@S YAMAHA

SERVICE MANUAL

Tracer 9 GT+

2024

MTT9GPR

MTT9GPRC

LIT-11616-37-16

@YAMAHA

SERVICE MANUAL

BASIC INFORMATION

LIT-11616-MC-BO YOA-28197-10

IMPORTANT

This manual was produced by the Yamaha Motor Company, Ltd. primarily for use by Yamaha dealers

and their qualified mechanics.

This manual contains only basic instructions that must be observed during servicing. Refer to the ap-

plicable service manual for detailed information on checking, adjustment, and replacement.

TIP.

Designs and specifications are subject to change without notice.

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following notations.

This is the safety alert symbol. It is used to alert you to potential personal

a&d injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

] A WARNING indicates a hazardous situation which, if not avoided, could

WATZENIT _result in death or serious injury.

‘A NOTICE indicates special precautions that must be taken to avoid

NOTICE damage to the vehicle or other property.

TIP ATIP provides key information to make procedures easier or clearer.

BASIC INFORMATION

SERVICE MANUAL

©2017 by Yamaha Motor Corporation, U.S.A.

First edition, January 2017

All rights reserved.

Any reproduction or unauthorized use

without the written permission of

Yamaha Motor Corporation, U.S.A.

is expressly prohibited.

Printed in U.S.A.

PIN LIT-11616-MC-BO

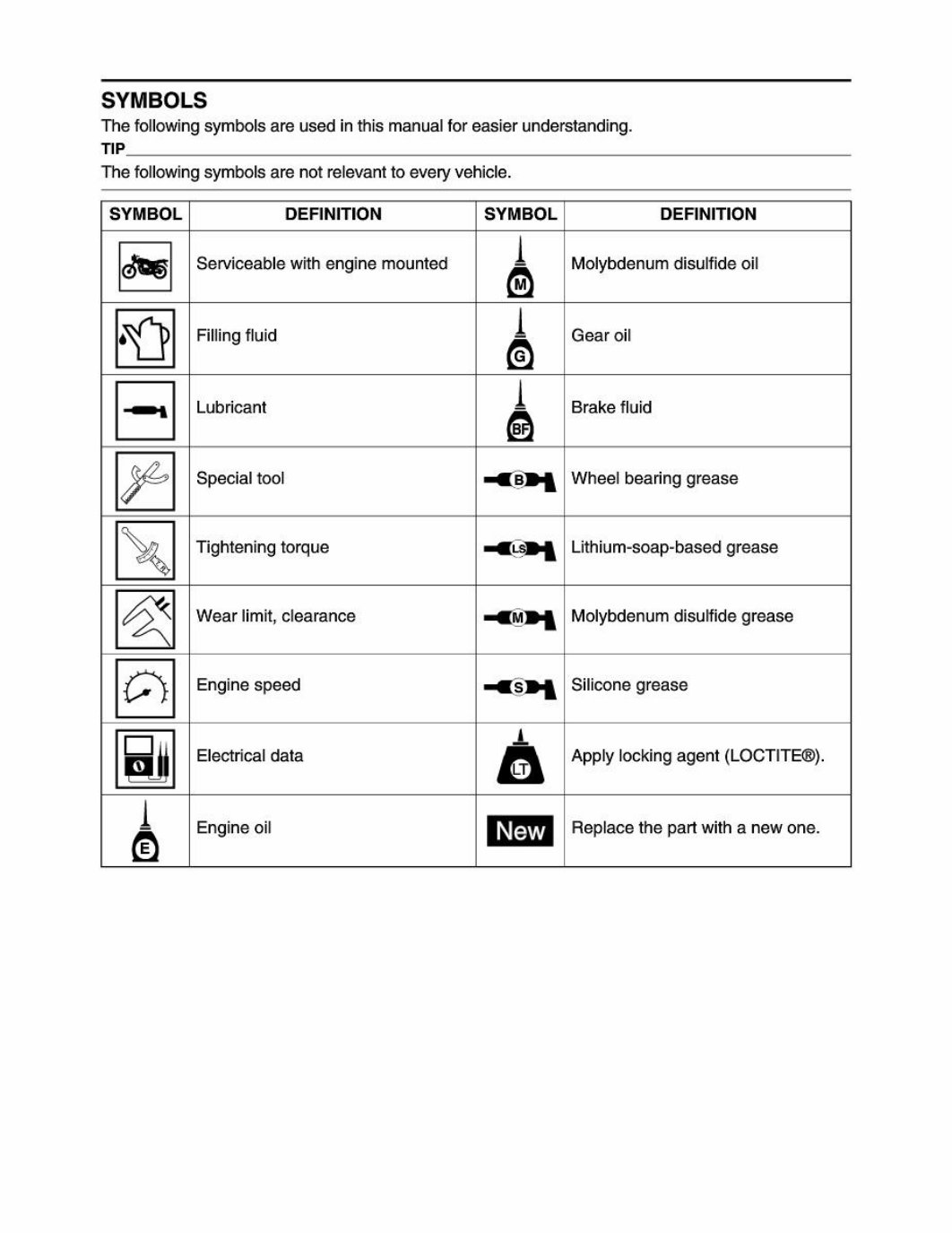

SYMBOLS

The following symbols are used in this manual for easier understanding.

TIP.

The following symbols are not relevant to every vehicle.

SYMBOL DEFINITION SYMBOL DEFINITION

Serviceable with engine mounted Molybdenum disulfide oil

p-— |© Tae _p-

Filling fluid Gear oil

Lubricant Brake fluid

Special tool Wheel bearing grease

Tightening torque

<4

Lithium-soap-based grease

Wear limit, clearance

«14

Molybdenum disulfide grease

Engine speed

“ashy

Silicone grease

Electrical data Apply locking agent (LOCTITE®).

(HS |p] SJL Ica a

Engine oil Replace the part with a new one.

CONTENTS

IMPORTANT INFORMATION...

PREPARATION FOR REMOVAL AND DISASSEMBLY.

REPLACEMENT PARTS...

GASKETS, OIL SEALS AND O-RINGS ..

LOCK WASHERS/PLATES AND COTTER PINS

BEARINGS AND OIL SEALS...

CIRCLIPS ....

REASSEMBLY OF PARTS USING LOCKING AGENT (LOCTITE®)

RUBBER PARTS..

BASIC SERVICE INFORMATION.

QUICK FASTENERS..

ELECTRICAL SYSTEM

GENERAL TIGHTENING TORQUE SPECIFICATIONS.

ADJUSTING THE WHEEL STATIC BALANCE

CHECKING THE SWITCHES ....

CHECKING THE BULBS AND BULB SOCKETS.

CHECKING AND CHARGING THE BATTERY...

TROUBLESHOOTING...

GENERAL INFORMATION .

TROUBLESHOOTING OF ENGINE (fault code not detected)

TROUBLESHOOTING OF CLUTCH...

TROUBLESHOOTING OF TRANSMISSION

TROUBLESHOOTING OF COOLING SYSTEM.

TROUBLESHOOTING OF BRAKE... 32

TROUBLESHOOTING AT ABS WARNING LIGHT. 33

TROUBLESHOOTING OF SUSPENSION .. 34

TROUBLESHOOTING OF STEERING/HANDLING 36

TROUBLESHOOTING OF CHARGING SYSTEM .

TROUBLESHOOTING OF LIGHTING SYSTEM.

TROUBLESHOOTING OF SIGNALING SYSTEM.

IMPORTANT INFORMATION

IMPORTANT INFORMATION

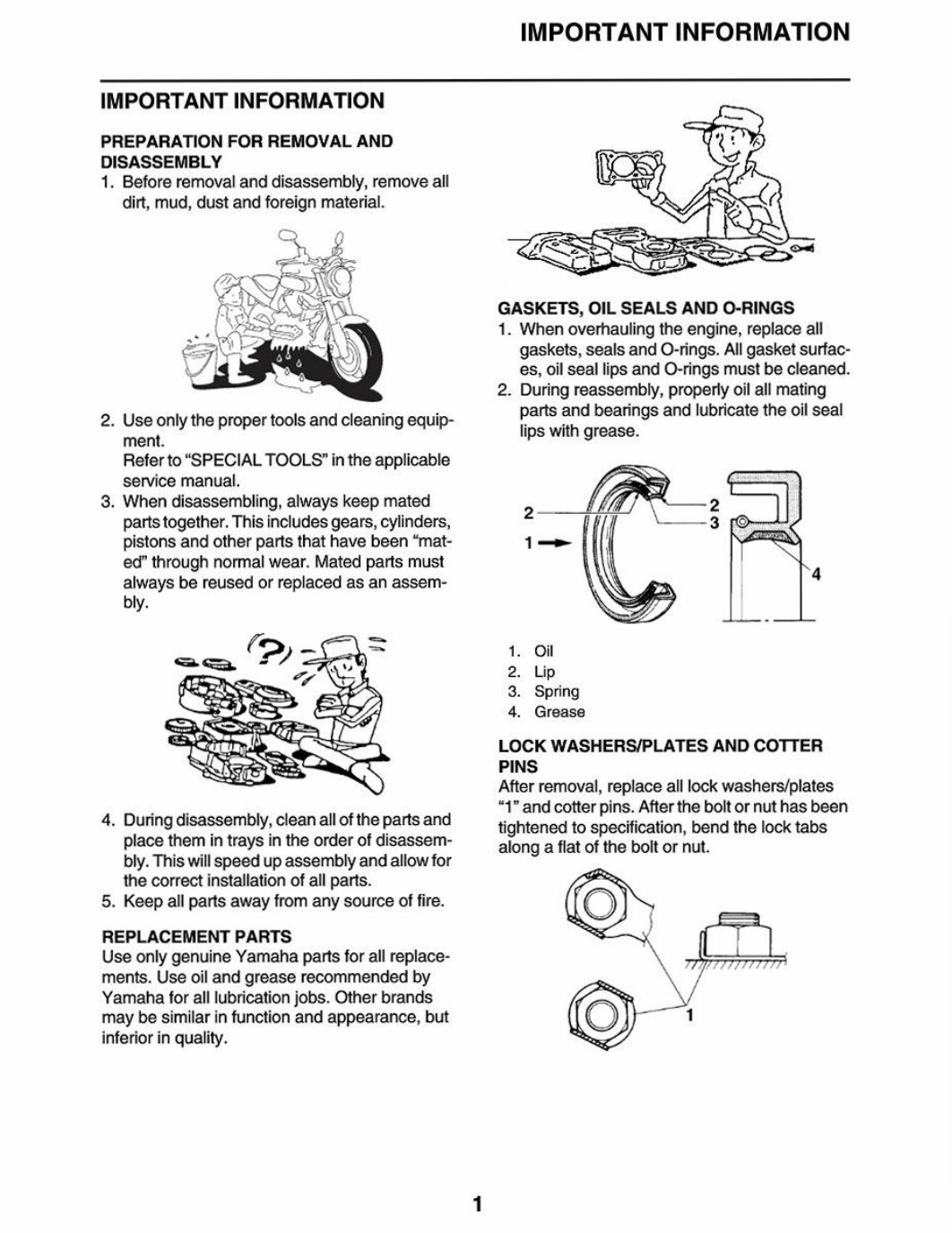

PREPARATION FOR REMOVAL AND

DISASSEMBLY

1. Before removal and disassembly, remove all

dirt, mud, dust and foreign material.

2. Use only the proper tools and cleaning equip-

ment.

Refer to “SPECIAL TOOLS?’ in the applicable

service manual.

3. When disassembling, always keep mated

parts together. This includes gears, cylinders,

pistons and other parts that have been “mat-

ed” through normal wear. Mated parts must

always be reused or replaced as an assem-

bly.

4. During disassembly, clean all of the parts and

place them in trays in the order of disassem-

bly. This will speed up assembly and allow for

the correct installation of all parts.

5. Keep all parts away from any source of fire.

REPLACEMENT PARTS

Use only genuine Yamaha parts for all replace-

ments. Use oil and grease recommended by

Yamaha for all lubrication jobs. Other brands

may be similar in function and appearance, but

inferior in quality.

GASKETS, OIL SEALS AND O-RINGS

1. When overhauling the engine, replace all

gaskets, seals and O-rings. All gasket surfac-

es, oil seal lips and O-rings must be cleaned.

2. During reassembly, properly oil all mating

parts and bearings and lubricate the oil seal

lips with grease.

1. Oil

2. Lip

3. Spring

4, Grease

LOCK WASHERS/PLATES AND COTTER

PINS

After removal, replace all lock washers/plates

“1” and cotter pins. After the bolt or nut has been

tightened to specification, bend the lock tabs

along a flat of the bolt or nut.

IMPORTANT INFORMATION

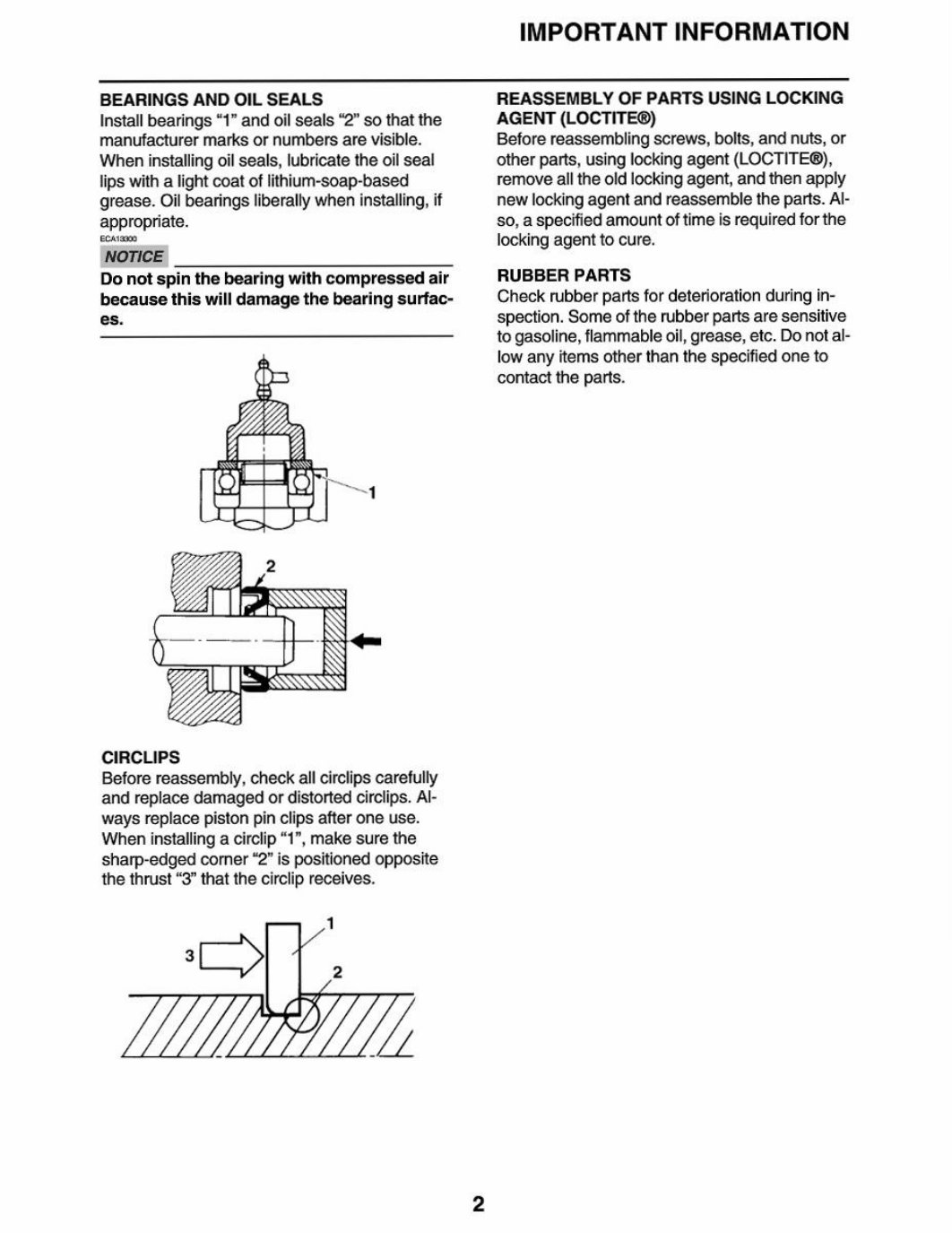

BEARINGS AND OIL SEALS

Install bearings “1” and oil seals “2” so that the

manufacturer marks or numbers are visible.

When installing oil seals, lubricate the oil seal

lips with a light coat of lithium-soap-based

grease. Oil bearings liberally when installing, if

appropriate.

NOTICE

Do not spin the bearing with compressed air

because this will damage the bearing surfac-

es.

CIRCLIPS

Before reassembly, check all circlips carefully

and replace damaged or distorted circlips. Al-

ways replace piston pin clips after one use.

When installing a circlip “1”, make sure the

sharp-edged comer “2” is positioned opposite

the thrust “3” that the circlip receives.

REASSEMBLY OF PARTS USING LOCKING

AGENT (LOCTITE®)

Before reassembling screws, bolts, and nuts, or

other parts, using locking agent (LOCTITE®),

remove all the old locking agent, and then apply

new locking agent and reassemble the parts. Al-

0, a specified amount of time is required for the

locking agent to cure.

RUBBER PARTS

Check rubber parts for deterioration during in-

spection. Some of the rubber parts are sensitive

to gasoline, flammable oil, grease, etc. Do not al-

low any items other than the specified one to

contact the parts.

BASIC SERVICE INFORMATION

BASIC SERVICE INFORMATION

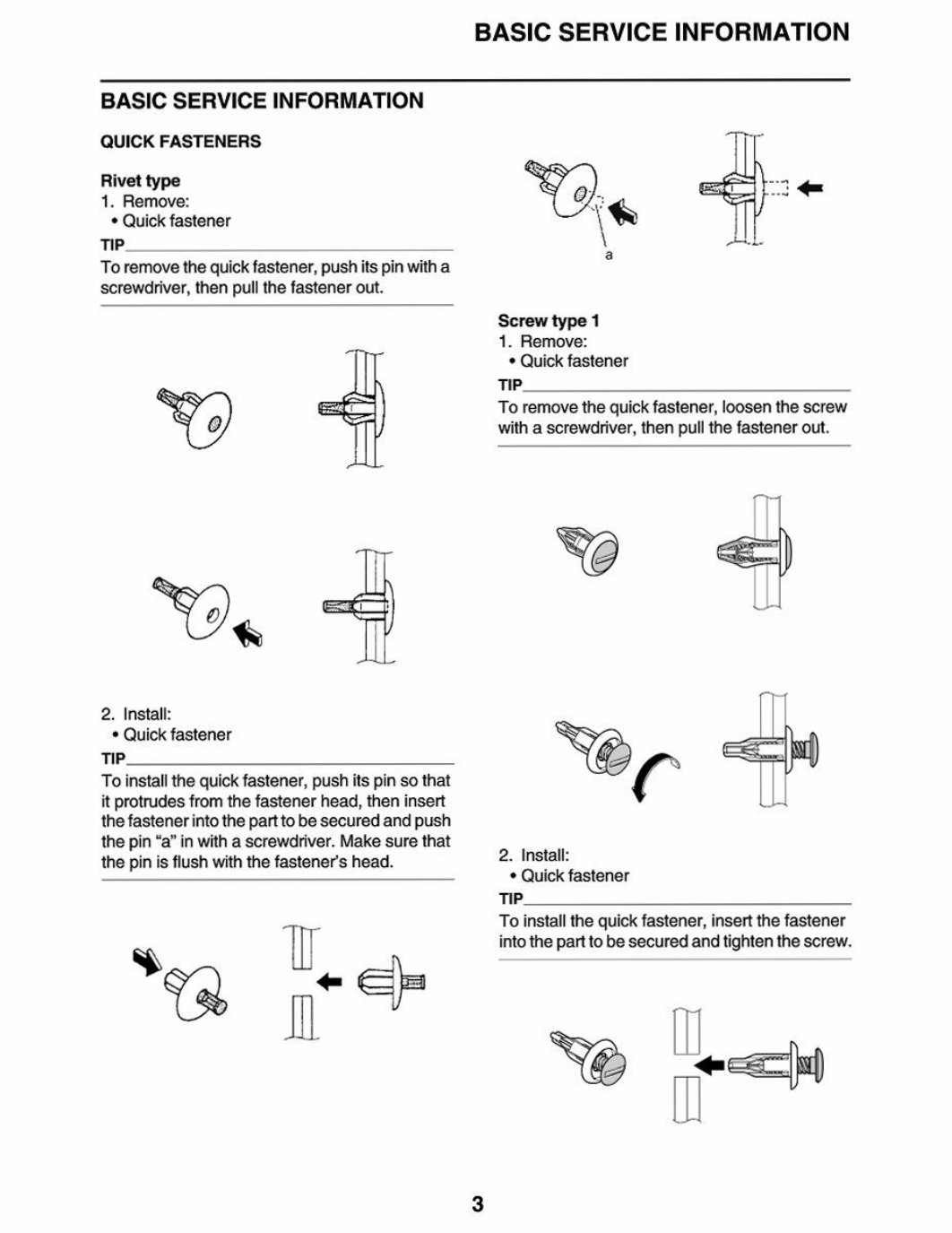

QUICK FASTENERS

Rivet type

1. Remove:

* Quick fastener

TIP.

To remove the quick fastener, push its pin with a

‘screwdriver, then pull the fastener out.

3 a

2. Install:

* Quick fastener

TIP.

To install the quick fastener, push its pin so that

it protrudes from the fastener head, then insert

the fastener into the part to be secured and push

the pin “a” in with a screwdriver. Make sure that

the pin is flush with the fastener’s head.

*93 - Gz

We

\ ALL

a

Screw type 1

1. Remove:

* Quick fastener

TIP.

To remove the quick fastener, loosen the screw

with a screwdriver, then pull the fastener out.

eo 6

er

2. Install:

* Quick fastener

TIP.

To install the quick fastener, insert the fastener

into the part to be secured and tighten the screw.

UD,

Ye =

You're Reading a Preview

What's Included?

Lifetime Access

Access PDF Contents & Bookmarks

Print one or all pages of your manual