2007-2012 Hyosung Ms3 125 250 Scooter Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

ELECTRICAL SYSTEM

COOLING SYSTEM

GROUP INDEX

GENERAL INFORMATION

1

PERIODIC MAINTENANCE

2

ENGINE

3

FI SYSTEM DIAGNOSIS

4

FUEL SYSTEM AND THROTTLE BODY

5

6

7

CHASSIS

8

SERVICING INFORMATION

9

� COPYRIGHT S&T Motors Co., Ltd.

FOREWORD

This manual contains an introductory description on

HYOSUNG and procedures

for its inspection/service and overhaul of its main

components.

Other information considered as generally known is

not included.

Read GENERAL INFORMATION section to familiar-

ize yourself with outline of the vehicle and MAINTE-

NANCE and other sections to use as a guide for

proper inspection and service.

This manual will help you know the vehicle better so

that you can assure your customers of your optimum

and quick service.

WARNING

This manual is intended for those who have

enough knowledge and skills for servicing

HYOSUNG vehicles. Without such knowledge and

skills, you should not attempt servicing by relying

on this manual only.

Instead, please contact your nearby authorized

HYOSUNG motorcycle dealer.

� This manual has been prepared on the basis of

the latest specification at the time of publica-

tion.

If modification has been made since then,

difference may exist between the content of

this manual and the actual vehicle.

� Illustrations in this manual are used to show

the basic principles of operation and work pro-

cedures.

They may not represent the actual vehicle

exactly in detail.

COPYRIGHTED

HOW TO USE THIS MANUAL

TO LOCATE WHAT YOU ARE LOOKING FOR :

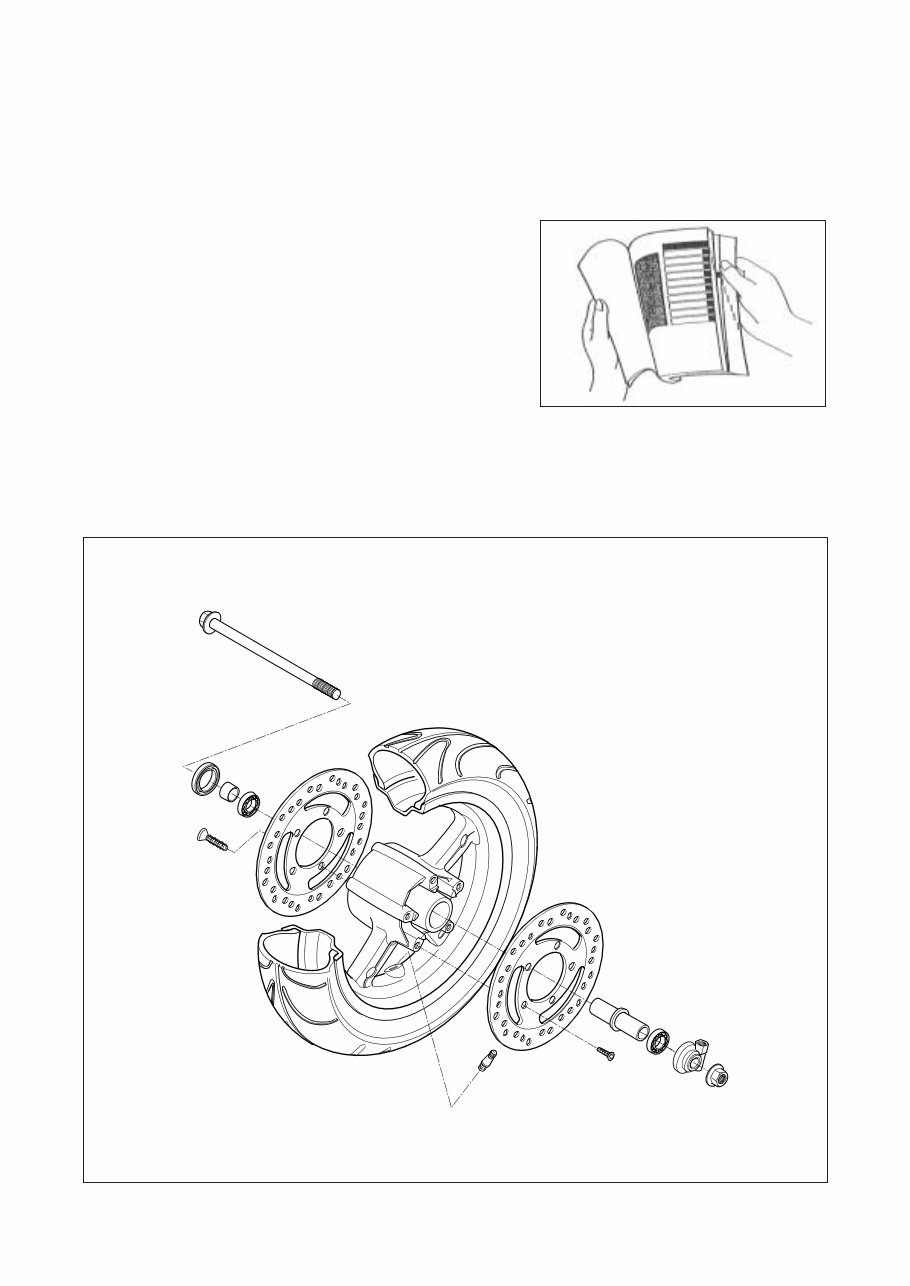

1. The text of this manual is divided into sections.

2. As the title of these sections is listed on the previous page as

GROUP INDEX, select the section where you are looking for.

3. Holding the manual as shown at the right will allow you to find

the first page of the section easily.

4. On the first page of each section, its contents are listed. Find

the item and page you need.

COMPONENT PARTS

Example : Front wheel

COPYRIGHTED

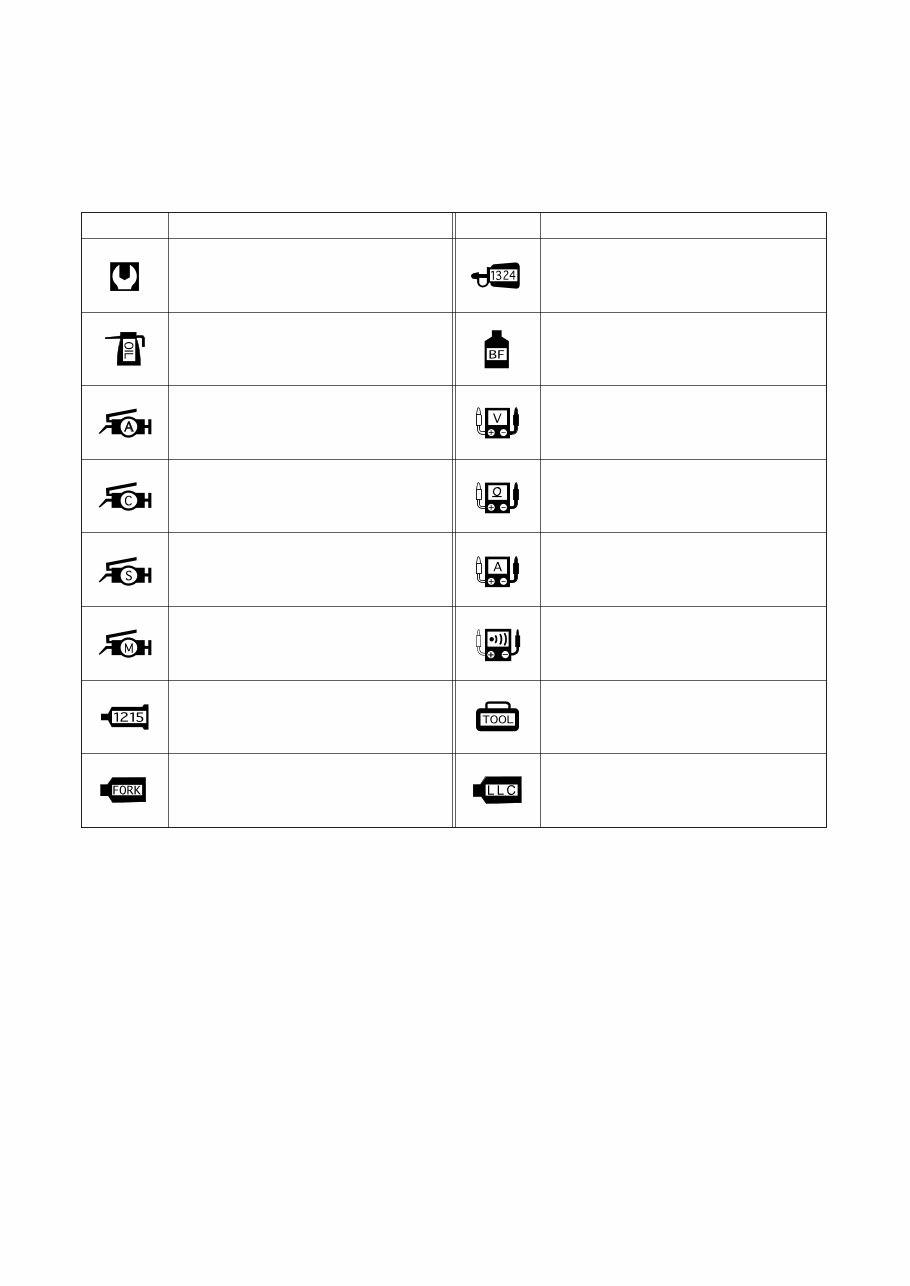

SYMBOL

Listed in the table below are the symbols indicating instructions and other information necessary for servicing and

meaning associated with them respectively.

Apply THREAD LOCK “1324” .

Apply or use brake fluid.

Measure in voltage range.

Measure in resistance range.

Measure in current range.

Use special tool.

Use engine coolant.

Torque control required.

Data beside it indicates specified torque.

Apply oil.

Use engine oil unless otherwise specified.

Apply SUPER GREASE “A” .

Apply SILICONE GREASE.

Apply MOLY PASTE.

Apply BOND “1215” .

Use fork oil.

DEFINITION SYMBOL DEFINITION SYMBOL

Apply SUPER GREASE “C” .

Measure in continuity test range.

COPYRIGHTED

A

ABDC : After Bottom Dead Center

AC : Alternating Current

API : American Petroleum Institute

ATDC : After Top Dead Center

B

BBDC : Before Bottom Dead Center

BDC : Bettom Dead Center

BTDC : Before Top Dead Center

D

DC : Direct Current

DOHC : Double Over Head Camshaft

E

ECU : Engine Control Unit,

FI Control Unit

F

FI : Fuel Injection, Fuel Injector

FP : Fuel Pump

I

IAP Sensor : Intake Air Pressure Sensor

(IAPS)

IAT Sensor : Intake Air Temperature Sensor

(IATS)

IG : Ignition

ISC Solenoid : Idle Speed Control Solenoid

L

LCD : Liquid Crystal Display

LED : Light Emitting Diode

LH : Left Hand

M

Max : Maximum

Min : Minimum

O

O2 Sensor : Oxygen Sensor (O2S)

R

RH : Right Hand

S

SAE : Society of Automotive Engineers

SAV Solenoid : Secondary Air Valve Solenoid

T

TDC : Top Dead Center

TO Sensor : Tip Over Sensor (TOS)

TP Sensor : Throttle Position Sensor (TPS)

W

WT Sensor : Water Temperature Sensor

(WTS)

ABBREVIATIONS USED IN THIS MANUAL

COPYRIGHTED

BL : Black with Blue tracer BBr : Black with Brown tracer

BG : Black with Green tracer BO : Black with Orange tracer

BR : Black with Red tracer BW : Black with White tracer

BY : Black with Yellow tracer LB : Blue with Black tracer

LG : Blue with Green tracer LR : Blue with Red tracer

LW : Blue with White tracer LY : Blue with Yellow tracer

BrB : Brown with Black tracer BrW : Brown with White tracer

GB : Green with Black tracer GR : Green with Red tracer

GY : Green with Yellow tracer GrB : Gray with Black tracer

GrR : Gray with Red tracer GrW : Gray with White tracer

OB : Orange with Black tracer OL : Orange with Blue tracer

OG : Orange with Green tracer OR : Orange with Red tracer

OW : Orange with White tracer OY : Orange with Yellow tracer

RB : Red with Black tracer RW : Red with White tracer

WB : White with Black tracer WL : White with Blue tracer

WR : White with Red tracer YB : Yellow with Black tracer

YL : Yellow with Blue tracer YG : Yellow with Green tracer

YR : Yellow with Red tracer

B : Black Gr : Gray Sb : Light blue

L : Blue Lg : Light green W : White

Br : Brown O : Orange Y : Yellow

G : Green R : Red

WIRE COLOR

COPYRIGHTED

NOTE

Difference between photographs and actual motorcycles depends on the markets.

COPYRIGHTED

GENERAL INFORMATION

INFORMATION LABELS ………………………………………………… 1- 1

GENERAL PRECAUTIONS …………………………………………… 1- 2

SERIAL NUMBER LOCATION ………………………………………… 1- 3

FUEL, OIL AND ENGINE COOLANT RECOMMENDATIONS …… 1- 4

BREAK-IN PROCEDURES……………………………………………… 1- 6

EXTERIOR ILLUSTRATION …………………………………………… 1- 7

SPECIFICATIONS ………………………………………………………… 1- 8

CONTENTS

1

COPYRIGHTED

1-1 GENERAL INFORMATION

Please note, however, that the warning and cautions contained in this manual cannot possibly cover all potential

hazards relating to the servicing, or lack of servicing, of the motorcycle. In addition to the WARNING and CAUTION

stated, you must use good judgement and basic mechanical safety principles. If you are unsure about how to per-

form a particular service operation, ask a more experienced mechanic for advice.

WARNING / CAUTION / NOTE

Please read this manual and follow its instructions carefully.

To emphasize special information, the symbol and the words WARNING, CAUTION and NOTE have special mean-

ings. Pay special attention to the messages highlighted by these signal words.

CAUTION

Indicates a potential hazard that could result in vehicle damage.

WARNING

Indicates a potential hazard that could result in death or injury.

NOTE

Indicates special information to make maintenance easier or instructions cleaner.

COPYRIGHTED

GENERAL INFORMATION 1-2

GENERAL PRECAUTIONS

WARNING

� Proper service and repair procedures are important for the safety of the service machanic and the safety

and reliability of the vehicle.

� When 2 or more persons work together, pay attention to the safety of each other.

� When it is necessary to run the engine indoors, make sure that exhaust gas is forced outdoors.

� When working with toxic or flammable materials, make sure that the area you work in is well-ventilated and

that you follow all off the material manufacturer’s instructions.

� Never use gasoline as a cleaning solvent.

� To avoid getting burned, do not touch the engine, engine oil, exhaust system or radiator during or for a

while after engine operation.

� After servicing fuel, oil, engine coolant, exhaust or brake systems, check all lines and fittings related to the

system for leaks.

WARNING

� If parts replacement is necessary, replace the parts with HYOSUNG Genuine Parts or their equivalent.

� When removing parts that are to be reused, keep them arranged in an orderly manner so that they may be

reinstalled in the proper order and orientation.

� Be sure to use special tools when instructed.

� Make sure that all parts used in reassembly are clean, and also lubricated when specified.

� When use of a certain type of lubricant, bond, or sealant is specified, be sure to use the specified type.

� When removing the battery, disconnect the � battery lead wire first and then the � battery lead wire.

When reconnecting the battery, connect the � battery lead wire first and then the � battery lead wire.

Finally, cover the � battery terminal with the terminal cover.

� When performing service to electrical parts, if the service procedures do not require use of battery power,

diconnect the � battery lead wire at the battery.

� Tighten cylinder head and case bolts and nuts, beginning with larger diameter and ending with smaller

diameter, from inside to outside diagonally, to the specified tightening torque.

� Whenever you remove oil seals, gaskets, packing, O-rings, locking washers, cotter pins, circlips, and cer-

tain other parts as specified, be sure to replace them with new ones. Also, before installing these new

parts, be sure to remove any material left over from the mating surfaces.

� Never reuse a circlip. When installing a new circlip, take care not to expand the end gap larger than

required to slip the circlip over the shaft. After installing a circlip, always ensure that it is completely seated

in its groove and securely fitted.

� Do not use self-locking nuts a few times over.

� Use a torque wrench to tighten fasteners to the torque values when specified. Wipe off grease or oil if a

thread is smeared with them.

� After reassembly, check parts for tightness and operation.

WARNING

� To protect environment, do not unlawfully dispose of used motor oil and other fluids: batteries, and tires.

� To protect Earth’s natural resouces, properly dispose of used vehicles and parts.

COPYRIGHTED

1-3 GENERAL INFORMATION

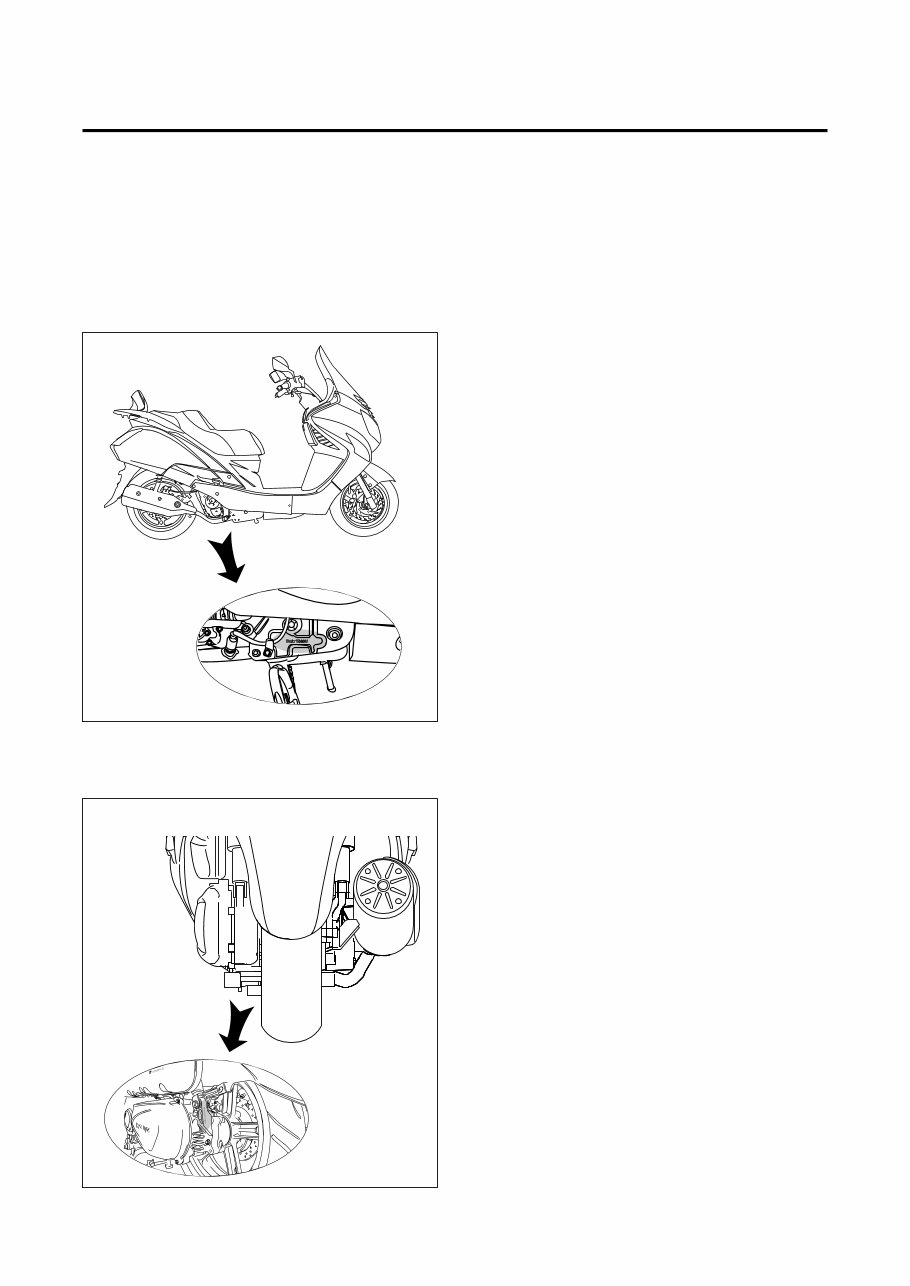

SERIAL NUMBER LOCATION

The frame serial number or V.I.N. (Vehicle Identification Number) is stamped on the right downside frame.

The engine serial number is stamped on the left rearside of the crankcase assembly.

These numbers are required especially for registering the machine and ordering spare parts.

◉ FRAME SERIAL NUMBER

◉ ENGINE SERIAL NUMBER

COPYRIGHTED

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 17 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get instant access to the Complete Factory Service Repair Workshop Manual without any extra fees or expiry dates. This Professional Manual is suitable for both professional Mechanics and DIY enthusiasts, covering all repairs, servicing, and troubleshooting procedures with step-by-step instructions, detailed photos, diagrams, and highly detailed exploded diagrams & pictures.

Print out a single page or the entire manual as per your choice. The Manual can be used on multiple computers without any limitations or trial periods and can be used for life without the need to renew or pay any extra. It is fully compatible with all Windows & MAC Computers.

Click the button to get your hands on this comprehensive manual.