2001-2012 Triumph Bonneville T100 Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Triu h 0 n ill

T100, Speedmaster, America, Thruxton

and Scrambler

erv1 e n epair Manu I

Models covered

Bonneville. 790cc. 2001to 2006

Bonneville. 865cc. 2007 to 2012

Bonneville SE. 865cc. 2009 to 2012

T100. 790cc. 2002to 2004

T100.865cc.2005to 2012

America. 790cc. 2002 to 2006

America. 865cc. 2007 to 2012

Speedmaster. 790cc. 2003 to 2004

Speedmaster. 865cc. 2005 to 2012

Thruxton. 865cc. 2004to 2012

Scrambler.865cc 2006to 2012

LIVING WITH YOUR TRIUMPH

Introduction

A Phoenix from the ashes

Page

0•4

Page

0•7

About this manual Page

0•7

Model development

Page

0•8

Identification numbers

Page

0•9

Buying spare

Page 0•9

Page

0•10

Pre-ride checks

Engine oil level Page

0°11

Brake fluid levels Page

0•12

checks

Page

0•14

Page

0•15

Suspension, steering and drive chain Page

0•15

Bike spec Page

0•16

MAINTENANCE

Routine maintenance and servicing

Specifications

1•2

Lubricants and fluids

Page

1•2

Maintenance schedule Page

1•3

Component locations

Page

1•5

Maintenance procedures Page

1•7

REPAIRS AND OVERHAU

transmission and

Engine, clutch and transmission

Chassis and bodywork components

Frame, suspension and final drive

Brakes, wheels and

Bodywork

Electrical system

Wiring diagrams

REFERENCE

Tools and Workshop Tips

Security

Lubricants and fluids

Conversion Factors

MOT test checks

Storage

Fault finding

Fault finding equipment

Technical terms explained

systems

Page 2•1

Page 38•1

Page 4•1

Page 5•1

6•1

Page

7•1

Page 8•1

Page

8•28

Page REF•2

REF•20

Page REF•23

Page REF•26

Page REF•27

Page REF•32

REF•35

Page REF•47

Page REF•51

Page REF•55

0°4 Introduction

nix from

h

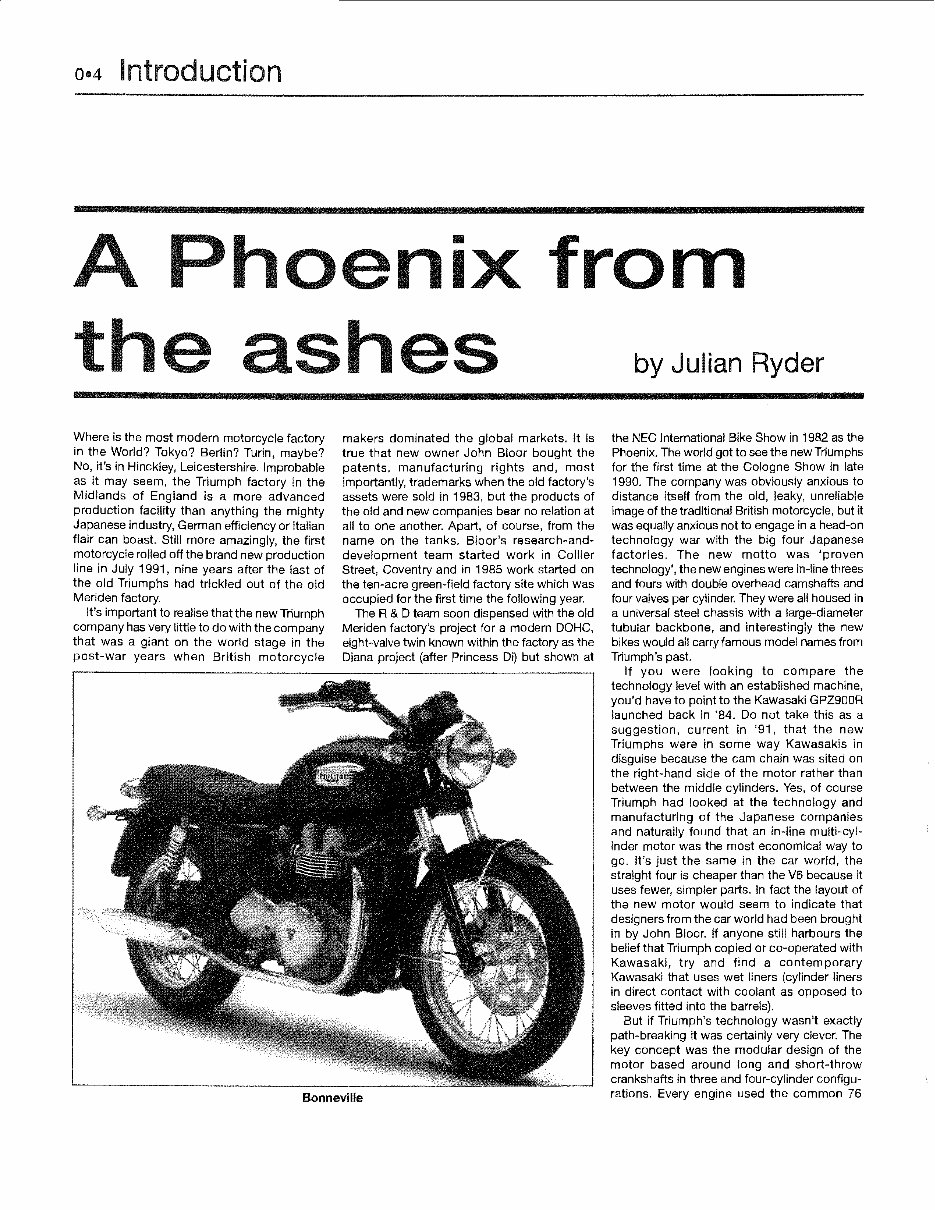

Where is the most modern motorcycle factory

in the World? Tokyo? Berlin? Turin, maybe?

No, it's in Hinckley, Leicestershire, Improbable

as it may seem, the Triumph factory in the

Midlands of England is a more advanced

production facility than anything the mighty

Japanese industry, German efficiency or Italian

flair can boast. Still more amazingly, the first

motorcycle rolled off the brand new production

line in July 1991, nine years after the last of

the old Triumphs had trickled out of the old

Meriden factory.

It's important to realise that the new Triumph

company has very little to do with the company

that was a giant on the world stage in the

post-war years when British motorcycle

h

makers dominated the global markets. It is

true that new owner John Bloor bought the

patents, manufacturing rights and, most

importantly, trademarks when the old factory's

assets were sold in 1983, but the products of

the old and new companies bear no relation at

all to one another. Apart, of course, from the

name on the tanks. Bloor's research-and-

development team started work in Collier

Street, Coventry and in 1985 work started on

the ten-acre green-field factory site which was

occupied for the first time the following year.

The R & D team soon dispensed with the old

Meriden factory's project for a modern DOHC,

eight-valve twin known within the factory as the

Diana project (after Princess Di) but shown at

Bonneville

by Julian Ryder

the NEC International Bike Show in 1982 as the

Phoenix. The world got to see the new Triumphs

for the first time at the Cologne Show in late

1990. The company was obviously anxious to

distance itself from the old, leaky, unreliable

image of the traditional British motorcycle, but it

was equally anxious not to engage in a head-on

technology war with the big four Japanese

factories. The new motto was 'proven

technology', the new engines were in-line threes

and fours with double overhead camshafts and

four valves per cylinder. They were all housed in

a universal steel chassis with a large-diameter

tubular backbone, and interestingly the new

bikes would all carry famous model names from

Triumph's past.

If you were looking to compare the

technology level with an established machine,

you'd have to point to the Kawasaki GPZ900R

launched back in '84. Do not take this as a

suggestion, current in '91, that the new

Triumphs were in some way Kawasakis in

disguise because the cam chain was sited on

the right-hand side of the motor rather than

between the middle cylinders. Yes, of course

Triumph had looked at the technology and

manufacturing of the Japanese companies

and naturally found that an in-line multi-cyl-

inder motor was the most economical way to

go. It's just the same in the car world, the

straight four is cheaper than the V6 because it

uses fewer, simpler parts. In fact the layout of

the new motor would seem to indicate that

designers from the car world had been brought

in by John Bloor. If anyone still harbours the

belief that Triumph copied or co-operated with

Kawasaki, try and find a contemporary

Kawasaki that uses wet liners (cylinder liners

in direct contact with coolant as opposed to

sleeves fitted into the barrels).

But if Triumph's technology wasn't exactly

path-breaking it was certainly very clever. The

key concept was the modular design of the

motor based around long and short-throw

crankshafts in three and four-cylinder configu-

rations. Every engine used the common 76

mm bore with either 55 or 65 mm throw cranks

so that the short-stroke engine would be 750

cc in three-cylinder form and 1000 cc as a

four. Put the long-stroke crank in and you get

a 900 cc triple and a 1200 cc four. The first

bike to hit the shops was the 1200 Trophy, a

four-cylinder sports tourer which was

immediately competitive in a very strong class.

There was also a 900 cc, three-cylinder

Trophy. The 750 and 1000 Dayton as used the

short-stroke motor in three and four-cylinder

forms in what were intended to be the

sportsters of the range. The other two models,

750 and 900 cc three-cylinder Tridents,

cashed in on the early-'90s fad for naked retro

bikes that followed the world-wide success of

the Kawasaki Zephyr.

The reborn Triumphs were received with

acclaim from the motorcycle press - tinged

with not a little surprise. They really were very

good motorcycles, the big Trophy was a match

for the Japanese opposition in a class full of

very accomplished machinery. The fact it could

live with a modern day classic like the Yamaha

FJ1200 straight off the drawing board was a

tribute to John Bloor's designers and production

engineers. The bike was big, fast, heavy and

quite high, but it worked and worked well. And

it didn't leak oil or break down, it was obvious

that whatever else people were going to say

about Triumphs they weren't going to able to

resurrect the old jokes about British bangers

leaving puddles of lubricant under them. As the

rest of the range arrived and tests of them got

into print, the star of the show emerged; it was

the long-stroke, three-cylinder, 900 cc motor. It

didn't matter how it was dressed up, the big

triple had that indefinable quality - character. It

was the motor the Japanese would never have

made, very torquey but with a hint of vibration

that endears rather than annoys. Somewhere

among the modern, water-cooled, multi-valve

technology, the 900-triple had the genes of the

old air-cooled OHV Triumph Tridents that

appeared in 1969 and stayed in production

until '75.

The range stayed basically unchanged for

two years, until the Cologne Show of '92.

Looking back at the first range it is now easy

to see - hindsight again - that the identity of

all the models was far too close. The sports

tourer Trophy models were reckoned to be a

little too sporting, the basic Tridents still had

the handlebar and footrest positions of faired

bikes. Triumph management later agreed that

the first range evinced a certain lack of

confidence, that was certainly not the case

with the revamped 1993 range.

Visitors to the Cologne Show in September

'92 agreed that the Triumphs were the stars, any

lack of confidence there may have been two

years earlier was completely gone. Any shyness

the management may have felt about the

Triumph name's past was shaken off as the new

Tridents went retro style. Overall, the identities of

the original bikes became more individual and

more obviously separated; the Trophy models

became more touring oriented, the Daytona

Introduction o·s

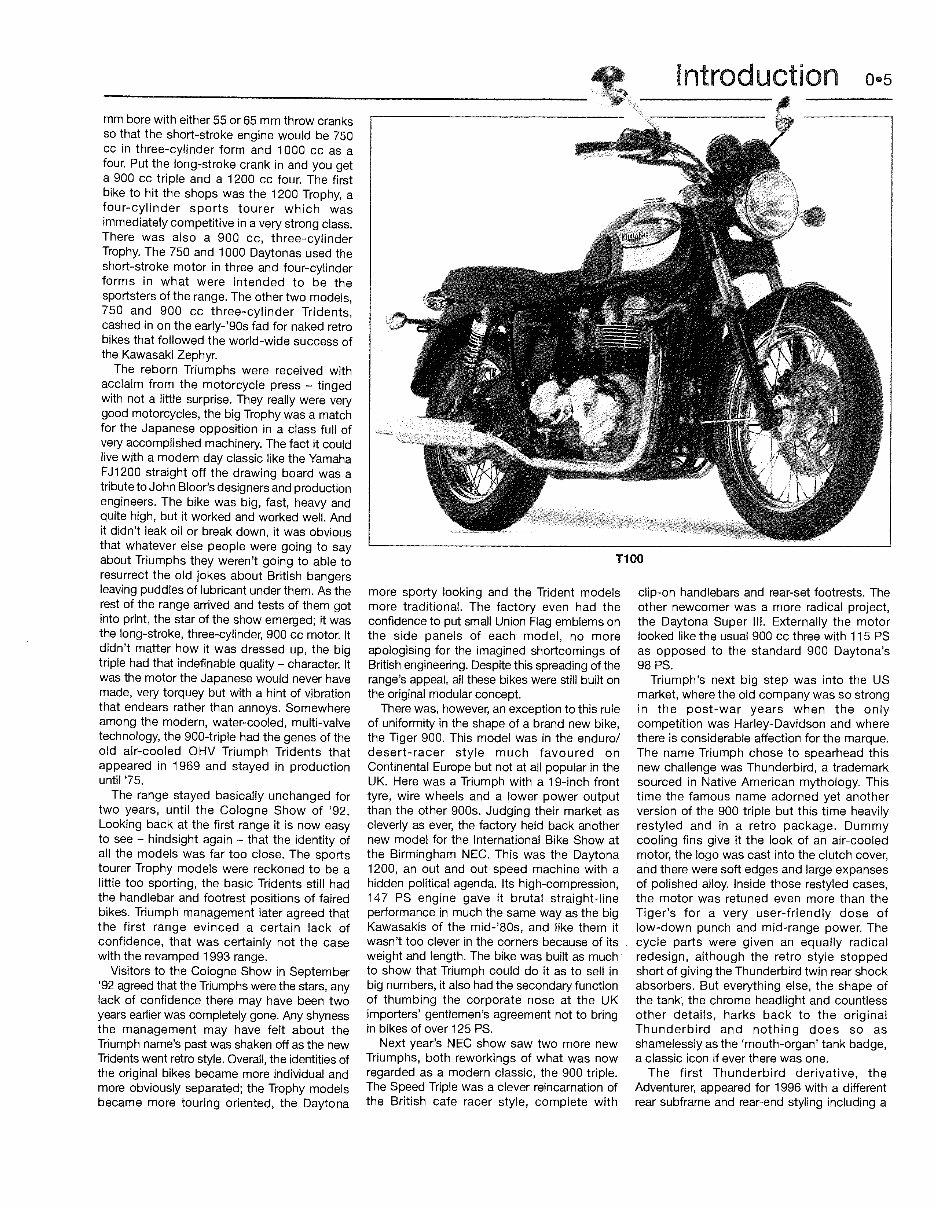

T100

more sporty looking and the Trident models

more traditional. The factory even had the

confidence to put small Union Flag emblems on

the side panels of each model, no more

apologising for the imagined shortcomings of

British engineering. Despite this spreading of the

range's appeal, all these bikes were still built on

the original modular concept.

There was, however, an exception to this rule

of uniformity in the shape of a brand new bike,

the Tiger 900. This model was in the enduro/

desert-racer style much favoured on

Continental Europe but not at all popular in the

UK. Here was a Triumph with a 19-inch front

tyre, wire wheels and a lower power output

than the other 900s. Judging their market as

cleverly as ever, the factory held back another

new model for the International Bike Show at

the Birmingham NEC. This was the Daytona

1200, an out and out speed machine with a

hidden political agenda. Its high-compression,

14 7 PS engine gave it brutal straight-line

performance in much the same way as the big

Kawasakis of the mid-'80s, and like them it

wasn't too clever in the corners because of its

weight and length. The bike was built as much

to show that Triumph could do it as to sell in

big numbers, it also had the secondary function

of thumbing the corporate nose at the UK

importers' gentlemen's agreement not to bring

in bikes of over 125 PS.

Next year's NEC show saw two more new

Triumphs, both reworkings of what was now

regarded as a modern classic, the 900 triple.

The Speed Triple was a clever reincarnation of

the British cafe racer style, complete with

clip-on handlebars and rear-set footrests. The

other newcomer was a more radical project,

the Daytona Super Ill. Externally the motor

looked like the usual 900 cc three with 115 PS

as opposed to the standard 900 Daytona's

98 PS.

Triumph's next big step was into the US

market, where the old company was so strong

in the post-war years when the only

competition was Harley-Davidson and where

there is considerable affection for the marque.

The name Triumph chose to spearhead this

new challenge was Thunderbird, a trademark

sourced in Native American mythology. This

time the famous name adorned yet another

version of the 900 triple but this time heavily

restyled and in a retro package. Dummy

cooling fins give it the look of an air-cooled

motor, the logo was cast into the clutch cover,

and there were soft edges and large expanses

of polished alloy. Inside those restyled cases,

the motor was retuned even more than the

Tiger's for a very user-friendly dose of

low-down punch and mid-range power. The

cycle parts were given an equally radical

redesign, although the retro style stopped

short of giving the Thunderbird twin rear shock

absorbers. But everything else, the shape of

the tank, the chrome headlight and countless

other details, harks back to the original

Thunderbird and nothing does so as

shamelessly as the 'mouth-organ' tank badge,

a classic icon if ever there was one.

The first Thunderbird derivative, the

Adventurer, appeared for 1996 with a different

rear subframe and rear-end styling including a

o·s Introduction

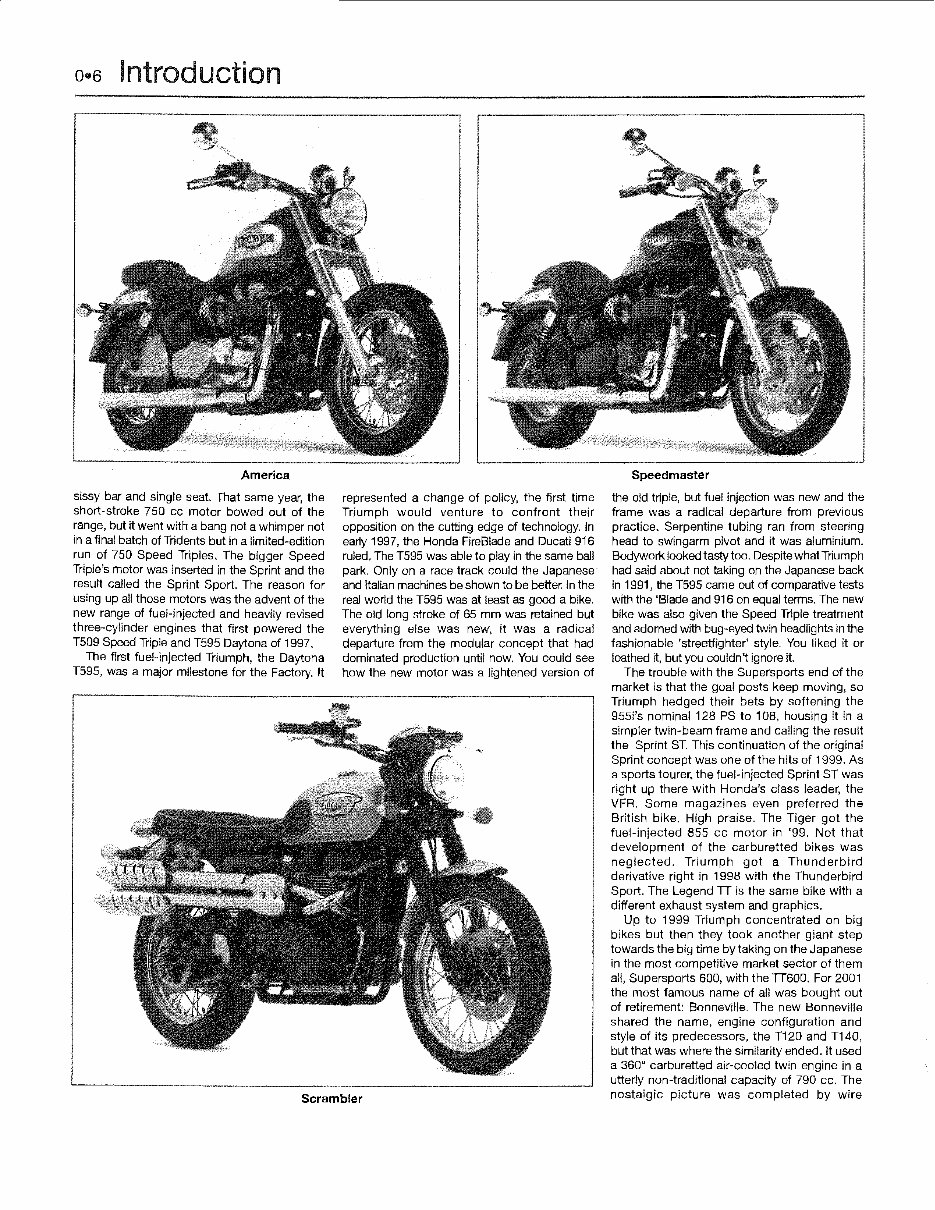

America

sissy bar and single seat. That same year, the

short-stroke 750 cc motor bowed out of the

range, but it went with a bang not a whimper not

in a final batch of Tridents but in a limited-edition

run of 750 Speed Triples. The bigger Speed

Triple's motor was inserted in the Sprint and the

result called the Sprint Sport. The reason for

using up all those motors was the advent of the

new range of fuel-injected and heavily revised

three-cylinder engines that first powered the

T509 Speed Triple and T595 Daytona of 1997.

The first fuel-injected Triumph, the Daytona

T595, was a major milestone for the Factory. It

represented a change of policy, the first time

Triumph would venture to confront their

opposition on the cutting edge of technology. In

early 1997, the Honda FireBlade and Ducati 916

ruled. The T595 was able to play in the same ball

park. Only on a race track could the Japanese

and Italian machines be shown to be better. In the

real world the T595 was at least as good a bike.

The old long stroke of 65 mm was retained but

everything else was new, it was a radical

departure from the modular concept that had

dominated production until now. You could see

how the new motor was a lightened version of

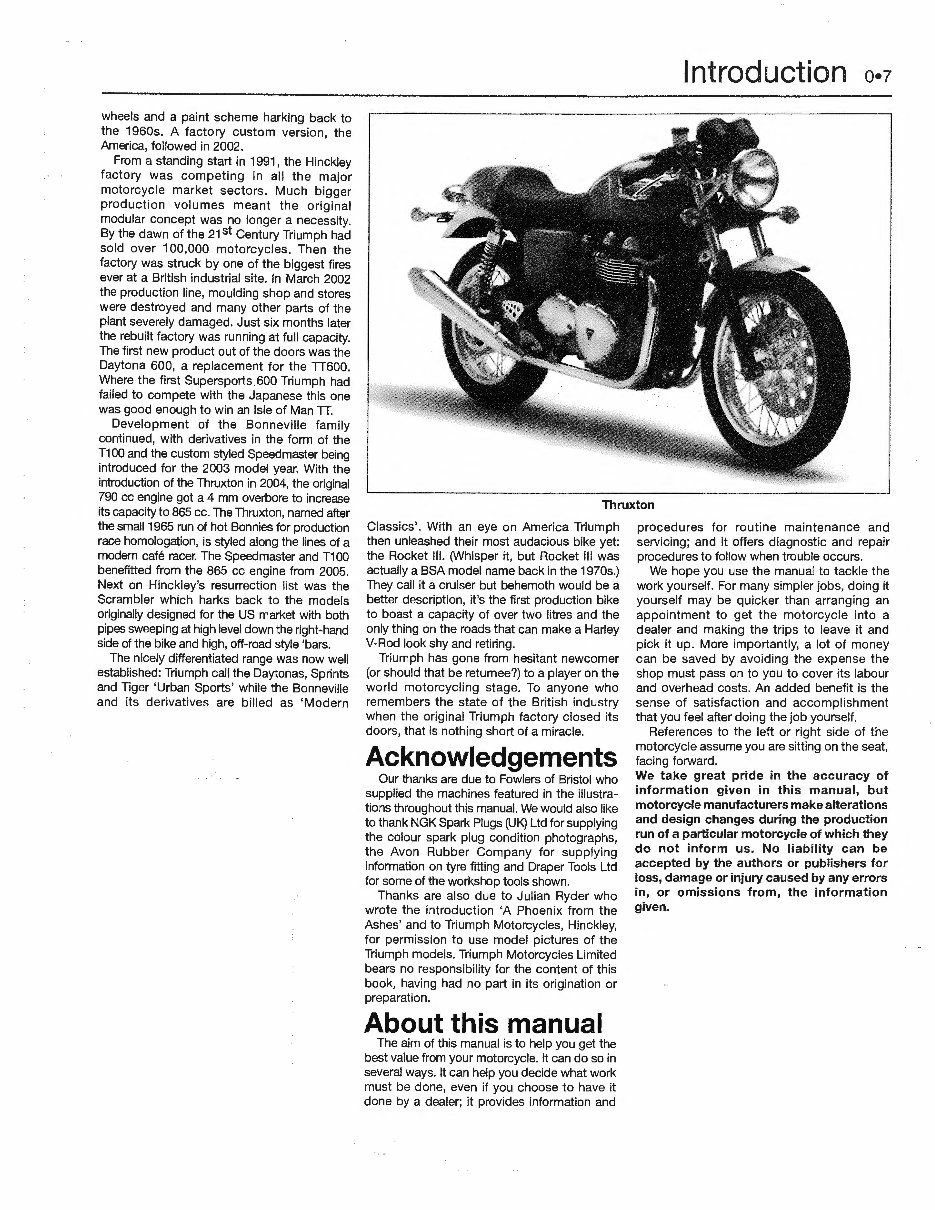

Scrambler

Speedmaster

the old triple, but fuel injection was new and the

frame was a radical departure from previous

practice. Serpentine tubing ran from steering

head to swingarm pivot and it was aluminium.

Bodywork looked tasty too. Despite what Triumph

had said about not taking on the Japanese back

in 1991, the T595 came out of comparative tests

with the 'Blade and 916 on equal terms. The new

bike was also given the Speed Triple treatment

and adorned with bug-eyed twin headlights in the

fashionable 'streetfighter' style. You liked it or

loathed it, but you couldn't ignore it

The trouble with the Supersports end of the

market is that the goal posts keep moving, so

Triumph hedged their bets by softening the

955i's nominal 128 PS to 108, housing it in a

simpler twin-beam frame and calling the result

the Sprint ST. This continuation of the original

Sprint concept was one of the hits of 1999. As

a sports tourer, the fuel-injected Sprint ST was

right up there with Honda's class leader, the

VFR. Some magazines even preferred the

British bike. High praise. The Tiger got the

fuel-injected 855 cc motor in '99. Not that

development of the carburetted bikes was

neglected. Triumph got a Thunderbird

derivative right in 1998 with the Thunderbird

Sport. The Legend TT is the same bike with a

different exhaust system and graphics.

Up to 1999 Triumph concentrated on big

bikes but then they took another giant step

towards the big time by taking on the Japanese

in the most competitive market sector of them

all, Supersports 600, with the TT600. For 2001

the most famous name of all was bought out

of retirement: Bonneville. The new Bonneville

shared the name, engine configuration and

style of its predecessors, the T120 and T140,

but that was where the similarity ended. It used

a 360° carburetted air-cooled twin engine in a

utterly non-traditional capacity of 790 cc. The

nostalgic picture was completed by wire

wheels and a paint scheme harking back to

the 1960s. A factory custom version, the

America, followed in 2002.

From a standing start in 1991, the Hinckley

factory was competing in all the major

motorcycle market sectors . Much bigger

production volumes meant the original

modular concept was no longer a necessity.

By the dawn of the 21st Century Triumph had

sold over 100,000 motorcycles. Then the

factory was struck by one of the biggest fires

ever at a British industrial site. In March 2002

the production line, moulding shop and stores

were destroyed and many other parts of the

plant severely damaged. Just six months later

the rebuilt factory was running at full capacity.

The first new product out of the doors was the

Daytona 600, a replacement for the TT600.

Where the first Supersports 600 Triumph had

failed to compete with the Japanese this one

was good enough to win an Isle of Man TI.

Development of the Bonneville family

continued, with derivatives in the form of the

T100 and the custom styled Speed master being

introduced for the 2003 model year. With the

introduction of the Thruxton in 2004, the original

790 cc engine got a 4 mm overbore to increase

its capacity to 865 cc. The Thruxton, named after

the small 1965 run of hot Sonnies for production

race homologation, is styled along the lines of a

modern cafe racer. The Speed master and T100

benefitted from the 865 cc engine from 2005.

Next on Hinckley's resurrection list was the

Scrambler which harks back to the models

originally designed for the US market with both

pipes sweeping at high level down the right-hand

side of the bike and high, off-road style 'bars.

The nicely differentiated range was now well

established: Triumph call the Daytonas, Sprints

and Tiger 'Urban Sports' while the Bonneville

and its derivatives are billed as 'Modern

Introduction 0· 1

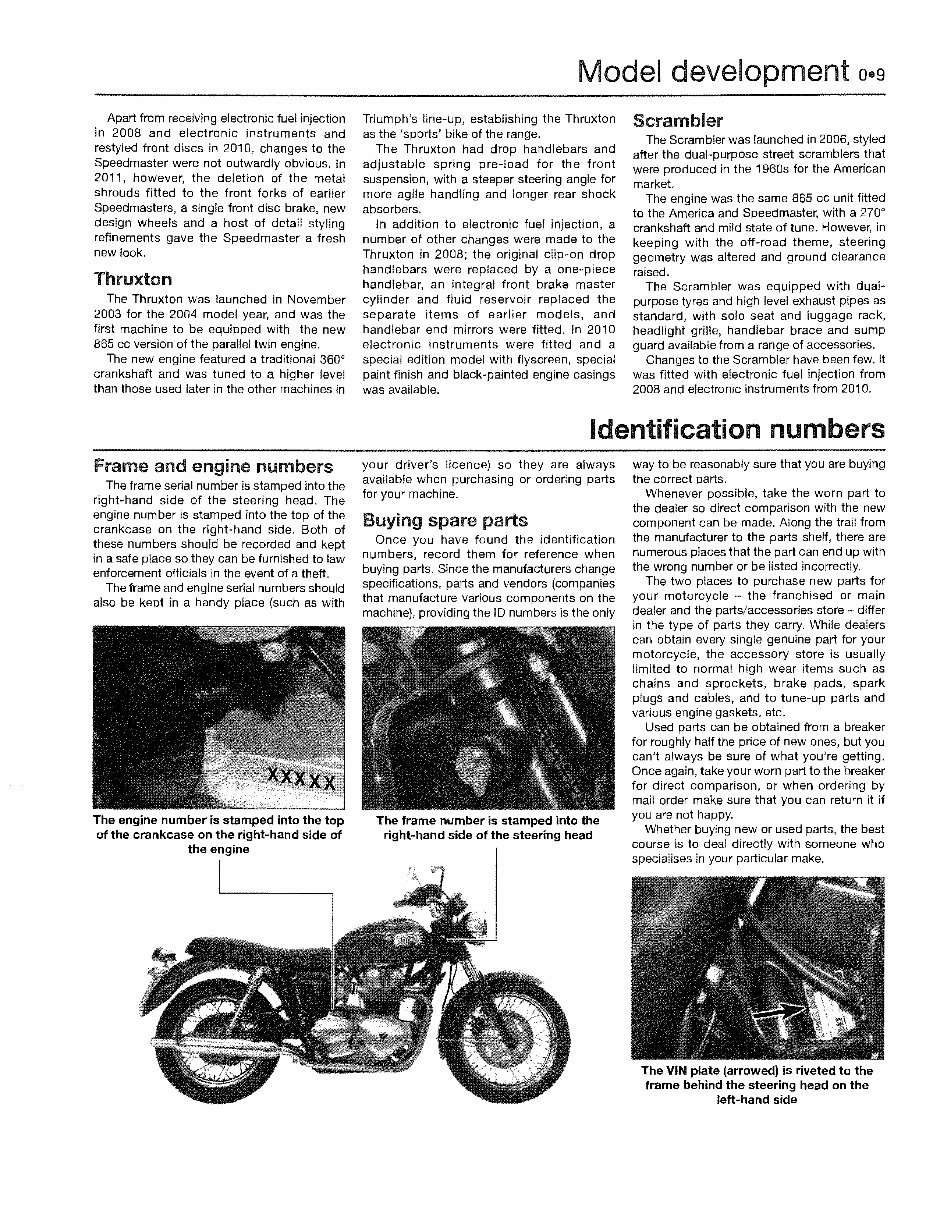

Thruxton

Classics'. With an eye on America Triumph

then unleashed their most audacious bike yet:

the Rocket Ill. (Whisper it, but Rocket Ill was

actually a BSA model name back in the 1970s.)

They call it a cruiser but behemoth would be a

better description, it's the first production bike

to boast a capacity of over two litres and the

only thing on the roads that can make a Harley

V-Rod look shy and retiring.

Triumph has gone from hesitant newcomer

(or should that be returnee?) to a player on the

world motorcycling stage. To anyone who

remembers the state of the Briti sh industry

when the original Triumph factory closed its

doors, that is nothing short of a miracle.

Acknowledgements

Our thanks are due to Fowlers of Bristol who

supplied the machines featured in the illustra-

tions throughout this manual. We would also like

to thank NGK Spark Plugs (UK) Ltd for supplying

the colour spark plug condition photographs,

the Avon Rubber Company for supplying

information on tyre fitting and Draper Tools Ltd

for some of the workshop tools shown.

Thanks are also due to Julian Ryder who

wrote the introduction 'A Phoenix from the

Ashes' and to Triumph Motorcycles, Hinckley,

for permissi on to use model pictures of the

Triumph models. Triumph Motorcycles Limited

bears no responsibility for the content of this

book, having had no part in its origination or

preparation.

About this manual

The aim of this manual is to help you get the

best value from your motorcycle. It can do so in

several ways. It can help you decide what work

must be done, even if you choose to have it

done by a dealer; it provides information and

procedures for routine maintenance and

servicing; and it offers diagnostic and repair

procedures to follow when trouble occurs.

We hope you use the manual to tackle the

work yourself. For many simpler jobs, doing it

yourself may be quicker than arranging an

appointment to get the motorcycle into a

dealer and making the trips to leave it and

pick it up. More importantly, a lot of money

can be saved by avoiding the expense the

shop must pass on to you to cover its labour

and overhead costs. An added benefit is the

sense of satisfaction and accomplishment

that you feel after doing the job yourself.

References to the left or right side of the

motorcycle assume you are sitting on the seat,

facing forward .

We take great pride in the accuracy of

informatio n given in this manual, but

motorcycle manufacturers make alterations

and design changes during the production

run of a particular m otorcycl e of which they

do n ot i nform us. No liability can be

accepted by the authors or publishers for

loss, damage or injury caused by any errors

in, or omissions from, the i nformation

given.

o·a Model development

Bonneville

The first model in this new parallel twin

range, the Bonneville, was launched in

November 2000 for the 2001 model year. It

combined the styling and character derived

from the most popular of the original Meriden

models with the technology of modern design

and technology.

The Bonneville used a 790 cc parallel twin

air- and oil-cooled unit engine. Its 360° crank

meant the pistons rose and fell simultaneously,

but were set to fire on alternate strokes. Twin

balancer shafts ran off a gear on the right-hand

end of the crankshaft to eliminate most of the

vibration, leaving enough to provide some

essential character. A central cam chain drove

the double overhead camshafts actuating the

four valves per cylinder.

The cable-operated clutch was a wet,

multi-plate unit with conventional springs. The

five-speed constant-mesh transmission drove

the rear wheel via chain and sprockets that

run unconventionally down the right-hand side

of the bike, allowing the looks of the original

design engine covers to be retained.

The engine had a wet-sump lubrication

system incorporating two pumps. The rear

pump drew oil from the sump via a strainer

and distributed it, via the filter, to the crank-

shaft's main and big-end bearings, the

camshafts, and to the transmission output

shaft. The front pump drew oil in the same

way and circulated it around the cylinder block

and head to cool them before sending it to the

oil cooler at the front. The cooled oil then

returned to the sump. The front pump also fed

a lubrication circuit for the transmission input

shaft and the clutch.

Fuel was fed by gravity to the two 36 mm

CV carburettors. The carburettors were elec-

trically heated to prevent icing and incorpo-

rated a throttle position sensor that transmitted

information on throttle angle and rate of

change to the ignition control unit (ICU).

The ignition system was fully digital electronic.

A pick-up coil mounted on the right-hand side

of the engine received signals from projections

on the alternator rotor and sent information on

crankshaft position and speed to the ICU. This,

together with information from the throttle

position sensor, was used to determine and the

ideal firing point. A primary voltage was sent to

the single ignition coil which provided the HT

voltage to each spark plug simultaneously on a

'wasted spark' system.

The engine sat in a tubular steel, twin-cradle

frame with removable sections. Front

suspension was by 41 mm oil-damped

telescopic forks. Rear suspension was by

tubular steel swingarm pivoting through the

crankcase and acting on twin shock absorbers

that were adjustable for spring pre-load.

The front brake had an hydraulic, twin-piston

sliding caliper acting on a single 31 O mm disc,

and the rear brake had an hydraulic, twin-piston

sliding caliper acting on a 255 mm disc. The

wheels were steel-spoked and ran tubed tyres.

In 2007 the Bonneville was given the new,

larger capacity 865 cc engine originally fitted

to the Thruxton. The engine was all-black with

polished covers.

A major mechanical change took place in

2008 with the introduction of electronic fuel

injection, ensuring the 865cc twin kept within

Euro 3 legislation. The throttle bodies were

cleverly designed to give the appearance of

carburettors and thus retain the bike's

traditional look.

The year 2009 was significant because it

marked the 50th anniversary of the Bonneville

name. There were no mechanical changes for

2009, but the bike's styling reflected many

features of the 1970s T1400. Cast wheels

replaced the wire-spoked items of the 2008

models, the mudguards were smaller and

neater, the shorter silencers were borrowed

from the Thruxton, the front brake master

cylinder had a remote reservoir and decals

replaced the chromed fuel tank badges of the

earlier model.

For 2010, new electronic instruments were

fitted and the speedometer was activated by a

pick-up off the gearbox rather than via a cable

off the front wheel.

Bonneville SE

A slightly higher spec Special Edition

Bonneville was introduced for 2009. It was as

the regular model (including its 2009 improve-

ments), but with a tachometer included in the

instruments, brushed alloy engine covers and

a chrome tank badge. The SE model received

uprated electronic instruments in 2010.

T100

Launched initially as a centennial edition of

the Bonneville for the 2002 model year, the

T100 was then incorporated into the Triumph

range in its own right the following year.

From 2002 to 2004 it used the same engine,

frame and suspension as the Bonneville, but

with added styling cues reminiscent of the

sixties machine. Differences included the

addition of a tachometer, rubber knee pads

mounted on the fuel tank, alternative colour

schemes and polished engine covers.

In November 2004, for the 2005 model year,

the T100 was given a slightly de-tuned version of

the new 865 cc engine first used in the Thruxton.

Apart from receiving electronic fuel injection

in 2008, changes to the T100 have amounted

to the addition of fork gaiters in 2009 and

electronic instruments in 2010. In celebration of

the Bonneville's 50th, an anniversary model

was produced for 2009 only with a special logo

on the side panels, two-tone paintwork and

chromed valve cover. A Steve McQueen edition

T100 was released in 2012 in the style of the

TR6 Trophy he rode in the film The Great

Escape; it differed from the standard model in

having a single seat, bash plate, khaki

paintwork and special graphics. Also in 2012, a

special edition T100 was launched to celebrate

11 O years of Triumph motorcycles and is rec-

ognisable by its two-tone silver and Brooklands

green paintwork, black mudguards, chromed

valve cover, chainguard and grabrail and its

tank-mounted jubilee crest.

The Bonneville America was launched in

2002 and was designed to compete directly

with the cruisers and low-riders so popular in

America.

It used the 790 cc engine of the Bonneville

but with a different crankshaft throw, giving it a

firing interval between the cylinders of 270°, and

a resultant off-beat feel and sound. Combined

with slightly taller gearing achieved by changing

the final drive ratio, it mimicked the traditional

V-twin cruiser characteristics of the bikes against

which it was designed to compete.

While the core of the bike remained the same

as the Bonneville, with shared frame,

suspension and braking components, a number

of design features such as the forward-

mounted foot-controls, low-slung seat,

raked-back handlebars and raked-out forks,

and instruments mounted on the fuel tank,

gave it an entirely different character and

establish it as a significantly different machine.

In 2007 the America was given the new,

larger capacity 865 cc engine originally fitted to

the Thruxton. The engine was all-black with

polished covers. Additional changes Included

newly styled cast al!oy wheels, and re-designed

pillion footrest brackets, fork shrouds drive

sprocket cover and front fork shrouds.

In 2008 the America received electronic fuel

injection and a new fuel tank with increased

capacity. Electronic instruments were fitted in

201 0, then for the following year the America

received a make-over with changes to riding

position and steering geometry. The front

wheel diameter was reduced by two inches to

16", the front turn signals were repositioned

from the handlebars to the bottom yoke and

the separate rider and passenger seats were

replaced by the dual.seat already fitted to

Speedmaster models.

Speedmaster

The Speedmaster was launched in 2003

and was designed to be a Bonneville America

with attitude.

For 2003 and 2004 it used the 790 cc

engine of the America but with shorter gearing,

achieved by altering the final drive ratio, to

give it more acceleration. For 2005 the

Speedmaster was given the new, larger

capacity 865 cc engine, further detuned than

the 2005 T100, giving it more torque at lower

engine speeds, and again utilising the 270°

crankshaft of the original America to retain the

off-beat firing pattern.

The Speedmaster had twin front brake

calipers and discs, different handlebars,

controls and seat, and cast alloy wheels which

ran tubeless tyres.

In 2007 the Speedmaster was equipped

with newly styled cast alloy wheels, and

re-designed pillion footrest brackets, fork

shrouds and drive sprocket cover.

Apart from receiving electronic fuel injection

in 2008 and electronic instruments and

restyled front discs in 2010, changes to the

Speedmaster were not outwardly obvious. In

2011, however, the deletion of the metal

shrouds fitted to the front forks of earlier

Speedmasters, a single front disc brake, new

design wheels and a host of detail styling

refinements gave the Speedmaster a fresh

new look.

Thru:xton

The Thruxton was launched in November

2003 for the 2004 model year, and was the

first machine to be equipped with the new

865 cc version of the parallel twin engine.

The new engine featured a traditional 360°

crankshaft and was tuned to a higher level

than those used later in the other machines in

Frame and

numbers

The frame serial number is stamped into the

right-hand side of the steering head. The

engine number is stamped into the top of the

crankcase on the right-hand side. Both of

these numbers should be recorded and kept

in a safe place so they can be furnished to law

enforcement officials in the event of a theft.

The frame and engine serial numbers should

also be kept in a handy place (such as with

The engine number is stamped into the top

of the crankcase on the right-hand side of

the engine

Model development o•9

Triumph's line-up, establishing the Thruxton

as the 'sports' bike of the range.

The Thruxton had drop handlebars and

adjustable spring pre-load for the front

suspension, with a steeper steering angle for

more agile handling and longer rear shock

absorbers.

In addition to electronic fuel injection, a

number of other changes were made to the

Thruxton in 2008; the original clip-on drop

handlebars were replaced by a one-piece

handlebar, an integral front brake master

cylinder and fluid reservoir replaced the

separate items of earlier models, and

handlebar end mirrors were fitted. In 201 O

electronic instruments were fitted and a

special edition model with flyscreen, special

paint finish and black-painted engine casings

was available.

The Scrambler was launched in 2006, styled

after the dual-purpose street scramblers that

were produced in the 1960s for the American

market.

The engine was the same 865 cc unit fitted

to the America and Speedmaster, with a 270°

crankshaft and mild state of tune. However, in

keeping with the off-road theme, steering

geometry was altered and ground clearance

raised.

The Scrambler was equipped with dual-

purpose tyres and high level exhaust pipes as

standard, with solo seat and luggage rack,

headlight grille, handlebar brace and sump

guard available from a range of accessories.

Changes to the Scrambler have been few. It

was fitted with electronic fuel injection from

2008 and electronic instruments from 2010.

Identification numbers

your driver's licence) so they are always

available when purchasing or ordering parts

for your machine.

Buying spare

Once you have found the identification

numbers, record them for reference when

buying parts. Since the manufacturers change

specifications, parts and vendors (companies

that manufacture various components on the

machine), providing the ID numbers is the only

The frame number is stamped into the

right-hand side of the steering head

way to be reasonably sure that you are buying

the correct parts.

Whenever possible, take the worn part to

the dealer so direct comparison with the new

component can be made. Along the trail from

the manufacturer to the parts shelf, there are

numerous places that the part can end up with

the wrong number or be listed incorrectly.

The two places to purchase new parts for

your motorcycle - the franchised or main

dealer and the parts/accessories store differ

in the type of parts they carry. While dealers

can obtain every single genuine part for your

motorcycle, the accessory store is usually

limited to normal high wear items such as

chains and sprockets, brake pads, spark

plugs and cables, and to tune-up parts and

various engine gaskets, etc.

Used parts can be obtained from a breaker

for roughly half the price of new ones, but you

can't always be sure of what you're getting.

Once again, take your worn part to the breaker

for direct comparison, or when ordering by

mail order make sure that you can return it if

you are not happy.

Whether buying new or used parts, the best

course is to deal directly with someone who

specialises in your particular make.

The VIN plate (arrowed) is riveted to the

frame behind the steering head on the

left-hand side

0·10 Safety First!

Professional mechanics are trained in safe

working procedures. However enthusiastic

you may be about getting on with the job at

hand, take the time to ensure that your safety

is not put at risk. A moment's lack of attention

can result in an accident, as can failure to

observe simple precautions.

There will always be new ways of having

accidents, and the following is not a compre-

hensive list of all dangers; it ls intended rather

to make you aware of the risks and to

encourage a safe approach to all work you

carry out on your bike.

Asbestos

• Certain friction, insulating, sealing and

other products - such as brake pads, clutch

linings, gaskets, etc. - contain asbestos.

Extreme care must be taken to avoid inhalation

of dust from such products since it is

hazardous to health. If in doubt, assume that

they do contain asbestos.

• Remember at all times that petrol is highly

flammable. Never smoke or have any kind of

naked flame around, when working on the

vehicle. But the risk does not end there - a

spark caused by an electrical short-circuit, by

two metal surfaces contacting each other, by

careless use of tools, or even by static

electricity built up in your body under certain

conditions, can ignite petrol vapour, which in a

confined space is highly explosive. Never use

petrol as a cleaning solvent. Use an approved

safety solvent.

• Always disconnect the battery earth

terminal before working on any part of the fuel

or electrical system, and never risk spilling fuel

on to a hot engine or exhaust.

• It is recommended that a fire extinguisher

of a type suitable for fuel and electrical fires is

kept handy in the garage or workplace at all

times. Never try to extinguish a fuel or

electrical fire with water.

Fumes

e Certain fumes are highly toxic and can

quickly cause unconsciousness and even

death if inhaled to any extent. Petrol vapour

comes into this category, as do the vapours

from certain solvents such as trichloro-eth-

ylene. Any draining or pouring of such volatile

fluids should be done in a well ventilated

area.

e When using cleaning fluids and solvents,

read the instructions carefully. Never use

materials from unmarked containers - they

may give off poisonous vapours.

• Never run the engine of a motor vehicle in

an enclosed space such as a garage. Exhaust

fumes contain carbon monoxide which is

extremely poisonous; if you need to run the

engine, always do so in the open air or at least

have the rear of the vehicle outside the

workplace.

The battery

e Never cause a spark, or allow a naked

light near the vehicle's battery. It will normally

be giving off a certain amount of hydrogen

gas, which is highly explosive.

8 Always disconnect the battery ground

(earth) terminal before working on the fuel or

electrical systems (except where noted).

• If possible, loosen the filler plugs or cover

when charging the battery from an external

source. Do not charge at an excessive rate or

the battery may burst.

• Take care when topping up, cleaning or

carrying the battery. The acid electrolyte,

evenwhen diluted, is very corrosive and should

not be allowed to contact the eyes or skin.

Always wear rubber gloves and goggles or a

face shield. If you ever need to prepare

electrolyte yourself, always add the acid

slowly to the water; never add the water to the

acid.

Electricity

• When using an electric power tool,

inspection light etc., always ensure that the

appliance is correctly connected to its plug

and that, where necessary, it is properly

grounded (earthed). Do not use such

appliances in damp conditions and, again,

beware of creating a spark or applying

excessive heat in the vicinity of fuel or fuel

vapour. Also ensure that the appliances meet

national safety standards.

• A severe electric shock can result from

touching certain parts of the electrical system,

such as the spark plug wires (HT leads), when

the engine is running or being cranked, par-

ticularly if components are damp or the

insulation is defective. Where an electronic

ignition system is used, the secondary (Hn

voltage is much higher and could prove fatal.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$32.99

Viewed 19 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$32.99

The 2001-2012 Triumph Bonneville T100 Service & Repair Manual is a comprehensive guide designed to facilitate easy repairs for both professional mechanics and DIY enthusiasts. It includes detailed instructions covering the following:

- Introduction

- General Information

- Routine Maintenance

- Cylinder Head & Camshafts

- Barrels & Pistons

- Crankshaft/Rods/Balancers

- Transmission

- Lubrication System

- Fuel System & Exhaust

- Brakes

- Front Suspension & Steering

- Rear Suspension

- Final Drive

- Wheel & Tyre

- Frames & Bodywork

- Electrical & Ignition System

The manual is available in English and is compatible with both Windows and Mac operating systems. It is designed for quick and efficient navigation, allowing users to easily locate information within each chapter. For any inquiries, please feel free to contact us via email. We appreciate your visit!