle is the push-pull type.

A knurled friction-type locknut is in-

corporated on the throttle to secure

it in any desired setting. Clockwise

rotation of the locknut increases

friction to prevent creeping.

The push-pull mixture control in-

corporates a lock button to prevent

inadvertent leaning or shutting off

the fuel supply. To operate the con-

trol, depress the lock button, then

push the knob in for rich mixture or

pull it out for lean mixture. Pulling

the knob all the way out is idle cutoff

for stopping the engine. Release

pressure on the lock button to lock

the control. To make minor ad-

justments simply screw the control

in or out without pressing the button.

The propeller control is the push-

pull type and changes the setting of

the propeller governor to regulate

For all ground operations, and for

take-off, the propeller control should

be full in (high RPM). After take-off,

reduce throttle first, then reduce

RPM. Since a small control move-

ment will produce a considerable

RPM change, you should set up climb

and cruise RPM by screwing the knob

in or out.

Propeller surging (RPM variation

up and down several times before en-

gine smooths out and becomes steady)

can be prevented by smooth throttle

and propeller control knob operation.

Do not change the throttle and pro-

peller control settings with jerky and

rapid motions.

INDUCTION HOT AIR KNOB.

The induction hot air knob is used

to select either filtered cold air from

www.powersportsupply.co

' 1 Description

!

the induction air scoop or heated air

from the accessory compartment. In

the unlikely event that ice should

form in the induction system, as

evidenced by an unexplained drop in

manifold pressure, pull the induc-

tion hot air knob full out. Do not use

an intermediate position.

IGNITION-STARTER SWITCH.

A five-position ignition-starter

switch controls the dual magneto

ignition and starter systems. The

switch positions are labeled clock-

wise as follows: "OFF, " "R, " "L, "

"BOTH" and "START. "

The engine should be operated on

both magnetos ("BOTH" position).

The "R" and " L" positions are for

checking purposes only. When the

switch is turned to the spring-loaded

"START' position, the starter turns

over the engine for starting. As the

switch is released, it automatically

returns to "BOTH. "

b

Refer to Sections I1 and 111 for

further discussion on the use of the

ignition-starter switch.

ENGINE INSTRUMENTS.

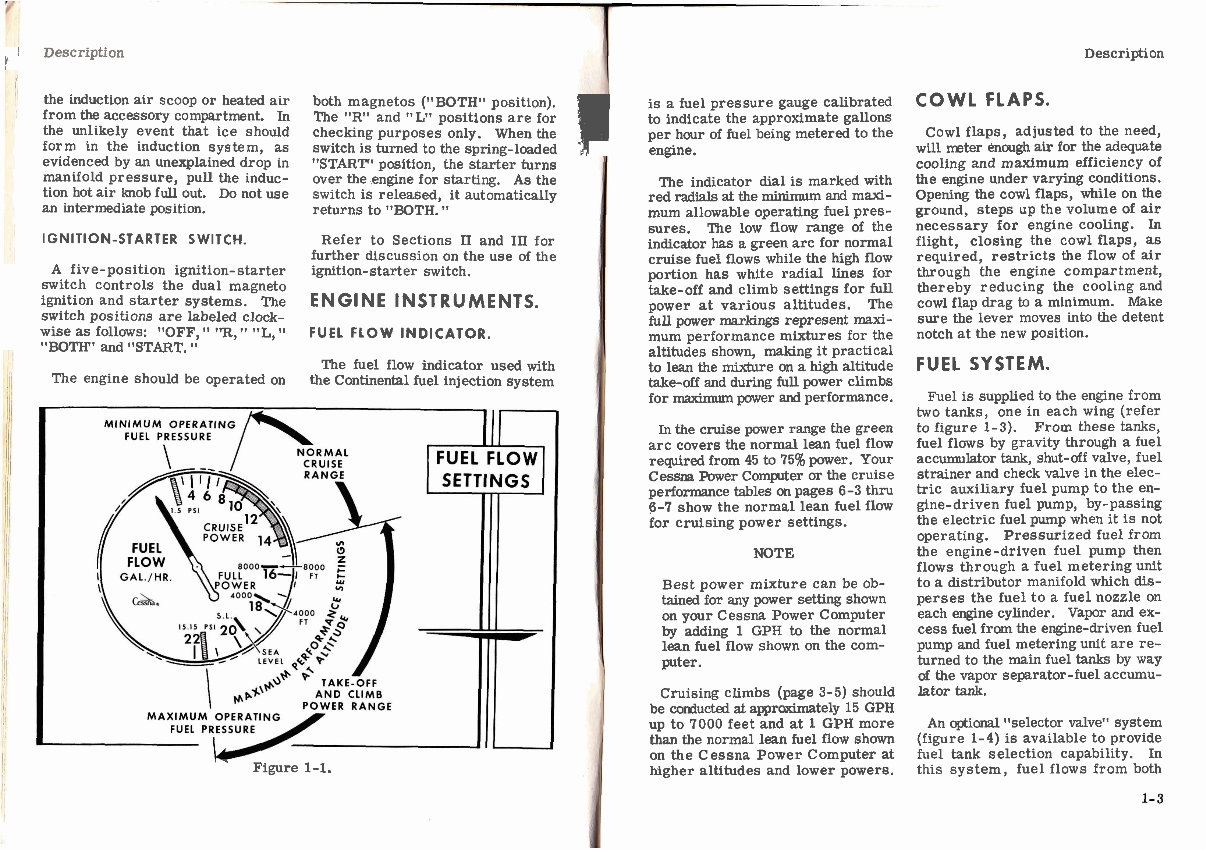

FUEL FLOW INDICATOR.

The fuel flow indicator used with

the Continental fuel injection system

IT

Figure 1-1.

is a fuel pressure gauge calibrated

to indicate the approximate gallons

per hour of fuel being metered to the

engine.

The indicator dial is marked with

red radials at the minimum and maxi-

mum allowable operating fuel pres-

sures. The low flow range of the

indicator has a green arc for normal

cruise fuel flows while the high flow

portion has white radial lines for

take-off and climb settings for full

power at various altitudes. The

full power markings represent maxi-

mum performance mixtures for the

altitudes shown, making it practical

to lean the mixture on a high altitude

take-off and during full power climbs

for maximum power and performance.

In the cruise power range the green

arc covers the normal lean fuel flow

required from 45 to 75% power. Your

Cessna Power Complter or the cruise

performance tables on pages 6-3 thru

6-7 show the normal lean fuel flow

for cruising power settings.

NOTE

Best power mixture can be ob-

tained for any power setting shown

on your Cessna Power Computer

by adding 1 GPH to the normal

lean fuel flow shown on the com-

puter.

Cruising climbs (page 3-5) should

be conducted at apprcximately 15 GPH

up to 7000 feet and at 1 GPH more

than the normal lean fuel flow shown

on the Cessna Power Computer at

higher altitudes and lower powers.

Description

COWL FLAPS.

Cowl flaps, adjusted to the need,

will mter enough air for the adequate

cooling and maximum efficiency of

the engine under varying conditions.

Opening the cowl flaps, while on the

ground, steps up the volume of air

necessary for engine cooling. In

flight, closing the cowl flaps, as

required, restricts the flow of air

through the engine compartment,

thereby reducing the cooling and

cowl flap drag to a minimum. Make

sure the lever moves into the detent

notch at the new position.

FUEL SYSTEM.

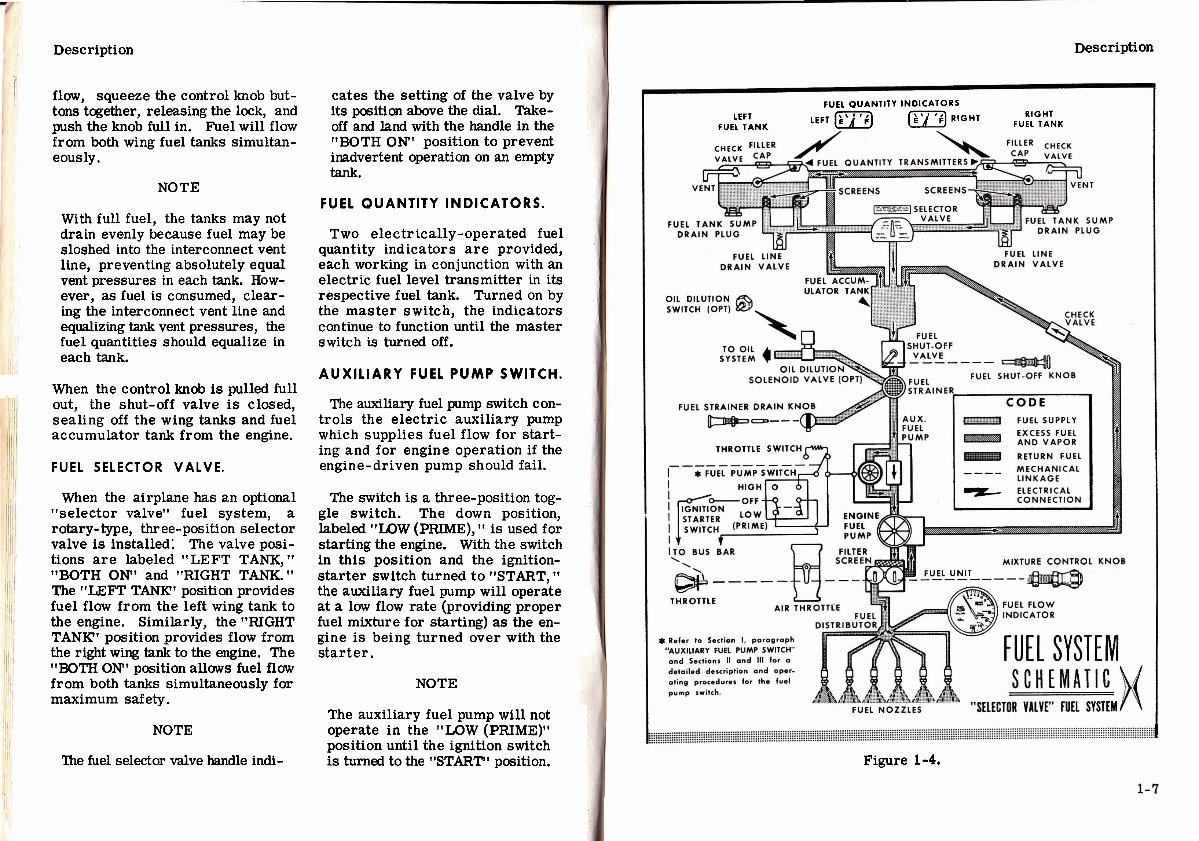

Fuel is supplied to the engine from

two tanks, one in each wing (refer

to figure 1-3). From these tanks,

fuel flows by gravity through a fuel

accumulator tank, shut-off valve, fuel

strainer and check valve in the elec-

tric auxiliary fuel pump to the en-

gine-driven fuel pump, by-passing

the electric fuel pump when it is not

operating. Pressurized fuel from

the engine-driven fuel pump then

flows through a fuel metering unit

to a distributor manifold which dis-

perses the fuel to a fuel nozzle on

each engine cylinder. Vapor and ex-

cess fuel from the engine-driven fuel

pump and fuel metering unit are re-

turned to the main fuel tanks by way

of the vapor separator-fuel accumu-

liltor tank.

An optional "selector valve" system

(figure 1-4) is available to provide

fuel tank selection capability. In

this system, fuel flows from both

www.powersportsupply.co

Description

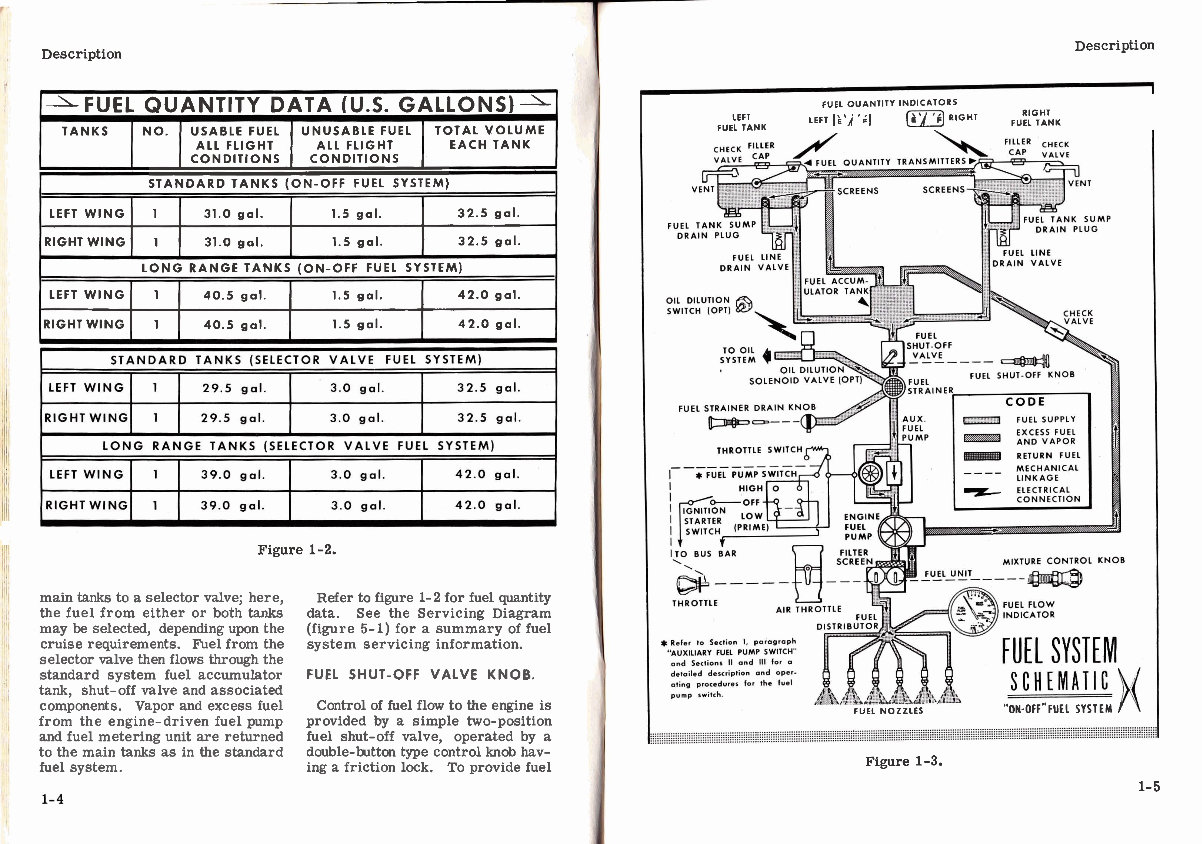

-FUEL QUANTITY DATA (U.S. GALLONS)-1

TANKS NO. USABLE FUEL UNUSABLE FUEL TOTAL VOLUME

ALL FLIGHT ALL FLIGHT EACH TANK

CONDITIONS CONDITIONS

STANDARD TANKS (ON-OFF FUEL SYSTEM)

LEFT W I N G 1 31.0 gal. 1.5 gal. 32.5 gal.

RIGHT WING 1 31.0 gal. 1.5 gal. 32.5 gal.

LONG RANGE TANKS (ON-OFF FUEL SYSTEM)

LEFT WING 1 40.5 gal. 1.5 gal. 42.0 gal.

RIGHTWING 1 40.5 gal. 1.5 gal. 42.0 gal.

Figure 1-2.

main tanks to a selector valve; here,

the fuel from either or both tanks

may be selected, depending upon the

cruise requirements. Fuel from the

selector valve then flows through the

standard system fuel accumulator

tank, shut-off valve and associated

components. Vapor and excess fuel

from the engine-driven fuel pump

and fuel metering unit are returned

to the main tanks as in the standard

fuel system.

Refer to figure 1- 2 for fuel quantity

data. See the Servicing Diagram

(figure 5-1) for a summary of fuel

system servicing information.

FUEL SHUT-OFF VALVE KNOB.

Control of fuel flow to the engine is

provided by a simple two-position

fuel shut-off valve, operated by a

double-button type control knob hav-

ing a friction lock. To provide fuel

Description

r LEFT

FUEL TANK

FUEL OUANTITY INDICATORS

RIGHT

EFT RIGHT FUEL T A ~ ~

.

FUEL NOZZLES "ON-OFF"FUEL SYSTEM I

Figure 1-3.

1-5

www.powersportsupply.co

Description

flow, squeeze the control knob but-

tons together, releasing the lock, and

push the knob full in. Fuel will flow

from both wing fuel tanks simultan-

eously.

NOTE

With full fuel, the tanks may not

drain evenly because fuel may be

sloshed into the interconnect vent

line, preventing absolutely equal

vent pressures in each tank. How-

ever, as fuel is consumed, clear-

ing the interconnect vent line and

equalizing tank vent pressures, the

fuel quantities should equalize in

each tank.

When the control knob is pulled full

out, the shut-off valve is closed,

sealing off the wing tanks and fuel

accumulator tank from the engine.

FUEL SELECTOR VALVE.

When the airplane has an optional

"selector valve" fuel system, a

rotary-type, three-position selector

valve is installed; The valve posi-

tions are labeled "LEFT TANK,"

"BOTH ON" and "RIGHT TANK."

The "LEFT TANK' position provides

fuel flow from the left wing tank to

the engine. Similarly, the "RIGHT

TANK' position provides flow from

the right wing tank to the engine. The

"BOTH ON" position allows fuel flow

from both tanks simultaneously for

maximum safety .

NOTE

The fuel selector valve handle indi-

cates the setting of the valve by

its pasition above the dial. Take-

off and land with the handle in the

"BOTH OW1 position to prevent

inadvertent operation on an empty

tank.

FUEL QUANTITY INDICATORS.

Two electrically-operated fuel

quantity indicators are provided,

each working in conjunction with an

electric fuel level transmitter in its

respective fuel tank. Turned on by

the master switch, the indicators

continue to function until the master

switch is turned off.

AUXILIARY FUEL PUMP SWITCH.

The auxiliary fuel pump switch con-

trols the electric auxiliary pump

which supplies fuel flow for start-

ing and for engine operation if the

engine-driven pump should fail.

The switch is a three-position tog-

gle switch. The down position,

labeled "LOW (PRIME), " is used for

starting the engine. With the switch

in this position and the ignition-

starter switch turned to "START, 'I

the auxiliary fuel pump will operate

at a low flow rate (providing proper

fuel mixture for starting) as the en-

gine is being turned over with the

starter.

NOTE

The auxiliary fuel pump will not

operate in the "LOW (PRIME)"

position until the ignition switch

is turned to the "START" position.

Description

FUEL OUANTITY INDICATORS

LEFT LEFT li) RIGHT RIGHT

FUEL TANK FUEL TANK

I

Figure 1-4.

www.powersportsupply.co

Description

The up position of the switch, la-

beled ItHIGH, " is used for engine op-

eration if the engine-driven pump

should fail, or for vapor purging in

extremely hot weather. When the

switch is in this position, the pump

can operate at two f l m rates depend-

ing upon the setting of the throttle.

With the throttle at a cruise setting,

the pump is operating at maximum

capacity, supplying sufficient fuel

flow to maintain flight with the en-

gine-driven pump inoperative. When

the throttle is moved toward the

closed position, as during let-down,

landing and taxiing, a mechanically-

actuated switch electrically reduces

the auxiliary fuel pump flow rate by

means of a resistor in the pump

power circuit. This action auto-

matically prevents an excessively

rich mixture during these periods of

reduced engine speed.

The auxiliary fuel pump is not to

be on "HIGHt7 during normal oper-

ation, because, with the engine-driven

pump functioning, a fuel/air ratio

considerably richer than best power

is produced. If fuel vapor is affect-

ing engine operation, the vapor may

be purged by turning the auxiliary

pump to "HIGH" and leaning the mix-

ture as required to prevent exces-

sively rich mixture. Successful vapor

purging is evidenced by smooth en-

gine operation and steady and normal

fuel flow indications with the auxiliary

fuel pump switch "OFF. It

NOTE

If the auxiliary fuel pump switch is

accidentally turned to "HIGHt (with

master switch on) with the engine

stopped, intake manifolds will be

flooded unless the mixture is in

idle cut-off.

The center position of the auxiliary

fuel pump switch is "OFF. "

FUEL STRAINER DRAIN KNOB.

A fuel strainer drain knob marked

"STRAWER DRAIN' provides a quick,

convenient method of draining water

and sediment that may have collected

in the fuel strainer. The strainer is

located on the lower front side of the

f irewall.

About two ounces of fuel (3 to 4

seconds of drain knob operation)

should be drained from the strainer

before the initial flight of the day to

insure against the presence of water

or sediment in the fuel.

The spring-loaded drain valve in

the strainer is open when the fuel

strainer drain knob is pulled out all

the way. The drain valve automatic-

ally closes when the knob is released.

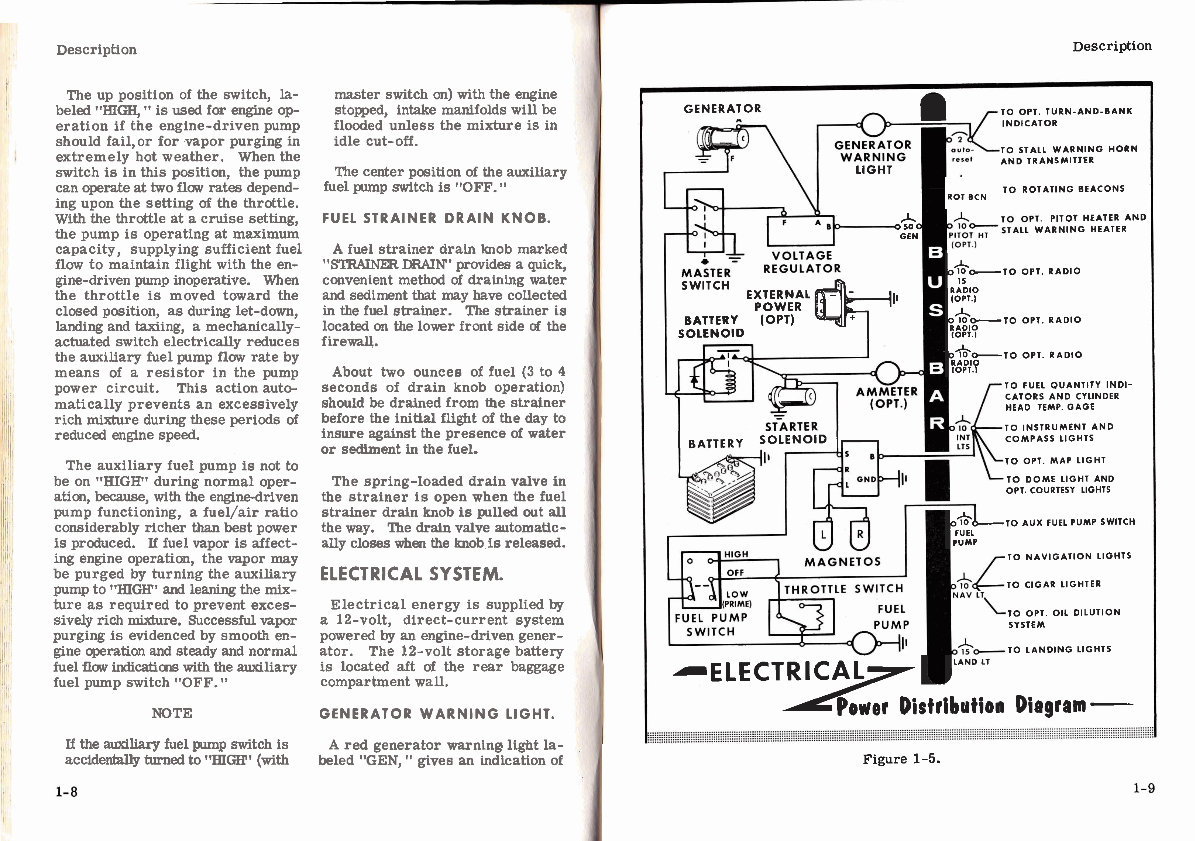

ELECTRICAL SYSTEM.

Electrical energy is supplied by

a 12-volt, direct-current system

powered by an engine-driven gener-

ator. The 12-volt storage battery

is located aft of the rear baggage

compartment wall.

GENERATOR WARNING LIGHT.

A red generator warnine light la-

beled "GEN, " gives an indication of

Description

GENERATOR

TO OPT. TURN-AND-BANK

INDICATOR

TO STALL WARNING HORN

AND TRANSMITTER

LlGHT

oCa

GEN

SWITCH EXTERNAL$ {I,

POWER

BATTERY (OPT)

SOLENOID

I BATTERY SOLENoiD I)-,

TO ROTATING BEACONS

ROT BCN

PITOT HEATER AND

WARNING HEATER

/-To RADIO OPT RADIO

(OPT.)

I&TO RADIO on. RADIO

10PT.l

/*-To OPT. RADIO

RADlO

I0PT.I

TO FUEL QUANTITY INDI-

CATORS AND CYLINDER

HEAD TEMP. GAGE

TO INSTRUMENT AND

COMPASS LIGHTS

TO OPT. MAP LIGHT

TO DOME LIGHT AND

OPT. COURTESY LIGHTS

bF$LLTo

AUX FUEL PUMP SWITCH

PUMP

TO NAVIGATION LIGHTS

TO CIGAR LIGHTER

TO OPT. OIL DILUTION

SYSTEM

TO LANDING LIGHTS

-ELECT? ) LAND LT

Power Distribution Diagram -

Figure 1-5.

www.powersportsupply.co

Description

generator output. It will remain off

at all times when the generator is-

functioning properly. The light will

not show drainage on the battery. It

'

will illuminate when the battery or

external power is turned on prior to

starting the engine, and when there

is insufficient engine RPM to produce

generator current. Also, it will

illuminate if the generator becomes

defective.

CIRCUIT BREAKERS.

All electrical circuits in the air-

plane are protected by circuit break-

ers. The stall warning, generator

warning light, and optional turn-and-

bank indicator circuits are protected

by a single automatically resetting

circuit breaker mounted behind the

instrument panel. The remaining

electrical circuits are protected by

"push-to-resetM breakers on the in-

strum ent panel. The name of the

circuit is indicated above each cir-

cuit breaker.

LANDING LIGHTS.

The landing light switch is a three-

position, push-pull switch. To turn

one lamp on for taxiing, pull the

switch out to the first stop. To turn

both lamps on for landing, pull the

switch out to the second stop.

ROTATING BEACONS.

The beacons should not be used

when flying through clouds o r over-

cast; the m oving beams reflected

from water droplets or particles in

the atmosphere, particularly at night,

can produce vertigo and loss of ori-

entation.

STALL WARNING INDICATOR

The stall warning indicator is an

electric horn controlled by a trans-

mitter unit in the leading edge of the

left wing. This system is in oper-

ation whenever the master switch

is turned on. The transmitter re-

sponds to changes in the airflow over

the leading edge of the wing as a stall

is approached. In straight-ahead

and turning flight, the warning horn

will sound 5 to 10 MPH ahead of the

stall.

Under safe flight conditions, the

only time you may hear the warning

horn will be a short beep a s you land.

CABIN HEATING AND

VENTILATION SYSTEM.

Fresh air for heating and venti-

lating the cabin is supplied by two

sources, a manifold cabin heater and

a ventilating air scoop on the right

side of the fuselage.

The temperature and amount of air

entering the cabin is controlled by

two knobs on the instrument panel.

The "CABIN AIR" knob operates the

air scoop on the right side of the

fuselage and controls cool fresh air

entering the manifold on the firewall.

The "CABIN HT' knob regulates the

amount of heat entering the cabin.

The "CABIN HT" knob is the double-

button type with a friction lock to

permit intermediate settings. To

operate the knob, squeeze the buttons

together, releasing the lock, then

adjust the knob.

For cabin ventilation, pull the

"CABIN AIRf7 knob out. To raise

the air temperature, pull the "CABIN

HT1 knob out approximately 1/4" to

1/2" for a small am& of cabin heat.

Adjust the knob as desired from this

position to the full out (maximum

heat) position.

NOTE

Always pull out the "CABIN AIR"

knob slightly when the "CABIN

HT" knob is out. This action in-

creases the airflow through the

system, increasing efficiency,

and blends cool outside air with

the manifold heated air, thus

eliminating the possibility of

overheating the system ducting.

When no heat is desired in the cabin,

push the "CABIN HT" knob full in.

Description

VENTILATORS.

Two ventilators, one in each upper

corner of the windshield, are provided

to supply additional ventilating air.

To operate, pull the ventilator out

and rotate to the desired position.

Two additional ball and socket venti-

lators are installed just forward of

each rear door post in the ceiling,

for rear seatpassengers. To regu-

late the air, turn the knurled ring on

the rim of the ventilator.

REMOVABLE CABIN DOOR.

The right cabin door has removable

hinge pins and a detachable door stop

permitting door removal when large

or bulky cargo must be loaded. To

disconnect the door stop, simply re-

move the cotter pin and clevis pin

from the door stop rod at the door

frame. To remove the hinge pins,

pull them up and out of the hinges.

Support the door as the pins are re-

moved.

www.powersportsupply.co

32~

i

0

.

r( 4

a OP I

9 2-

+I

m

oa%

5

u YZl

E Z ~

.-P d

T$

a+

' d m .g k IC

.. -

I w

is

9

I

5

3

*

'PI 8

sad "Q~Z

lE 0"

z I G ~

Ikth

a22 2

5x9;.

4~81

hhhh

FIN*)*

VYWV

www.powersportsupply.co

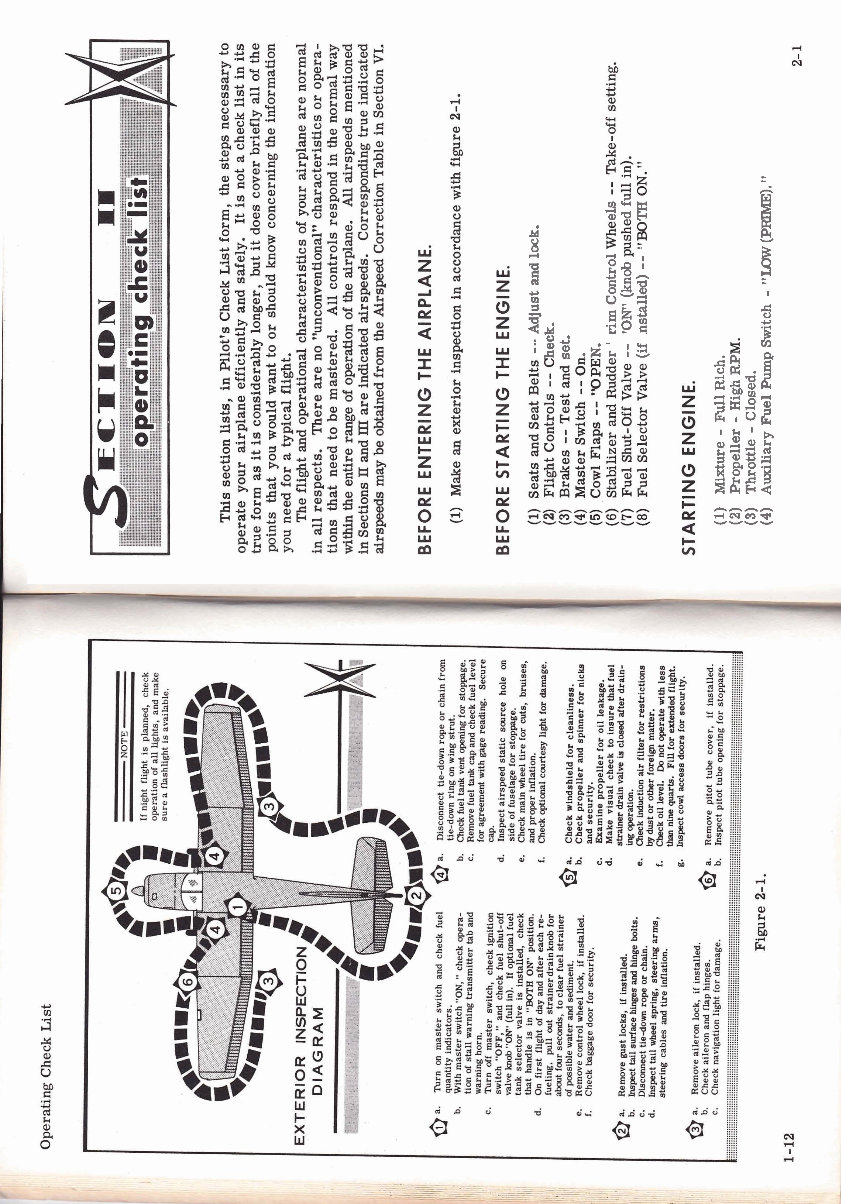

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

$46.99

Viewed 19 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

$46.99

The Cessna 185 Skywagon 1963 185B owner's manual is a comprehensive guide for maintaining and repairing the aircraft. It contains essential technical information relevant to the Cessna 185B model, making it valuable for both professional mechanics and DIY enthusiasts.