2006-2009 Piaggio Typhoon 50 Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SERVICE STATION MANUAL

633665 - . . . - 633672

Typhoon 50

SERVICE STATION

MANUAL

Typhoon 50

The descriptions and illustrations given in this publication are not binding. While the basic specifications

as described and illustrated in this manual remain unchanged, PIAGGIO-GILERA reserves the right, at

any time and without being required to update this publication beforehand, to make any changes to

components, parts or accessories, which it considers necessary to improve the product or which are

required for manufacturing or construction reasons.

Not all versions/models shown in this publication are available in all countries. The availability of each

model should be checked at the official Piaggio sales network.

"© Copyright 2008 - PIAGGIO & C. S.p.A. Pontedera. All rights reserved. Reproduction of this publication

in whole or in part is prohibited."

PIAGGIO & C. S.p.A. - After sales

V.le Rinaldo Piaggio, 23 - 56025 PONTEDERA (Pi)

SERVICE STATION MANUAL

Typhoon 50

This service station manual has been drawn up by Piaggio & C. Spa to be used by the workshops of Piaggio-Gilera dealers. It

is assumed that the user of this manual for maintaining and repairing Piaggio vehicles has a basic knowledge of mechanical

principles and vehicle repair technique procedures. Any significant changes to vehicle characteristics or to specific repair

operations will be communicated by updates to this manual. Nevertheless, completely satisfactory work cannot be carried out

without the necessary equipment and tools. It is therefore advisable to read the sections of this manual relating to appropriate

tools, along with the appropriate tool catalogue.

N.B. Provides key information to make the procedure easier to understand and carry out.

CAUTION Refers to specific procedures to carry out for preventing damages to the vehicle.

WARNING Refers to specific procedures to carry out to prevent injuries to the repairer.

Personal safety Failure to completely observe these instructions will result in serious risk of personal

injury.

Safeguarding the environment Sections marked with this symbol indicate the correct use of the vehicle

to prevent damaging the environment.

Vehicle intactness The incomplete or non-observance of these regulations leads to the risk of serious

damage to the vehicle and sometimes even the invalidity of the guarantee.

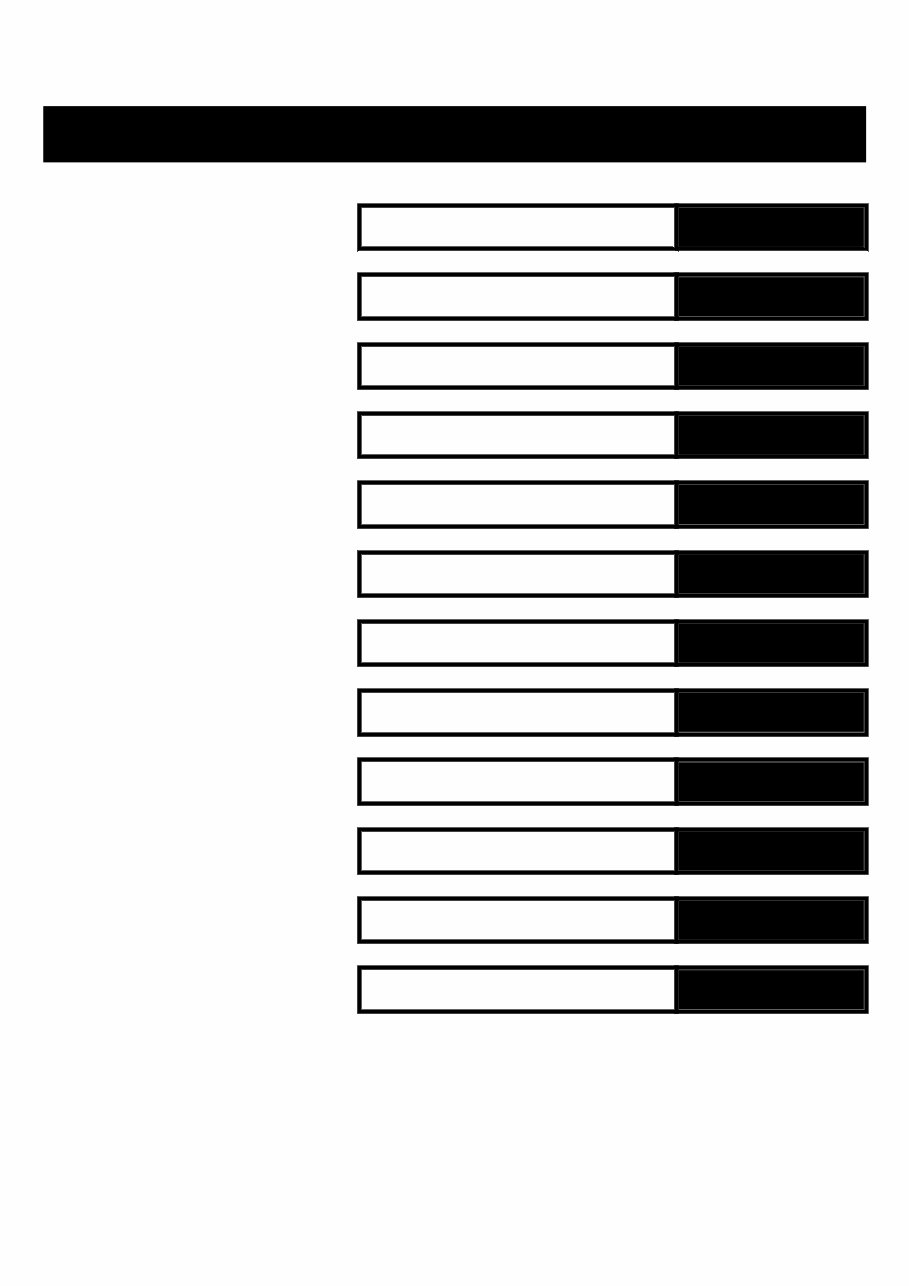

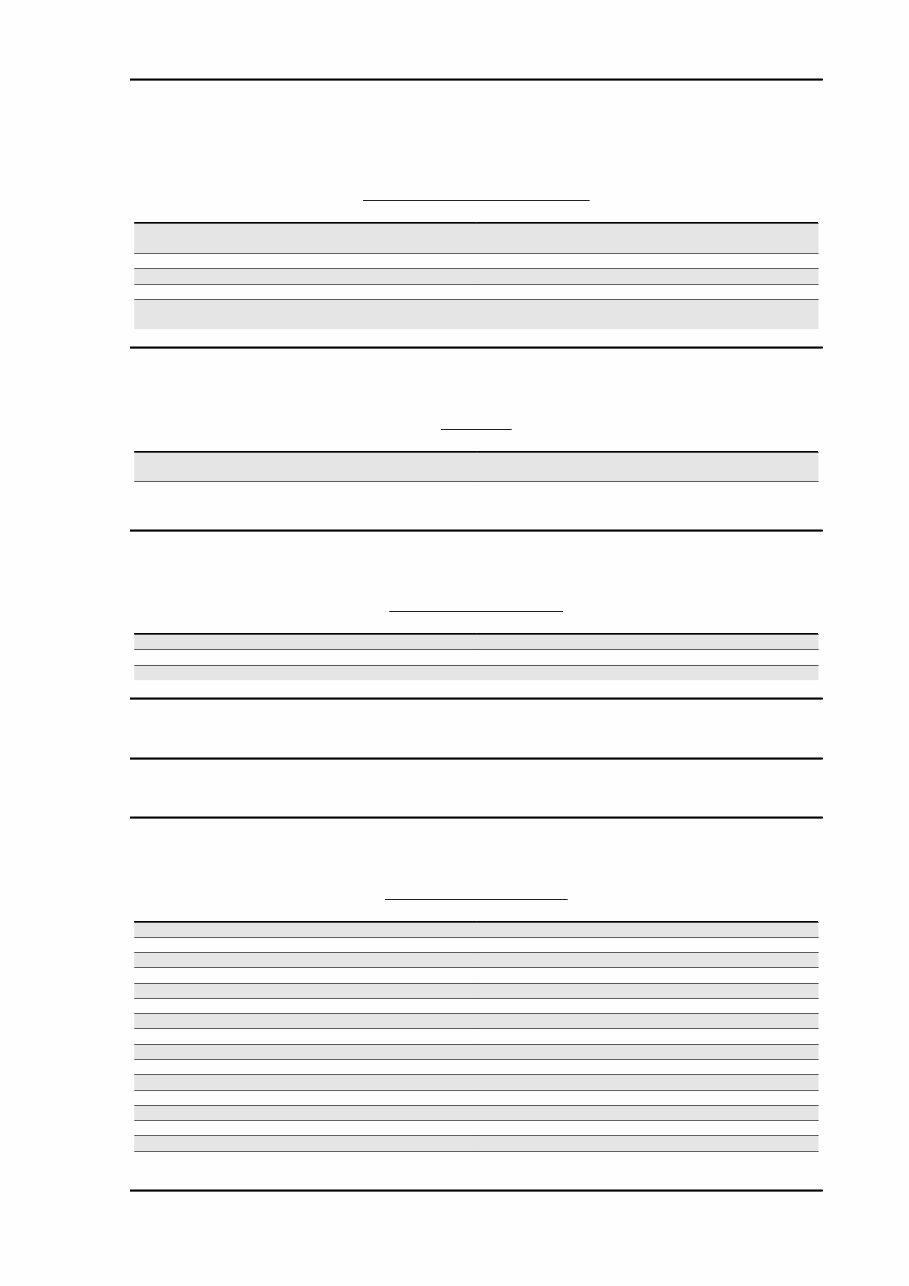

INDEX OF TOPICS

CHARACTERISTICS CHAR

TOOLING TOOL

MAINTENANCE MAIN

TROUBLESHOOTING TROUBL

ELECTRICAL SYSTEM ELE SYS

ENGINE FROM VEHICLE ENG VE

ENGINE ENG

SUSPENSIONS SUSP

BRAKING SYSTEM BRAK SYS

CHASSIS CHAS

PRE-DELIVERY PRE DE

TIME TIME

INDEX OF TOPICS

CHARACTERISTICS CHAR

Rules

This section describes general safety rules for any maintenance operations performed on the vehicle.

Safety rules

- If work can only be done on the vehicle with the engine running, make sure that the premises are well

ventilated, using special extractors if necessary; never let the engine run in an enclosed area. Exhaust

fumes are toxic.

- The battery electrolyte contains sulphuric acid. Protect your eyes, clothes and skin. Sulphuric acid is

highly corrosive; in the event of contact with your eyes or skin, rinse thoroughly with abundant water

and seek immediate medical attention.

- The battery produces hydrogen, a gas that can be highly explosive. Do not smoke and avoid sparks

or flames near the battery, especially when charging it.

- Fuel is highly flammable and it can be explosive given some conditions. Do not smoke in the working

area, and avoid naked flames or sparks.

- Clean the brake pads in a well-ventilated area, directing the jet of compressed air in such a way that

you do not breathe in the dust produced by the wear of the friction material. Even though the latter

contains no asbestos, inhaling dust is harmful.

Maintenance rules

- Use original PIAGGIO spare parts and lubricants recommended by the Manufacturer. Non-original or

non-conforming spares may damage the vehicle.

- Use only the appropriate tools designed for this vehicle.

- Always use new gaskets, sealing rings and split pins upon refitting.

- After removal, clean the components using non-flammable or low flash-point solvents. Lubricate all

the work surfaces, except tapered couplings, before refitting these parts.

- After refitting, make sure that all the components have been installed correctly and work properly.

- Use only equipment with metric sizes for removal, service and reassembly operations. Metric bolts,

nuts and screws are not interchangeable with coupling members using English measurements. Using

unsuitable coupling members and tools may damage the vehicle.

- When carrying out maintenance operations on the vehicle that involve the electrical system, make

sure the electrical connections have been made properly, particularly the ground and battery connec-

tions.

Characteristics Typhoon 50

CHAR - 6

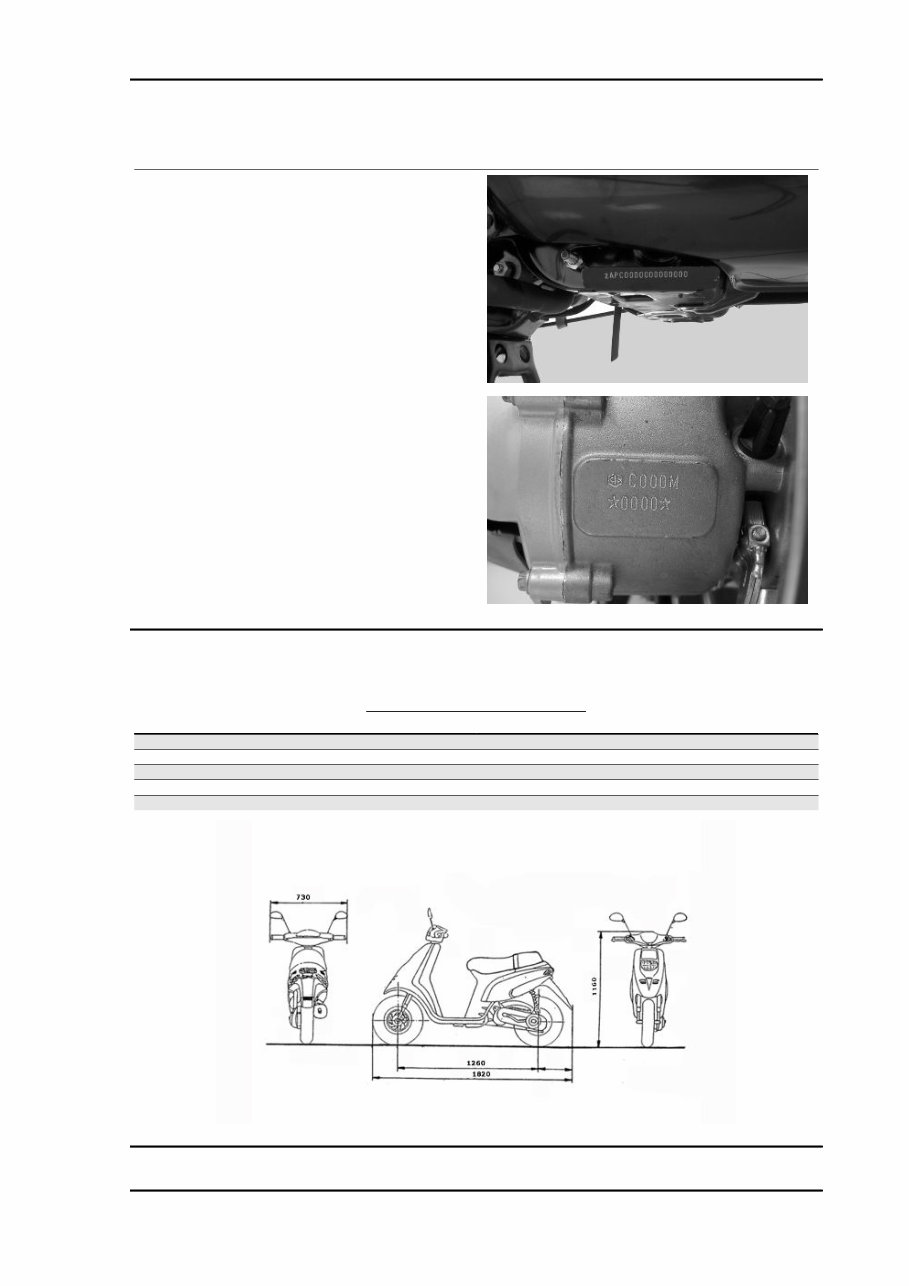

Vehicle identification

Chassis prefix ZAPC29 xxxx xxxxxxx

Engine prefix C216M xxxx

Dimensions and mass

WEIGHT AND DIMENSIONS

Specification Desc./Quantity

Maximum length 1820

Maximum width 730

Maximum height 1160

Lead 1260

Kerb weight 84 Kg

Typhoon 50 Characteristics

CHAR - 7

Engine

ENGINE

Specification Desc./Quantity

Engine type Two-stroke, single cylinder Piaggio Hi-PER2

Bore x stroke 40 X 39.3 mm

Cubic capacity 49.40 cc

Compression ratio 9.4 to 10.4 :1

Carburettor DELL'ORTO PHVA 17.5

CO adjustment 3.5% ± 0.5

Engine idle speed 1800 to 2000 r.p.m.

Air filter Sponge, soaked in a mixture (50% SELENIA Air Filter Oil and

50% unleaded petrol).

Starting system electric starter/kick starter

Lubrication With blend and variable oil variable according to the engine

revolutions and the throttle valve opening by means of a pump

controlled by the driving shaft with toothed belt.

Fuel supply With vacuum operated cock, lead-free gasoline (with 95 octane

minimum) by means of the carburettor.

Cooling Forced air circulation.

Transmission

TRANSMISSION

Specification Desc./Quantity

Transmission With automatic expandable pulley variator, torque server, V-

belt, automatic clutch, gear reduction unit.

Capacities

CAPACITY

Specification Desc./Quantity

Petrol tank In plastic, with a capacity of 5.5 lit. (approximate value) includ-

ing reserve ~ 2 lit.

Oil mixer tank In plastic, with a capacity of 1.5 lit. (including reserve ~0.500

lit).

Rear hub oil Quantity: approx. 80 cm³

Electrical system

ELECTRICAL SYSTEM

Specification Desc./Quantity

Ignition type Capacitive discharge electronic ignition, with incorporated HV

coil

Ignition advance (before TDC) Fixed 17° ± 1

Recommended spark plug CHAMPION RN3C

Battery 12V-4Ah

Main fuse 7.5 A

Generator In alternate current with three output sections

Characteristics Typhoon 50

CHAR - 8

Frame and suspensions

FRAME AND SUSPENSIONS

Specification Desc./Quantity

Type of chassis Welded tubular steel chassis with stamped sheet reinforce-

ments.

Front suspension upside-down hydraulic telescopic fork.

Front stroke 73 mm

Front suspension stroke 58 mm

Rear suspension With coaxial spring and hydraulic shock absorber. Chassis to

engine support with swinging arm.

Brakes

BRAKES

Specification Desc./Quantity

Front brake Disc D=190 / 200 mm with hydraulic control, operated by right

brake lever on the handlebars.

Rear brake Drum D=110 mm with expansion brake shoes, mechanically

controlled by the left brake lever on the handlebars.

Wheels and tyres

WHEELS AND TYRES

Specification Desc./Quantity

Front tyre Tubeless 120/90 x -10''

Rear tyre Tubeless 120/90 x -10''

Wheels with 3.50x10" wheel rims in light alloy.

Carburettor

50cc Version

Dell'Orto

ORTO CARBURETTOR

Specification Desc./Quantity

Type PHVA 17.5 RD

Diffuser diameter Ø 17.5

Regulation reference number 8423

Maximum nozzle: 53

Maximum air nozzle (on the body): Ø 1.5

Tapered pin stamped code: A22

Pin position (notches from above): 1

Diffuser: 209 HA

Minimum nozzle: 32

Minimum air nozzle (on the body): Free

Secondary minimum air hole Ø 2.5

Initial minimum mix screw opening: 1 1/2

Starter jet 50

Starter air nozzle (on the body): Ø 1.5

Stroke of starter pin: 11 mm

Gasoline inlet hole Ø 1.5

Typhoon 50 Characteristics

CHAR - 9

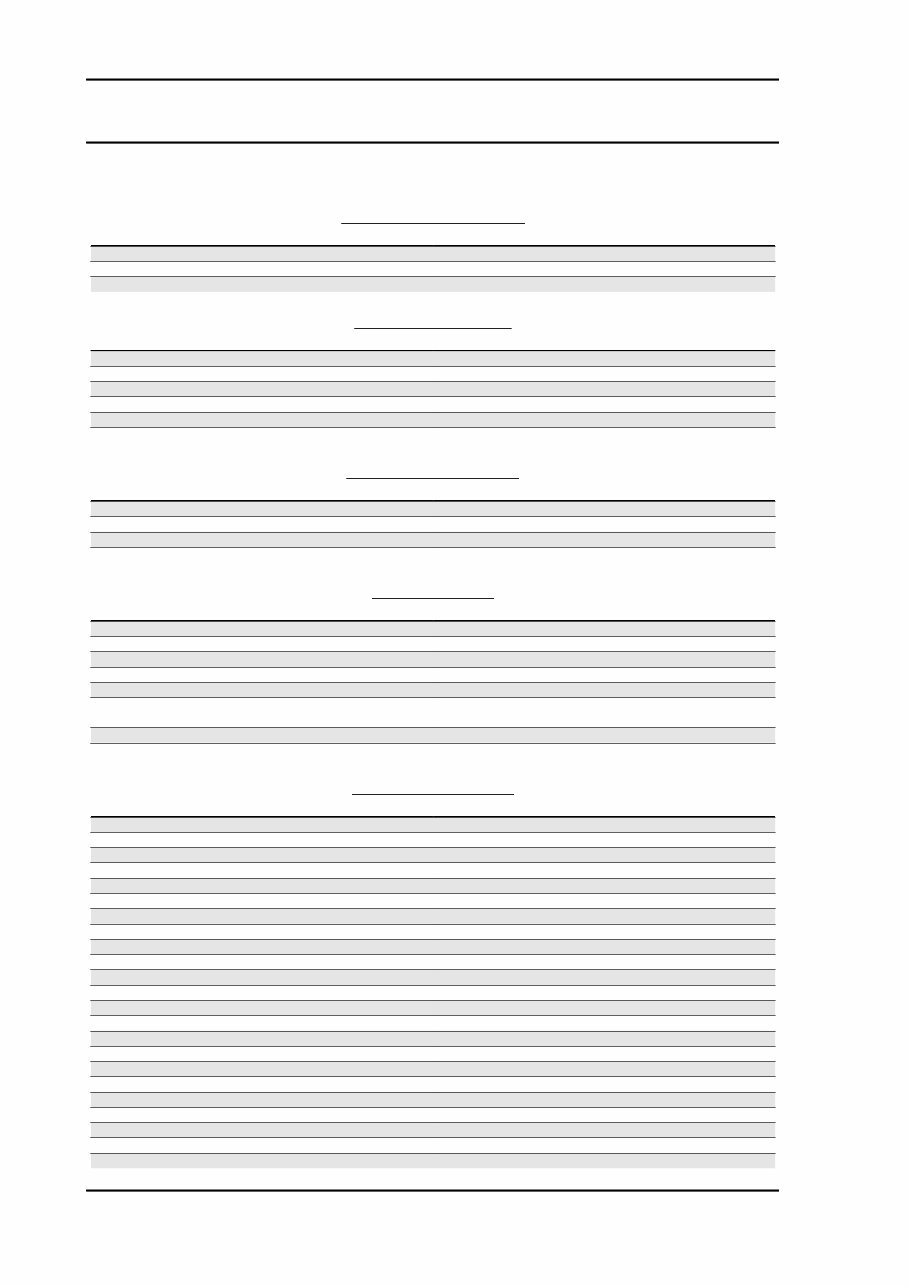

Tightening Torques

STEERING ASSEMBLY

Name Torque in Nm

Upper steering ring nut (safety locks) 35 to 40 Nm

Lower steering ring nut (safety locks) 8 to 10 Nm

Handlebar fixing pin (safety locks) 45 to 50 Nm

FRAME ASSEMBLY

Name Torque in Nm

Swinging arm-engine pin (safety locks) 33 to 41 Nm

Swinging arm-frame pin (safety locks) 64 to 72 Nm

Shock absorber - frame nut (safety locks) 20 to 25 Nm

Shock absorber-engine pin (safety locks) 33 to 41 Nm

Rear wheel axis (safety locks) 104 to 126 Nm

Bolt holding stand to the engine 18 to 19 Nm

FRONT SUSPENSION

Name Torque in Nm

Front wheel axle nut (safety locks) 45 to 50 Nm

Wheel axle clamp screw 6 ÷ 7 Nm

Lower leg screw 15 to 20 Nm

Hydraulic cartridge stem nut 15 to 18 Nm

FRONT BRAKE

Name Torque in Nm

Viti fissaggio coperchio pompa freno 1,5 ÷ 2 Nm

Brake pump support fixing screw 7 to 10 Nm

Brake fluid pump - hose fitting 13 to 18 Nm

Brake fluid tube - calliper fitting 20 to 25 Nm

Calliper tightening screw 20 to 25 Nm

Disc tightening screw (safety locks - lock with LOCTITE

THREADLOCK MEDIUM TYPE 243)

6 ÷ 7 Nm

Oil bleed screw 7 to 10 Nm

Calliper coupling screw 20 to 25 Nm

ENGINE ASSEMBLY

Name Torque in Nm

Clutch bell nut 40 to 44 Nm

Clutch lock ring nut 55 ÷ 60

nut locking driving pulley on the crankshaft 40 to 44 Nm

Start-up lever screw 12 ÷ 13

Flywheel nut 40 to 44 Nm

Flywheel fan screws 3 to 4

Half-crank case joint bolts 12 ÷ 13

Bolts holding exhaust pipe to the crankcase 22 ÷ 24

Screws holding the filter box to the crank case 4 ÷ 5

Head nuts 10 ÷ 11

Starter screws 12 ÷ 13

Ignition spark plug 25 ÷ 30

Hub oil drainage cap 3 ÷ 5

Oil hub level dipstick Manual

Rear hub cap screws 12 ÷ 13

Transmission cover screws 12 ÷ 13

Inlet manifold screws 8 ÷ 9

Flywheel hood fixing screws 1 ÷ 2

Cylinder hood fixing screws 3.5 ÷ 5

Stator clamping screws 3 ÷ 4

Pick-Up clamping screw 4 ÷ 5

Mixer clamping screws 3 ÷ 4

Screw fixing brake lever to the journal on the engine 12 ÷ 13

Characteristics Typhoon 50

CHAR - 10

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 38 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

The Piaggio Typhoon 50 2006-2009 Service Manual is a comprehensive resource for vehicle maintenance and repair. It is a valuable tool for both professional mechanics and DIY enthusiasts.

- The manual covers a wide range of topics including characteristics, special tools, maintenance, troubleshooting, electrical system, engine, power supply, suspensions, chassis, braking system, cooling system, and bodywork.

- With hundreds of pages of diagrams and detailed information, this manual provides the most accurate and complete guidance for vehicle repair.

- It is available in a PDF format, compatible with all versions of Windows and Mac, and is written in English.

- Whether you need to perform routine maintenance or troubleshoot a complex issue, this manual offers the necessary information to keep your Piaggio Typhoon 50 in top condition.