2007-2009 Honda VT750C2 Shadow Spirit Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

HOW TO USE THIS MANUAL

This service manual describes the service procedures for the

VT750C2IC2F.

Follow the Maintenance Schedule (Section 4) recommendations to

ensure that the vehicle is in peak operating condition and the emission

levels are with the standards set by the U.S. Environmental Protection

Agency, California Air Resources Board (CARB) and Transport

Canada.

Performing the first scheduled maintenance is very important. It

compensates for the initial wear that occurs during the break-in

period.

CONTENTS

•

GENERAL INFORMATION •.

i==========

~T=E=C=H=N=I=CA=L=FE=,;.=:r=U=R=E=========.

===FR=A=M=EIB==O=DY=PA=N=E=L=S=/E=X=H=A=U=S=T=S=Y=S=T=EM===_

r----i==M=A=IN=T=E=N=A=N=C=E===========_

Sections 1 and 4 apply to the whole motorcycle. Section 3 illustrates

procedures for removal/installation of components that may be

required to perform service described In the following sections.

Section 5 through 21 describe parts of the motorcycle, grouped

according to location.

Find the section you want on this page, then turn to the table of

contents on the first page of the section.

Most sections start with an assembly or system illustration, service

information and trOUbleshooting for the section. The subsequent

pages give detailed procedure.

If you don't know the source of the trouble, go to section 23

Troubleshooting.

Your safely, and the safely of others, is very important. To help

you make informed decisions we have provided safely

messages and other information throughout this manual. Of

course, it is not practical or possible to warn you about all the

hazards associated with servicing this vehicle.

You must use your own good judgement.

You will find important safely information in a variely of forms

including:

• Safely Labels - on the vehicle

• Safely Messages - preceded by a safely alert symbol & and

one of three signal words, DANGER, WARNING, or CAU-

TION.

These signal words mean:

~ You WILL be KILLED or SERIOUSLY

~ HURT if you don't follow instructions.

~ You CAN be KILLED or SERIOUSLY

~ HURT if you don't follow instructions.

~ You CAN be HURT if you don't follow

~ instructions.

• Instructions - how to service this veh Icle correctly and safely.

As you read this manual, you will find information that is preceded by a

[NOm:EJ symbol. The purpose of this message is to help prevent

damage to your vehicle, other property. or the environment.

LUBRICATION SYSTEM

ALTERNATOR/STARTER CLUTCH

CRANKSHAFTrrRANSMISSION

COOLING SYSTEM

CYLINDERJPISTON'

ENGINE REMOVAL/INSTALLATION

CYLINDER HEADNALVE

REAR WHEELlBAAKElSUSPENSION

IGNITION SYSTEM

WIRING DIAGRAMS

BATTERY/CHARGING SYSTEM

FRONT WHEEL/SUSPENSIONISTEERING

CLUTCH/GEARSHIFT LINKAGE

FUEL SYSTEM

FINAL DRIVE

HYDRAULIC BRAKE

ELECTRIC STARTER

LIGHTSIMETERSISWITCHES

z

:it

0:

...

W

>

~

C

C

z

<t

w

z

a

z

w

....I

<t

o

~

t;

.~

W

TROUBLESHOOTING

INDEX

-

Date of Issue: September. 2006

.. .. -

---_.---_.

SYMBOLS

"The symbols used throughout this manual show specific service procedures. If supplementary information is required pertaining to

these symbols, it would be explained specifically in the text without the use of the symbols.

.. ~

IIiiiil'

Replace the part (s) with new one (s) before assembly.

Use recommended engine oil, unless otherwise specified.

Use molybdenum oil solution (mixture of the engine oil and molybdenum grease in a ratio of 1 : 1) .

""""1

-,

.. ..wM

Use multi-purpose grease (Lithium based multi-purpose grease NLGI #2 or equivalent).

Use molybdenum disulfide grease (containing more than 3% molybdenum disulfide, NLGI #2 or

equivalent).

Example: Molykote® BR-2 plus manufactured by Dow Corning U.S.A.

Multi-purpose M-2 manufactured by Mitsubishi Oil, Japan

Use molybdenum disulfide paste (containing more than 40% molybdenum disulfide, NLGI #2 or

equivalent).

Example: Molykote® G-n Paste manufactured by Dow Corning U.S.A.

Honda Moly 60 (US.A. only)

Rocol ASP manufactured by Rocol Limited, UK.

Rocol Paste manufactured by Sumico Lubricant, Japan

Use silicone grease.

Apply a locking agent. Use a middle strength locking agent unless otherwise specified.

,..

~

~

ew

JI~

Apply sealant.

Use DOT 4 brake fluid. Use the recommended brake fluid unless otherwise specified.

Use Fork or Suspension Fluid.

I

..

1. GENERAL INFORMATION

B·

SERVICE RULES .. ·······································1-2

MODEL IDENTIFICATION· .. ·· .. ·.. ····· .. ·········· 1-2

GENERAL SPECIFICATIONS .... ··· .... ···· .. ····· 1-5

LUBRICATION SYSTEM

SPECIFICATIONS······ .... ··· .. ········ ...... ·.... ······ 1-7

FUEL SYSTEM SPECIFICATIONS·· .. ·········· 1-7

COOLING SYSTEM SPECIFICATIONS ······1-7

CYLINDER HEAD/VALVE

SPECIFICATIONS· .. ·· .. ·····:· .... ·················... ·· 1-8

CYLINDER/PISTON SPECIFICATIONS ······1-8

CLUTCH/GEARSHIFT LINKAGE

SPECIFICATIONS 1-9

ALTERNATOR/STARTER CLUTCH

SPECIFICATIONS·· 1-9

CRANKSHAFT/TRANSMISSION

SPECiFiCATIONS···· 1-10

FINAL DRIVE SPECIFICATIONS· .... ·········· 1-10

FRONT WHEEL/SUSPENSION/STEERING

SPECIFICATIONS ·.. ··············· .. ·········· .. ·····1-11

REAR WHEEUBRAKE/SUSPENSION

SPECIFICATIONS 1-11

HYDRAULIC BRAKE SPECIFICATIONS··· 1-11

BATTERY/CHARGING SYSTEM

SPECIFICATIONS .. ······· .. ········· .. · .... ··· ...... ·1-12

IGNITION SYSTEM SPECIFICATIONS ····1-12

ELECTRIC STARTER

SPECIFICATIONS 1-12

LIGHTS/METERS/SWITCHES

SPECIFICATIONS 1-12

STANDARD TORQUE VALUES· .. ····· .. ····· 1-13

ENGINE & FRAME TORQUE VALUES·· .. 1·13

LUBRICATION & SEAL POINTS ··········· .. ·1-19

CABLE & HARNESS ROUTING ···············1·22

EMISSION CONTROL SYSTEMS 1·39

1-1

------ . - --------- --------

GENERAL INFORMATION

SERVICE RULES

1. Use genuine Honda or Honda-recommended parts and lubricants or their equivalents. Parts that don't meet Honda's

design specifications may cause damage to the motorcycle.

2. Use the special tools designed for this product to avoid damage and incorrect assembly.

3. Use only metric tools when servicing the motorcycle. Metric bolts, nuts and screws are not interchangeable with

English fasteners.

4. Install new gaskets, a-rings, cotter pins, and lock plates when reassembling.

5. When tightening bolts or nuts, begin with the larger diameter or inner bolt first. Then tighten to the specified torque

diagonally in incremental steps unless a particular sequence is specified.

6. Clean parts in cleaning solvent upon disassembly. Lubricate any sliding surfaces before reassembly.

7. After reassembly, check all parts for proper installation and operation.

8. Route all electrical wires as shown in the Cable and Harness Routing (page 1-22).

ABBREVIAl"ION

Throughout this manual, the following abbreviations are used to identify the respective parts or systems.

Abbrev. tenn Full tenn

SE valve Starting Enrichment valve

TP sensor Throttle Position sensor

EOP switch Engine Oil Pressure switch

VS sensor Vehicle Speed sensor

ICM Ignition Control Module

CAV control valve Carburetor Air Vent control valve

PAIR Pulsed Secondary Air Injection

EVAP Evaporative Emission

ECT sensor Engine Coolant Temperature sensor

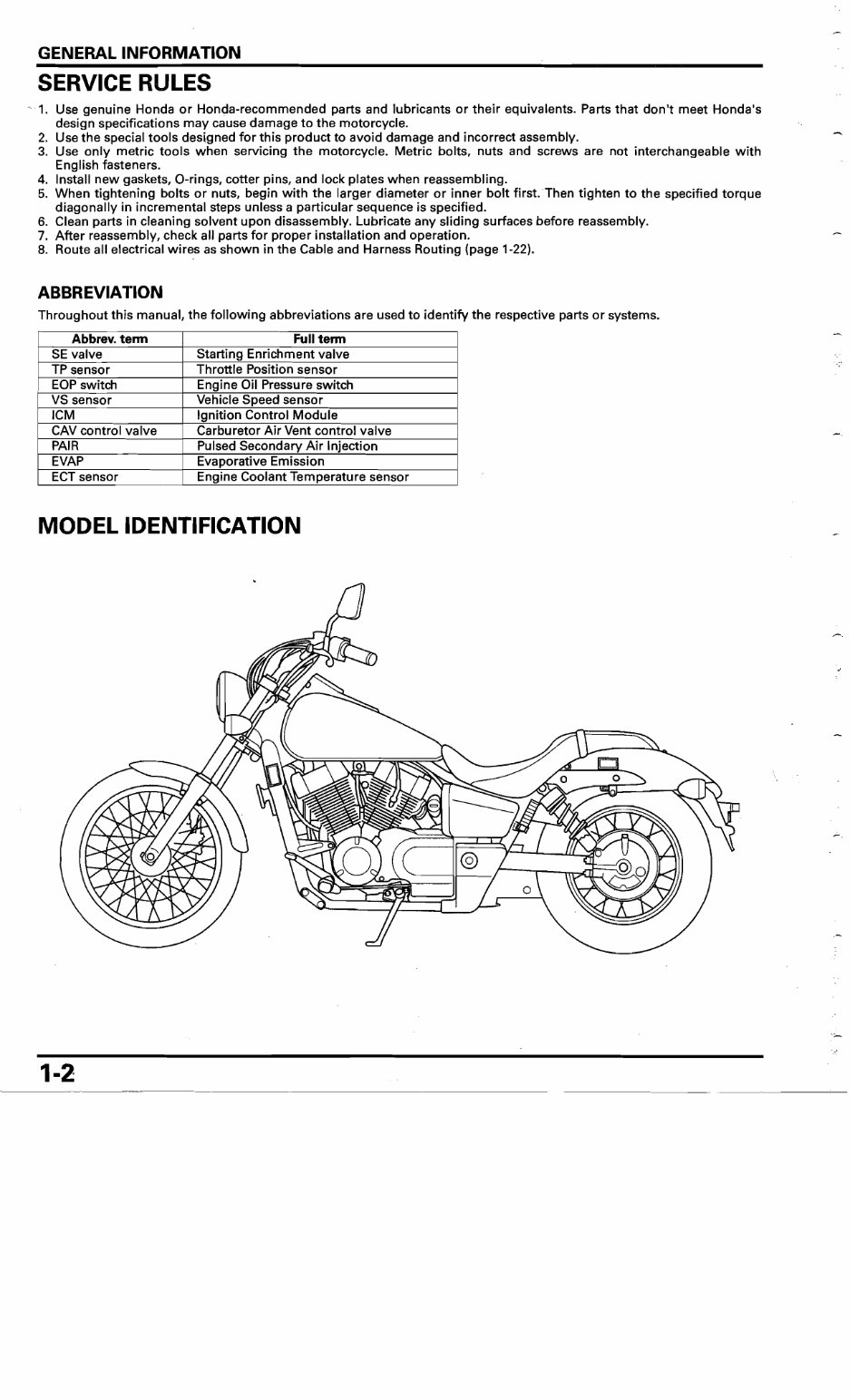

MODEL IDENTIFICATION

1-2

GENERAL INFORMATION

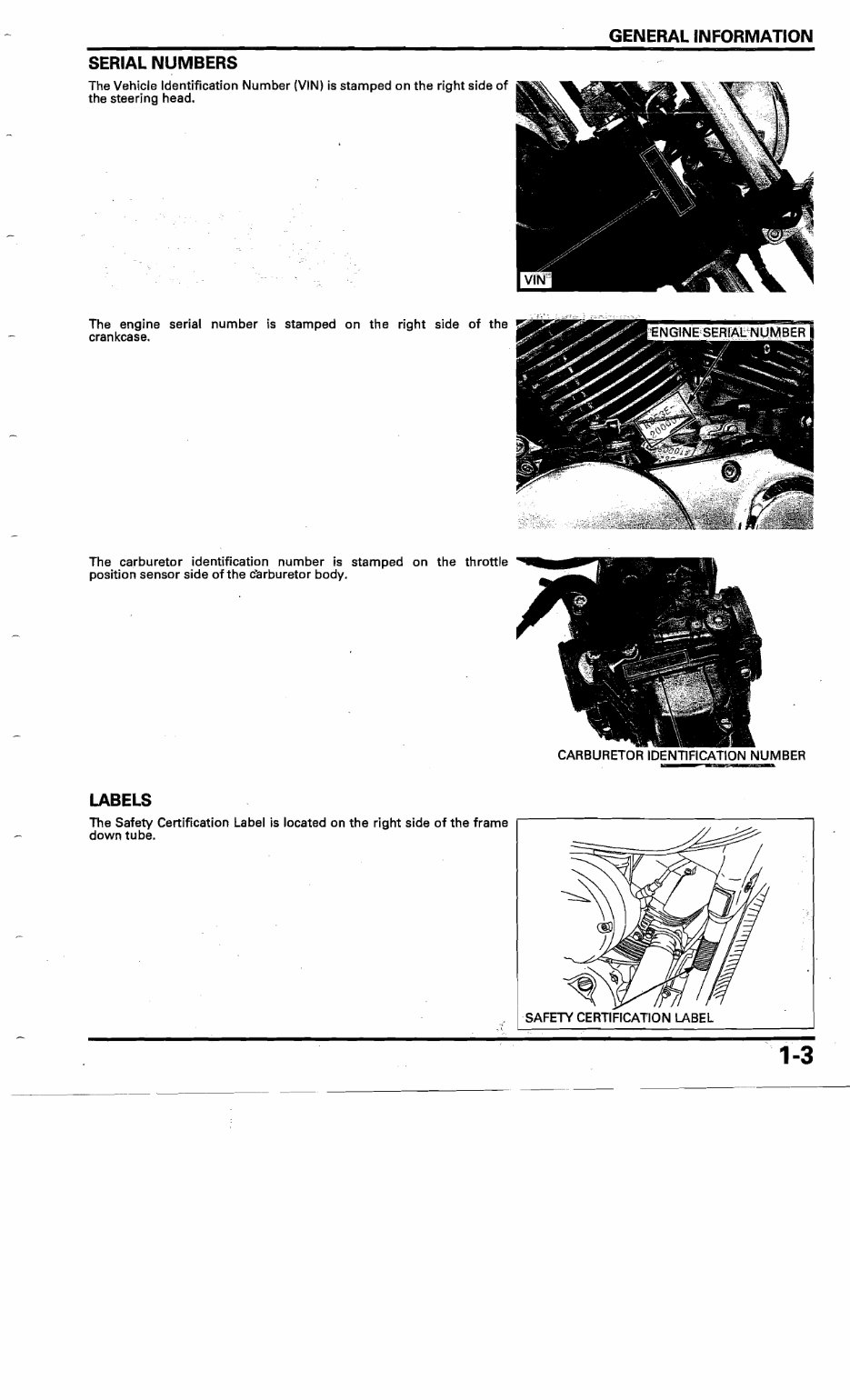

SERIAL NUMBERS

The Vehicle Identification Number (VIN) is stamped on the right side of

the steering head.

The engine serial number is stamped on the right side of the

crankcase.

The carburetor identification number is stamped on the throttle

position sensor side ofthe c'arburetor body.

......... ~

CARBURETOR IDENTIFICATION NUMBER

~ .

LABELS

The Safety Certification Label is located on the right side of the frame

down tube.

1-3

GENERAL INFORMATION

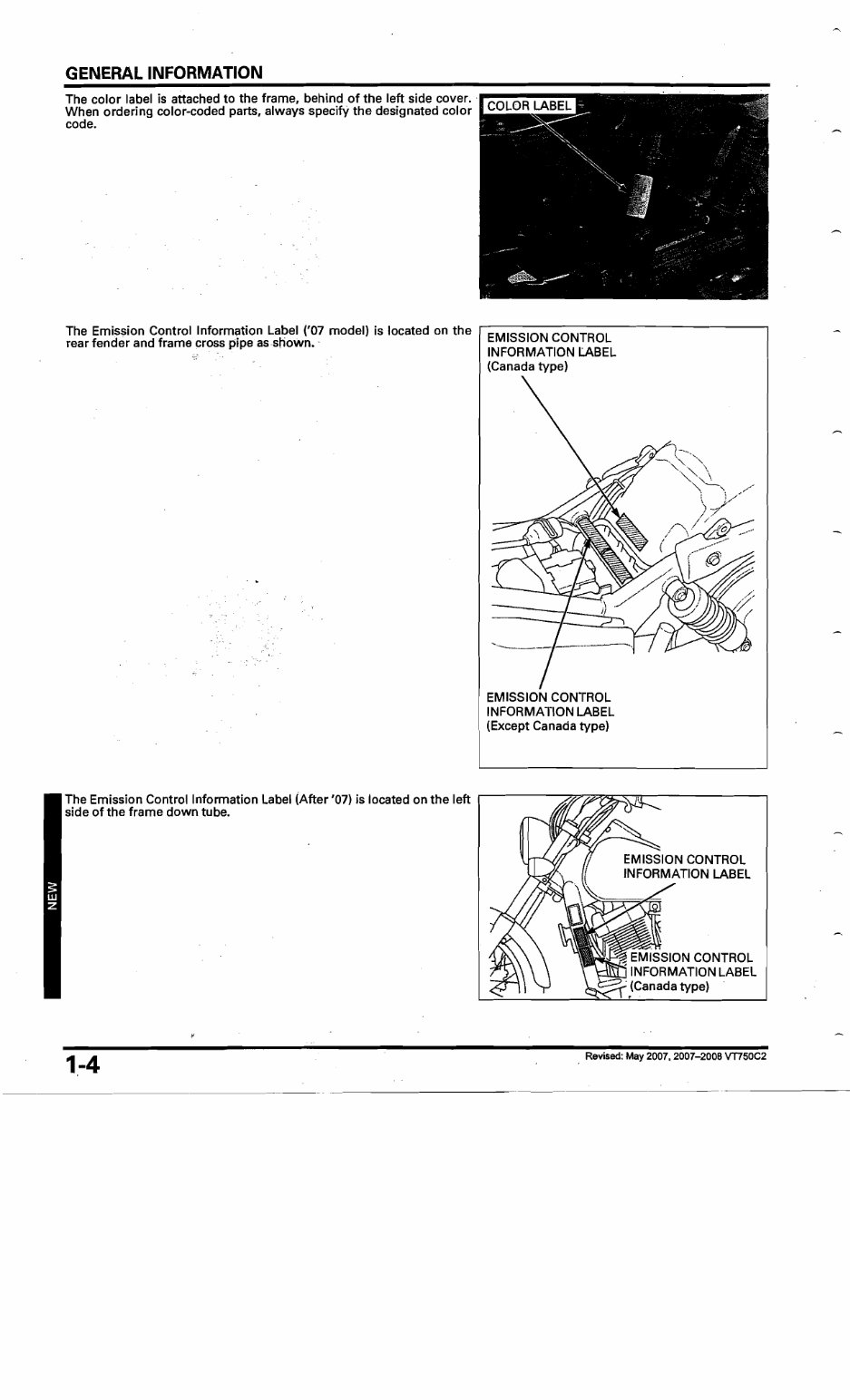

The color label is attached to the frame, behind of the left side cover ..

When ordering color-coded parts, always specifY the designated color

code.

The Emission Control Information Label ('07 model) is located on the r-EM-IS-S-I-O-N-C-O-N-T-R-O-L---------..

rear fender and frame cross pipe as shown•.

INFORMATION LABEL

(Canada type)

EMISSION CONTROL

INFORMATION LABEL

(Except Canada type)

The Emission Control Information Label (After '07) is located on the left 1------:&~7)~;::N:=-------__"l

side of the frame down tube.

z

, EMISSION CONTROL

"INFORMATION LABEL

~ . (Canada type)

,

. Revised: May 2007. 2007-2006 Vf750C2

1.-4

GENERAL INFORMATION

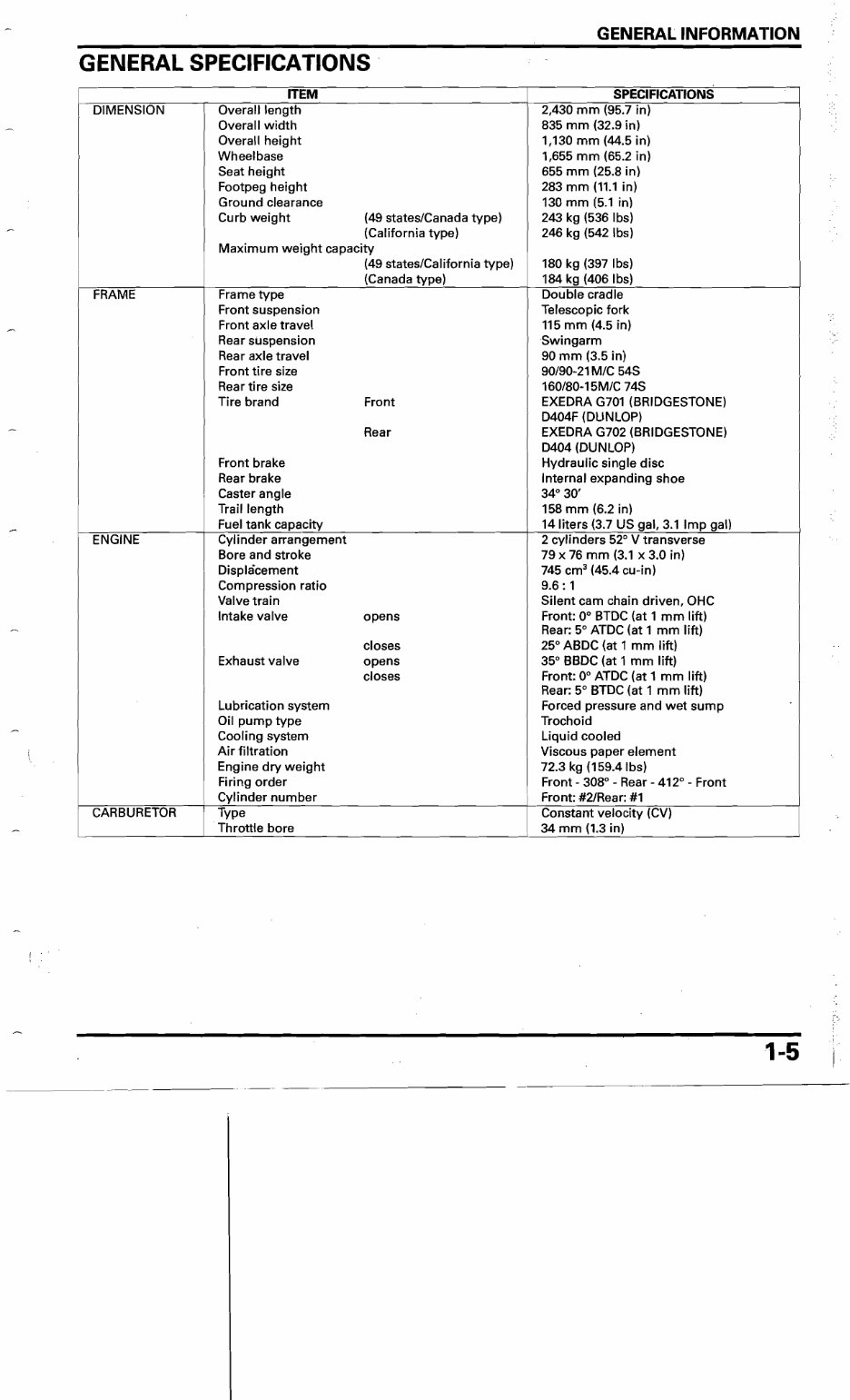

GENERAL SPECIFICATIONS

ITEM SPECIFICATIONS

DIMENSION Overall length

Overall width

Overall height

Wheelbase

Seat height

Footpeg height

Ground clearance

Curb weight (49 states/Canada type)

(California type)

Maximum weight capacity

(49 states/California type)

(Canada type)

2,430 mm (95.7 in)

835 mm (32.9 in)

1,130 mm (44.5 in)

1,655 mm (65.2 in)

655 mm (25.8 in)

283 mm (11.1 in)

130 mm (5.1 in)

243 kg (536 Ibs)

246 kg (542 Ibs)

180 kg (397 Ibs)

184 kg (406 Ibs)

FRAME Frame type

Front suspension

Front axle travel

Rear suspension

Rear axle travel

Front tire size

Rear tire size

Tire brand Front

Rear

Front brake

Rear brake

Caster angle

Trail length

Fuel tank capacity

Double cradle

Telescopic fork

115 mm (4.5 in)

Swingarm

90 mm (3.5 in)

90/90-21 M/C 54S

160/80-15M/C 74S

EXEDRA G701 (BRIDGESTONE)

D404F (DUNLOP)

EXEDRA G702 (BRIDGESTONE)

D404 (DUNLOP)

Hydraulic single disc

Internal expanding shoe

34° 30'

158 mm (6.2 in)

14 liters (3.7 US gal, 3.1 Imp gal)

ENGINE Cylinder arrangement

Bore and stroke

Displacement

Compression ratio

Valve train

Intake valve opens

closes

Exhaust valve opens

closes

Lubrication system

Oil pump type

Cooling system

Air filtration

Engine dry weight

Firing order

Cylinder number

2 cylinders 52° V transverse

79 x 76 mm (3.1 x 3.0 in)

745 cm

3

(45.4 cu-in)

9.6: 1

Silent cam chain driven, OHC

Front: 0° BTDC (at 1 mm lift)

Rear: 5° ATDC (at 1 mm lift)

25° ABDC (at 1 mm lift)

35° BBDC (at 1 mm lift)

Front: 0° ATDC (at 1 mm lift)

Rear: 5° BTDC (at 1 mm lift)

Forced pressure and wet sump

Trochoid

Liquid cooled

Viscous paper element

72.3 kg (159.4Ibs)

Front - 308° - Rear - 412° - Front

Front: #2/Rear: #1

CARBURETOR Type

Throttle bore

Constant velocity (CV)

34 mm (1.3 in)

'-5

-----~ --- ---- -----------

I

GENERAL INFORMATION

ITEM SPECIFICATIONS

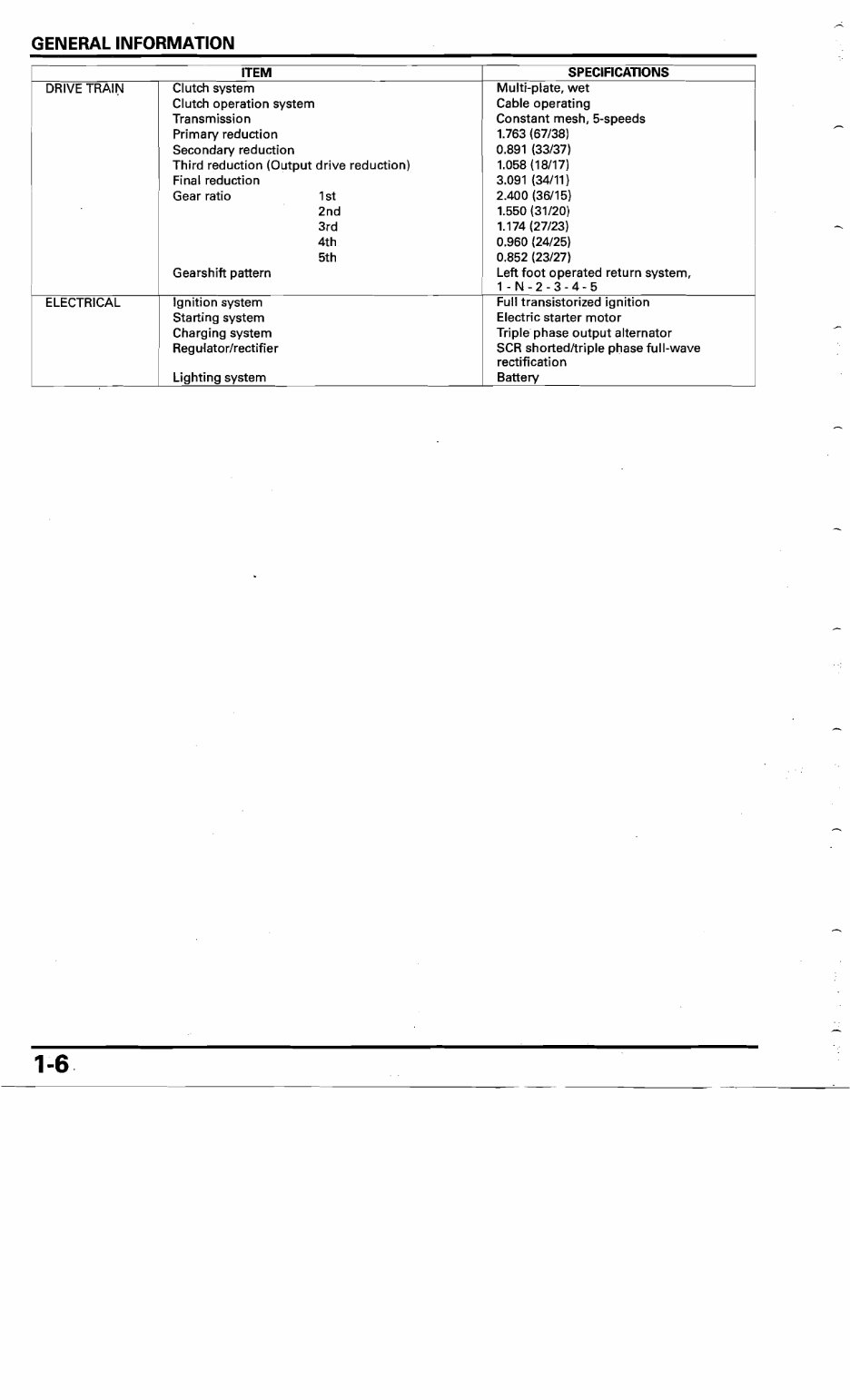

DRIVE TRAII;II Clutch system

Clutch operation system

Transmission

Primary reduction

Secondary reduction

Third reduction (Output drive reduction)

Final reduction

Gear ratio 1st

2nd

3rd

4th

5th

Gearshift pattern

Multi-plate, wet

Cable operating

Constant mesh, 5-speeds

1.763 (67/38)

0.891 (33/37)

1.058 (18117)

3.091 (34111)

2.400 (36/15)

1.550 (31/20)

1.174 (27/23)

0.960 (24/25)

0.852 (23/27)

Left foot operated return system,

1-N-2-3-4-5

ELECTRICAL Ignition system

Starting system

Charging system

Regu'lator/rectifier

Lighting system

Full transistorized ignition

Electric starter motor

Triple phase output alternator

SCR shortedltriple phase full-wave

rectification

Battery

1-6.

GENERAL INFORMATION

LUBRICATION SYSTEM SPECIFICATIONS

Unit· mm (in)

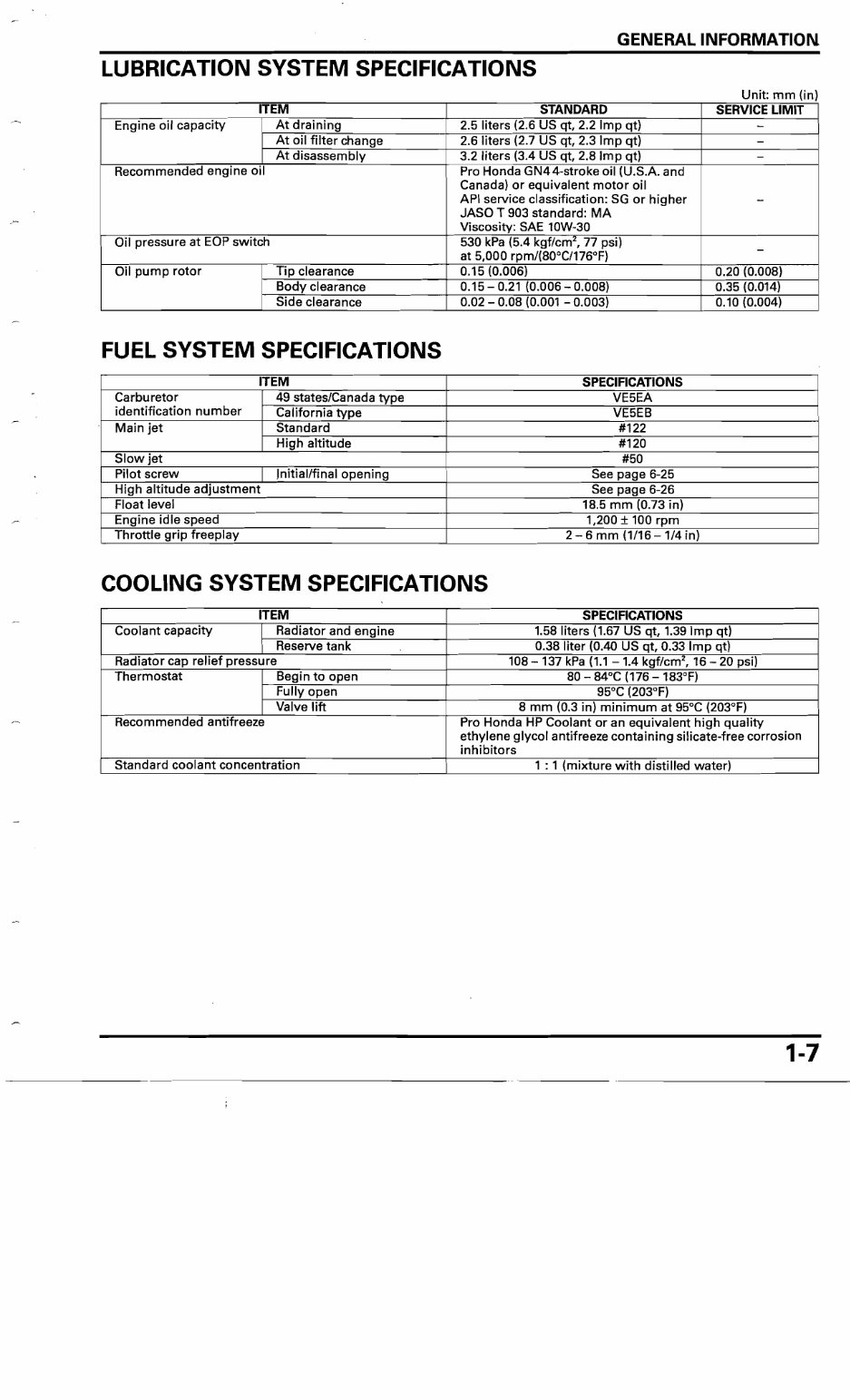

ITEM STANDARD SERVICE LIMIT

Engine oil capacity At draining 2.5 liters (2.6 US qt, 2.2 Imp qt) -

At oil filter change 2.6 liters (2.7 US qt, 2.3 Imp qt) -

At disassembly 3.2 liters (3.4 US qt, 2.8 Imp qt) -

Recommended engine oil Pro Honda GN44-stroke oil (U.S.A. and

Canada) or equivalent motor oil

API service classification: SG or higher -

JASO T 903 standard: MA

Viscosity: SAE 10W-30

Oil pressure at EOP switch 530 kPa (5.4 kgf/cm

2

, 77 psi)

-

at 5,000 rpm/(80°C/176°F)

Oil pump rotor Tip clearance 0.15 (0.006) 0.20 (0.008)

Body clearance 0.15 - 0.21 (0.006 - 0.008) 0.35 (0.014)

Side clearance 0.02 - 0.08 (0.001 - 0.003) 0.10 (0.004)

FUEL SYSTEM SPECIFICATIONS

ITEM SPECIFICATIONS

Carburetor

identification number

49 states/Canada type VE5EA

California type VE5ES

Main jet Standard #122

High altitude #120

Slow jet #50

Pilot screw Initial/final opening See page 6-25

High altitude adjustment See page 6-26

Float level 18.5 mm (0.73 in)

Engine idle speed 1,200 ± 100 rpm

Throttle grip freeplay 2 - 6 mm (1/16 -1/4 in)

COOLING SYSTEM SPECIFICATIONS

ITEM SPECIFICATIONS

Coolant capacity Radiator and engine 1.58 liters (1.67 US qt, 1.39 Imp qt)

Reserve tank 0.38 liter (0.40 US qt, 0.33 Imp qt)

Radiator cap relief pressure 108 - 137 kPa (1.1 -1.4 kgf/cm

2

, 16 - 20 psi)

Thermostat Begin to open 80 - 84°C (176 -183°F)

Fully open 95°C (203°F)

Valve lift 8 mm (0.3 in) minimum at 95°C (203°F)

Recommended antifreeze Pro Honda HP Coolant or an equivalent high quality

ethylene glycol antifreeze containing silicate-free corrosion

inhibitors

Standard coolant concentration 1 : 1 (mixture with distilled water)

1-7

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 25 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

- This complete factory service repair workshop manual is available for instant access on your computer, tablet, or smartphone.

- It covers all repairs, servicing, and troubleshooting procedures with detailed photos and diagrams.

- Professional mechanics and technicians use this manual, which contains step-by-step instructions and highly detailed exploded diagrams and pictures.

- You have the option to print out a single page or the entire manual.

- This manual can be used on multiple computers without any limitations or trial periods.

- There is no expiry date, renewal fee, or need to pay extra for continued use.

- It is fully compatible with Windows and MAC computers.

For more information, please click on the button.