HONDA NSR150SP NSR 150 SP* Factory Service / Repair/ Workshop Manual !

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

NSR150SP General Information

CONTENTS

NSR150SP General Information

______________________________________________

1-1

HOW TO USE THIS MANUAL

Follow the Maintenance Schedule (Section 3) recommendations to ensure that the

motorcycle is in peak operating condition.

Performing the first schedule maintenance is very important. It compensates for the

initial wear that occurs during the break-in period.

Sections 1 through 3 apply to the whole unit, while sections 4 through 19 describe parts

of the unit, grouped according to location.

Find the section you want on this page, then turn to the table of contents on page 1 of

that section.

Most sections start with an assembly or system illustration, service information and

troubleshooting for the section. The subsequent pages give detailed procedures.

If you don’t know the source of the trouble, go to section 20, TROUBLESHOOTING.

All information contained in this manual is based on the latest product information available at the time of printing.

Honda Australia Motorcycle & Power Equipment Pty. Ltd., and Honda Motor Co. Ltd, Japan, reserve the rights to make

changes at any time without notice.

Apart from criticism or reviews permitted under the Copyright Act 1968, no part of this publication may be reproduced,

stored in a retrieval system, or transmitted, in any form by any means, electronic, mechanical, photocopying or

recording or otherwise, without the prior written permission of Honda Motorcycle & Power Equipment Pty. Ltd., and/or

Honda Motor Co Ltd. Japan.

This includes test, figures and tables.

HONDA MOTOR CO., LTD

Service Publications Office

IMPORTANT SAFETY NOTICE

Indicate a strong possibility of severe personal injury or death if instructions are not followed.

CAUTION Indicate a possibility of personal injury or equipment damage if instructions are not followed.

NOTE: Gives helpful information

Detailed descriptions of standard workshop procedures, safety principles and service operations are not included. It

is important to note that this manual contains some warnings and cautions against some specific service methods

which could cause PERSONAL INJURY to service personnel or could damage a vehicle or render it unsafe.

Please understand that those warnings could not cover all conceivable ways in which service, whether or not

recommended by Honda, might be done or of the possibly hazardous consequences of each conceivable way, nor

could Honda investigate all such ways. Anyone using service procedures or tools, whether or not recommended by

HONDA, must satisfy himself thoroughly that neither personal safety nor vehicle safety will be jeopardised by the

service methods or tools selected.

NSR150SP General Information

______________________________________________

1-2

SYMBOL

The symbols used throughout this manual show specific service procedures. If

supplementary information is required pertaining to these symbols, it would be

explained specifically in the text without the use to the symbols.

Replace the part (s) with new one (s) before assembly.

Use recommended engine oil, unless otherwise specified.

Use molybdenum oil solution

(mixture of the engine oil and molybdenum grease in a ratio of 1:1)

Use multi-purpose grease (lithium based multi-purpose grease NLGI#2 or

equivalent).

Use molybdenum disulfide grease (containing more than 3% molybdenum disulfide,

NLGI#2 or equivalent).

Example: Molykote ® BR-2 plus manufactured by Dow Corning, U.S.A.

Multi-purpose M-2 manufactured by Mitsubishi Oil Japan.

Use molybdenum disulfide paste (containing more than 40% molybdenum disulfide,

NLGI#2 or equivalent).

Example: Molykote ® G-n Paste manufactured by Dow Corning, U.S.A.

Honda Moly 60 (U.S.A. only)

Rocol ASP manufactured by Rocol Limited, U.K.

Rocol Paste manufactured by Sumico Lubricant, Japan

Use Silicone grease.

Apply a locking agent. Use a middle strength-locking agent unless otherwise

specified.

Apply sealant.

Use brake fluid, DOT 4. Use the recommended brake fluid, unless otherwise

specified.

Use Fork or Suspension Fluid.

NSR150SP General Information

______________________________________________

1-3

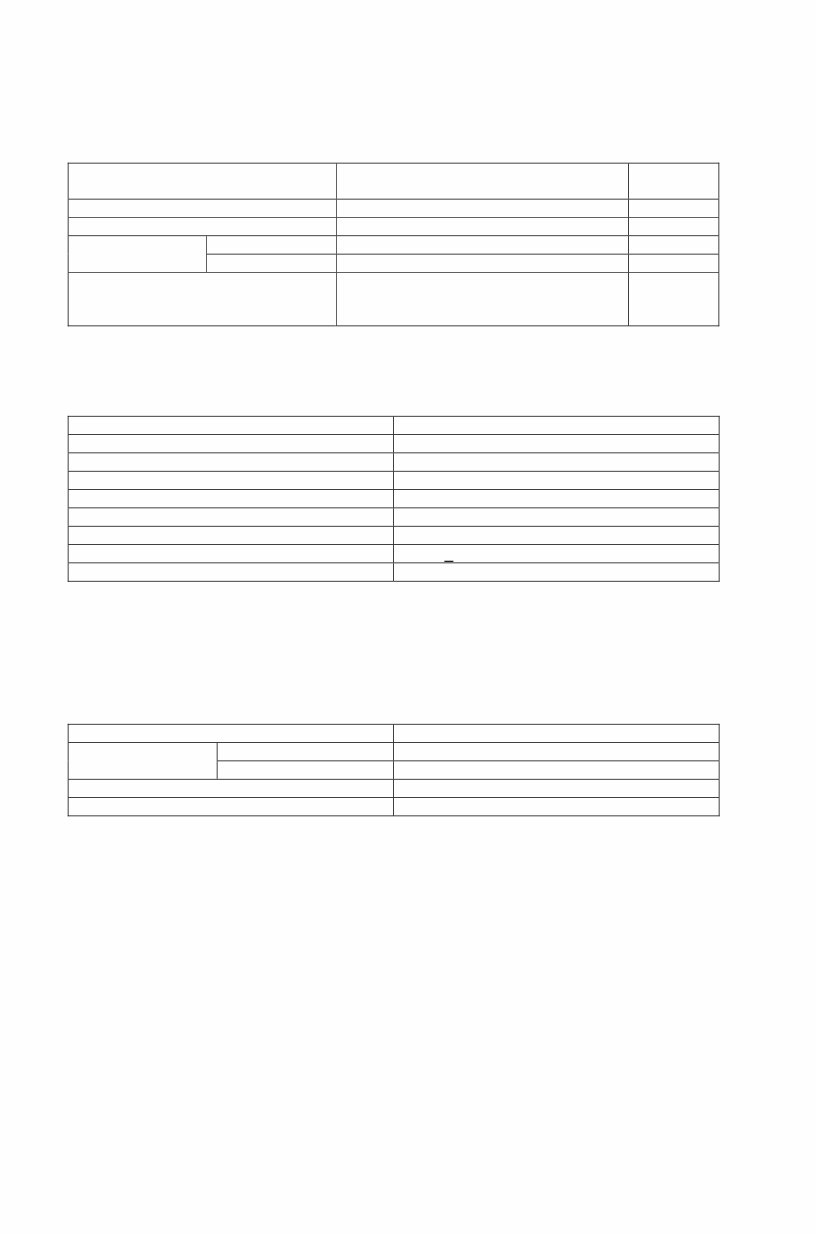

General Safety 1-3 Torque Values 1-14

Service Rules 1-5 Tools 1-17

Model Identification 1-6 Lubrication & Seal Points 1-18

Specification 1-7 Cable & Harness Routing 1-21

GENERAL SAFETY

Carbon Monoxide

If the engine must be running to do some work, make sure the area is well ventilated.

Never run the engine in an enclosed area.

Run the engine in an open area or with an exhaust evacuation system in an enclosed

area.

Gasoline

Work in a well ventilated area. Keep cigarettes, flames or sparks from work area or

where gasoline is stored.

Hot Components

Used Engine / Transmission Oil

Brake Dust

Never use an air hose or dry brush to clean brake assemblies.

Brake Fluid

CAUTION:

• Spilling fluid on painted, plastic or rubber parts will damage them. Place a clean shop towel over these

parts whenever the system is serviced. KEEP OUT OF REACH OF CHILDREN.

The exhaust contains poisonous carbon monoxide gas that can cause loss of consciousness and may lead to death.

Gasoline is extremely flammable and is explosive under certain conditions. KEEP OUT OF REACH OF CHILDREN.

Engine and exhaust system parts become very hot and remain hot for some time after the engine is run. Wear insulated

gloves or wait until the engine and exhaust system have cooled before handling these parts.

Inhaled asbestos fibers have been found to cause respiratory disease and cancer.

Used engine oil may cause skin cancer if repeatedly left in contact with the skin for prolonged periods. Although this is

unlikely unless you handle used oil on a daily basis, it is still advisable to thoroughly wash your hands with soap and

water as soon as possible after handling used oil. KEEP OUT OF REACH OF CHILDREN.

NSR150SP General Information

______________________________________________

1-4

Coolant

Under some conditions, the ethylene glycol in engine coolant is combustible and its

flame is not visible. If the engine ethylene glycol does ignite, you will not see any flame,

but you can be burned.

If it contacts your skin, wash the affected areas immediately with soap and water. If it contacts

your eyes, flush them thoroughly with fresh water and get immediate medical attention. If it is

swallowed, the victim must be forced to vomit then rinse mouth and throat with fresh water

before obtaining medical attention. Because of these dangers, away from the reach of children.

Recycle used coolant in an ecologically correct manner.

NITROGEN PRESSURE

For shock absorber with a gas-filled reservoir.

To prevent the possibility of an explosion, release the nitrogen by pressing the valve core. Then

remove the valve stem from the shock absorber reservoir.

Before disposal of the shock absorber, release the nitrogen by pressing the valve core. Then

remove the valve stem from the shock absorber.

BATTERY HYDROGEN GAS & ELECTROLYTE

• Avoid spilling engine coolant on the exhaust system or engine parts. They may be hot enough to cause the

coolant to ignite and burn without a visible flame.

• Coolant (ethylene glycol) can cause some skin irritation and is poisonous if swallowed, KEEP OUT OF

REACH OF CHILDREN.

• Keep out of reach of pets. Some pets are attracted to the smell and taste of coolant and can die if they

drink it.

• Do not remove the radiator cap when the engine is hot. The coolant is under pressure and could scald you.

• Use only nitrogen to pressurize the shock absorb. The use of an unstable gas can cause a fire or explosion

resulting in serious injury.

• The shock absorber contains nitrogen under high pressure. Allowing fire or heat near the shock absorber

could lead to and explosion that could result in serious injury.

• Failure to release the pressure from a shock absorber before disposing of it may lead to a possible explosion

and serious injury if it is heated or pierced.

- The battery gives off explosive gases; keep sparks, flames and cigarettes away. Provide adequate ventilation

when charging.

- The battery contains sulfuric acid (electrolyte). Contact with skin or eyes may cause severe burns. Wear

protective clothing and face Shield.

- If electrolyte gets on your skin, flush with water. - If electrolyte gets in your eyes, flush with water for at least 15

minutes and call a physician If swallowed, drink large quantities of water or milk of magnesia or vegetable oil

and call a physician. KEEP OUT OF REACH OF CHILDREN.

NSR150SP General Information

______________________________________________

1-5

SERVICE RULES

1. Use genuine HONDA or HONDA-recommended parts and lubrications or their

equivalents. Parts that do not meet HONDA's design specifications may damage

the motorcycle.

2. Use the special tools designed for this product.

3. Use only metric tools when servicing this motorcycle. Metric bolts, nets and screws

are not interchangeable with English fasteners. The use of incorrect tools and

fasteners may damage the motorcycle.

4. Install new gaskets, 0-rings, cotter pins, lock plates, etc. When reassembling.

4. When tightening a series of bolts or nuts, begin with the larger-diameter of inner

bolts first, and tighten to specified torque diagonally, in incremental steps unless a

particular sequence is specified.

6. Clean parts in cleaning solvent upon disassembly. Lubricate any sliding surfaces

before re-assembly.

7. After assembly, check all parts for proper installation and operation.

8. Route all electrical wires as shown on pages 1-22 through 1-27, Cable and

Harness Routing.

NSR150SP General Information

______________________________________________

1-6

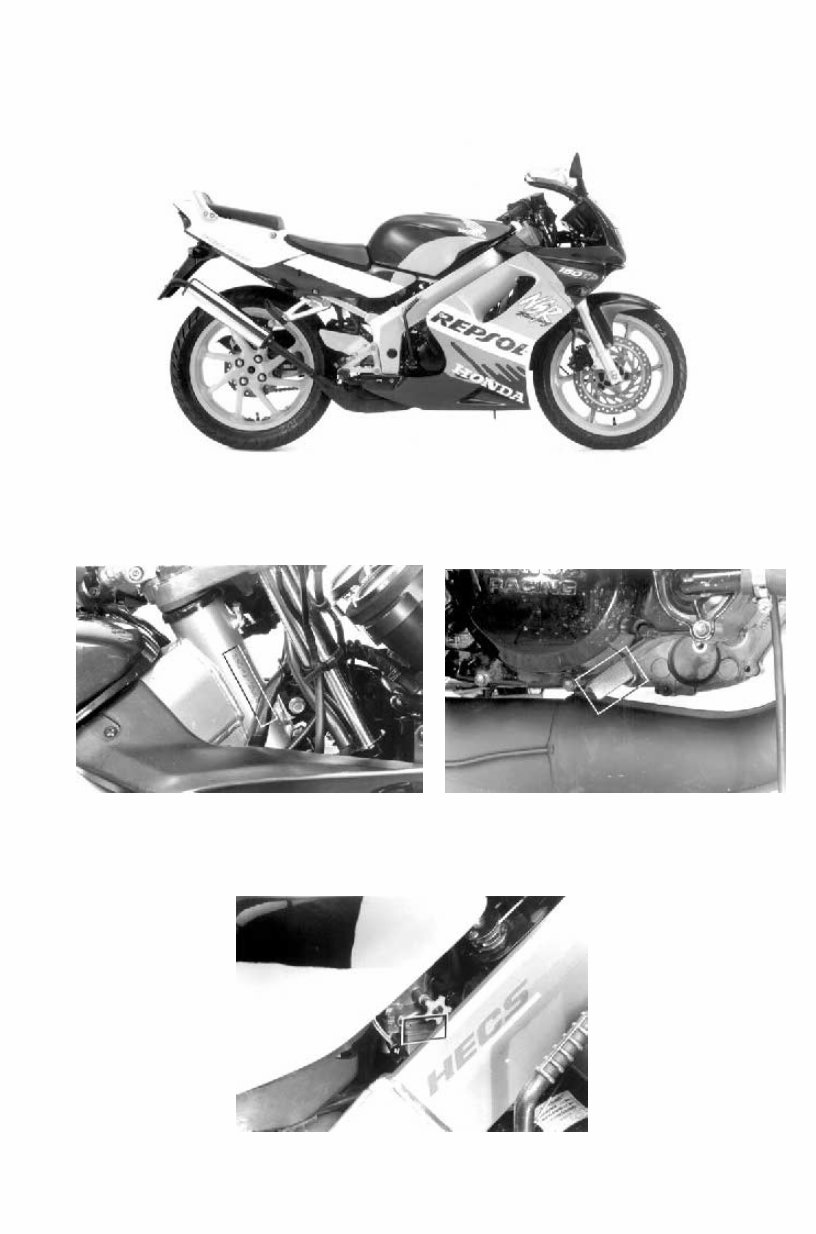

Model Identification

(1) FRAME SERIAL NUMBER (2) ENGINE SERIAL NUMBER

The frame serial number is stamped The engine serial number is

On the right side of the steering head. Stamped on the right crankcase.

(3) CARBURETTOR IDENTIFICATION NUMBER

The carburettor identification number is stamped

carburettor body.

NSR150SP General Information

______________________________________________

1-7

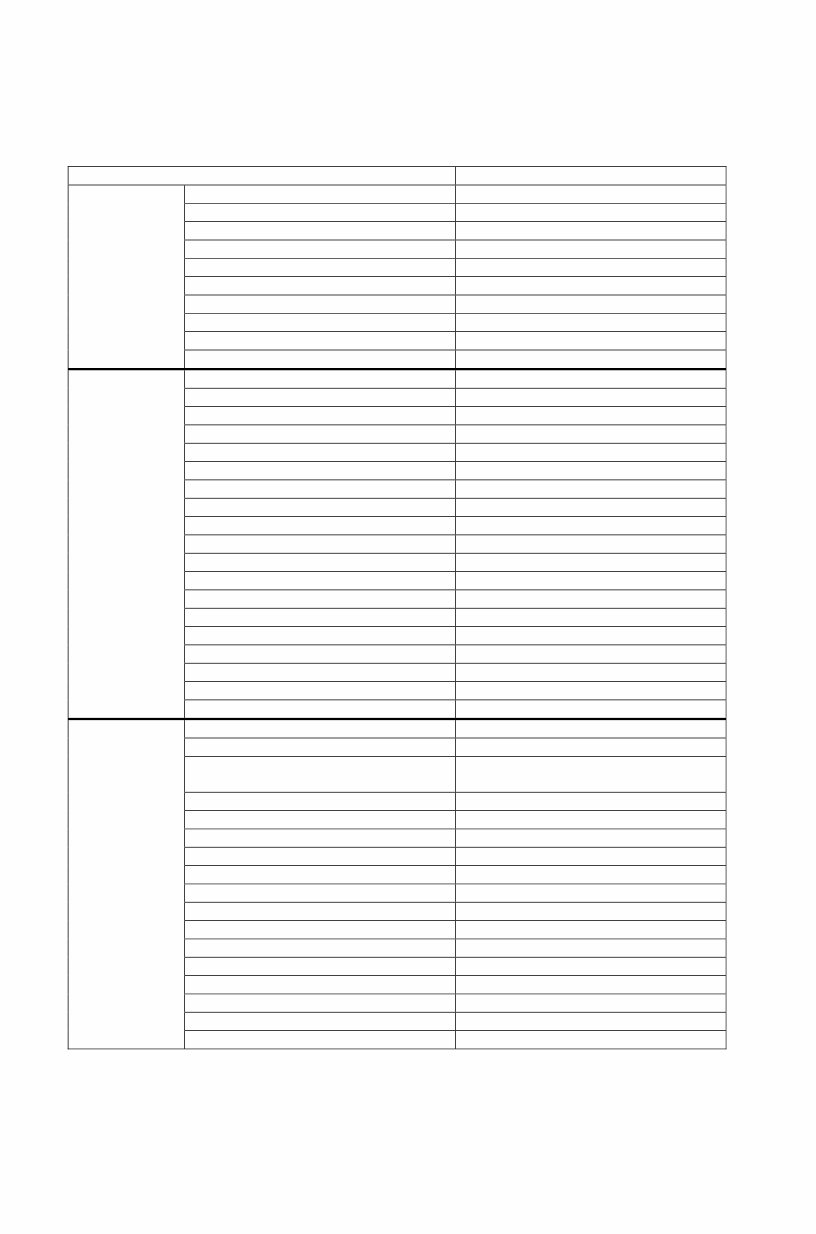

SPECIFICATIONS

General

ITEM SPECIFICATIONS

Overall length 1,972mm (77.6 in)

Overall width 683 mm (26.9 in )

Overall height 1,062mm (41.8 in )

Wheel base 1,337 mm (52.6 in )

Seat height 780 mm (30.7 in )

Foot peg height 325 mm (12.8 in)

Ground clearance 142 mm (5.6 in)

Dry Weight 122.4kg (269.8 lb )

Curb Weight 131.4kg (289.7 lb )

DIMENSION

Maximum Weight capacity 118kg (260.1 lb )

Frame Type Diamond

Front Suspension Telescopic fork

Fork Inner tube diameter 35 mm (1.4 in)

Fork fluid capacity (per leg) 322 cm

3

(10.9 US oz, 11.3 Imp oz)

Front wheel travel 117 mm (4.6 in)

Steering head bearing Ball Bearing

Rear suspension Swingarm

Rear wheel travel 125 mm (4.9 in)

Rear damper Both side operation tube type

Damper / reservoir gas pressure 908 kPa (10kgf/cm

2

, 142psi)

Pressurized gas material Nitrogen

Front tyre size 90/80-17 46S

Rear tyre size 120/80-17 61S

Front brake Hydraulic single disc

Rear brake Hydraulic single disc

Caster angle 25

O

36’

Trail 91 mm (3.6 in)

Fuel Tank capacity 10.5 litre (2.8 US gal, 2.3 Imp gal)

FRAME

Fuel Tank reserve capacity 2.7 litre (0.7 US gal, 0.6 Imp gal)

Bore and Stroke 59 mm x 54.5 mm (2.3 in x 2.1 in)

Displacement 149 cm

3

(9.1 cu-in)

Compression ratio 108 kPa (11.0kgf cm

2

,156 psi) at

400min-

1

(rpm)

Port timing intake open Reed valve controlled

Port timing intake close Reed valve controlled

Port timing exhaust open - Hi 97.6

O

BBDC

- Low 73.9

O

BBDC

Port timing exhaust close - Hi 97.7

O

ABDC

Low 74.0

O

ABDC

Port timing scavenge open 62.6

O

BBDC

Port timing scavenge close 62.8

O

ABDC

Lubrication system Oil automatically mixed with gasoline

Oil pump type Plunger type

Cooling system Liquid cooled

Air filtration Urethane form

Crankshaft type Assembly type

ENGINE

Engine weight 23.9kg (52.7lb)

NSR150SP General Information

______________________________________________

1-8

General (cont..)

ITEM SPECIFICATIONS

Carburettor type Piston Valve CARBURETTOR

Throttle bore 30 mm (1.2 in)

Clutch System Multi-plate, wet

Clutch operation system Cable operating

Transmission 6 speeds constant mesh

Primary reduction 2.954 (65/22)

Final reduction 2.857 (40/14)

Gear ratio 1

st

2.916 (35/12)

Gear ratio 2

nd

1.937 (31/16)

Gear ratio 3

rd

1.470 (25/17)

Gear ratio 4

th

1.210 (23/19)

Gear ratio 5

th

1.043 (24/23)

Gear ratio 6

th

0.916 (22/24)

DRIVE TRAIN

Gearshift pattern Left foot operated return system

(1N-2-3-4-5-6)

Ignition system DC-CDI

Charging system Triple phase output alternator

Alternator /capacity 188 W/5,000 min

1

(rpm)

Regulator/rectifier type Semi conductor type

ELECTRICAL

Lighting system Battery

NSR150SP General Information

______________________________________________

1-9

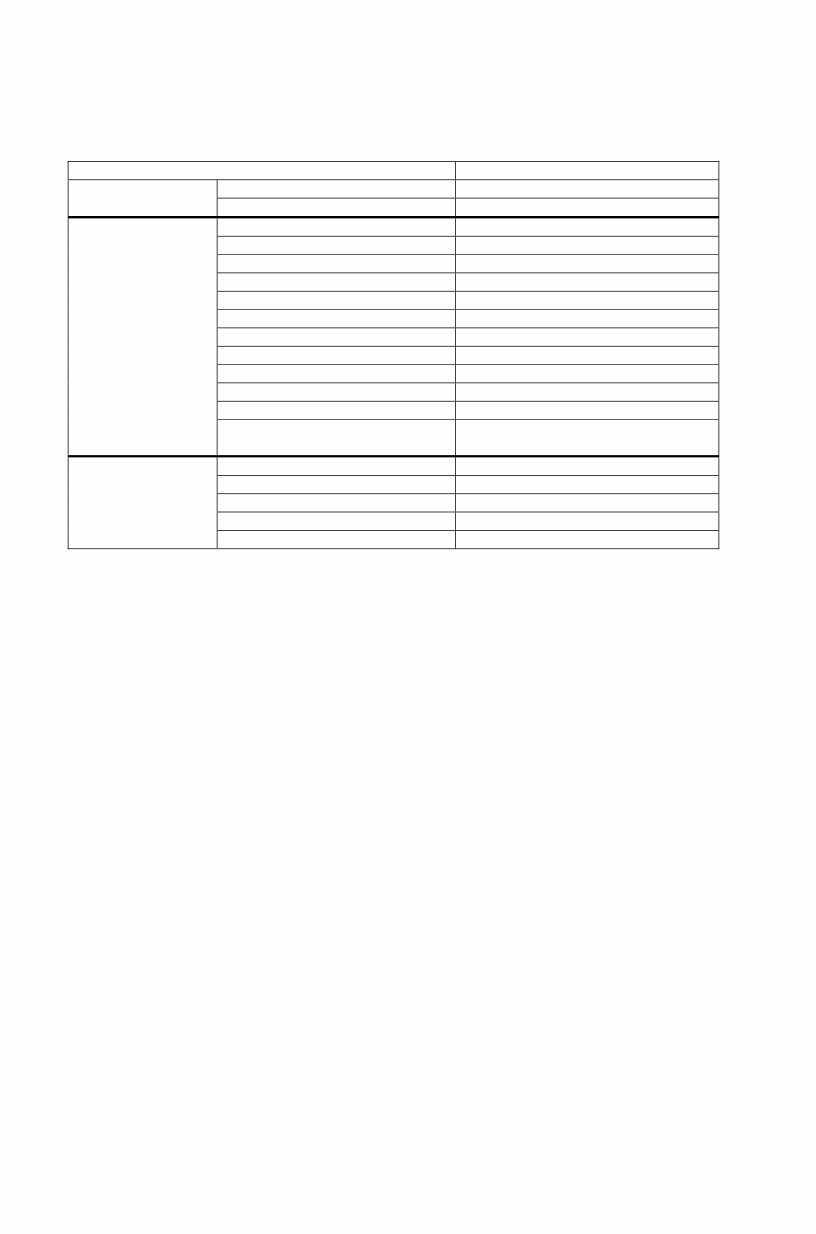

LUBRICATION SYSTEM

Unit: mm (in)

ITEM STANDARD SERVICE

LIMIT

Engine Oil Capacity 0.76 litre (0.83 US qt, 0.67 Imp, qt)

Recommended engine oil Honda 2-stroke oil or equivalent

At draining 0.7 litre (0.73 US qt, 0.62 Imp, qt) Transmission oil

capacity At disassembly 0.8 litre (0.85 US qt, 0.70 Imp, qt)

Recommended transmission oil Honda 4-stroke oil or equivalent API

Service Classification: SE,SF,or SG

Viscosity: SAE 10W – 40

FUEL SYSTEM

ITEM STANDARD

Carburettor identification number PE74A

Choke type Starting enrichment circuit system

Main jet #152

Slow jet #42

Air screw initial opening 2 turns out

Float level 19mm (0.7 in)

Idle speed 1,300 + 100 min

1

(rpm)

Throttle grip free play 2 – 6mm (0.08 – 0.24in)

COOLING SYSTEM

ITEM STANDARD

Radiator and engine 1.2 Litre (1.27US qt, 1.06 Imp qt) Cooling capacity

Radiator cap relief pressure 108 – 137 kPa (1.1 – 1.4kgf/cm

2

, 16-21 psi)

Standard coolant concentration 50% mixture with soft water

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

Viewed 14 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

This workshop manual provides maintenance and repair procedures for the HONDA NSR150SP, offering step-by-step instructions and detailed diagrams for DIY enthusiasts and professional mechanics. The manual covers a wide range of repair procedures, including:

- Maintenance & Servicing

- Engine & Clutch

- Transmissions

- Cooling Systems

- Fuel & Exhaust

- Ignition & Electrical

- Brakes & Brake Assembly

- Wheels & Tires

- Steering & Suspension

- Frame & Bodywork

- Wiring Diagrams

- Fault Finding Troubleshooting

This manual is available in PDF format for instant access without any shipping costs. It is compatible with all versions of Windows and Mac, and can be printed for convenience. The language of the manual is English, and it requires Adobe Reader and Win for access.