SYM XS125 K Scooter Full Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SERVICE MANUAL

中华战马修护手册

PREFACE

PREFACE

l This shop manual describes the technical feature and

servicing procedures for the SANYANG XS125-K.

l All information, illustrations, directions and

specifications included in this publication are base on

SANYANG XS125-K.

l SANYANG reserves the right to make changes at any

time without notice and without incurring any

obligation whatever.

SANYANG INDUSTRY CO.,LTD.

SERVICE DIVISION

CONTENTS

CONTENTS

GENERAL INFORMATION............................................................................. 1

INSPECTION/ADJUSTMENT ........................................................................ 2

LUBRICATION SYSTEM ................................................................................ 3

ENGINE REMOVAL/INSTALLATION ........................................................... 4

CYLINDER HEAD/VALVE .............................................................................. 5

CYLINDER/PISTON ........................................................................................ 6

CLUTCH/OIL PUMP/GEAR SHIFT ................................................................ 7

A.C. GENERATOR .......................................................................................... 8

CRANK SHAFT/CRANK CASE/TRANSMISSION ........................................ 9

CARBURETOR ................................................................................................ 10

HEADLIGHT/STEERING/FRONT WHEEL/FRONT FORK ......................... 11

REAR WHEEL/REAR SUSPENSION............................................................. 12

BATTERY/CHARGING SYSTEM .................................................................. 13

IGNITION SYSTEM ......................................................................................... 14

SWITCHES/HORN ........................................................................................... 15

WIRING DIAGRAM .......................................................................................... 16

1.GENERAL INFORMATION

1-1

SERVICE RULES ................................... 1-1

SPECIFICATIONS .................................. 1-2

TORQUE VALUES ................................. 1-3

TROUBLE SHOOTING ........................... 1-4

SERVICE RULES:

(1)Use new packings, gaskets,O-rings and cotter

pins space and clipes whenever reassembling.

(5)Clean all removed parts in or with solvent, and

lubricate their sliding surfaces upon disassembly.

(2)When tightening bolts or nuts, begin on center or

larger diameter bolts and tighten them in criss-

cross pattern in two or more steps if necessary.

(6)Coat or fill parts with specified grease where

specified.

(3)Use genuine SANYANG parts and lubricants or

those equivalent. When parts are to be reused,

they must be inspected carefully to make sure they

are not damaged or deteriorated and in good

usable condition.

(7)Upon assembling, check every possible part for

proper installation and movement or operation.

(4)Use special tool when use of such a tool is

specified.

(8)Work safely and give your work your undivided

attention. Exchange signals as frequently as possi-

ble when a work involves two or more workers. Do

not run the engine unless the shop or working area

is well ventilated.

Symbol Marks:

:Apply engine oil. NOTE: Things must be noticed.

CAUTION: Things that could cause damage to the

engine parts.

:Apply grease.

WARNING: Things that could cause damage to

the person or partner.

1.GENERAL INFORMATION

1-2

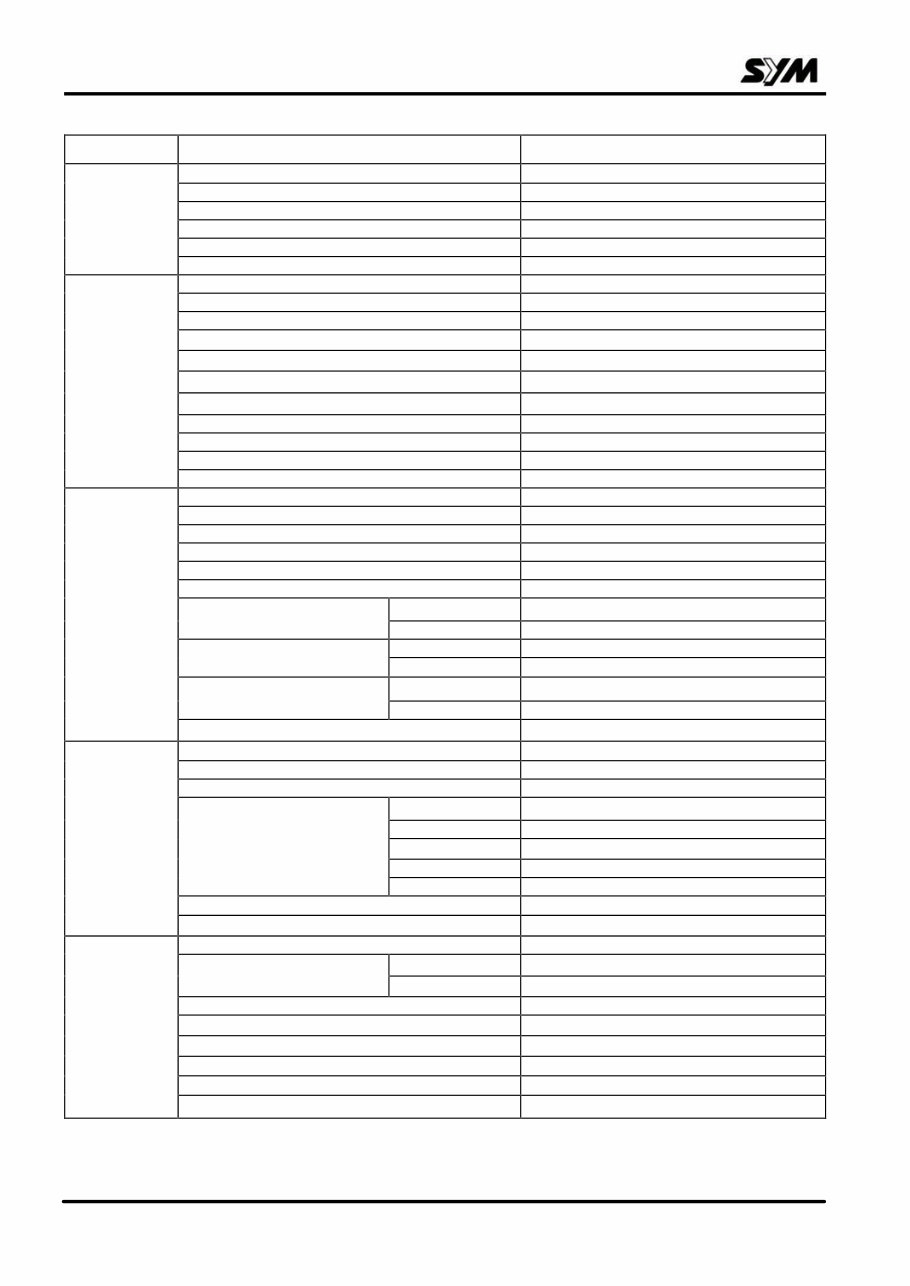

SPECIFICATIONS

ITEM XS125-K

Overall length 2040mm

Overall width 750mm

Overall height 1100mm

Wheel base 1280mm

Ground clearance 150mm

DIMENSIONS

Dry weight 130kg

Type Single pipe

Front suspension and travel Telescope 165mm

Rear suspension and travel Swing arm 63mm

Front tire size and tire pressure 2.75-18 2.25Kg/C ㎡

Rear tire size and tire pressure 90/90-18 2.50Kg/C ㎡

Front brake Disk type

Rear brake Drum type

Fuel capacity 14.5 liter

Fuel reserve capacity 2.0 liter

Caster angle 26 °

FRAME

Front fork oil capacity 160c.c

Type Air cooled 4 stroke engine

Cylinder arrangement Single cylinder 15~ inclinde from vertical

Bore & stroke 56.5 x49.5mm

Displacement 124.1c.c.

Compression ratio 9.0:1

Oil capacity 0.80 ~0.95liter (0.9 liter for change)

opens 5°BTDC

Intake valve

closes 35 °ABDC

opens 30°BBDC

Exhaust valve

closes 5 °ATDC

IN. 0.10mm

Valve clearance

EX. 0.15mm

ENGINE

Idle speed 1400±100 rpm

Clutch Wet muti-plate type

Transmission 5-speed internationl

Primary reduction ratio 4.05

I 2.769

II 1.722

III 1.318

IV 1.1250

Gear ratio

V 0.962

Final reduction ratio 2.53

DRIVE TRAIN

Gearshift pattern 1→N→2→3→4→5

Ignition system C.D.I. unit

"F" mark BTDC 15° ±20°/1500rpm

Ignition timing

Full advance BTDC 29.5° ±2°/4000rpm

Starting system Electrical motor and kickstarter

Alternator A.C. generator

Battery capacity 12N7A-3A(8AH)

Fuse 15A

Spark plug D7RC

ELECTRICAL

Spark plug gap 0.6~0.7mm

1.GENERAL INFORMATION

1-3

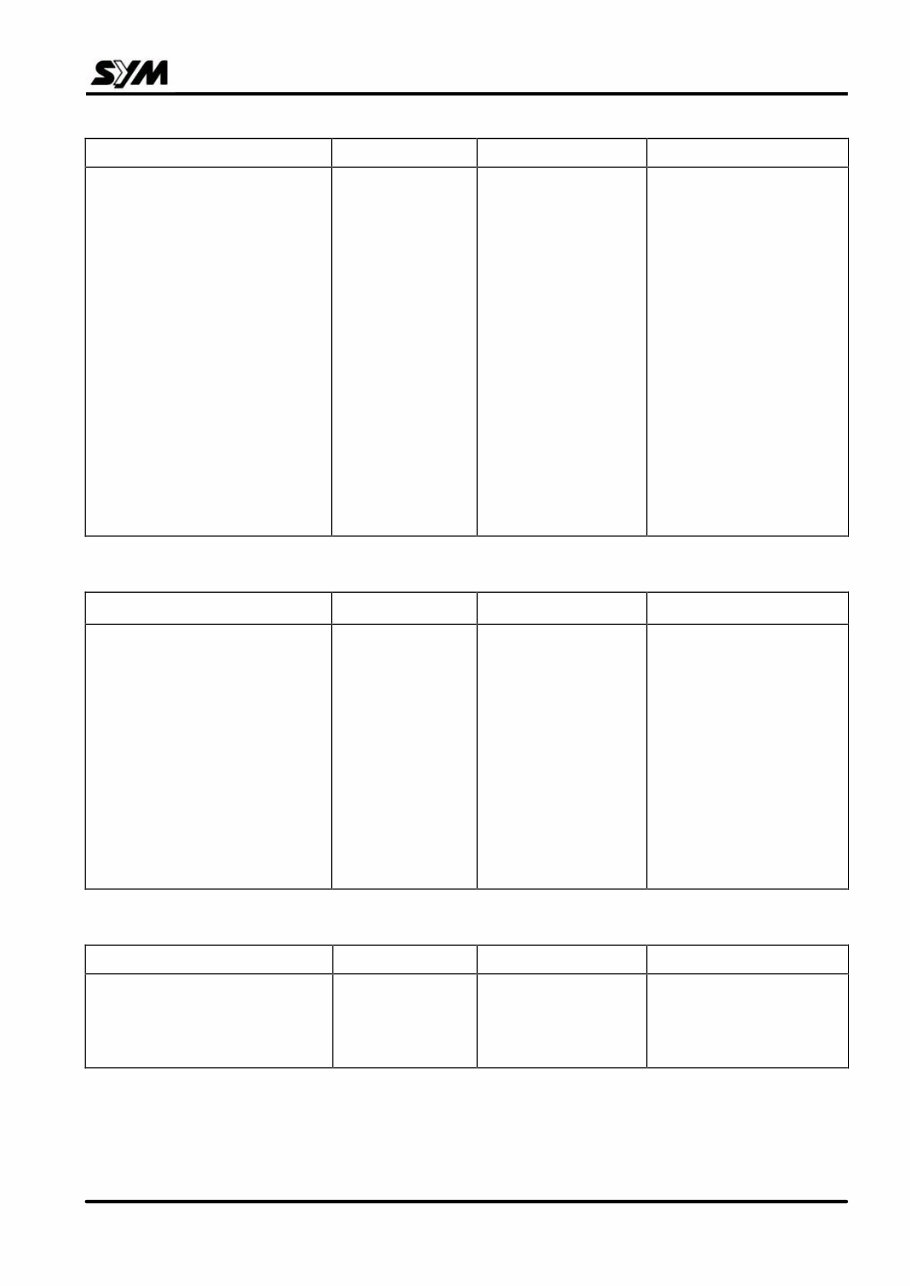

ENGINE

TIGHTEN LOCATION Q'TY THREAD DIA(mm) TORQUE(kgf ·cm)

Starting clutch outer bolt socket

Cylinder stud bolt

Shift drum stopper hex bolt

Gear shift cam hex bolt

Cylinder stud bolt

Cylinder head cap nut

Driven gear hex bolt

Chain adjuster

Oil filter screen cover

Starter moror bolt

Oil pump HEX bolt

Primary drive gear nut

Cylinder head bolt

Cylinder head nut

Fly wheel bolt

Cylinder head cover

Reduction gear cover bolt

L. Crank case cover bolt

R. Crank case cover

A.C.G.pluse bolt

A.C.G.flange bolt

3

10

1

1

4

4

2

2

1

2

2

1

1

4

1

4

3

8

11

2

3

8

6

6

6

8

8

6

6

10

6

6

16

8

8

10

6

6

6

6

4

5

100~150

80~120

80~120

80~120

180~220

280~300

100~150

80~120

150-300

80~120

70~110

400~500

280~320

280~320

400~500

80~120

80~120

80~120

80~120

40~50

40~70

FRAME

TIGHTEN LOCATION Q'TY THREAD DIA(mm) TORQUE(kgf ·cm)

Front wheel axle nut

Rear wheel axle nut

Rear fork pivot nut

Engine upper hanger nut

Engine front hanger nut

Handle pipe upper holder bolt

Steering stem nut

Front fork nut

Rear shock absorber

Rear brake torque link

Front fork top bridge

Front fork bottom bridge

Final drive sprocket

Seat bolt

Drive sprocket bolt

1

1

1

3

4

4

1

1

4

1

2

2

4

2

2

14

14

14

10

10

8

22

22

10

8

8

12

8

8

6

600~800

1000~1200

800~1000

400~550

450~550

180~ 250

600~900

400~500

300~400

150~200

400~550

400~500

270~330

200~250

100~140

STANDARD TORQUE

TYPE TORQUE(kgf·cm) TYPE TORQUE(kgf·cm)

5 mm bolt, nut

6 mm bolt, nut

8 mm bolt, nut

10 mm bolt, nut

12 mm bolt, nut

45~60

80~120

180~250

300~400

500~600

5 mm bolt

6 mm bolt

6 mm flange bolt, nut

8 mm flange bolt, nut

10 mm flange bolt, nut

35~50

70~110

100~140

240~300

350~450

1.GENERAL INFORMATION

1-4

Torque specifications listed below for respective locations.

TROUBLE SHOOTING

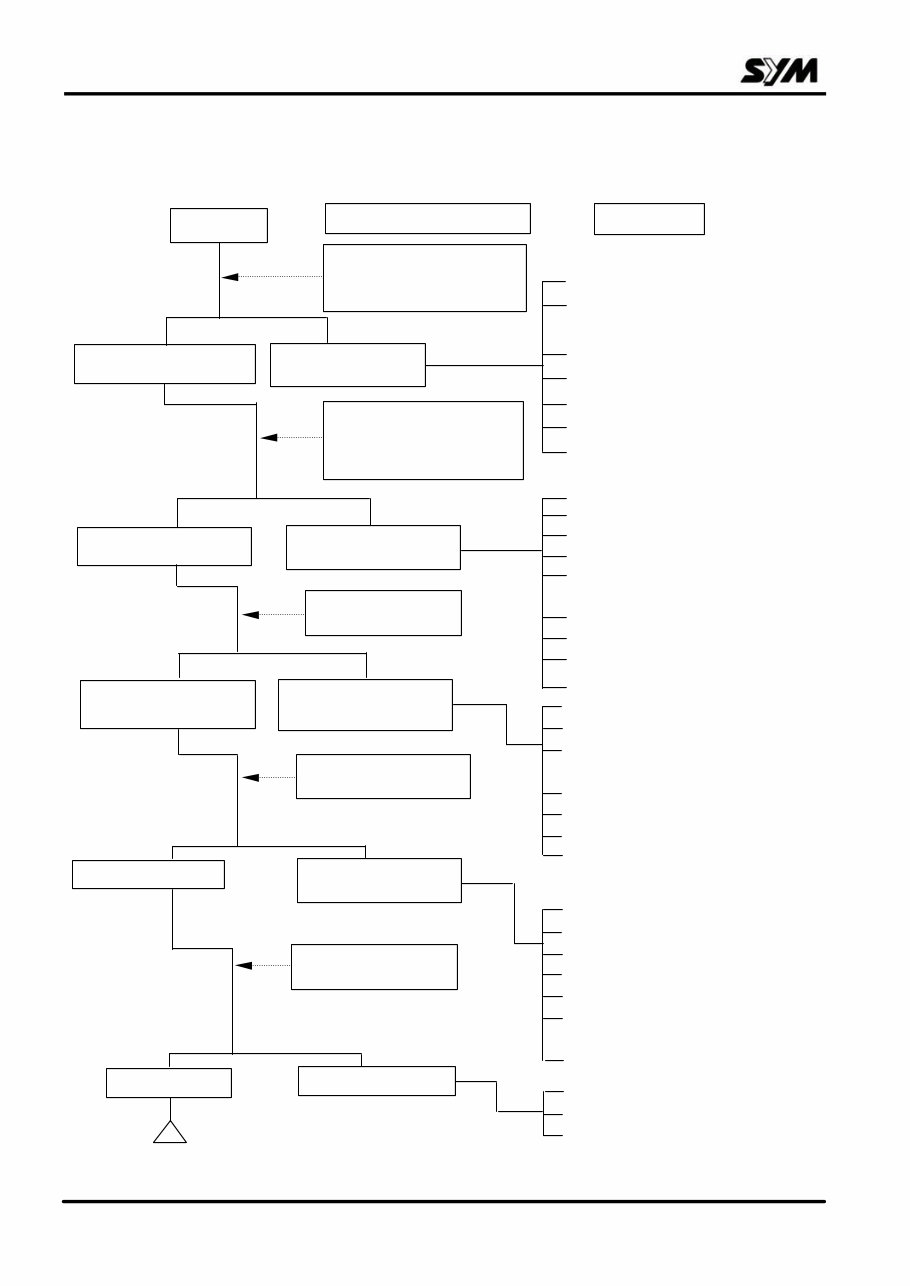

A. HARD START OR CANNOT START

start engine with choke closed

engine knocks, but no

starting

follow the starter

keypoints to re-start

inspection adjustment cause

loosen carburetor drain

screw, check inner side for

gasoline

enough gasoline supplied

for carbuertor

remove spark plug,insert it

into plug cap, check the

spark by touching engine

grid

test cylinder

compression

spark plug jump spark weak or no spark

normal compression

pressure too low or no

pressure

engine dose not fire

spark plug dry

no gasoline in the tank

fuel tube between gasoline tank and

carburetor clogged.

float chamber fuel tube clogged

gasoline cover air hole clogged

fuel filter clogged

fuel filter screen clogged

gasoline auto fuel cup faulty

spark plug faulty

fouled spark plug

CDI unit fualty

pulse coil faulty

high voltage coil cable open or

short

high voltage coil open or short

main switch faulty

A.C.G. faulty

Battery faulty

valve too tight, no gap

valve seat faulty

cylinder, piston, piston ring

faulty

cylinder gasket leak

valve burnt out

valve timing faulty

crankcase leak when wmpress

Fuel tube clogged

muffler clogged

auto air cut poor action

inlet duct has air in

ignition timing incorrect

carburetor fuel adjusting

screw set faulty

air cleaner clogged

symptom

no gasoline supplied

for carburetor

remove and check the

spark plug again

spark plug wet

carburetor fuel level too high

auto air cut poor action

throttle excessively

1.GENERAL INFORMATION

1-5

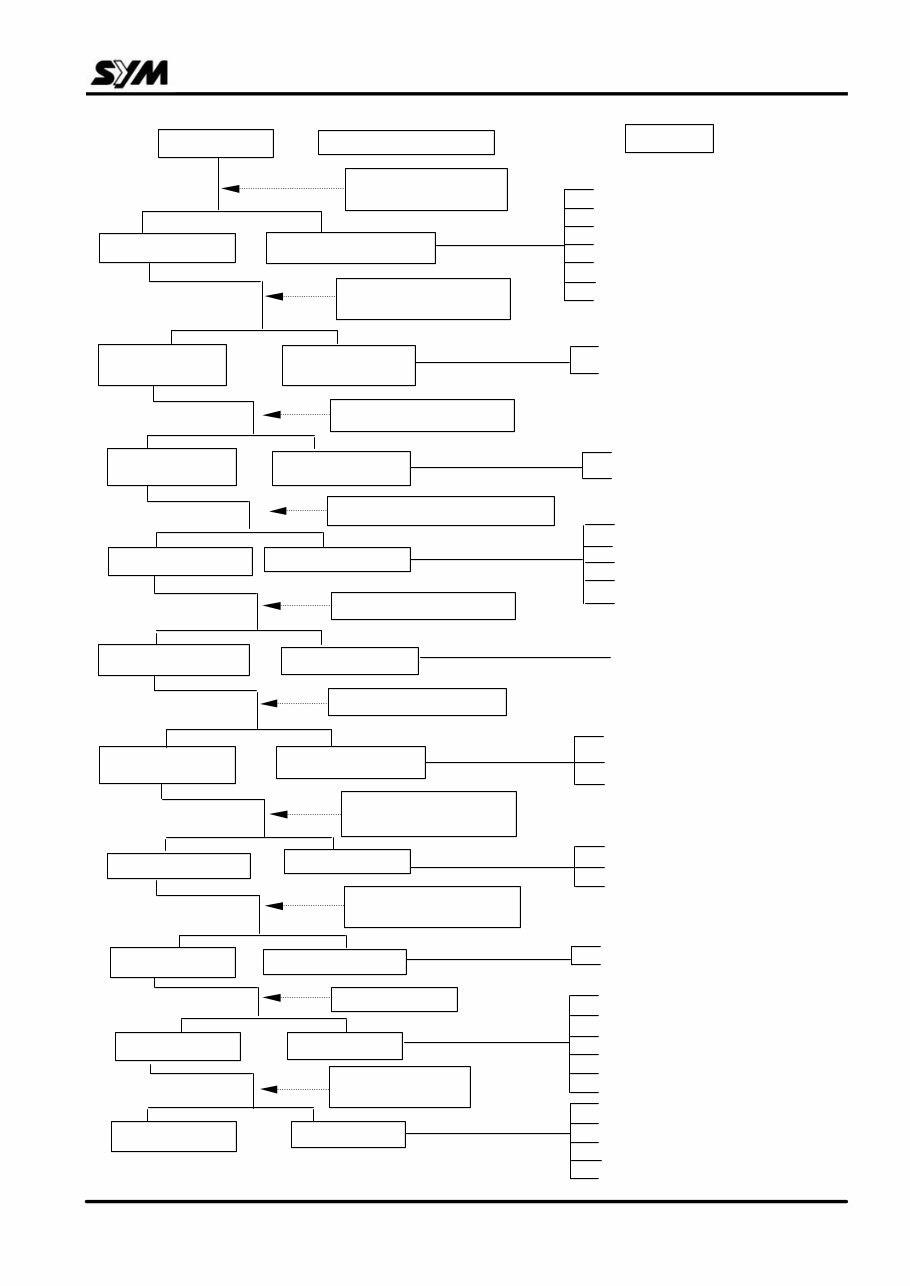

B. ROTATION ROUGH (LACKS POWER)

symptom inspection adjustment

cause

start engine and slightly

apply fuel

engine speed up

engine speed can't up

adjust ignition timing use

timing tester

valve adjuster poor

ignition timing

correct

ignition timing

incorrect

valve clearance

correct

valve coearance

incorrect

compression pressure check

compression normal pressure to low

carburetor block check

remove spark plug

no clogged

block

air cleaner clogged

fuel tube clogged

air hole on the fuel tank cap blocked

exhaust tube clogged

auto air cut faulty

carburetor vacuum diaphragm worn

auto fuel cup faulty

faulty CDI unit

faulty A.C.Generator

fualty valve seat

cylinder, piston worn

gasket leak

valve timing incorrect

piston ring worn

remove and clean

remove dirt

spark plug improper heat range

spark plug clearance misadjustment

no fouled

discolored

dirt and color change

valve clearance misadjustment

valve seat worn

check crankcase oil level

for too much or dirt

oil lever normal

oil too much

too much oil

too little oil

oil no replacement

check cylinder head

lubrication

normal

abnormal

oil tube clogged

lean projection from oil pump

engine too hot

no overheating overheated

piston, cylinder worn

lean mixture

poor gasoline

carbon in burning chamber too much

ignition timing too early (C.D.I. faulty)

clutch slip

high speed

continue working

no knock shock knocks

carbon in burning chamber too much

poor gasoline

clutch slip

lean mixture

ignition timing too early(C.D.I.faulty)

1.GENERAL INFORMATION

1-6

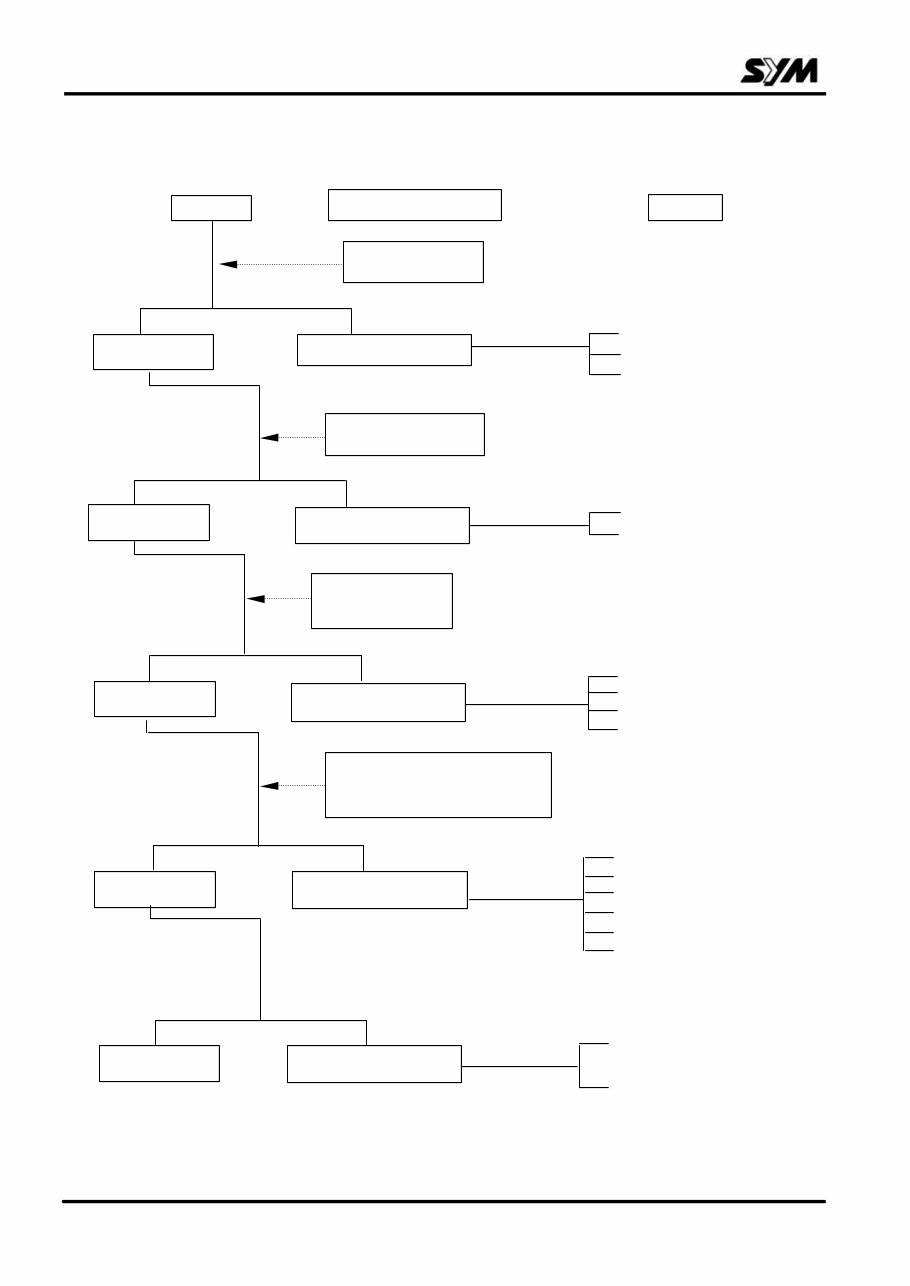

C. ROTATION ROUGH (ESPECIALLY IN THE LOW SPEED AND IDLE SPEED)

symptom

inspection adjustment cause

ignition timing

adjustment

faulty CDI unit

faulty A.C.Generator

valve gap adjust faulty

normal abnormal

adjust carburetor fuel

adjusting screw

adjust OK adjust faulty

lean mixture(loosen screw)

rich mixture(tighten screw)

no air inlet

has air inlet

carburetor gasket

has air inlet

insulator plate gasket poor

carburetor locking nut loose

insulator plate gasket torn

vacuum tube crack

Remove spark plug,insert to the

plugcap, check spark by toucning

engine irongrid.

sparking well poor sparking

poor or dirty spark plug

faulty CDI unit

faulty A.C.Genertor

poor ignition coil

spark plug cable open or short

poor main switch

good no good

vacuum tube damaged

air inlet duct clogged, damaged

1.GENERAL INFORMATION

1-7

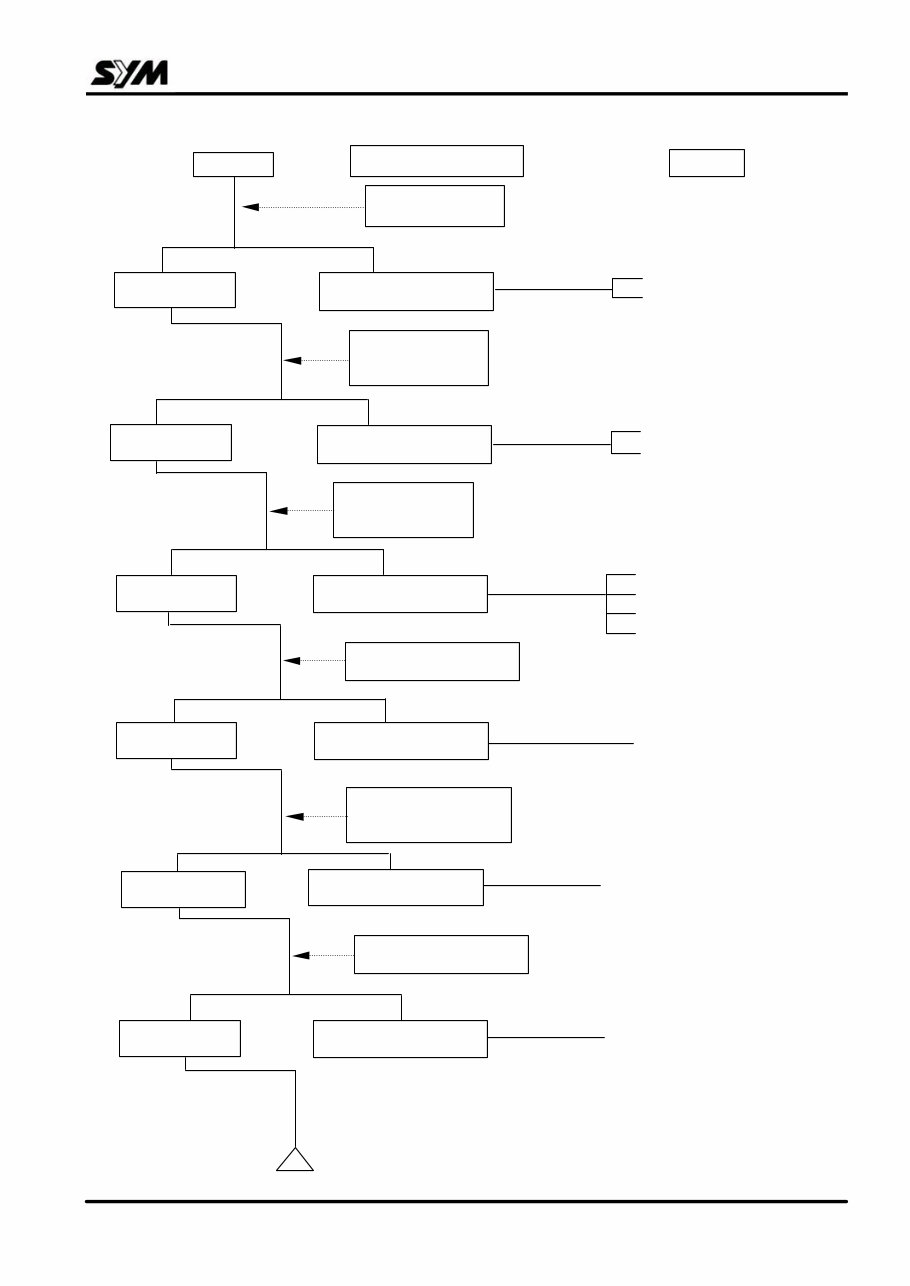

D. ROTATION ROUGH (HIGH SPEED)

symptom

inspection adjustment

cause

ignition timing

adjustment

faulty CDI unit

faulty pulse generator

normal abnormal

valve clearance

adjustment

normal

abnormal

poor adjustment

valve seat faulty

normal abnormal

check auto fuel

cup for fuel

supplied.

too little fuel in the fuel tank

fuel tube, fuel filter clogged

air hole on the fuel tank colgs

auto fuel cup faulty

no blocked blocked

valve timing

adjusting

inspection

timing correct

timing incorrect cam sprocket aligning marks incorrect

carburetor blocked

check valve spring

clean

good

spring broken

loose elasticity

faulty spring

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 28 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get instant access to the Complete Factory Service Repair Workshop Manual without any extra fees or expiry dates. This Professional Manual is suitable for both professional Mechanics and DIY enthusiasts, covering all repairs, servicing, and troubleshooting procedures with step-by-step instructions, detailed photos, diagrams, and highly detailed exploded diagrams & pictures.

Print out a single page or the entire manual as per your choice. The Manual can be used on multiple computers without any limitations or trial periods and can be used for life without the need to renew or pay any extra. It is fully compatible with all Windows & MAC Computers.

Click the button to get your hands on this comprehensive manual.