Kymco People 250 repair service manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

PEOPLE 250

C 2003 by KWANG YANG Motor Co., Ltd.

First Edition, Mar 2003

All rights reserved. Any reproduction or unauthorized

use without the written permission of KWANG YANG

Motor Co., Ltd.

is expressly prohibited.

4122-LLJ3-S00

Downloaded from www.Manualslib.com manuals search engine

PEOPLE 250

PREFACE

This Service Manual describes the

technical features and servicing

procedures for the KYMCO People 250.

Section 1 contains the precautions for

all operations stated in this manual.

Read them carefully before any

operation is started.

Section 2 is the removal/installation

procedures for the frame covers which

are subject to higher removal/installation

frequency during maintenance and

servicing operations.

Section 3 describes the inspection/

adjustment procedures, safety rules and

service information for each part, starting

from periodic maintenance.

Sections 5 through 13 give instructions

for disassembly, assembly and adjustment

of engine parts. Section 14 is the

removal/ installation of chassis. Section

16 states the testing and measuring

methods of electrical equipment.

Most sections start with an assembly or

system illustration and troubleshooting

for the section. The subsequent pages

give detailed procedures for the section.

KWANG YANG MOTOR CO., LTD.

OVERSEAS SALES DEPARTMENT

OVERSEAS SERVICE SECTION

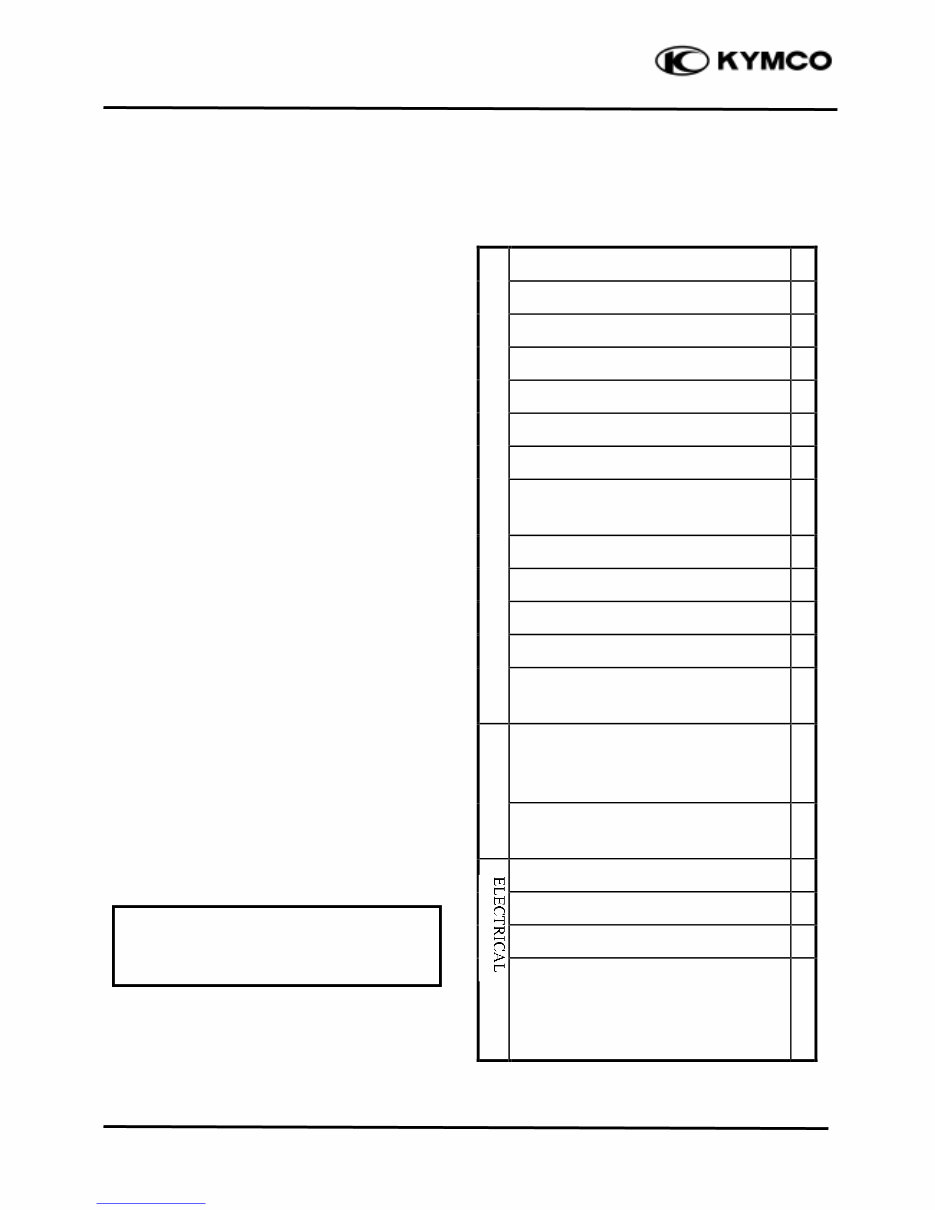

TABLE OF CONTENTS

GENERAL INFORMATION 1

EXHAUST MUFFLER/FRAME COVERS 2

INSPECTION/ADJUSTMENT 3

LUBRICATION SYSTEM 4

ENGINE REMOVAL/INSTALLATION 5

CYLINDER HEAD/VALVES 6

CYLINDER/PISTON 7

DRIVE AND DRIVEN PULLEYS/V-

BELT

8

FINAL REDUCTION 9

A.C. GENERATOR/STARTER CLUTCH 10

CRANKCASE/CRANKSHAFT 11

COOLING SYSTEM 12

FUEL SYSTEM/CARBURETOR/FUEL

PUMP FUEL TANK

13

STEERING HANDLEBAR/FRONT

WHEEL/FRONT BRAKE/FRONT

SHOCK ABSORBER/FRONT FORK

14

REAR BRAKE/REAR FORK/REAR

WHEEL/REAR SHOCK ABSORBER`

15

BATTERY/CHARGING SYSTEM 16

IGNITION SYSTEM 17

STARTING SYSTEM 18

SWITCHES/HORN/FUEL UNIT /

THERMO-STATIC

SWITCH/TEMPERATURE

GAUGE/INSTRUMENTS/ LIGHTS

19

The information and contents included in

this manual may be different from the

motorcycle in case specifications are

changed.

CHASSIS

EQUIPMENT

ENGINE

Downloaded from www.Manualslib.com manuals search engine

1. GENERAL INFORMATION

1-0

PEOPLE 250

1

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

GENERAL INFORMATION

__________________________________________________________________________________

SERIAL NUMBER-------------------------------------------------------- 1-1

SPECIFICATION---------------------------------------------------------- 1-2

SERVICE PRECAUTIONS----------------------------------------------- 1-3

TORQUE VALUES------------------------------------------------------- 1-7

SPECIAL TOOLS--------------------------------------------------------- 1-8

LUBRICATION POINTS------------------------------------------------- 1-9

CABLE & HARNESS ROUTING-----------------------------------------1-11

WIRING DIAGRAM-------------------------------------------------------------------1-18

TROUBLESHOOTING --------------------------------------------------1-19

1

Downloaded from www.Manualslib.com manuals search engine

1. GENERAL INFORMATION

1-1

PEOPLE 250

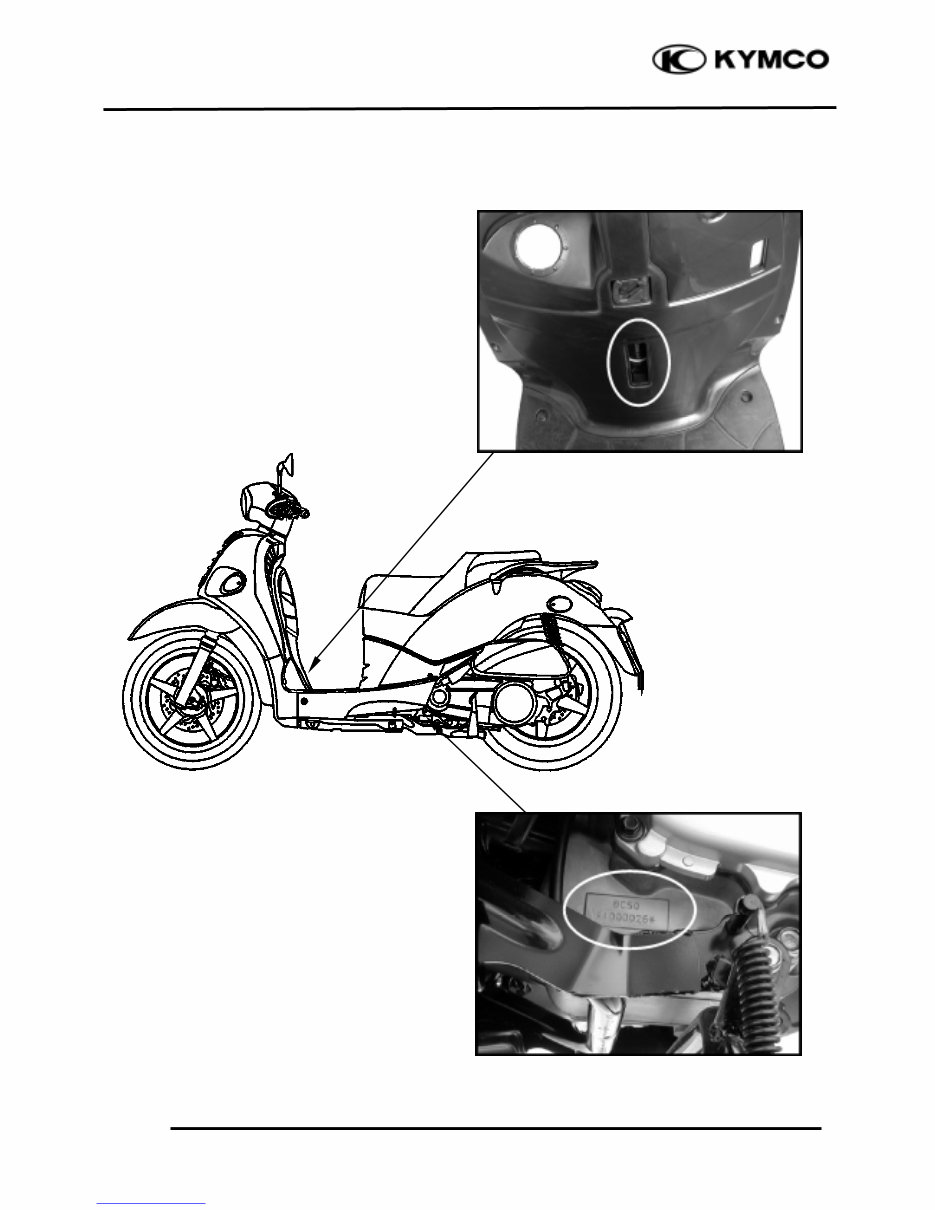

SERIAL NUMBER

Location of Engine Serial Number

Location of Frame Serial Number

Downloaded from www.Manualslib.com manuals search engine

1. GENERAL INFORMATION

1-2

PEOPLE 250

SPECIFICATIONS

Name & Model No. BC50AA

Motorcycle Name & Type PEOPLE 250

Overall length 2219mm

Overall width 742mm

Overall height 1145mm

Wheel base 1515mm

Engine type

Water cooled 4-stroke,

OHC engine

Displacement 249.1cc

Fuel Used 92# nonleaded gasoline

1 person (55kg) Front wheel 86

weight (kg) Rear wheel 127

Total 213

2 person

(110kg)

Front wheel 93

weight(kg) Rear wheel 175

Total 268

Front wheel 110/70-16 52P

Rear wheel 140/70-16 65P

Ground clearance 145mm

Perform

-

Braking distance (m) 4.0m/30km/hr

ance

Min. turning radius 2180mm

Starting system

Starting motor

Type Gasoline, 4-stroke

Cylinder arrangement Single cylinder

Combustion chamber type Semi-sphere

Valve arrangement O.H.C.

Bore x stroke (mm) 72.7 x 60

Compression ratio 10.3:1

Compression pressure

(kg/cm_)

15±2

Max. output (kw/rpm) 13.93/7000

Max. torque (kg.m/rpm) 2.0/5500

BTDC -8°

Port

Intake

ABDC 42°

timin

g

BBDC 33°

Exhaust

ATDC 1°

Valve

Intake 0.1

clearance (cold)

Exhaust 0.1

Idle speed (rpm) 1700±100rpm

Lubrication type

Forced pressure &

Wet sump

Oil pump type Inner/outer rotor

type

Oil filter type Full-flow filtration

Oil capacity 1.1 liters

Air cleaner type & No Paper element, wet

Fuel capacity 8.0 liters

Type CVK

Piston dia. 30

Venturi dia. 30 equivalent

Throttle type Butterfly type

Type CDI

Ignition timing Repeatedly

Contact breaker Non-contact point

type

Spark plug

NGK

DPR7EA-9

Spark plug gap 0.7mm

Battery Capacity 12V10AH

Clutch Type Dry multi-disc clutch

Type Non-stage transmission

Operation

Automatic

centrifugal

Type

Type Two-stage reduction

Reduction 1st 0.83~2.2

ratio

Final 8.72

Front Caster angle 27°

Axle

Connecting rod

Front 1.75

Tire pressure

(kgf/cm_) Rear 2.0

Turning Left 45°

angle

Right 45°

Front Disk brake

Brake system

type Rear Disk brake

Suspension

Front Telescope

type

Rear Double swing

Shock absorber

Front Telescope

type

Rear Double swing

Frame type Under bone

Tires

Engine

System

Fuel System

Carburetor

Electrical

Ignition System

Power Drive System

Transmis-

sion Gear

Reduction

Gear

Moving Device

Damping

Device

Downloaded from www.Manualslib.com manuals search engine

1. GENERAL INFORMATION

1-3

PEOPLE 250

SERVICE PRECAUTIONS

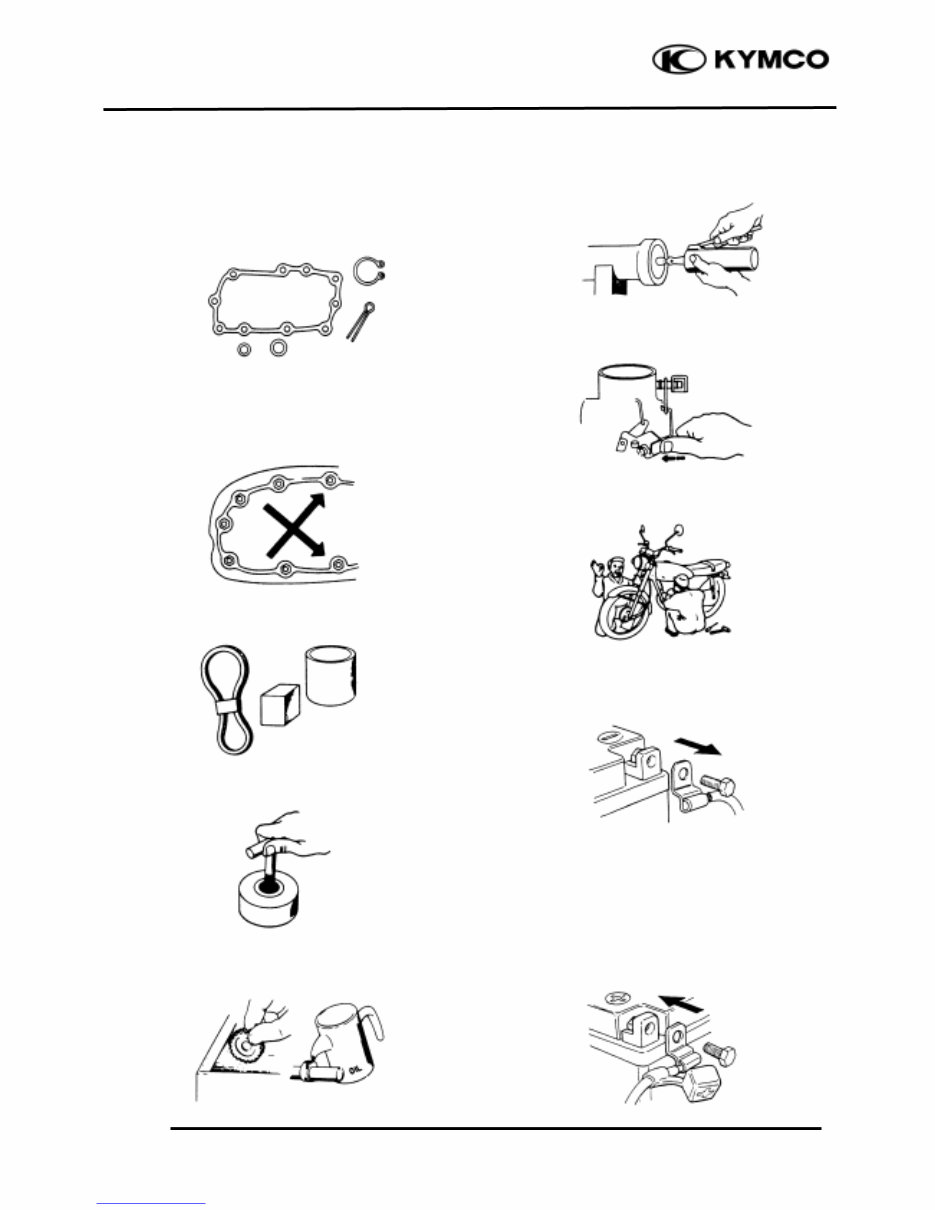

n Make sure to install new gaskets, O-rings,

circlips, cotter pins, etc. when

reassembling.

n When tightening bolts or nuts, begin with

larger-diameter to smaller ones at several

times, and tighten to the specified torque

diagonally.

n Use genuine parts and lubricants.

n When servicing the motorcycle, be sure to

use special tools for removal and

installation.

n After disassembly, clean removed parts.

Lubricate sliding surfaces with engine oil

before reassembly.

n Apply or add designated greases and

lubricants to the specified lubrication

points.

n After reassembly, check all parts for

proper tightening and operation.

n When two persons work together, pay

attention to the mutual working safety.

n Disconnect the battery negative (-) terminal

before operation.

n When using a spanner or other tools, make

sure not to damage the motorcycle surface.

n After operation, check all connecting

points, fasteners, and lines for proper

connection and installation.

n When connecting the battery, the positive

(+) terminal must be connected first.

n After connection, apply grease to the

battery terminals.

n Terminal caps shall be installed securely.

Downloaded from www.Manualslib.com manuals search engine

1. GENERAL INFORMATION

1-4

PEOPLE 250

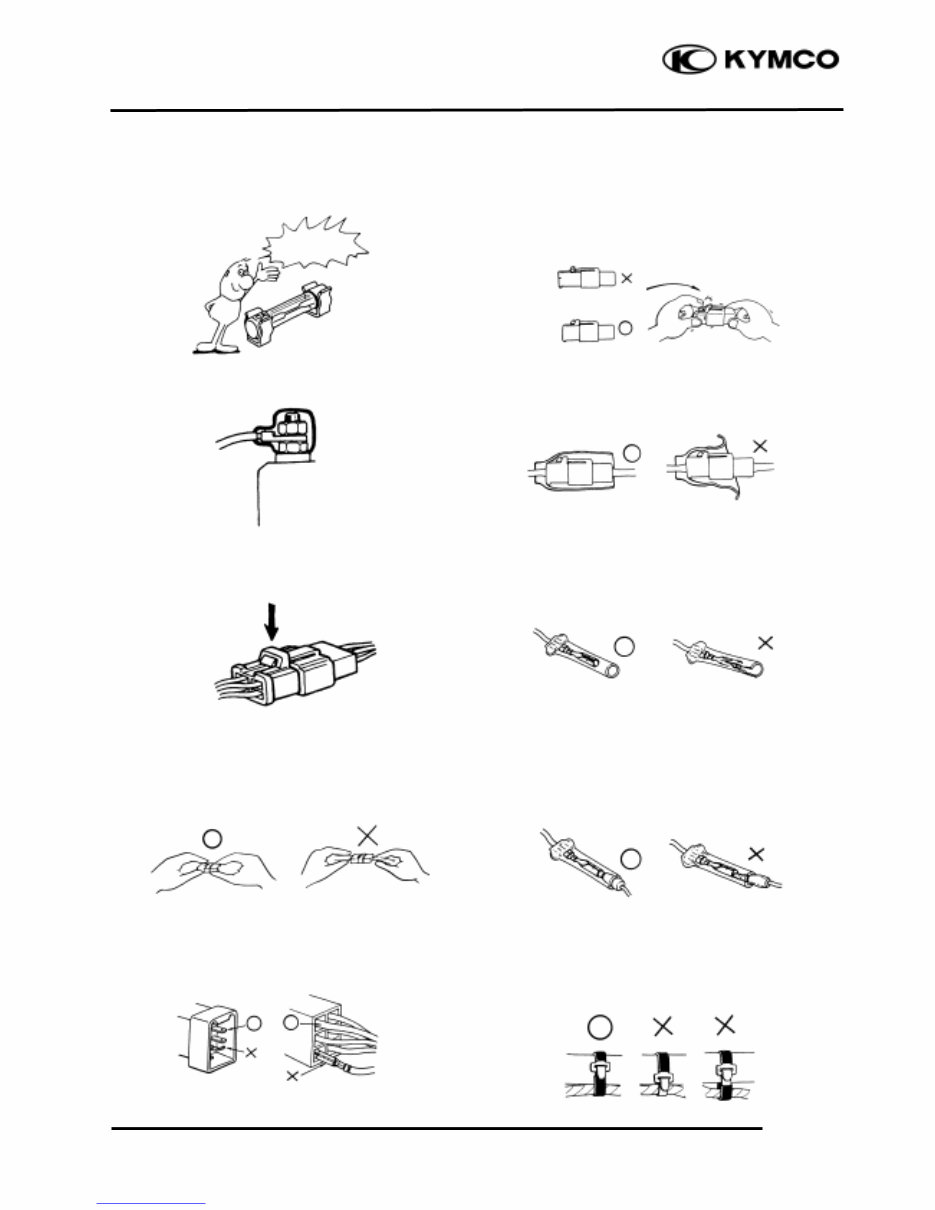

n If the fuse is burned out, find the cause and

repair it. Replace it with a new one

according to the specified capacity.

n After operation, terminal caps shall be

installed securely.

n When taking out the connector, the lock on

the connector shall be released before

operation.

n Hold the connector body when connecting

or disconnecting it.

n Do not pull the connector wire.

n Check if any connector terminal is bending,

protruding or loose.

n The connector shall be inserted

completely.

n If the double connector has a lock, lock

it at the correct position.

n Check if there is any loose wire.

n Before connecting a terminal, check for

damaged terminal cover or loose negative

terminal.

n Check the double connector cover for

proper coverage and installation.

n Insert the terminal completely.

n Check the terminal cover for proper

coverage.

n Do not make the terminal cover opening

face up.

n Secure wire harnesses to the frame with

their respective wire bands at the

designated locations.

Tighten the bands so that only the

insulated surfaces contact the wire

harnesses.

Confirm

Capacity

Downloaded from www.Manualslib.com manuals search engine

1. GENERAL INFORMATION

1-5

PEOPLE 250

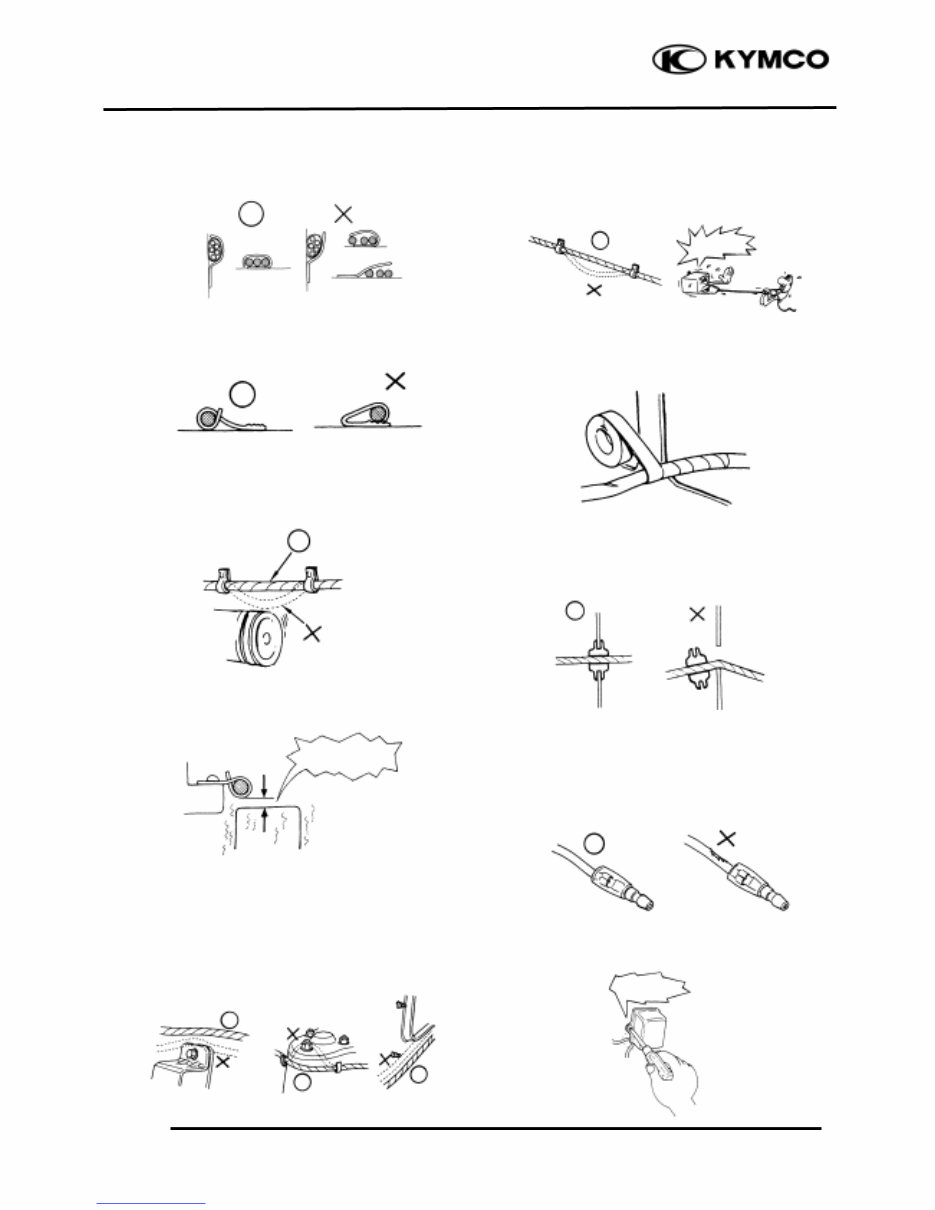

n After clamping, check each wire to make

sure it is secure.

n Do not squeeze wires against the weld or

its clamp.

n After clamping, check each harness to make

sure that it is not interfering with any

moving or sliding parts.

n When fixing the wire harnesses, do not

make it contact the parts which will

generate high heat.

n Route wire harnesses to avoid sharp edges

or corners. Avoid the projected ends of

bolts and screws.

n Route wire harnesses passing through the

side of bolts and screws. Avoid the

projected ends of bolts and screws.

n Route harnesses so they are neither

pulled tight nor have excessive slack.

n Protect wires and harnesses with electrical

tape or tube if they contact a sharp edge or

corner.

n When rubber protecting cover is used to

protect the wire harnesses, it shall be

installed securely.

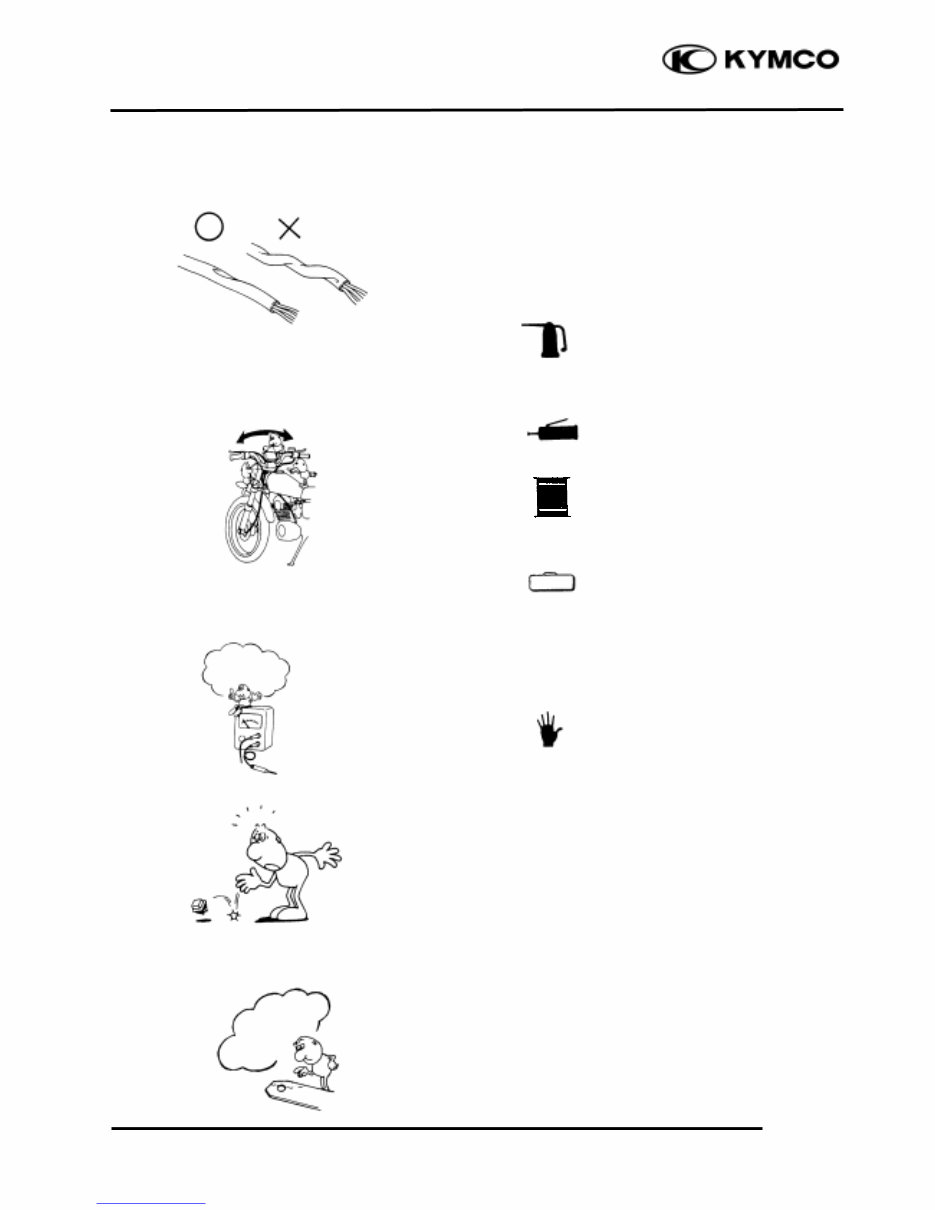

n Do not break the sheath of wire.

n If a wire or harness is with a broken sheath,

repair by wrapping it with protective tape

or replace it.

n When installing other parts, do not press or

squeeze the wires.

Do not pull

too tightð

No Contact

Do not press

or squeeze the

wire

Downloaded from www.Manualslib.com manuals search engine

1. GENERAL INFORMATION

1-6

PEOPLE 250

n After routing, check that the wire harnesses

are not twisted or kinked.

n Wire harnesses routed along with handlebar

should not be pulled tight, have excessive

slack or interfere with adjacent or

surrounding parts in all steering positions.

n When a testing device is used, make sure to

understand the operating methods

thoroughly and operate according to the

operating instructions.

n Be careful not to drop any parts.

n When rust is found on a terminal, remove

the rust with sand paper or equivalent

before connecting.

n Symbols:

The following symbols represent the

servicing methods and cautions included in

this service manual.

: Apply engine oil to the

specified points. (Use

designated engine oil for

lubrication.)

: Apply grease for lubrication.

: Transmission Gear Oil (90#)

: Use special tool.

: Caution

: Warning

Special

Engine Oil

Grease

Gear Oil

*

Do you

understand the

instrument?

Remove

Rust∴

Downloaded from www.Manualslib.com manuals search engine

1. GENERAL INFORMATION

1-7

PEOPLE 250

TORQUE VALUES

STANDARD TORQUE VALUES

Item Torque (N-m) Item Torque (N-m)

5mm bolt, nut

6mm bolt, nut

8mm bolt, nut

10mm bolt, nut

12mm bolt, nut

4.5_ 6

8 _ 12

18_ 25

30_ 40

50_ 60

5mm screw

6mm screw, SH bolt

6mm flange bolt, nut

8mm flange bolt, nut

10mm flange bolt, nut

3.5_ 5

7 _ 11

10_ 14

24_ 30

35_ 45

Torque specifications listed below are for important fasteners.

ENGINE

Item Q‘ty Thread dia.(mm) Torque (N-m) Remarks

Cylinder head bolt A

Cylinder head bolt B

Oil filter screen cap

Cylinder head cap nut

Valve adjusting lock nut

Cam chain tensioner slipper bolt

Oil bolt

Clutch outer nut

Clutch drive plate nut

Flywheel nut

Oil pump bolt

Cylinder head cover bolt

Spark plug

Cam chain tensioner bolt

Water pump impeller

Drive face nut

Transmission case cover bolt

Gear oil check bolt

2

2

1

4

2

1

1

1

1

1

2

4

1

1

1

1

9

1

8

8

30

8

5

6

12

12

12

14

5

6

10

6

8

12

8

8

8.9

8.9

12.7

24.5

8.8

8.8

14.7

53.9

53.9

58.8

3.9

11.8

17.2

11.8

11.8

93

20

10

Double end bolt

Double end bolt

Apply oil to

threads

Downloaded from www.Manualslib.com manuals search engine

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

Viewed 87 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

This manual is a comprehensive guide used by professional technicians and DIY enthusiasts for maintaining, servicing, diagnosing, and repairing vehicles. It includes step-by-step instructions, diagrams, illustrations, wiring schematics, and specifications for easy vehicle repair. All pages are printable, allowing for convenient access to the necessary information at the vehicle or workshop.

- General Information

- Exhaust Muffler/Frame Covers

- Inspection/Adjustment

- Lubrication System

- Engine Removal/Installation

- Cylinder Head/Cylinder/Piston

- Kick Starter/Drive

- Pulley/Clutch/Driven Pulley

- Final Reduction

- A.C. Generator

- Crankcase/Crankshaft

- Cooling System

- Carburetor/Fuel Pump

- Steering Handlebar/Front Wheel/Front Brake/Front Shock Absorber/Front Fork

- Rear Brake/Rear Fork/Rear Wheel/Rear Shock Absorber

- Fuel Tank

- Battery/Charging System

- Ignition System

- Starting System

- Switches/Horn/Fuel Unit

- Thermo-Static Switch/Temperature Gauge/Instruments/Lights

- High-Speed Tire (Tubeless Tire)

- And more...

Format: PDF

Language: English

Compatible: Win/Mac