SYM CITYCOM 300I Scooter Full Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

FOREWORD

HOW TO USE THIS MANUAL

CONTENTS

SERIAL NUMBER

Citycom.300i

SERVICE MANUAL

Homepage Contents

Foreword

This service manual contains the technical data of each component inspection and

repairment for the SANYANG LH30W series scooter. The manual is shown with

illustrations and focused on “Service Procedures”, “Operation Key Points”, and

“Inspection Adjustment”, providing technicians with service guidelines.

If the style or the mechanical structures of the scooter, LH30W series scooter, are

different from those of the photos or pictures shown in this manual, the actual

vehicle shall prevail. Specifications are subject to changes without notice.

Service Department

SANYANG INDUSTRY CO., LTD.

Homepage Contents

How To Use This Manual

This service manual describes the basic information of different system parts and

system inspection & service for SANYANG LH30W series scooter. In addition,

please refer to the manual contents in detail for the model you serviced in

inspection and adjustment.

The first chapter covers the general information and the trouble diagnosis.

The second chapter covers the periodic maintenance information and the special

tool models.

The third to the 11th chapters cover the engine and the driving systems.

The 12th chapter is the cooling system.

The 13th to the 16th chapter contain the relative parts of the body frame assembly.

The 17th chapter is the electrical system.

The 18th chapter is the emission control system.

The 19th chapter is the wiring diagram.

Please see index of content for quick having the special parts and system

information.

There are 4 buttons, “Foreword”, “Contents”, “How to use this manual” and

“Mechanism Illustrations” on the CD-R version, and can be access to these items

by click the mouse.

If user wants to look for the content of each chapter, selecting the words of each

chapter on the contents can reach to each chapter. There are two buttons,

“Homepage and contents, onto the top line of first page of the each chapter. Thus,

if the user needs to check other chapters, he can click the top buttons to back the

homepage or contents. The content of each chapter can be selected too.

Therefore, when needs to checking the content inside of the chapter, click the

content words of the chapter so that can back to the initial section of the content.

In addition, there is a “To this chapter contents” button at the second page of each

contents so that clicking the button can back to the contents of this chapter.

Contents

Homepage

Page Content Index

1-1 ~ 1-16 General Information 1

2-1 ~ 2-17 Maintenance Information 2

3-1 ~ 3-8 Lubrication System 3

4-1 ~ 4-60 Fuel Injection System 4

5-1 ~ 5-11 Engine Removal 5

6-1 ~ 6-16 Cylinder Head/ Valve 6

7-1 ~ 7-8 Cylinder/ Piston 7

8-1 ~ 8-14 “V” Type Belt Driving System/ Kick-Starter 8

9-1 ~ 9-8 Final Drive Mechanism 9

10-1 ~ 10-10 Alternator 10

11-1 ~ 11-8 Crankshaft/ Crankcase 11

12-1 ~ 12-14 Cooling System 12

13-1 ~ 13-16 Body Cover 13

14-1 ~ 14-12 Brake System 14

15-1 ~ 15-10 Steering/ Front Wheel/ Front Cushion 15

16-1 ~ 16-6 Rear Wheel/ Rear Fork/ Rear Cushion 16

17-1 ~ 17-23 Electrical Equipment 17

18-1 ~ 18-7 Emission Control System 18

19-1 Electrical Diagram 19

Home page

Contents

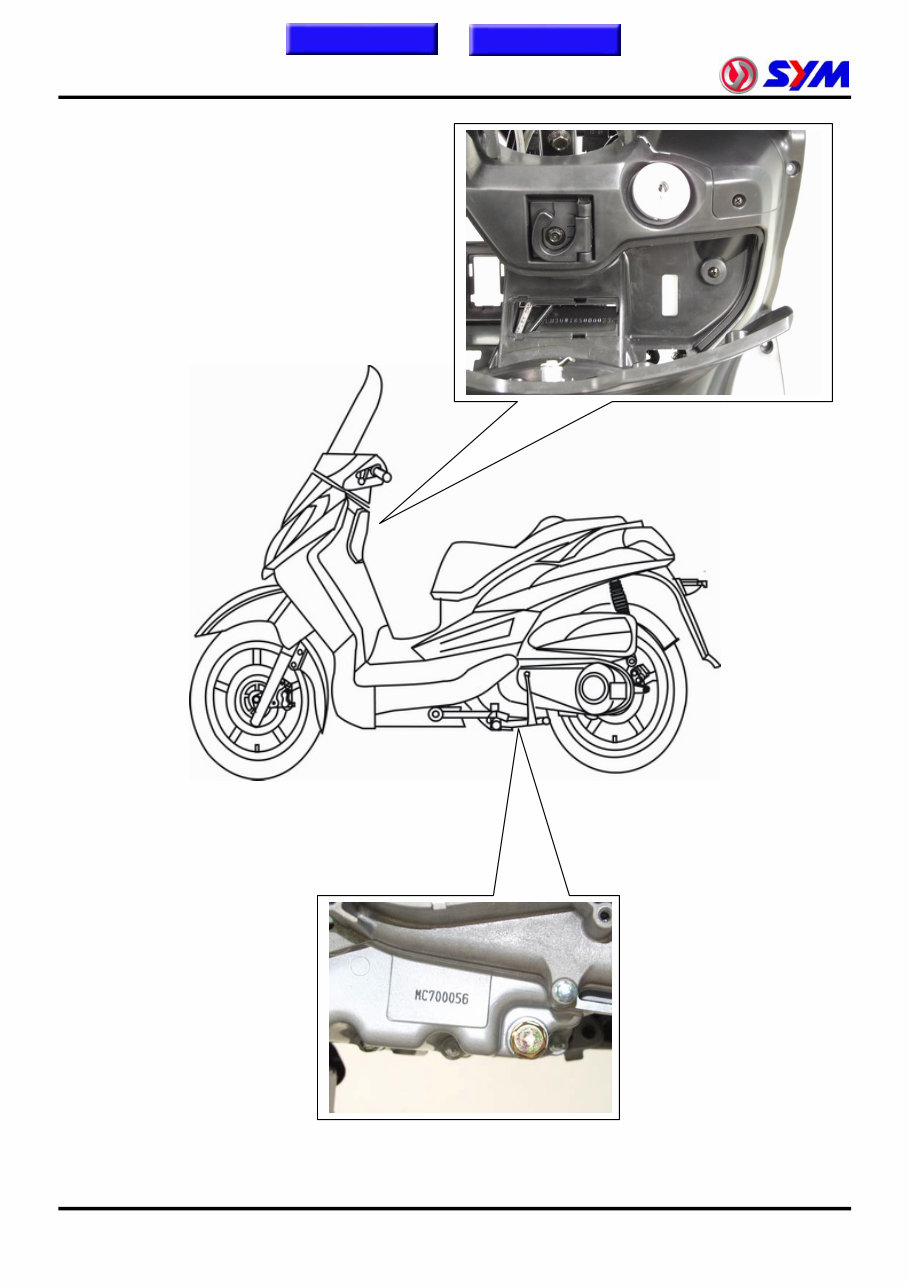

Serial Number

Homepage Contents

1. GENERAL INFORMATION

Symbols and Marks............................ 1-1

General Safty……………………………1-2

Service Precautions ........................... 1-3

Specifications ..................................... 1-9

Torque Values .................................... 1-10

Troubles Diagnosis ............................ 1-12

Parts to Be Greased ........................... 1-16

1-1

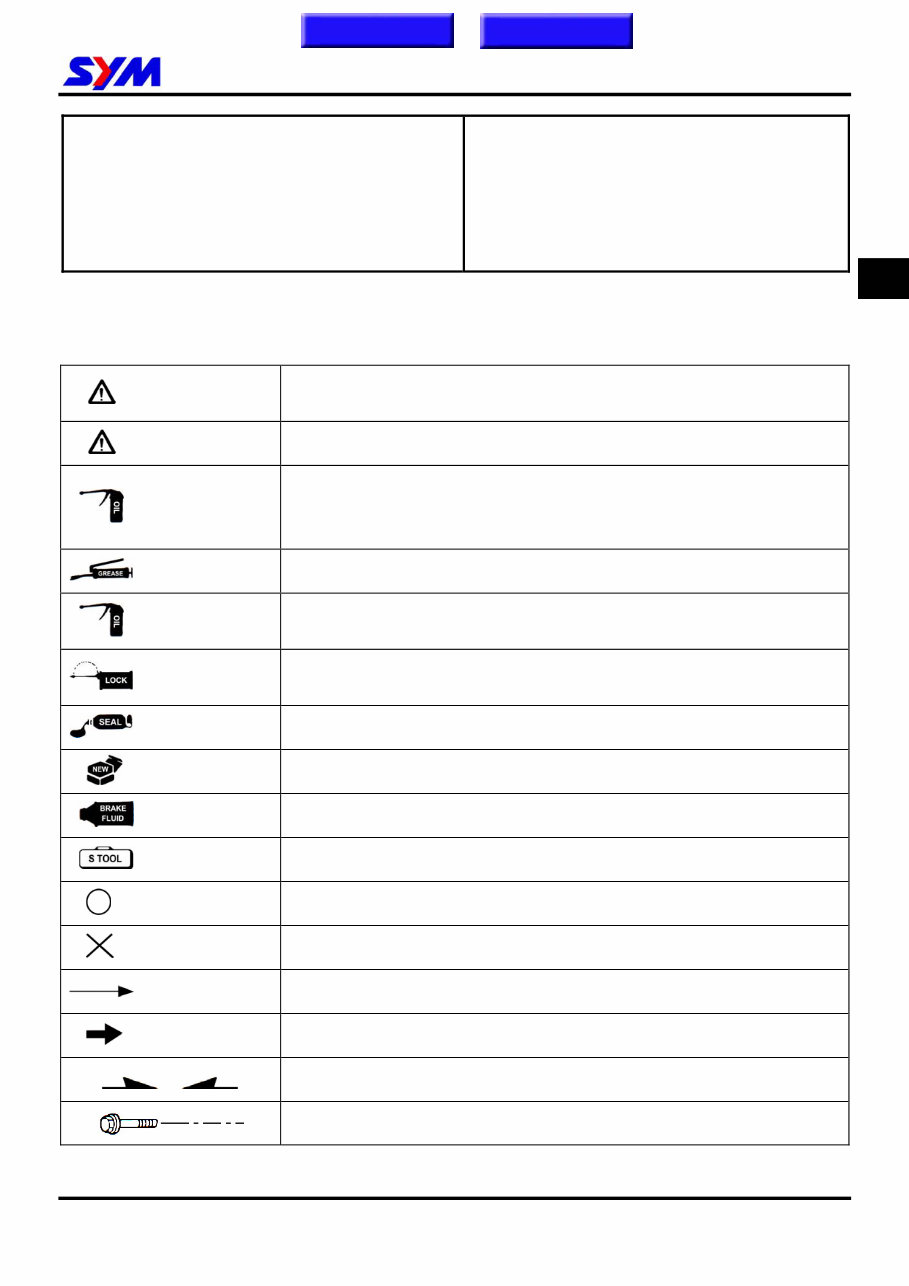

Symbols and Marks

Symbols and marks are used in this manual to indicate what and where the special service are needed, in

case supplemental information is needed for these symbols and marks, explanations will be added to the

text instead of using the symbols or marks only.

1

Warning

Means that serious injury or even death may result if procedures are not

followed.

Caution Means that equipment damages may result if procedures are not followed.

Engine oil

Limits to use SAE 10W-30 API SG class oil. Warranty will not cover the

damage that caused by not apply with the limited engine oil.

(Recommended oil: KING MATE G-3 oil)

Grease King Mate G-3 is recommended.

Gear oil

King Mate gear oil serials are recommended. (Bramax HYPOID GEAR OIL

# 140)

Locking sealant

Apply sealant, medium strength sealant should be used unless otherwise

specified.

Oil seal Apply with lubricant. .

Renew

Replace with a new part before installation.

Brake fluid Use recommended brake fluid DOT3 or WELLRUN brake fluid.

Special tools

Special tools

Correct

Meaning correct installation.

Wrong

Meaning wrong installation.

Indication Indication of components.

Directions

Indicates position and operation directions

Components assembly directions each other.

Indicates where the bolt installation direction, --- means that bolt cross

through the component (invisibility).

To this chapter contents

1. GENERAL INFORMATION

1-2

General safety

Carbon monoxide

If you have to run your engine, make sure

that the place is well ventilated. Never run

your engine in a closed area. Run your

engine in an open area, if you have to run your

engine in a closed area, be sure to use an

extractor.

Caution

Exhaust contains toxic gas which may cause one

to lose consciousness and even result in death.

Gasoline

Gasoline is a low ignition point and

explosive material. Work in a well-ventilated

place, no flame or spark should be allowed in the

work place or where gasoline is being stored.

Caution

Gasoline is highly flammable, and may explode

under some conditions. Keep it away from

children.

Used engine oil

Caution

Prolonged contact with used engine oil (or

transmission oil) may cause skin cancer although

it might not be verified.

We recommend that you wash your hands with

soap and water right after contacting. Keep the

used oil beyond reach of children.

Hot components

Caution

Components of the engine and exhaust system

can become extremely hot after running. They

remain very hot even after the engine has been

stopped for some time. When performing service

work on these parts, wear insulated gloves and

wait until cooling off.

Battery

Caution

‧ Battery emits explosive gases; flame is strictly

prohibited. Keep the places well ventilated

when charging the battery.

‧ Battery fluid contains sulfuric acid (electrolyte)

which can cause serious burns so be careful

do not be spray on your eyes or skin. If you

get battery fluid on your skin, flush it off

immediately with water. If you get battery fluid

in your eyes, flush it off immediately with

water and then go to a hospital.

‧ If you swallow the battery fluid by mistake,

drink a lot of water or milk, and take some

laxative such as castor oil or vegetable oil and

then go to see a doctor.

‧ Keep the battery fluid beyond the reach of

children.

Brake pad

Do not use compressed air or a cleaning brush to

clean the brake system; use a vacuum cleaner to

prevent the asbestos fiber from drifting in the air.

Caution

Inhaling asbestos fiber may result in lung disease

or cancer.

Brake fluid

Caution

Brake fluid may cause damage to the surface of

the painted parts, or even the structure of the

plastic or rubber parts. Place a clean cloth for

protection when servicing the brake system.

Keep the brake fluid beyond reach of children.

To this chapter contents

1. GENERAL INFORMATION

Service Precautions

1-3

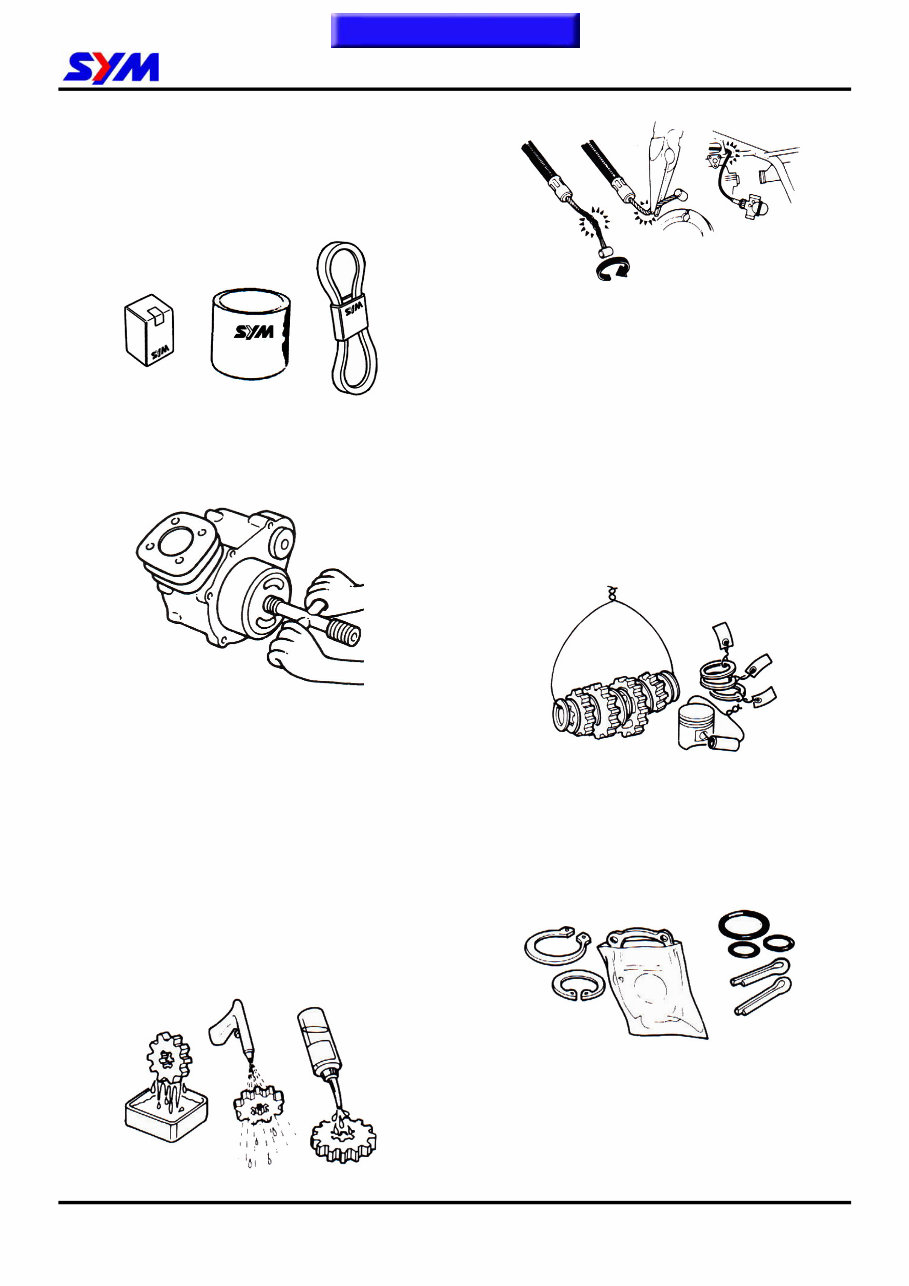

Always use with Sanyang genuine parts and

recommended oils. Using non-designed parts for

Sanyang motorcycle may damage the motorcycle.

Special tools are designed for remove and install

of components without damaging the parts being

work ed on. Using wrong tools may result in parts

damaged.

y When servicing this motorcycle, use only metric

tools. Metric bolts, nuts, and screws are not

interchangeable with the English system, using

wrong tools and fasteners may damage this

vehicle.

y Clean the outside of the parts or the cover

before removing it from the motorcycle.

Otherwise, dirt and deposit accumulated on the

part's surface may fall into the engine, chassis,

or brake system to cause a damage.

Wash and clean parts with high ignition point

solvent, and blow dry with compressed air. Pay

special attention to O-rings or oil seals because

most cleaning agents have an adverse effect on

them.

Never bend or twist a control cable to prevent

unsmooth control and premature worn out.

y Rubber parts may become deteriorated when

old, and prone to be damaged by solvent and oil.

Check these parts before installation to make

sure that they are in good condition, replace if

necessary.

y When loosening a component which has

different sized fasteners, operate with a

diagonal pattern and work from inside out.

Loosen the small fasteners first. If the bigger

ones are loosen first, small fasteners may

receive too much stress.

Store complex components such as transmission

parts in the proper assemble order and tie them

togethe r with a wire for ease of installation later.

y Note the reassemble position of the important

components before disassembling them to

ensure they wil l be reassembled in correct

dimensions (depth, distance or position).

Components not to be reused should be replaced

when disassembled including gaskets metal seal

rings, O-rings, oil seals, snap rings, and split pins.

To this chapter contents

1. GENERAL INFORMATION

y

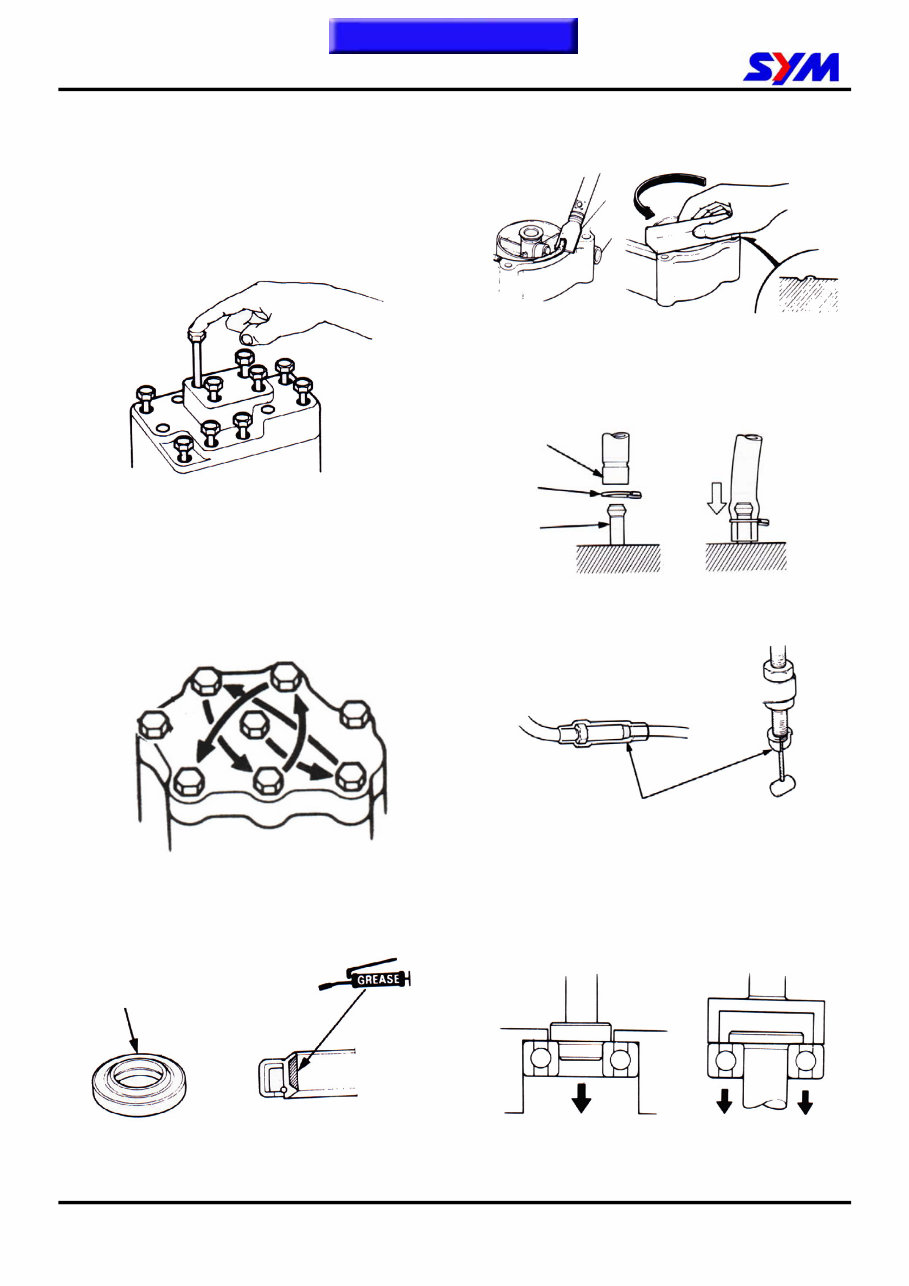

The length of bolts and screws for assemblies,

cover plates or boxes is different from one another,

be sure they are correctly installed. In case of

confusion, Insert the bolt into the hole to compare

its length with other bolts, if its length out side the

hole is the same with other bolts, it is a correct bolt.

Bolts for the same assembly should have the

same length.

Remove residues of the old gasket or sealant

before reinstallation, grind with a grindstone if the

contact surface has any damage.

The ends of rubber hoses (for fuel, vacuum, or

coolant) should be pushed as far as they can go to

their connections so that there is enough room

below the en larged ends for tightening the

clamps.

Groove

Clamp

Tighten assemblies with different dimension

fasteners as follows: Tighten all the fasteners with

fingers, then tighten the big ones with special tool

first diagonally from inside toward outside,

important components should be tightened 2 to 3

times with appropriate increments to avoid warp

unles s otherwise indicated. Bolts and fasteners

should be kept clean and dry. Do not apply oil to

the threads.

Connector

Rubber and plastic boots should be properly

reinstalled to the original correct positions as

designed.

Boots

The tool should be pressed against two (inner and

outer) bearing races when removing a ball bearing.

Damage may result if the tool is pressed against

only one race (either inner race or outer race). In

this case, the bearing should be replaced. To

avoid damaging the bearing, use equal force on

both races.

When oil seal is installed, fill the groove with

grease, install the oil seal with the name of the

manufacturer facing outside, check the shaft on

which the oil seal is to be installed for smoothness

and for burrs that may damage the oil seal.

Manufacturer's name

Both of these examples can result in bearing

damage.

1-4

1. GENERAL INFORMATION

To this chapter contents

y

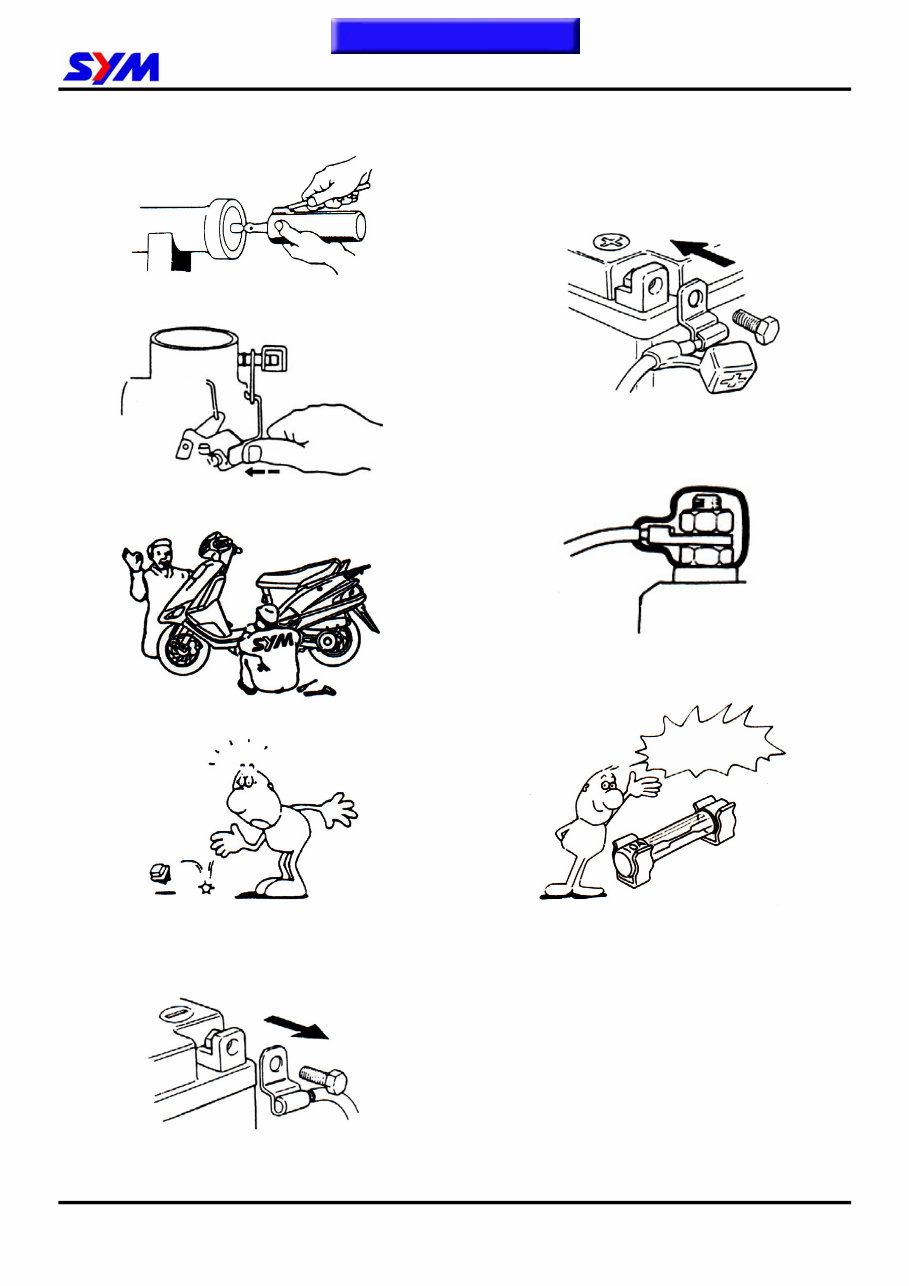

Lubricate the rotation face with specified lubricant

on the lubrication points before assembling.

y After service completed, make sure all

connection points is secured. Battery positive (+)

cable should be connected firstly.

And the two posts of battery have to be

greased after connected the cables.

Check if positions and operation for installed parts

is in correct and properly.

Make sure that the battery post caps are located in

properly after the battery posts had been service

d.

Make sure service safety each other when

conducting by two persons.

If fuse burned, it has to find out the cause and

solved it. And then replace with specified capacity

fuse.

Note that do not let parts fall down.

Capacity

verification

Before battery removal operation, it has to remove

the battery negative (-) cable firstly. Notre tools

like open-end wrench do not contact with body to

prevent from circuit short and create sp ark.

1-5

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 66 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get instant access to the Complete Factory Service Repair Workshop Manual without any extra fees or expiry dates. This Professional Manual is suitable for both professional Mechanics and Technicians, as well as DIY enthusiasts. It covers all repairs, servicing, and troubleshooting procedures with detailed photos, diagrams, step-by-step instructions, and highly detailed exploded diagrams & pictures to ensure every job is completed correctly.

Print out a single page or the entire manual as per your choice. This Manual can be used on multiple computers without any limitations or trial periods, and it does not expire or require any renewal fees. It is fully compatible with all Windows & MAC Computers.