2011 Yamaha C3 Motorcycle Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

XF50W

SERVICE MANUAL

LIT-11616-20-58 3B3-F8197-10

EAS00000

XF50W 2006

SERVICE MANUAL

©2006 by Yamaha Motor Taiwan Co., Ltd.

First edition, September 2006

All rights reserved.

Any reproduction or unauthorized use

without the written permission of

Yamaha Motor Taiwan Co., Ltd.

is expressly prohibited.

Printed in U.S.A.

LIT-11616-20-58

EAS00002

NOTICE

This manual was produced by the Yamaha Motor Taiwan Company, Ltd. primarily for use by Yamaha

dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in

one manual. Therefore, anyone who uses this book to perform maintenance and repairs on Yamaha

vehicles should have a basic understanding of mechanics and the techniques to repair these types

of vehicles. Repair and maintenance work attempted by anyone without this knowledge is likely to

render the vehicle unsafe and unfit for use.

Yamaha Motor Taiwan Company, Ltd. is continually striving to improve all of its models. Modifications

and significant changes in specifications or procedures will be forwarded to all authorized Yamaha

dealers and will appear in future editions of this manual where applicable.

NOTE:

Designs and specifications are subject to change without notice.

EAS00005

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

Failure to follow WARNING instructions could result in severe injury or death

to the scooter operator, a bystander or a person checking or repairing the

scooter.

A CAUTION indicates special precautions that must be taken to avoid dam-

age to the scooter.

A NOTE provides key information to make procedures easier or clearer.

NOTE:

w

cC

Q

ENG

5-32

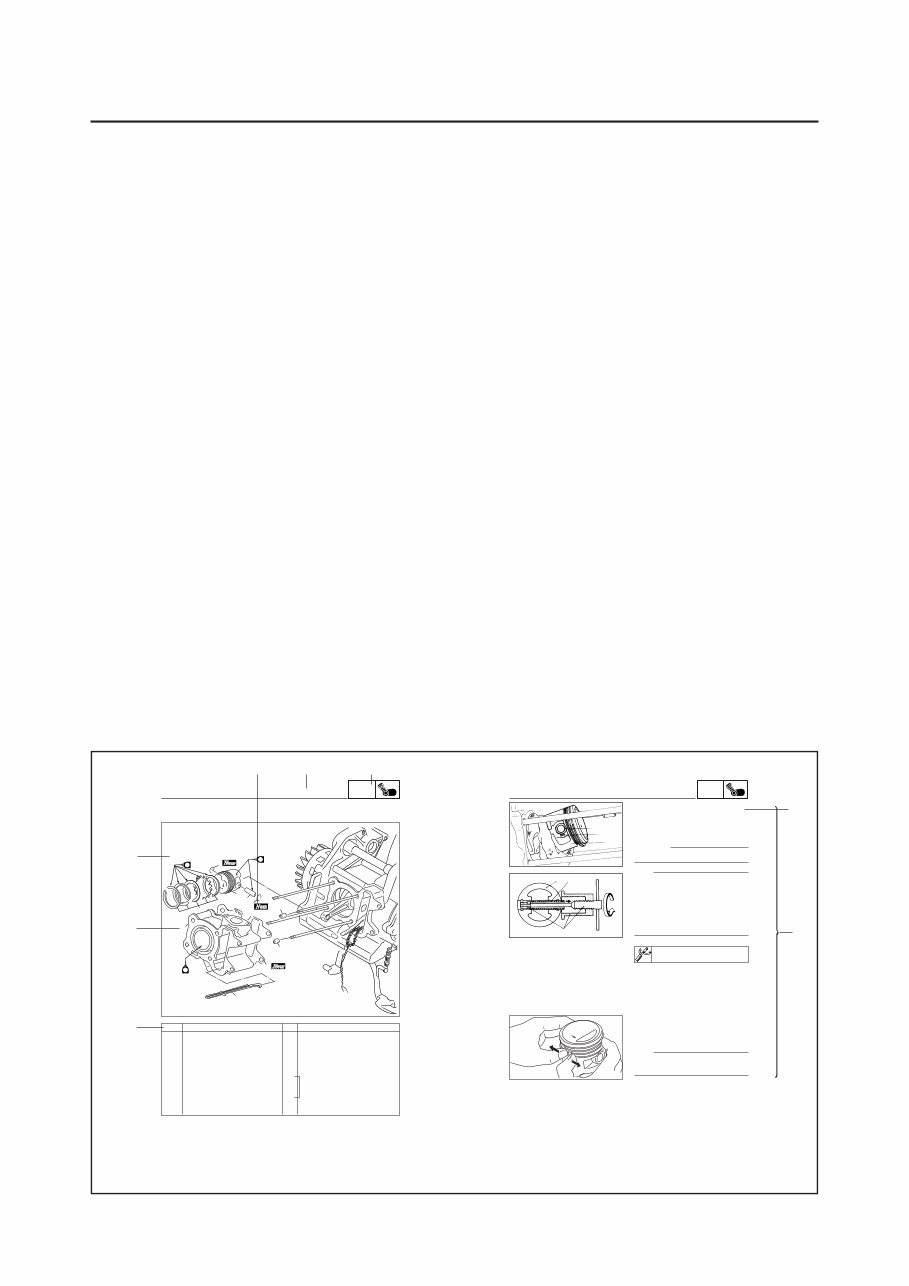

EAS00253

REMOVING THE CYLINDER AND PISTON

1. Remove:

8piston pin clip 1

8piston pin 2

8piston 3

cC

Do not use a hammer to drive the piston pin

out.

NOTE:

8 Before removing the piston pin clip, cover

the crankcase opening with a clean rag to

prevent the piston pin clip from falling into

the crankcase.

8 Before removing the piston pin, deburr the

piston pin clip’s groove and the piston’s pin

bore area. If both areas are deburred and

the piston pin is still difficult to remove, re-

move it with the piston pin puller set4.

Piston pin puller set

90890-01304(YU-01304)

CYLINDER AND PISTON

2. Remove:

8top ring

82nd ring

8oil ring

NOTE:

When removing a piston ring, open the end gap

with your fingers and lift the other side of the

ring over the piston crown.

1

3

2

3 2

4

5-31

ENG

Remarks Order Job/Part Q’ty

1

2

3

4

5

6

7

8

EAS00251

CYLINDER AND PISTON

Removing the cylinder and piston

Cylinder head

Timing chain guide(exhaust side)

Cylinder

Dowel pin

Cylinder gasket

Piston pin clip

Piston pin

Piston

Piston ring set

Remove the parts in the order listed.

Refer to”CYLINDER HEAD”.

Refer to”REMOVING THE CYLINDER

AND PISTON” and “INSTALLING THE

PISTON AND CYLINDER”.

For installation, reverse the removal pro-

cedure.

1

1

2

1

2

1

1

1

CYLINDER AND PISTON

5

4

4

4

7

6

5

8

2

3

3

4

1

EAS00007

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive

explanations of all installation, removal, disassembly, assembly, repair and check procedures are

laid out with the individual steps in sequential order.

1 The manual is divided into chapters. An abbreviation and symbol in the upper right corner of

each page indicate the current chapter. Refer to “SYMBOLS”.

2 Each chapter is divided into sections. The current section title is shown at the top of each page,

except in Chapter 3 (“PERIODIC CHECKS AND ADJUSTMENTS”), where the sub-section

title(s) appears.

3 Sub-section titles appear in smaller print than the section title.

4 To help identify parts and clarify procedure steps, there are exploded diagrams at the start of

each removal and disassembly section.

5 Numbers are given in the order of the jobs in the exploded diagram. A circled number indicates

a disassembly step.

6 Symbols indicate parts to be lubricated or replaced.Refer to “SYMBOLS”.

7 A job instruction chart accompanies the exploded diagram, providing the order of jobs, names of

parts, notes in jobs, etc.

8 Jobs requiring more information (such as special tools and technical data) are described se-

quentially.

8

4

5

7

1

3

2 6

GEN

INFO

SPEC

CHK

ADJ

ENG

TRBL

SHTG

FI

CHAS

- +

ELEC

4 M

B

LS

New

M

G

COOL

1 2

3 4

5 6

7 8

9 0

q w

e r

i o p

a s d

f g

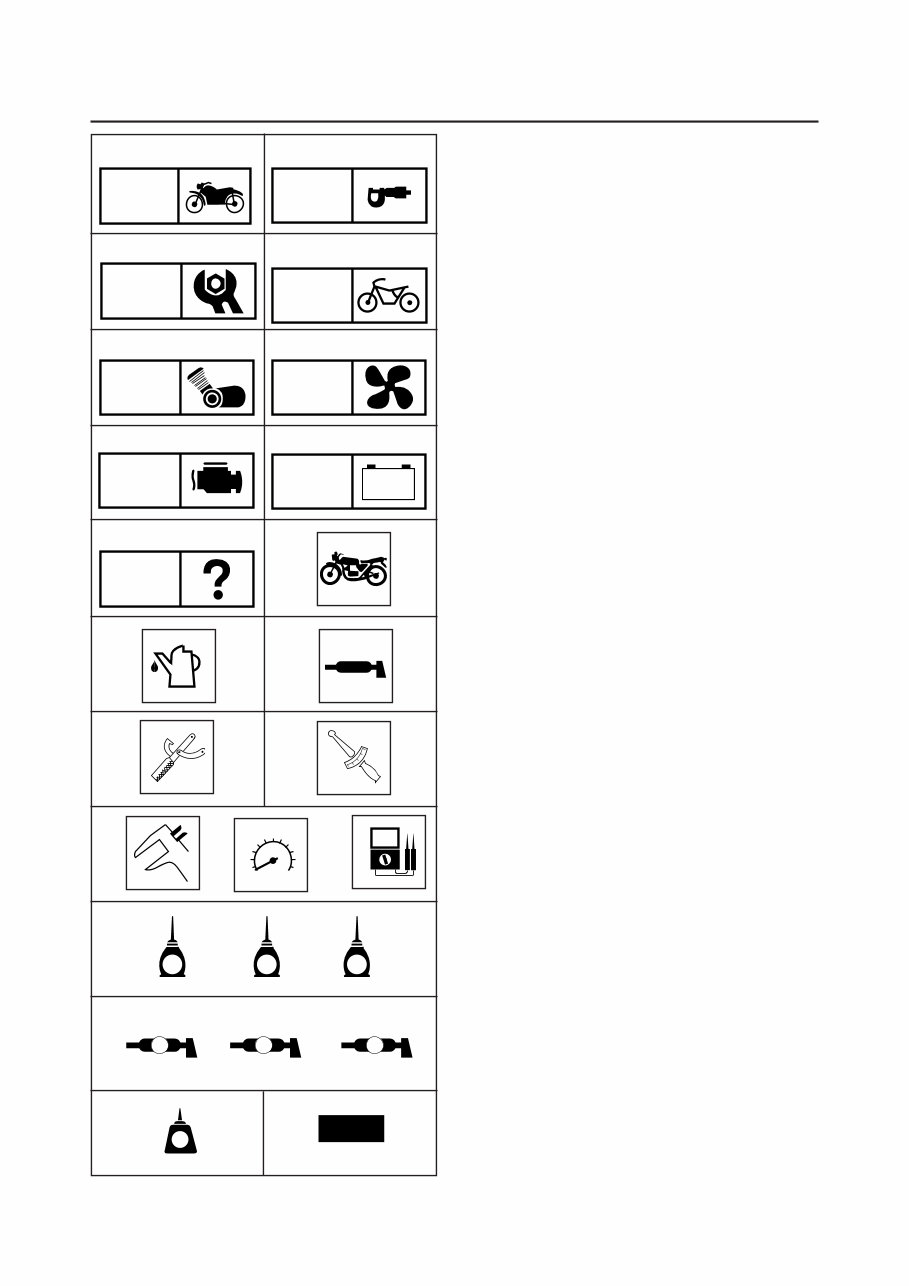

EAS00008

SYMBOLS

The following symbols are not relevant to every

vehicle.

Symbols 1 to 9 indicate the subject of each

chapter.

1 General information

2 Specifications

3 Periodic checks and adjustments

4 Chassis

5 Engine

6 Cooling system

7 Fuel injection system

8 Electrical system

9 Troubleshooting

Symbols 0 to u indicate the following.

0 Serviceable with engine mounted

q Filling fluid

w Lubricant

e Special tool

r Tightening torque

t Wear limit, clearance

y Engine speed

u Electrical data

Symbols i to d in the exploded diagrams indi-

cate the types of lubricants and lubrication

points.

i Engine oil

o Gear oil

p Molybdenum-disulfide oil

a Wheel-bearing grease

s Lithium-soap- based grease

d Molybdenum-disulfide grease

Symbols f to g in the exploded diagrams indi-

cate the following.

f Apply locking agent (LOCTITE

®

)

g Replace the part

T

R

.

.

t y u

LT

EAS00010

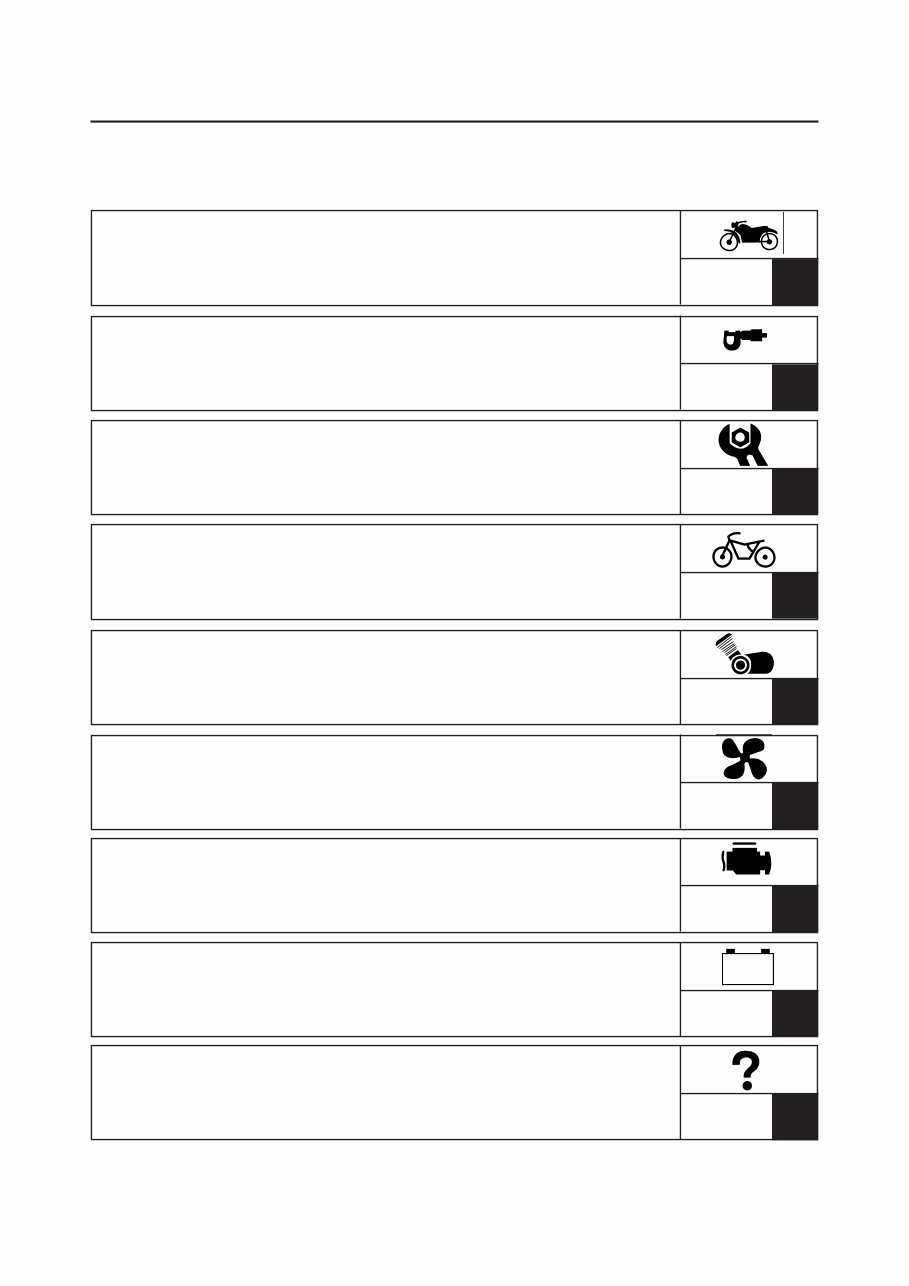

TABLE OF CONTENTS

GENERAL INFORMATION

SPECIFICATIONS

PERIODIC CHECKS AND

ADJUSTMENTS

CHASSIS

ENGINE

COOLING SYSTEM

FUEL INJECTION SYSTEM

ELECTRICAL SYSTEM

TROUBLESHOOTING

- +

GEN

INFO

SPEC

CHK

ADJ

CHAS

ENG

FI

ELEC

TRBL

SHTG

COOL

1

2

3

4

5

6

5

7

8

9

GEN

INFO

CHAPTER 1

GENERAL INFORMATION

SCOOTER IDENTIFICATION ................................................................... 1-1

VEHICLE IDENTIFICATION NUMBER ............................................. 1-1

MODEL LABEL .................................................................................. 1-1

FEATURES ............................................................................................... 1-2

OUTLINE OF THE FI SYSTEM ......................................................... 1-2

FI SYSTEM ........................................................................................ 1-3

IMPORTANT INFORMATION ................................................................... 1-4

PREPARATION FOR REMOVAL AND DISASSEMBLY ................... 1-4

REPLACEMENT PARTS ................................................................... 1-4

GASKETS, OIL SEALS AND O-RINGS ............................................ 1-4

LOCK WASHERS/PLATES AND COTTER PINS ............................. 1-5

BEARINGS AND OIL SEALS ............................................................ 1-5

CIRCLIPS ........................................................................................... 1-5

EQUIPMENT PREPARATION ........................................................... 1-6

CHECKING THE CONNECTIONS ........................................................... 1-7

SPECIAL TOOLS ...................................................................................... 1-8

1-1

GEN

INFO

SCOOTER IDENTIFICATION

EAS00015

GENERAL INFORMATION

SCOOTER IDENTIFICATION

EAS00017

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number 1 is stamped

into the frame.

EAS00018

MODEL LABEL

The model label 1 is affixed to the frame trunk.

This information will be needed to order spare

parts.

1

1

1-2

GEN

INFO

EAS00896

FEATURES

OUTLINE OF THE FI SYSTEM

The main function of a fuel supply system is to provide fuel to the combustion chamber at the opti-

mum air-fuel ratio in accordance with the engine operating conditions and the atmospheric tempera-

ture. In the conventional carburetor system, the air-fuel ratio of the mixture that is supplied to the

combustion chamber is created by the volume of the intake air and the fuel that is metered by the jet

used in the respective carburetor.

Despite the same volume of intake air, the fuel volume requirement varies by the engine operating

conditions, such as acceleration, deceleration, or operation under a heavy load. Carburetors that

meter the fuel through the use of jets have been provided with various auxiliary devices, so that an

optimum air-fuel ratio can be achieved to accommodate the constant changes in the operating con-

ditions of the engine.

As the requirements for the engine to deliver more performance and cleaner exhaust gases in-

crease, it becomes necessary to control the air-fuel ratio in a more precise and finely tuned manner.

To accommodate this need, this model has adopted an electronically controlled fuel injection(FI)

system, in place of the conventional carburetor system. This system can achieve an optimum air-

fuel ratio required by the engine at all times by using a microprocessor that regulates the fuel injec-

tion volume according to the engine operating conditions detected by various sensors.

The adoption of the FI system has resulted in a highly precise fuel supply, improved engine re-

sponse, better fuel economy, and reduced exhaust emissions.

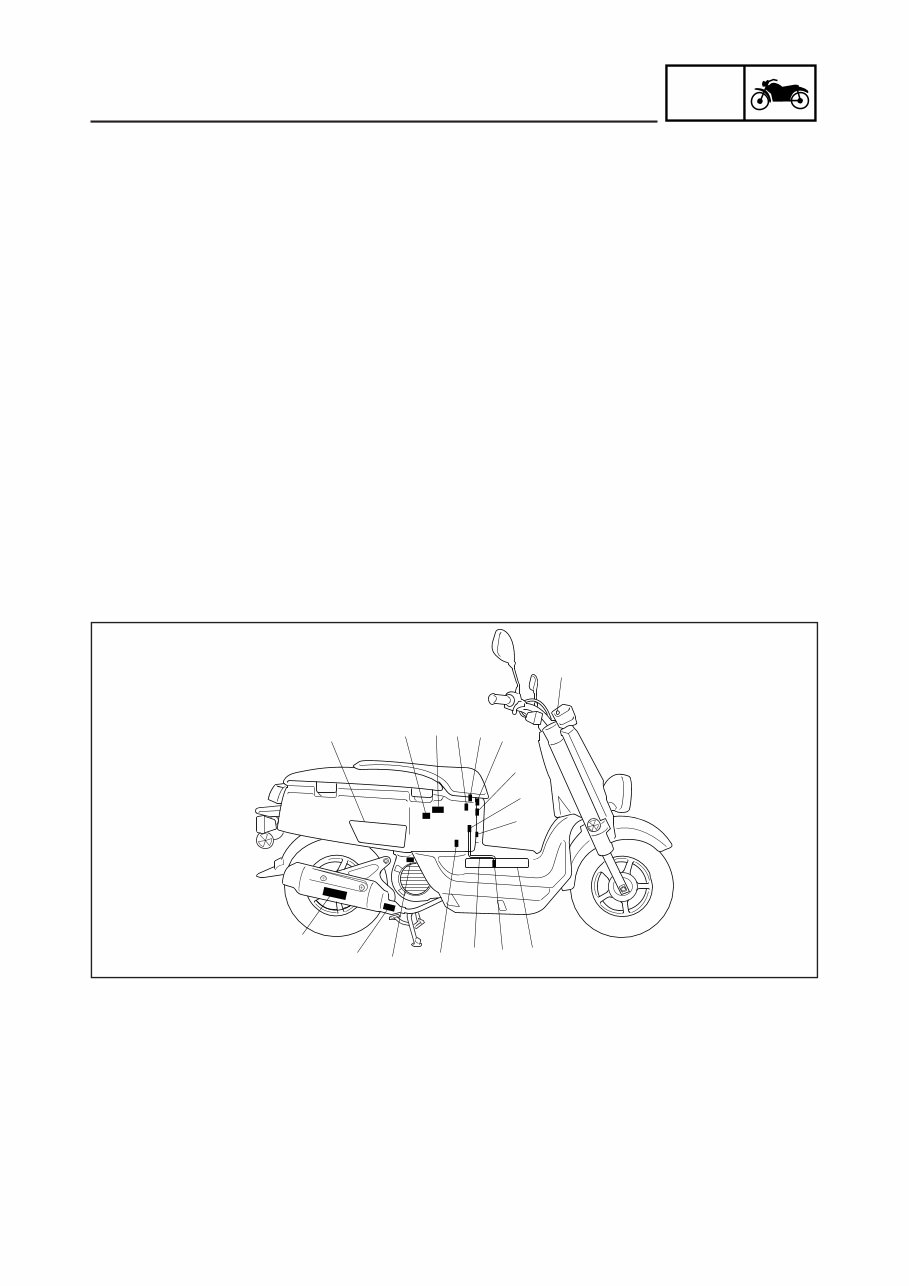

1 ECU

2 Engine trouble warning light

3 Lean angle cut-off switch

4 Fuel hose

5 Ignition coil

6 Fuel injector

7 Intake air pressure sensor

8 ISC(idle speed control) valve

9 Intake air temperature sensor

0 Battery

q Air filter case

w Catalytic converter

e Crankshaft position sensor

r Coolant temperature sensor

t Spark plug

y Fuel tank

u Fuel pump

i Throttle position sensor

FEATURES

q

8

w

e

r

4 u y

t

6

5

1

0 3

7

9

i

2

w

1-3

GEN

INFO

FEATURES

EAS00897

FI SYSTEM

The fuel pump delivers fuel to the fuel injector via the fuel filter. The pressure regulator maintains the

fuel pressure that is applied to the fuel injector at only 250 kPa (2.5 kg/cm

2

, 35.6 psi). Accordingly,

when the energizing signal from the ECU energizes the fuel injector, the fuel passage opens, caus-

ing the fuel to be injected into the intake manifold only during the time the passage remains open.

Therefore, the longer the length of time the fuel injector is energized (injection duration), the greater

the volume of fuel that is supplied. Conversely, the shorter the length of time the fuel injector is

energized (injection duration), the lesser the volume of fuel that is supplied.

The injection duration and the injection timing are controlled by the ECU. Signals that are input from

the crankshaft position sensor, intake air pressure sensor, intake temperature sensor and engine

temperature sensor enable the ECU to determine the injection duration. The injection timing is deter-

mined through the signals from the crankshaft position sensor. As a result, the volume of fuel that is

required by the engine can be supplied at all times in accordance with the driving conditions.

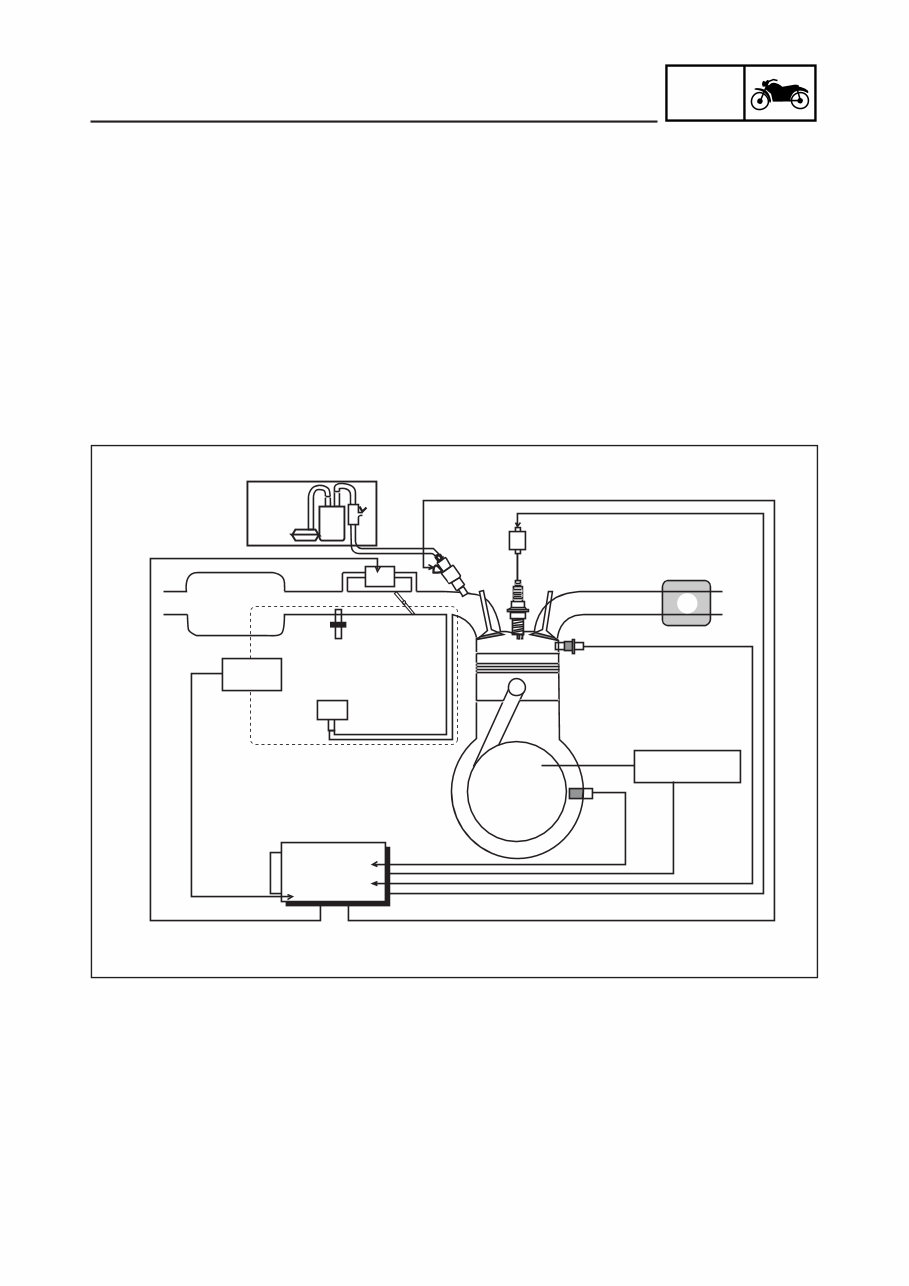

1 Fuel pump

2 Fuel injector

3 Ignition coil

4 ECU

5 Catalytic converter

6 Coolant temperature sensor

7 Crankshaft position sensor

8 Intake air pressure sensor

9 Throttle body assembly

0 Intake air temperature sensor

Illustration is for reference only.

q Air filter case

w ISC (idle speed control) valve

e Throttle position sensor

A Fuel system

B Air system

C Control system

1

A

3

4

5

6

7

9

0

q

e

w

C

MAQS

B

8

REC./REG.

2

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

Viewed 16 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

This manual covers the 2011 Yamaha C3 motorcycle service manual. It is a comprehensive guide used by professional mechanics and DIY enthusiasts for repairs and maintenance.