1990 1991 1992 1993 1994 1995 1996 1997 Suzuki GSX750F Katana models Factory Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Introduction 0-7

The GSX-R750 and

GSX-R1100

T

he phrase race-replica was bandied

about a lot when the first GSX-R was

launched in 1985. This was a mistake,

the smaller GSX-R was not a race-replica, it

was a racer: period. It even looked like the

factory endurance racer on which various

components had been developed. The GSX-R

didn't make any more power than its

competitors, both the Suzuki and the F2750

Yamaha claimed to make 100 bhp and the

900 cc GPZ Kawasaki made 115 bhp, it was

the fact the thing only weighed 388 Ib that

made it so amazing.

The old saying goes that the most expensive

thing to add to a bike is lightness, but Suzuki

managed it with a combination of lightweight

components, oil cooling, and a decided lack of

creature comforts. The frame weighed only 18

Ib without the swinging arm and wrapped

around a motor that was pared down to the

minimum possible weight thanks to oil cooling.

Five-and-a-half litres of the stuff were pumped

around the cylinder head and cooled in a big

radiator thus enabling all the top-end

components to be as light as possible.

On the road, the GSX-R felt like a racer. A

third of the power arrived between 7000 and

9000 rpm, the flat-slide carbs didn't like

being snapped open at low revs, and the

chassis was very, very sensitive. If you

twitched so did the bike, despite the

unfashionably large 18-inch front wheel. I

once took my left hand off the bars on one of

the first GSX-Rs to look over my shoulder

and was rewarded with a lock-to-lock

tank-slapper. I was on one of London's major

arterial roads at the time...

By contrast the first of the 1100 cc GSX-Rs

had all of the technology, lack of weight and

race-track cred of the 750, but it was

astoundingly civilised. The twitchiness was

gone, the fussy carburation banished. In its

place was a massively powerful yet very

usable if slightly plain sports tourer that could

hustle when asked. After all, this is still a

race-track bred machine we're talking about -

it just didn't seem like it.

The GSX750F Katana model

Over the years the 750 GSX-R was tamed

whereas the 1100 got less civilised. The

J-model 750 of 1988 was the first to get the

Slingshot designation - actually a reference to

a new carburettor design - and a new short-

stroke motor (73 x 44.7 mm replacing the

original 70 x 48.7 mm). It also got a

substantial, and very modern, restyle with

more rounded lines including air ducts either

side of the headlights. The 1990 L-model

changed again, this time back to the original

dimensions of 70 x 48.7 mm. The 1100's

major changes tended to lag a year behind

the 750's. It was the 1989 K-model that got

the short-stroke 78 x 59 mm 1127 cc motor to

replace the original 76 x 78 mm 1052 cc lump

and the following year it got upside-down

front forks.

Both the 750 and 1100 oil-cooled motors

were superseded by new, water-cooled

designs in 1992 and 1993, respectively.

The GSX600F, 750F and

11 OOF (Katana)

R

iders who didn't need a cutting-edge

sportster also benefited from the

GSX-R's development, because the

engines were used in a new generation of GSX

models (Katanas in the US). The 750 was

sleeved down for the GSX600, a budget bike

that was deliberately built to a price and not

intended to compete with the Supersports

600s like the FZR or CBR. All-enveloping

bodywork hid the steel chassis and produced

an effect that one observer likened to a teapot

when it appeared in 1987.

Aesthetics aside, the GSX was astounding

value for money and the following year a

better looking 750 cc version was launched.

In late '87 the 1100 motor was used in a GSX

aimed at the sports tourer segment occupied

by FJ Yamahas and CBR Hondas. It was one

of those bikes that wasn't well received on its

launch but as time went on it, like the GSXs,

revealed itself as yet another very

good motorcycle. And when you took the

price into account they were seen as

exceptional bikes.

Acknowledgements

O

ur thanks are due to Joe Ortiz who

suggested and arranged many of the

photographs in addition to performing

mechanical work. NGK Spark Plugs (UK) Ltd

supplied the color spark plug condition

photographs and the Avon Rubber Company

provided information on tire fitting.

Thanks are also due to Redcat Marketing

and Kel Edge for supplying colour

transparencies, to Fred Furlong of Yeovil for

supplying the GSX-R1100 on the front cover,

and to Phil Flowers who carried out the front

cover photography. The introduction, "Suzuki

- Every Which Way" was written by Julian

Ryder.

About this Manual

T

he aim of this manual is to help you get

the best value from your motorcycle. It

can do so in several ways. It can help

you decide what work must be done, even if

you choose to have it done by a dealer; it

provides information and procedures for

routine maintenance and servicing; and it

offers diagnostic and repair procedures to

follow when trouble occurs.

We hope you use the manual to tackle the

work yourself. For many simpler jobs, doing it

yourself may be quicker than arranging an

appointment to get the motorcycle into a

dealer and making the trips to leave it and

pick it up. More importantly, a lot of money

can be saved by avoiding the expense the

shop must pass on to you to cover its labour

and overhead costs. An added benefit is the

sense of satisfaction and accomplishment

that you feel after doing the job yourself.

References to the left or right side of the

motorcycle assume you are sitting on the

seat, facing forward.

We take great pride in the accuracy of

information given in this manual, but

motorcycle manufacturers make alterations

and design changes during the production

run of a particular motorcycle of which they

do not inform us. No liability can be

accepted by the authors or publishers for

loss, damage or injury caused by any errors

in, or omissions from, the information given.

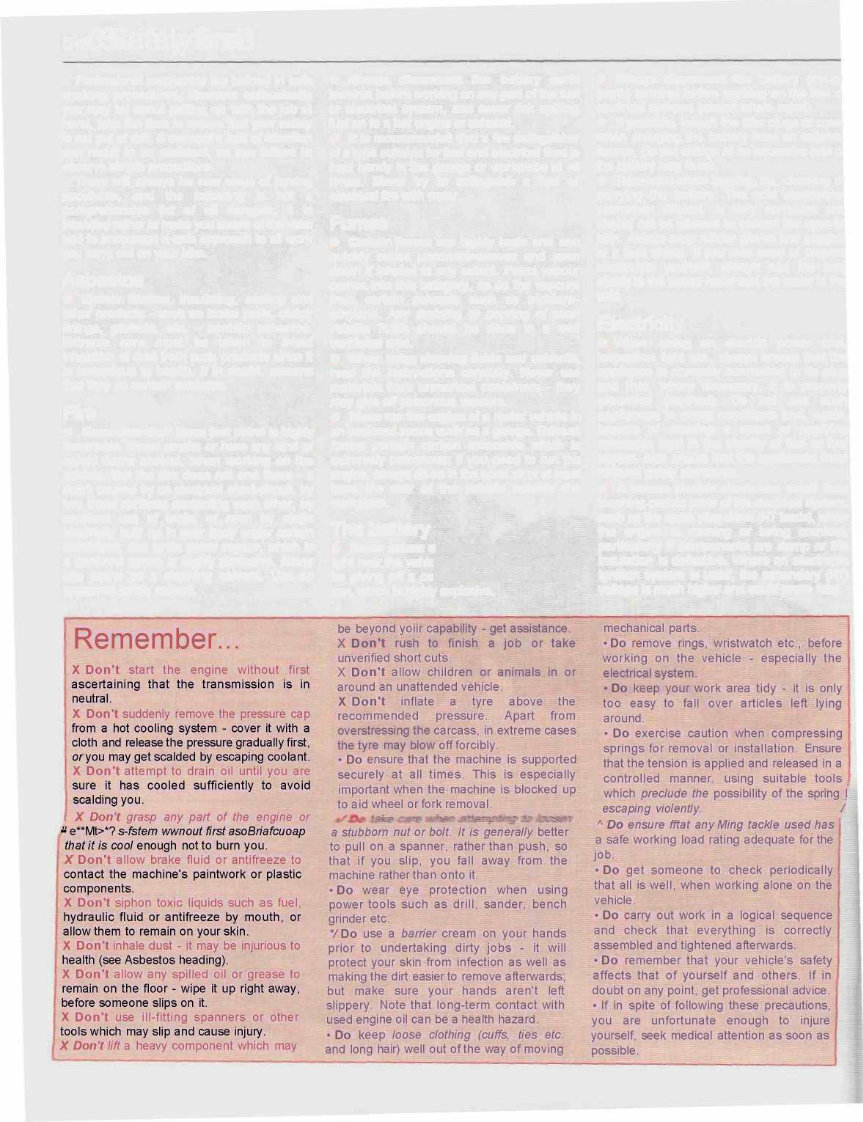

0-8 Safety first!

Professional mechanics are trained in safe

working procedures. However enthusiastic

you may be about getting on with the job at

hand, take the time to ensure that your safety

is not put at risk. A moment's lack of attention

can result in an accident, as can failure to

observe simple precautions.

There will always be new ways of having

accidents, and the following is not a

comprehensive list of all dangers; it is

intended rather to make you aware of the risks

and to encourage a safe approach to all work

you carry out on your bike.

Asbestos

• Certain friction, insulating, sealing and

other products - such as brake pads, clutch

linings, gaskets, etc. - contain asbestos.

Extreme care must be taken to avoid

inhalation of dust from such products since it

is hazardous to health. If in doubt, assume

that they do contain asbestos.

Fire

• Remember at all times that petrol is highly

flammable. Never smoke or have any kind of

naked flame around, when working on the

vehicle. But the risk does not end there - a

spark caused by an electrical short-circuit, by

two metal surfaces contacting each other, by

careless use of tools, or even by static

electricity built up in your body under certain

conditions, can ignite petrol vapour, which in

a confined space is highly explosive. Never

use petrol as a cleaning solvent. Use an

approved safety solvent.

• Always disconnect the battery earth

terminal before working on any part of the fuel

or electrical system, and never risk spilling

fuel on to a hot engine or exhaust.

• It is recommended that a fire extinguisher

of a type suitable for fuel and electrical fires is

kept handy in the garage or workplace at all

times. Never try to extinguish a fuel or

electrical fire with water.

Fumes

• Certain fumes are highly toxic and can

quickly cause unconsciousness and even

death if inhaled to any extent. Petrol vapour

comes into this category, as do the vapours

from certain solvents such as trichloro-

ethylene. Any draining or pouring of such

volatile fluids should be done in a well

ventilated area.

• When using cleaning fluids and solvents,

read the instructions carefully. Never use

materials from unmarked containers - they

may give off poisonous vapours.

• Never run the engine of a motor vehicle in

an enclosed space such as a garage. Exhaust

fumes contain carbon monoxide which is

extremely poisonous; if you need to run the

engine, always do so in the open air or at least

have the rear of the vehicle outside the

workplace.

• Always disconnect the battery groum

(earth) terminal before working on the fuel o

electrical systems (except where noted).

• If possible, loosen the filler plugs or cove

when charging the battery from an externa

source. Do not charge at an excessive rate o

the battery may burst.

• Take care when topping up, cleaning o'

carrying the battery. The acid electrolyte

evenwhen diluted, is very corrosive anc

should not be allowed to contact the eyes 01

skin. Always wear rubber gloves and goggles

or a face shield. If you ever need to prepare

electrolyte yourself, always add the acid

slowly to the water; never add the water to the

acid.

Electricity

The battery

• Never cause a spark, or allow a naked

light near the vehicle's battery. It will normally

be giving off a certain amount of hydrogen

gas, which is highly explosive.

• When using an electric power tool,

inspection light etc., always ensure that the

appliance is correctly connected to its plug

and that, where necessary, it is properly

grounded (earthed). Do not use such

appliances in damp conditions and, again,

beware of creating a spark or applying

excessive heat in the vicinity of fuel or fuel

vapour. Also ensure that the appliances meet

national safety standards.

• A severe electric shock can result from

touching certain parts of the electrical system,

such as the spark plug wires (HT leads), when

the engine is running or being cranked,

particularly if components are damp or the

insulation is defective. Where an electronic

ignition system is used, the secondary (HT)

voltage is much higher and could prove fatal.

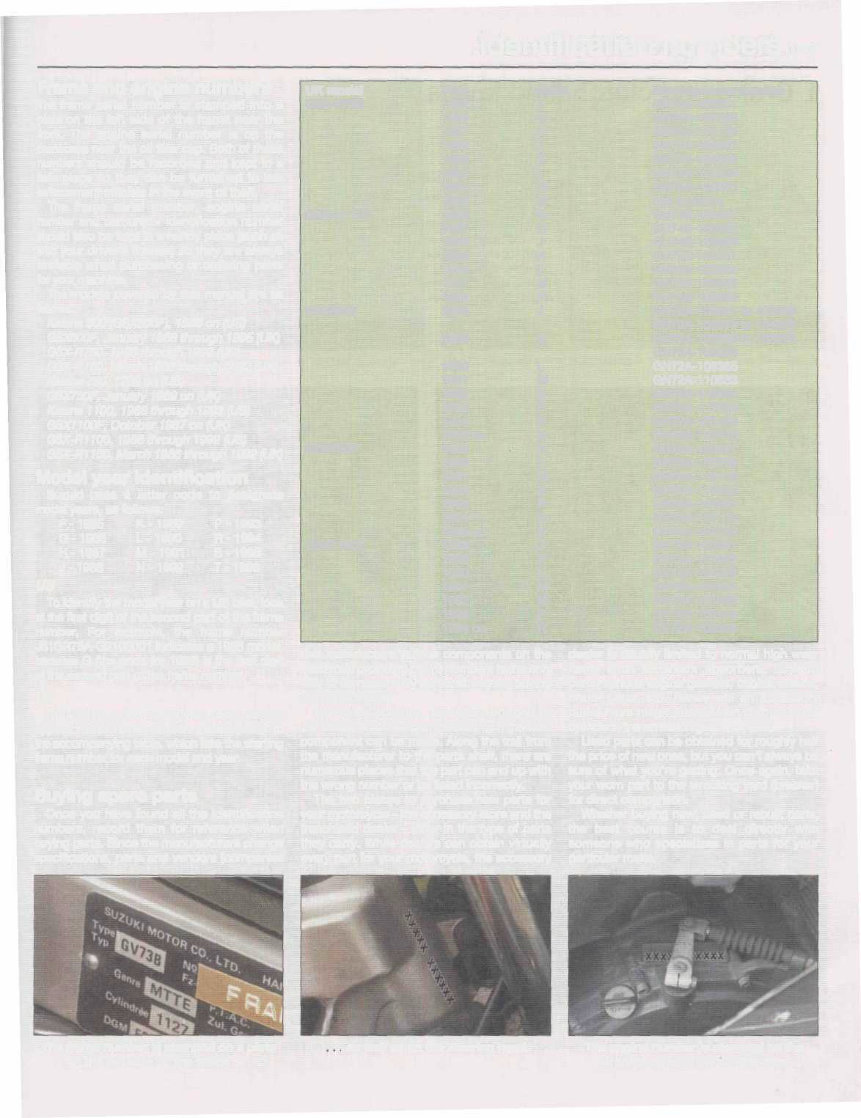

identification numbers 0-9

Frame and engine numbers

The frame serial number is stamped into a

plate on the left side of the frame near the

front. The engine serial number is on the

crankcase near the oil filler cap. Both of these

numbers should be recorded and kept in a

safe place so they can be furnished to law

enforcement officials in the event of theft.

The frame serial number, engine serial

number and carburetor identification number

should also be kept in a handy place (such as

with your driver's license) so they are always

available when purchasing or ordering parts

for your machine.

The models covered by this manual are as

follows:

Katana 600 (GSX600F), 1988 on (US)

GSX600F, January 1988 through 1995 (UK)

GSX-R750, 1986 through 1992 (US)

GSX-R750, March 1985 through 1992 (UK)

Katana 750, 1989 on (US)

GSX750F, January 1989 on (UK)

Katana 1100, 1988 through 1993 (US)

GSX1100F, October 1987 on (UK)

GSX-R1100, 1986 through 1992 (US)

GSX-R1100, March 1986 through 1992 (UK)

Model year identification

Suzuki uses a letter code to designate

model years, as follows:

F

G

H

J

-1985

-1986

- 1987

- 1988

K-

L-

M-

N-

1989

1990

1991

1992

P-

R-

S-

T-

1993

1994

1995

1996

US

To identify the model year on a US bike, look

at the first digit of the second part of the frame

number. For example, the frame number

JS1GR75A-G2100001 indicates a 1986 model,

because G (the code for 1986) is the first digit

of the second part of the frame number.

UK

On UK bikes, the model year code doesn't

appear in the frame number. Instead, refer to

the accompanying table, which lists the starting

frame number for each model and year.

Buying spare parts

Once you have found all the identification

numbers, record them for reference when

buying parts. Since the manufacturers change

specifications, parts and vendors (companies

UK model

GSX-R750

GSX-R1100

GSX600F

GSX750F

GSX1100F

Year

1985

1986

1987

1988

1989

1990

1991

1992

1986

1987

1988

1989

1990

1991

1992

1988

1989

1990

1991

1992

1993

1994

1995 on

1989

1990

1991

1992

1993

1994

1995 on

1988

1989

1990

1991

1992

1993

1994 on

Code

F

G

H

J

K

L

M

N

G

H

J

K

L

M

N

J

K

L

M

N

P

R

S

K

L

M

N

P

R

S

J

K

L

M

N

P

R

Starting frame number

GR75A-100001

GR75A-107368

GR75A-112130

GR77A-100001

GR77A-104392

GR7AA-100034

GR7AA-100001

Not available

GU74B-100001

GU74B-103282

GU74B-106265

GV73B-100001

GV73B-103392

GV73B-106082

GV73B-108660

GN72A-100001 to 103968

GN72A-103979 to 104098

GN72A-103969 to 103978

GN72A-104099

GN72A-106385

GN72A-110633

GN72A-115034

GN72A-118194

GN72A-121465

GN72A-123718

GR78A-100001

GR78A-105765

GR78A-113118

GR78A-119920

GR78A-125061

GR78A-131112

GR78A-134162

GV72A-100001

GV72A-101093

GV72A-101223

GV72A-101584

GV72A-101990

GV72D-101019

GV72A-102304

that manufacture various components on the

machine), providing the ID numbers is the only

way to be reasonably sure that you are buying

the correct parts.

Whenever possible, take the worn part to

the dealer so direct comparison with the new

component can be made. Along the trail from

the manufacturer to the parts shelf, there are

numerous places that the part can end up with

the wrong number or be listed incorrectly.

The two places to purchase new parts for

your motorcycle - the accessory store and the

franchised dealer - differ in the type of parts

they carry. While dealers can obtain virtually

every part for your motorcycle, the accessory

dealer is usually limited to normal high wear

items such as shock absorbers, tune-up

parts, various engine gaskets, cables, chains,

brake parts, etc. Rarely will an accessory

outlet have major suspension components,

cylinders, transmission gears, or cases.

Used parts can be obtained for roughly half

the price of new ones, but you can't always be

sure of what you're getting. Once again, take

your worn part to the wrecking yard (breaker)

for direct comparison.

Whether buying new, used or rebuilt parts,

the best course is to deal directly with

someone who specializes in parts for your

particular make.

The frame number is stamped on a plate

on the left side of the frame . . .

. as well as on the steering head The engine number is stamped on the

crankcase near the oil filler cap

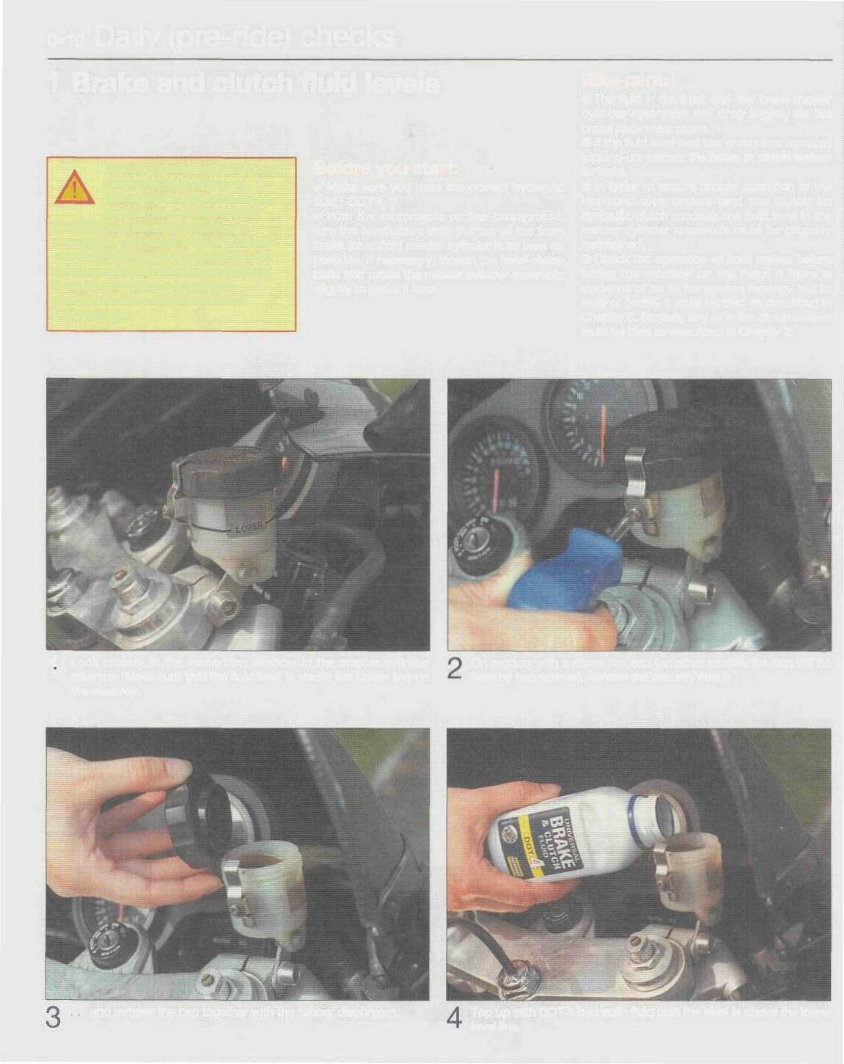

0-10 Daily (pre-ride) checks

1 Brake and clutch fluid levels

Warning: Brake hydraulic fluid

can harm your eyes and

damage painted surfaces, so

use extreme caution when

handling and pouring it and cover

surrounding surfaces with rag. Do not

use fluid that has been standing open

for some time, as it absorbs moisture

from the air which can cause a

dangerous loss of braking/clutch

effectiveness.

Before you start:

• Make sure you have the correct hydraulic

fluid - DOT 4.

• With the motorcycle on the centerstand,

turn the handlebars until the top of the front

brake (or clutch) master cylinder is as level as

possible. If necessary, loosen the lever clamp

bolts and rotate the master cylinder assembly

slightly to make it level.

Bike care:

• The fluid in the front and rear brake master

cylinder reservoirs will drop slightly as the

brake pads wear down.

• If the fluid level was low or requires repeated

topping-up, inspect the brake or clutch system

for leaks.

• In order to ensure proper operation of the

hydraulic disc brakes (and the clutch on

hydraulic clutch models), the fluid level in the

master cylinder reservoirs must be properly

maintained.

• Check the operation of both brakes before

taking the machine on the road; if there is

evidence of air in the system (spongy feel to

lever or pedal), it must be bled as described in

Chapter 6. Similarly any air in the clutch system

must be bled as described in Chapter 2.

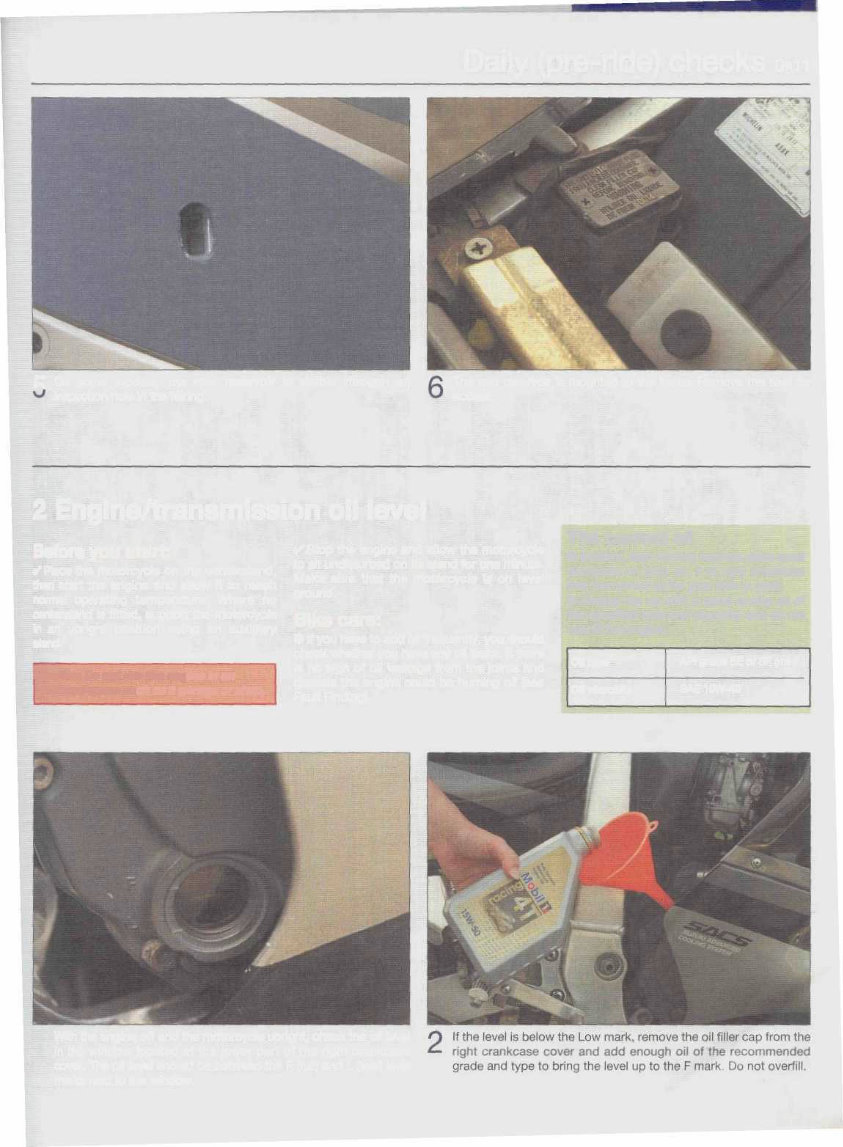

H Look closely at the inspection window in the master cylinder

' reservoir. Make sure that the fluid level is above the Lower line on

the reservoir.

On models with a screw top cap (on other models the cap will be

held by two screws), remove the security clamp . . .

. and remove the cap together with the rubber diaphragm. Top up with DOT 4 hydraulic fluid until the level is above the lower

level line.

Daily (pre-ride) checks 0-11

5 On some models, the rear reservoir is visible through an

inspection hole in the fairing.

The rear reservoir is mounted to the frame. Remove the seat for

access.

2 Engine/transmission oil level

Before you start:

• Place the motorcycle on the centerstand,

then start the engine and allow it to reach

normal operating temperature. Where no

centerstand is fitted, support the motorcycle

in an upright position using an auxiliary

stand.

f Caution: Do not run the engine in an

enclosed space such as a garage or shop.

• Stop the engine and allow the motorcycle

to sit undisturbed on its stand for one minute.

Make sure that the motorcycle is on level

ground.

Bike care:

• If you have to add oil frequently, you should

check whether you have any oil leaks. If there

is no sign of oil leakage from the joints and

gaskets the engine could be burning oil (see

Fault Finding).

The correct oil

• Modern, high-revving engines place great

demands on their oil. It is very important

that the correct oil for your bike is used.

• Always top up with a good quality oil of

the specified type and viscosity and do not

overfill the engine.

Oil type

Oil viscosity

API grade SE or SF (min)

SAE 10W-40

1

With the engine off and the motorcycle upright, check the oil level

in the window located at the lower part of the right crankcase

cover. The oil level should be between the F (full) and L (low) level

marks next to the window.

0-12 Daily (pre-ride) checks

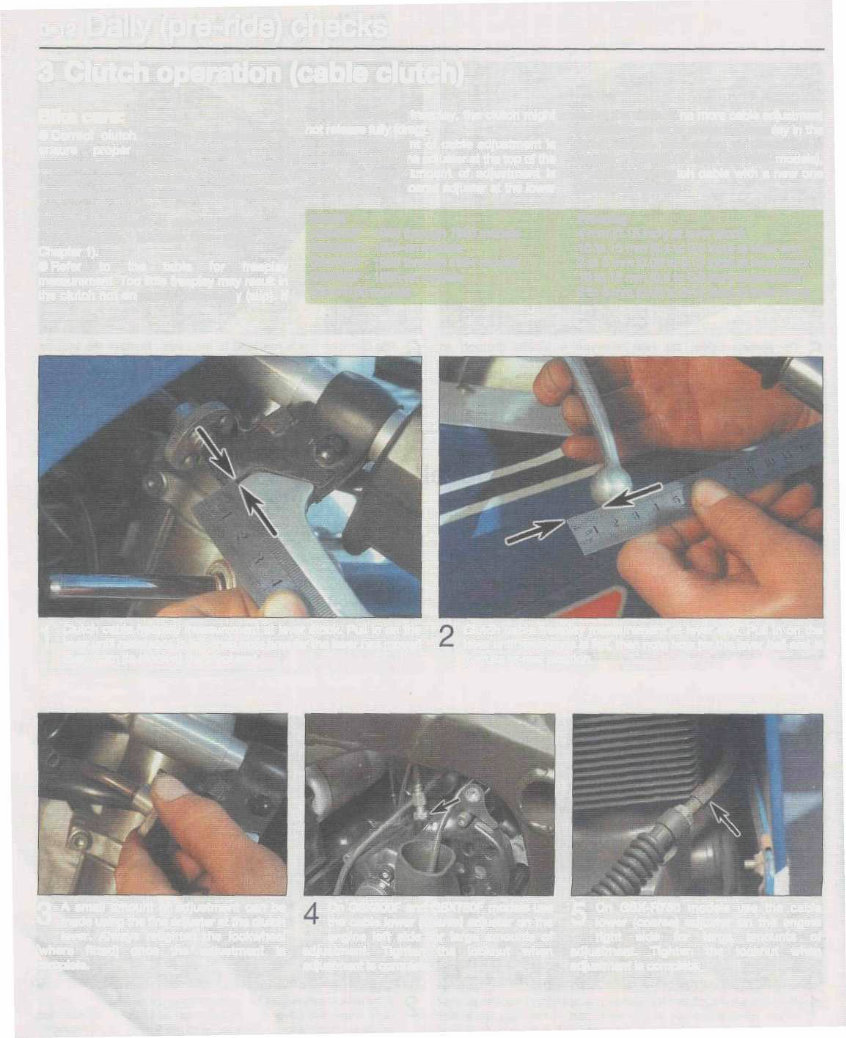

3 Clutch operation (cable clutch)

Bike care:

• Correct clutch freeplay is necessary to

ensure proper clutch operation and

reasonable clutch service life. Freeplay

normally changes because of cable stretch

and clutch wear, so it should be checked and

adjusted periodically.

• If the lever is stiff to operate and doesn;t

return quickly, lubricate the cable (see

Chapter 1).

• Refer to the table for freeplay

measurement. Too little freeplay may result in

the clutch not engaging completely (slip). If

there is too much freeplay, the clutch might

not release fully (drag).

• If a small amount of cable adjustment is

required, use the fine adjuster at the top of the

cable. If a large amount of adjustment is

required, use the coarse adjuster at the lower

Model

GSX600F -1988 through 1993 models

GSX600F - 1994-on models

GSX750F -1989 through 1994 models

GSX750F - 1995-on models

GSX-R750 models

end of the cable. If no more cable adjustment

is possible, go on to check the freeplay in the

clutch release mechanism as described in

Chapter 1 (GSX600F and GSX750F models),

or replace the clutch cable with a new one

(GSX-R750 models).

Freeplay

4 mm (0.16 inch) at lever stock

10 to 15 mm (0.4 to 0.6 inch) at lever end

2 to 3 mm (0.08 to 0.12 inch) at lever stock

10 to 15 mm (0.4 to 0.6 inch) at lever end

2 to 3 mm (0.08 to 0.12 inch) at lever stock

1

Clutch cable freeplay measurement at lever stock. Pull in on the

lever until resistance is felt, then note how far the lever has moved

away from its stock at the pivot end.

Clutch cable freeplay measurement at lever end. Pull in on the

lever until resistance is felt, then note how far the lever ball end is

from its at-rest position.

3

A small amount of adjustment can be

made using the fine adjuster at the clutch

lever. Always retighten the lockwheel

(where fitted) once the adjustment is

complete.

On GSX600F and GSX750F models use

the cable lower (coarse) adjuster on the

engine left side for large amounts of

adjustment. Tighten the locknut when

adjustment is complete.

5

On GSX-R750 models use the cable

lower (coarse) adjuster on the engine

right side for large amounts of

adjustment. Tighten the locknut when

adjustment is complete.

Daily (pre-ride) checks 0-13

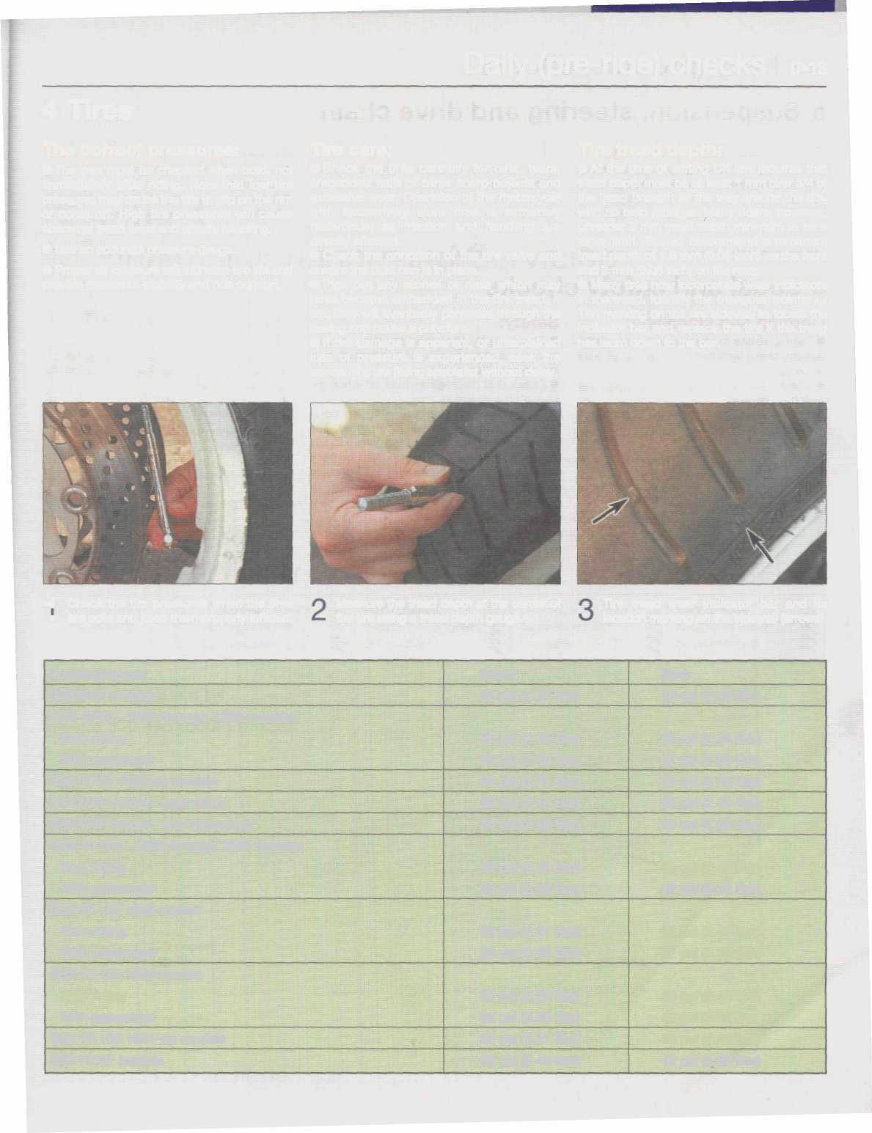

4 Tires

The correct pressures:

• The tires must be checked when cold, not

immediately after riding. Note that low tire

pressures may cause the tire to slip on the rim

or come off. High tire pressures will cause

abnormal tread wear and unsafe handling.

• Use an accurate pressure gauge.

• Proper air pressure will increase tire life and

provide maximum stability and ride comfort.

Tire care:

• Check the tires carefully for cuts, tears,

embedded nails or other sharp objects and

excessive wear. Operation of the motorcycle

with excessively worn tires is extremely

hazardous, as traction and handling are

directly affected.

• Check the condition of the tire valve and

ensure the dust cap is in place.

• Pick out any stones or nails which may

have become embedded in the tire tread. If

left, they will eventually penetrate through the

casing and cause a puncture.

• If tire damage is apparent, or unexplained

loss of pressure is experienced, seek the

advice of a tire fitting specialist without delay.

Tire tread depth:

• At the time of writing UK law requires that

tread depth must be at least 1 mm over 3/4 of

the tread breadth all the way around the tire,

with no bald patches. Many riders, however,

consider 2 mm tread depth minimum to be a

safer limit. Suzuki recommend a minimum

tread depth of 1.6 mm (0.06 inch) on the front

and 2 mm (0.08 inch) on the rear.

• Many tires now incorporate wear indicators

in the tread. Identify the triangular pointer or

TWI marking on the tire sidewail to locate the

indicator bar and replace the tire if the tread

has worn down to the bar.

A Check the tire pressures when the tires

• are cold and keep them properly inflated.

Measure the tread depth at the center of

the tire using a tread depth gauge.

Tire tread wear indicator bar and its

location marking on the sidewail (arrows).

Loading/speed

GSX600F models

GSX-R750 -1985 through 1989 models:

Solo riding

With passenger

GSX-R750 1990-on models

GSX750F model - solo riding

GSX750F model - with passenger

GSX-R1100 -1986 through 1988 models:

Solo riding

With passenger

GSX-R1100 1989 model:

Solo riding

With passenger

GSX-R1100 1990 model:

Solo riding

With passenger

GSX-R1100 1991 -on models

GSX11 OOF models

Front

33 psi (2.27 Bar)

36 psi (2,48 Bar)

36 psi (2.48 Bar)

33 psi (2.27 Bar)

36 psi (2.48 Bar)

36 psi (2.48 Bar)

36 psi (2.48 Bar)

36 psi (2.48 Bar)

33 psi (2.27 Bar)

36 psi (2.48 Bar)

32 psi (2.20 Bar)

32 psi (2.20 Bar)

33 psi (2.27 Bar)

36 psi (2.48 Bar)

Rear

36 psi (2.48 Bar)

36 psi (2.48 Bar)

42 psi (2.89 Bar)

36 psi (2.48 Bar)

36 psi (2.48 Bar)

42 psi (2.89 Bar)

36 psi (2.48 Bar)

42 psi (2.89 Bar)

36 psi (2.48 Bar)

42 psi (2.89 Bar)

36 psi (2.48 Bar)

42 psi (2.89 Bar

36 psi (2.48 Bar)

42 psi (2.89 Bar)

0-14 Daily (pre-ride) checks

5 Suspension, steering and drive chain

Suspension and steering: Drive chain:

• Make sure the steering operates smoothly, • Check front and rear suspension for • Make sure the drive chain isn't out of

without looseness and without binding. smooth operation, adjustment.

• Make sure the drive chain is adequately

lubricated.

6 Legal and safety checks

Lighting and signalling:

• Take a minute to check that the headlight,

taillight, brake light and turn signals all work

correctly.

• Check that the horn sounds when the

switch is operated.

• A working speedometer is a statutory

requirement in the UK.

Safety:

• Check that the throttle grip rotates

smoothly and snaps shut when released, in all

steering positions.

• Check that the engine shuts off when the

kill switch is operated.

• Check that sidestand return spring holds

the stand securely up when retracted. The

same applies to the centerstand (where fitted).

• Following the procedure in your owner's

manual, check the operation of the sidestand

switch.

Fuel:

• This may seem obvious, but check that you

have enough fuel to complete your journey. If

you notice signs of fuel leakage - rectify the

cause immediately.

• Ensure you use the correct grade fuel - see

Chapter 3 Specifications.

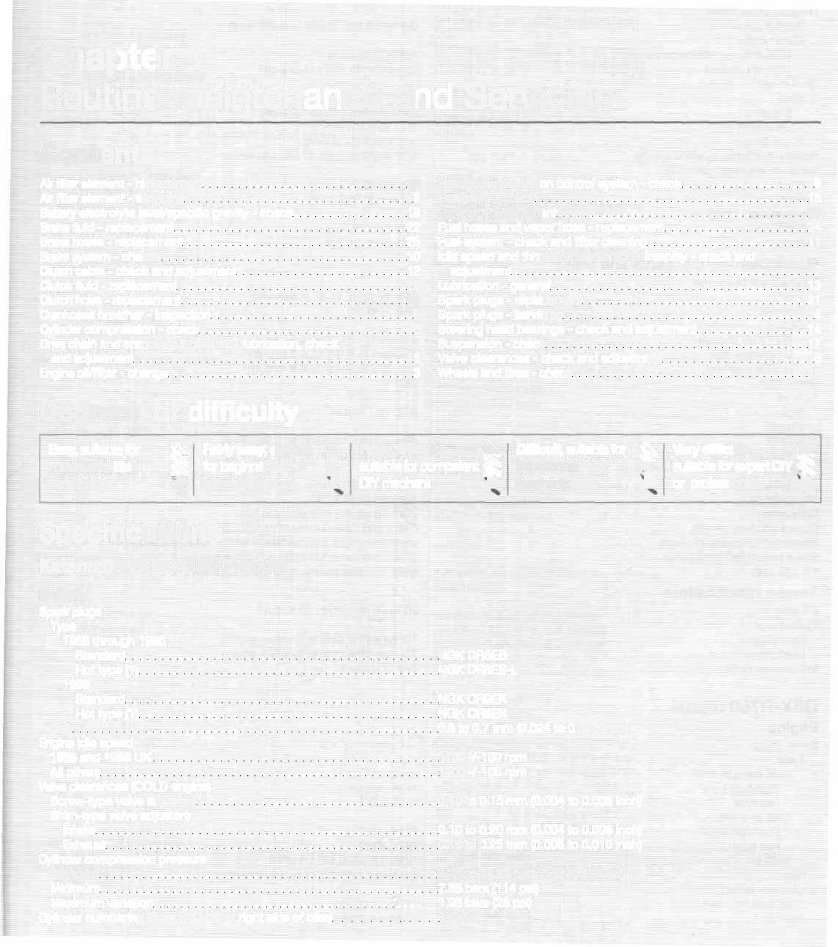

Chapter 1

Routine maintenance and Servicing

Contents

Air filter element - replacement 20

Air filter element - servicing 2

Battery electrolyte level/specific gravity - check 19

Brake fluid - replacement 22

Brake hoses - replacement 25

Brake system - checks 10

Clutch cable - check and adjustment 12

Clutch fluid - replacement 23

Clutch hose - replacement 26

Crankcase breather - inspection 9

Cylinder compression - check 6

Drive chain and sprockets - cleaning, lubrication, check

and adjustment 1

Engine oil/filter - change 3

Degrees of difficulty

Evaporative emission control system - check 8

Fasteners - check 18

Fork oil - replacement 16

Fuel hoses and vapor hose - replacement 24

Fuel system - check and filter cleaning 11

Idle speed and throttle operation/grip freeplay - check and

adjustment 7

Lubrication - general 13

Spark plugs - replacement 21

Spark plugs - servicing 4

Steering head bearings - check and adjustment 14

Suspension - check 17

Valve clearances - check and adjustment 5

Wheels and tires - check 15

Easy, suitable for §K

novice with little ^

experience g^

Fairly easy, suitable |k

for beginner with ^

some experience gS

Fairly difficult, ^,

suitable for competent ^

DIY mechanic gS

Difficult, suitable for ^

experienced DIY 3^

mechanic gS

Very difficult, ^

suitable for expert DIY 3^

or professional g^

Specifications

Katana 600 (GSX600F) model

Engine

Spark plugs

Type

1988 through 1995

Standard NGK DR8ES

Hot type (1) NGK DR8ES-L

1996

Standard NGK CR9EK

Hot type (1) NGK CR8EK

Gap 0.6 to 0.7 mm (0.024 to 0.028 inch)

Engine idle speed

1988 and 1989 UK 1100+/-100 rpm

All others 1300+/-100 rpm

Valve clearances (COLD engine)

Screw-type valve adjusters 0.10 to 0.15 mm (0.004 to 0.006 inch)

Shim-type valve adjusters

Intake 0.10 to 0.20 mm (0.004 to 0.008 inch)

Exhaust 0.15 to 0.25 mm (0.006 to 0.010 inch)

Cylinder compression pressure

Standard 9.78 to 14.67 bars (142 to 213 psi)

Minimum 7.85 bars (114 psi)

Maximum variation '' .... 1.93 bars (28 psi)

Cylinder numbering (from left side to right side of bike) 1 -2-3-4

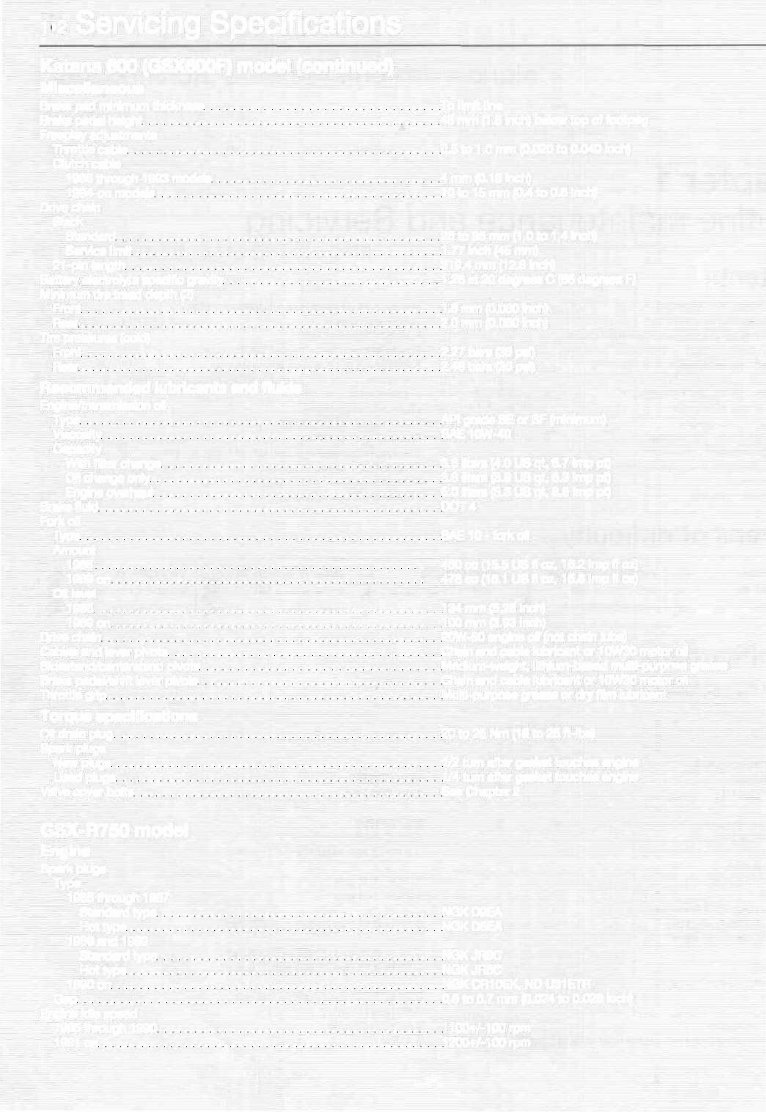

1 1-2 Servicing Specifications

Katana 600 (GSX600F) model (continued)

Miscellaneous

Brake pad minimum thickness To limit line

Brake pedal height 45 mm (1.8 inch) below top of footpeg

Freeplay adjustments

Throttle cable 0.5 to 1.0 mm (0.020 to 0.040 inch)

Clutch cable

1988 through 1993 models 4 mm (0.16 inch)

1994-on models 10 to 15 mm (0.4 to 0.6 inch)

Drive chain

Slack

Standard 25 to 35 mm (1.0 to 1.4 inch)

Service limit 1.77 inch (45 mm)

21-pin length 319.4 mm (12.6 inch)

Battery electrolyte specific gravity 1.28 at 20 degrees C (68 degrees F)

Minimum tire tread depth (2)

Front 1.6 mm (0.060 inch)

Rear 2.0 mm (0.080 inch)

Tire pressures (cold)

Front 2.27 bars (33 psi)

Rear 2.48 bars (36 psi)

Recommended lubricants and fluids

Engine/transmission oil

Type API grade SE or SF (minimum)

Viscosity SAE10W-40

Capacity

With filter change 3.8 liters (4.0 US qt, 6.7 Imp pt)

Oil change only 3.6 liters (3.8 US qt, 6.3 Imp pt)

Engine overhaul 5.0 liters (5.3 US qt, 8.8 Imp pt)

Brake fluid DOT 4

Fork oil

Type SAE 10 - fork oil

Amount

1988 460 cc (15.5 US fl oz, 16.2 Imp fl oz)

1989 on 478 cc (16.1 US fl oz, 16.8 Imp fl oz)

Oil level

1988 134 mm (5.28 inch)

1989 on 100 mm (3.93 inch)

Drive chain 20W-50 engine oil (not chain lube)

Cables and lever pivots Chain and cable lubricant or 10W30 motor oil

Sidestand/centerstand pivots Medium-weight, lithium-based multi-purpose grease

Brake pedal/shift lever pivots Chain and cable lubricant or 10W30 motor oil

Throttle grip Multi-purpose grease or dry film lubricant

Torque specifications

Oil drain plug 20 to 25 Nm (18 to 25 ft-lbs)

Spark plugs

New plugs 1/2 turn after gasket touches engine

Used plugs 1/4 turn after gasket touches engine

Valve cover bolts See Chapter 2

GSX-R750 model

Engine

Spark plugs

Type

1985 through 1987

Standard type NGK D9EA

Hot type NGK D8EA

1988 and 1989

Standard type NGK JR9C

Hot type NGK JR8C

1990 on NGKCR10EK, NDU31ETR

Gap 0.6 to 0.7 mm (0.024 to 0.028 inch)

Engine idle speed

1985 through 1990 1100+/-100 rpm

1991 on 1200+/-100 rpm

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

Viewed 75 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

This manual covers the following Suzuki Motorcycle Models:

- GSX750F Katana_1990-1997_99500-37068-03E

Number of pages in file: 344

This complete owner's service manual covers all repair topics such as:

- General Information

- Periodic Maintenance

- Fuel System

- Cooling System

- Engine Top End

- Engine Lubrication System

- Engine Removal/Installation

- Crankshaft/Crankcase

- Transmission

- Wheels/Tires

- Final Drive

- Brakes

- Suspension

- Steering

- Frame

- Electrical System

- Troubleshooting

- Detailed Diagrams, illustrations, photos, exploded views and step-by-step Instructions Diagnostics and similar topics

File Format: PDF

Compatible: All Versions of Windows & Mac

Language: English

Requirements: Adobe Reader