2002-2004 CRF450R Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

A Few Words About Safety

Service Infonnation

The servIce and repair information contained in this manual is intended for use by qualified, professional technicians.

Anempting service or repairs without the proper training, toots, and equipment could cause injury to you or others. II

could also damage the vehicle or create an unsafe condition.

This manual describes the proper methods and procedures for performing service, maintenance. and repairs. Some proce-

dUres require the use of specially designed tools and dedicated equipment. Anv person who intends to use a replacement

Wlrt, service procedure or a laol thai is not recommended by Honda. must determine the risks to their personal safety and

the safe operation of the ... ehicle.

If you need 10 replace a part , use genu i ne Honda parts with the correct part number or an equ ivalent part. We strongly

recommend that you do not use replacement parts of infenor quality .

For Your Customer 's Safety

Proper service and ma i ntenance are essential to the customer 's

safety and the reliabil ity of the vehicle . Any error or oversight while

servicing a vehicle can result in faulty operation. damage to the

veh icle, or injury to others.

For Your Safety

Because this manual is intended lor the professional service techni-

cian , we do not prov ide warnings about many basic shop safety

practices le.g. , hot parts-wear gloves). If you have nOI received

shop safety traini ng Of do not feel confident about your knowledge

01 sale servicing practice, we recommend that you do not attempt to

perform the procedures described in this manual.

Some of the most important general service safety precautions are

given below. Howeve r, we cannot ..... arn you of every conceivable

hazard that can arise in performing service and repair procedures.

Only you can decide whether or not you should perform a given

task.

Important Safety Precautions

AWARNING

Improper service or repai rs can create an

unsafe cond i tion that can cause your cus-

tomer or others to be seriously hurt or killed.

Follow the procedures and precaut ions in this

manual and other service matena !s carefully.

AWARNING

Failure to properly follow instruct i ons and

precautions can cause you to be seriously

hurt or killed.

Follow the procedures and precautions In this

manual carefully .

Make sure you have a clear understanding of aU basic shop safety practices and that you wear appropriate clothing and

use safety equipment. When performing any service task, be especially careful of the following:

• Read all of the instructions before you begin, and make sure you have the lools, the replacement or repair parts, and the

skills required to perform the tasks safely and completely.

• Protect your eyes by using proper safety glasses, goggles or face shields any time you hammer, drill, grind, pry or work

around pressurized air or liquids, and springs or other stored-energy components. If there is any doub l, put on eye

protection.

• Use other protective wear when necessary, for example gloves or safety shoes. Handling hot or sharp parts can cause

severe burns or cuts. Before you grab something that looks like it can hurt you, stop and put on gloves.

• Protect yourself and others whenever you have the vehicle up in the air. Any time you lift the vehicle, either with a hoist

or a jack, make sure it is always securely supported. Use jack stands.

Make sure the engine is turned off before you begin any servicing procedures, unless the instruction tells you to do

otherwise.

This will help eliminate several potential hazards:

• Carbon monoxide poisoning from engine exhaust. Be sure there is adequate ventilation whenever you run the engine.

• Burns from hot parts or coolant. Let the engine and elChausl system coo l before working in those areas.

• Injury from moving parts If the instruct ion tells you to run the engine , be sure your hands , fingers and cloth i ng are out

of the way.

Gasoline vapors and hydrogen gases from baneries are explosive. To reduce the pOSSibilI ty of a fire or explosion , be care·

lu i when working around gasoline or baneries.

• Use only a nonflammable solvent, not gasoline , to clean parts.

• Never drain or st ore gasoline in an open container.

• Keep all cigarenes, sparks and flames away Irom the battery and all fuel-related parts.

•

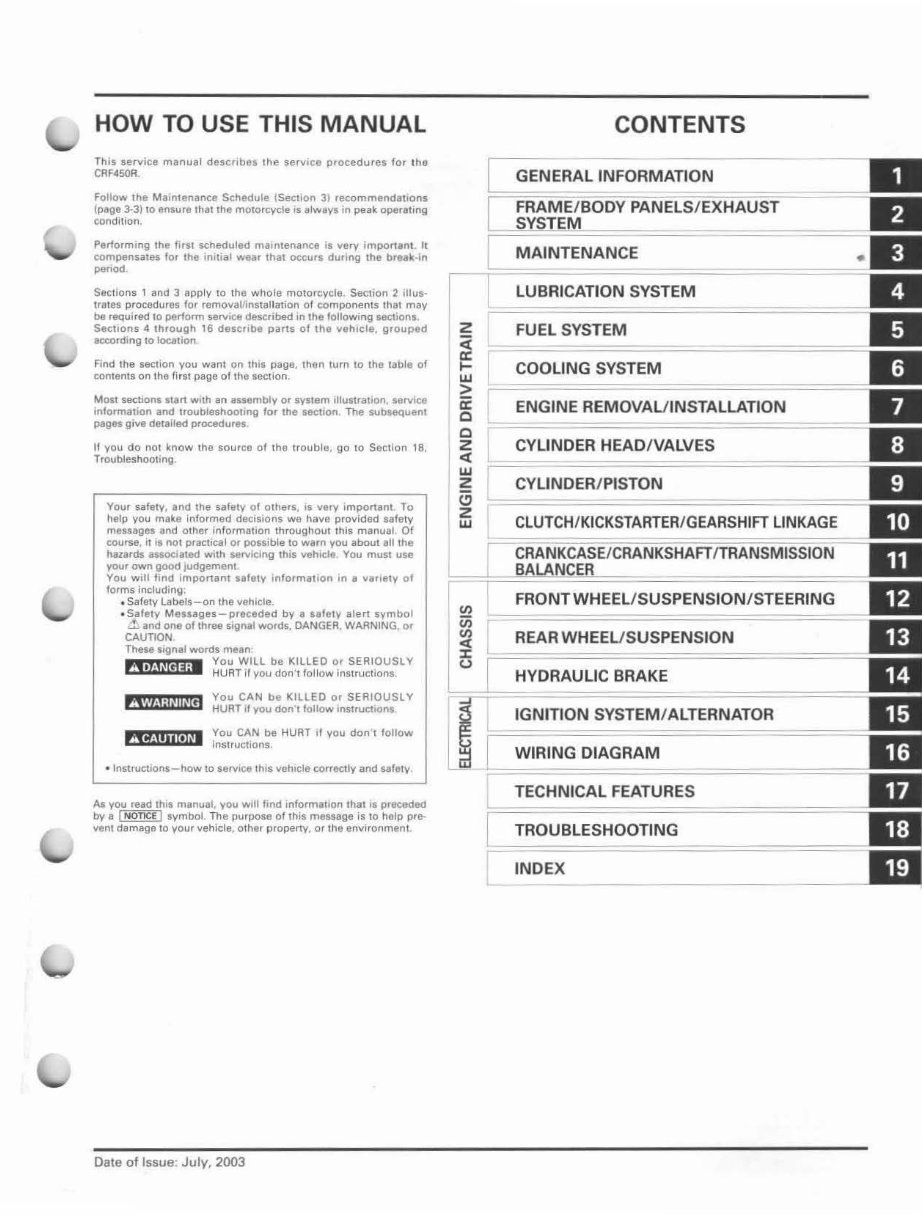

HOW TO USE THIS MANUAL

Th,s nrv;ce menual d~scribe. Ille 5e'~IC' procedur.s for the

CRF450R

Follow Ihe Mlloten.nee Schedule ISeclion 3) re<;ommendnons

Ipage 3-3)10 ensure Ihal the motorcycle is atw.y. in ~ak ope,atlng

cond,tion.

Performing Ih", li~1 SGheduled maintenance II very ImPOrt,nt It

compensates lor the inil,al wea. that o«ur, during the b'Nk·ln

period

Sections 1 and J apply 10 lhll whole motorcvcle. Section 2 illus-

,ralH procedufH lor removallinst.llation of components thai mllV

boll requlfed 10 perlarm SflfVice de$Clibed in Ihelollow'ng seetiOIl' .

Secllons 4 through 16 d .. ,c,ibe parl. of the ... ehlcle, grouped

.oeording 10 10000tion

Find Ihe secllon you want on Ihll pag8, then turn to the 'able 01

contents on the fi'$! page of !he . eClion.

Molt seellonslI." Wllh lin Hsembly Of SYllem ,IIUSlratlon. service

inlo.mittlon and troubleshooting 10. tha section The sub.equent

peges give det.lIed p<ocedures

II ~ou do not know the sourca 01 the tr ouble. 110 to Section 18.

Troubleshoot Ing .

Your $iI.ety, .nd the u.aty of othe,s. II very Imponant To

halp you make info'med decISIons we have provided safety

mess&ges and other info'mation thtoughoUi thil manual, Of

course. iIi. nol practical or possible 10 wI.n you about 8111he

h&<ards associated with servicIng Ihis vet"cleo You must use

you. own good Judgement.

You WIll find imponant .. 'ety informalion In I vI"lly 01

forms including;

• Safety Labell-on the vehicle

. Safely Me,sages-prece ded by. ufety alert symbol

.1l. and one of three sign.' words. DANGER. WARNING. or

CAUTION

These Ilgnal words mean

H,fMt!J4i

l

You WILL be KILLED or SERIOUSLY

- ~" .. "--"- HURT if vou don' tl ollow instructions.

ew.'iIJilmJ

You CAN be KJLLED or SERIOUSLY

HURT if you don't follow instruction,

t'!t4liitml You CAN be HURT II you don 't lollow

_." """ ". - InstructIon •.

• Instructlonl-how to service thl' vehICl e correctly ilnd salety

As you read thll manual. you will find inform.tlon that .. preceded

by • I NOncE I ,ymbol . The purpOse ollh's message is to help pre-

vent d.mage to \lour vehicle. other proP8rtv. or the environment

Date of Iss ue: July, 2003

z

g

'" ~

II:

C

C

Z

<

'" z

a

z

'"

CI)

~

:z:

u

CONTENTS

GENERAL INFORMATION

FRAME/BODY PANELS/EXHAUST

SYSTEM

MAINTENANCE

LUBRICATION SYSTEM

FUEL SYSTEM

COOLING SYSTEM

ENGINE REMOVAl/INSTALLATION

CYLINDER HEADIVALVES

CYLINDER/ PISTON

CLUTCH / KICKSTARTER / GEARSHIFT LINKAGE

BALANCER

FRONT WHEEl/SUSPENSION / STEERING

REAR WHEEl/SUSPENSION

HYDRAULIC BRAKE

IGNITION SYSTEM/ ALTERNATOR

WIRING DIAGRAM

TECHNICAL FEATURES

TROUBLESHOOTING

INDEX

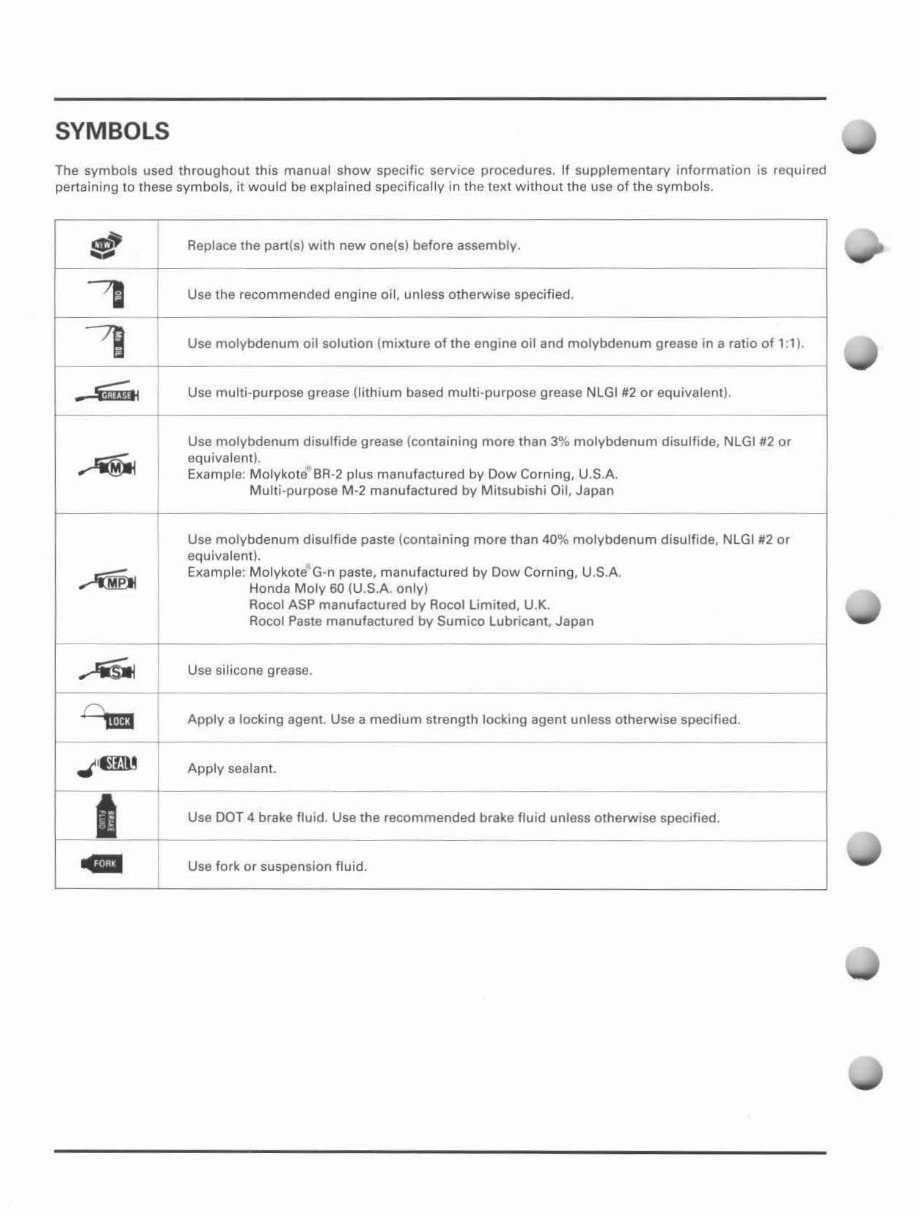

SYMBOLS

The symbols used throughout this manual show specific service procedures. If supplementary information is required

pertaining to these symbols. it would be explained specifically in the text without the use of the symbols.

fI

Replace the part{sl with new one(s) before assembly.

-, Use the recommended engine oil, unless otherwise specified.

-

,

Use molybdenum oil solution (mixture of the engine oil and molybdenum grease in a ratio of 1:1),

~..ijjjV,.

Use multi-purpose grease (lithium based multi -purpose grease NLGI #2 or equivalentJ.

Use molybdenum disulfide grease (containing more than 3% molybdenum disulfide, NlGI #2 or

~

equivalent).

Example: MotykolS' BR -2 plus manufactured by Dow Corning, U.S.A.

Multi-purpose M-2 manufactured by Mitsubishi Oil , Japan

Use molybdenum disulfide paste (containing more than 40% molybdenum disulfide, NLGI #2 or

equivalent).

~

Example: Molykote'G-n paste, manufactured by Dow Corning, U.S. A.

Honda Moly 60 (U.S.A. only)

Rocol ASP manufactured by Rocol Limited, U.K.

Rocol Paste manufactured by Sumico Lubricant, Japan

.AiSitI

Use silicone grease.

Da

Apply a locking agent. Use a medium strength locking agent unless otherwise specified.

,",'&llilll Apply sealant.

I

Use DOT 4 brake fluid . Use the recommended brake fluid unless otherwise specified .

--

.. Use fork or suspension fluid.

1. GENERAL INFORMATION

SERVICE RULES

MODEL IDENTIFICATION

SPECIFICATIONS

TORQUE VALUES

SERVICE RULES

1-1

1-2

1-3

1- 10

TOOLS

LUBRICATION & SEAL POINTS

CABLE & HARNESS ROUTING

OPTIONAL PARTS

1-14

1-16

1-18

1-23

1.Use genuine Honda or Honda-recommended parts and lubricants or their equivalents. Pans that do not meet

Honda 's design specifications may cause damage to the motorcycle .

2. Use the special toots designed for this product to avoid damage and incorrect assembl y.

3. Use only metric tools when servicing the motorcycle. Metric bolts, nuts and screws are not interchangeable with

English fasteners.

4. ln5lall new gaskets, O'rings , cotter pins, and lock plates when reassembling.

5. When lightening bolts or nuts, begin with the larger diameter or inner boll first. Then tighten 10 the specified torque

diagonally in incremental sleps unless a panicular sequence is specified.

6. Clean parts in cleaning solvent upon disassembly . lubricate any sliding surfaces before reassembly.

7. After reassembly, check all parts for proper installation and operation.

8. Route aU electrical wires as show on pages 1-18 through 1-22, Cable and Harness Routing .

1-1

GENERAL INFORMATION

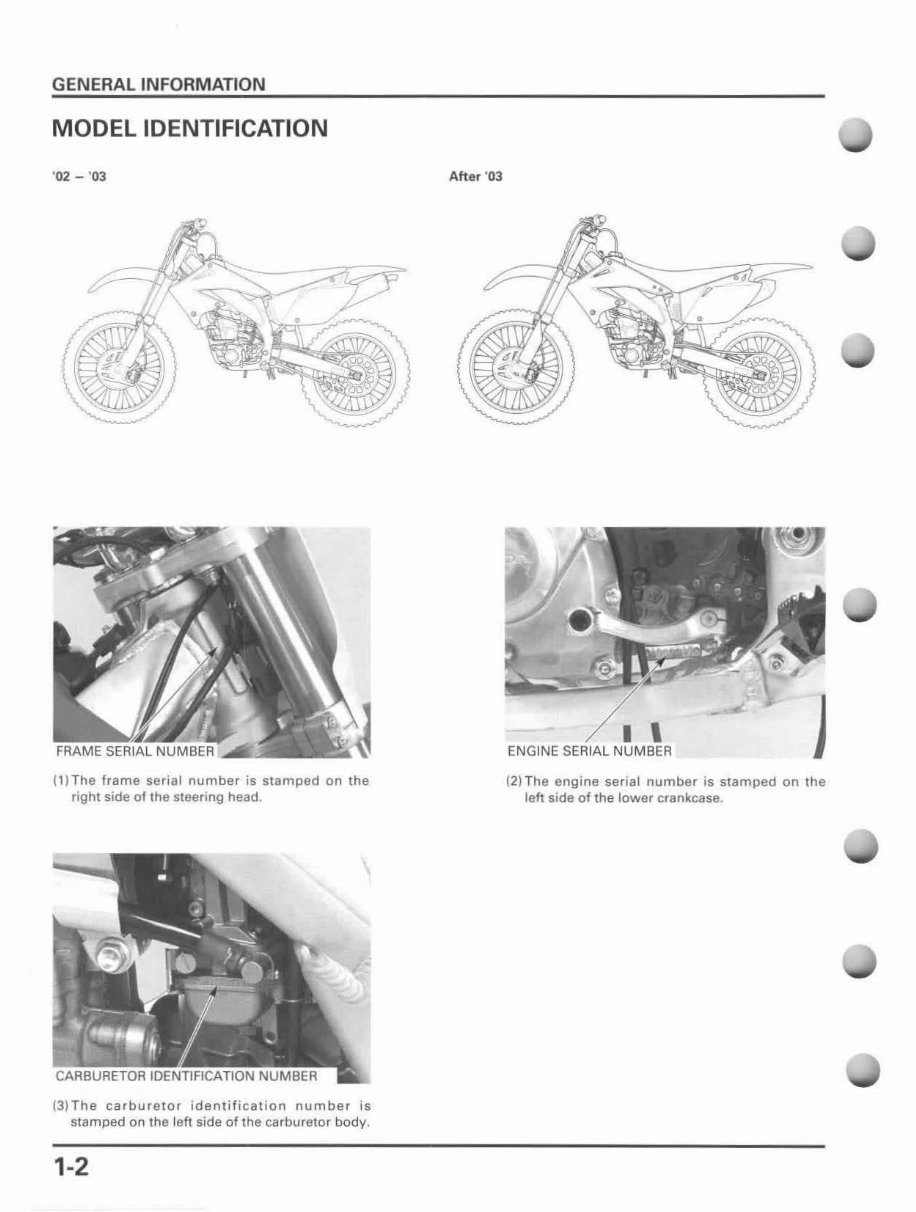

MODEl IDENTIFICATION

' 02 - '03

(1) The frame serial number is stamped on th e

tight side of the steering head.

(3)The carburetor identification number is

stamped on the left side of the carburetor body .

1-2

After '03

I ,

ENGINE SER"" NUMBER J

(2) The engine serial number is stamped on the

left side of the lower crankcase.

GENERAL INFORMATION

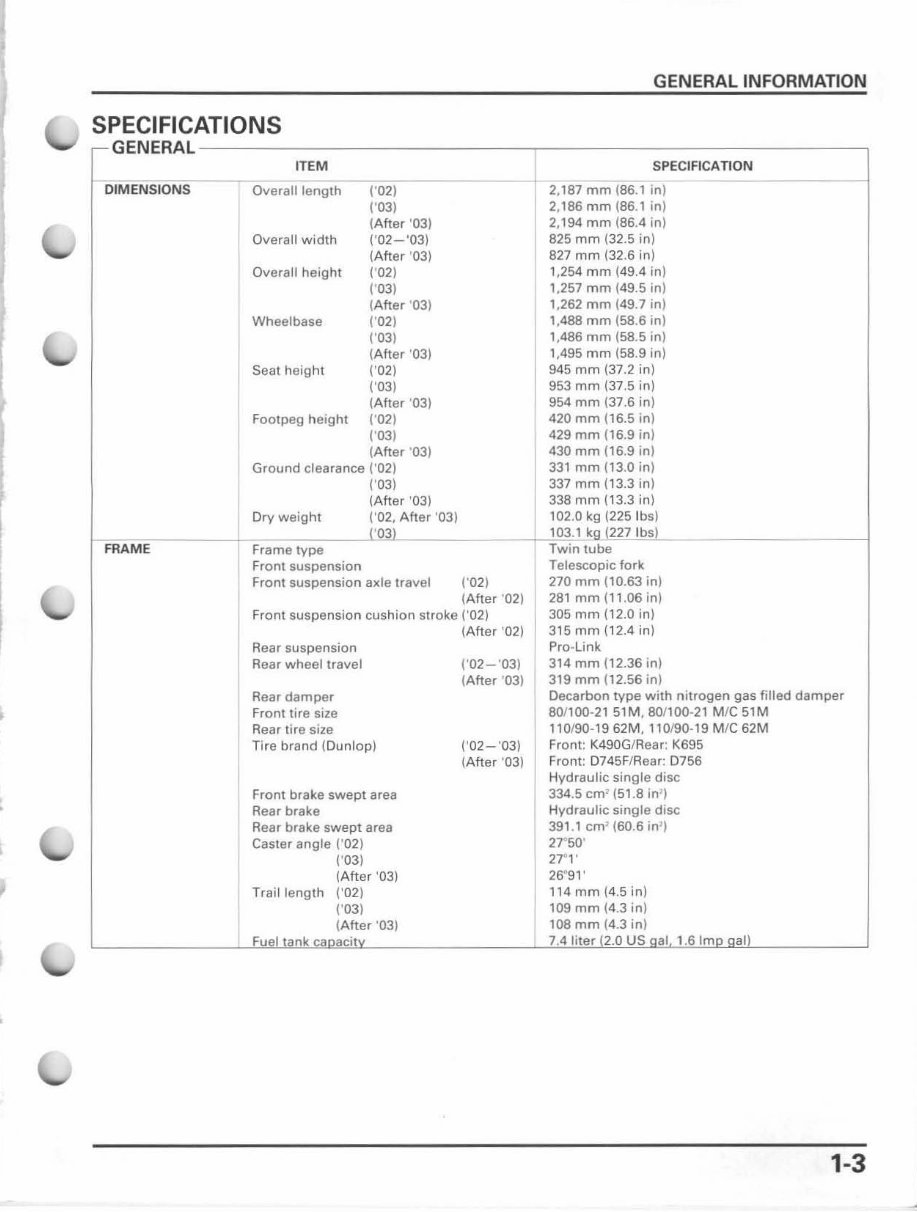

SPECIFICATIONS

~ GENERAL ------------------------~-------------------------

DIMENSIONS

ITEM

Overall length

Overall width

Overall height

Wheelbase

Seat height

(' 02)

(,03)

(After '03)

('02-'03)

(After '03)

(,02)

('03)

(After '03)

(' 02)

('03)

(After '03)

('02)

('03)

(After '03)

Footpeg h eight ('02)

('03)

(After '03)

SPECIFICATION

2,187 mm (86.1 in)

2,186 mm (8B.1 in)

2.194 mm (86.4 in)

825 mm (32.5 in)

827 mm (32.6 in)

1,254 mm (49.4 in)

1,257 mm (49.5 in)

1,262 mm (49.7 in)

1,488 mm (58.6 in)

1,486 mm (58.5 in)

1,495 mm (58.9 in)

945 mm (37.2 in)

953 mm (37.5 in)

954 mm (37.6 in)

420 mm (16.5 in)

429 mm (16.9 in)

430 mm (16.9 in)

~ME

---4

::::::~:"'"'" i~~~~~:; '03)

::-::-:--:-: ____ ilJ! 'O '1L-

Frame type

Front suspension

331 mm (13.0 in)

337 mm (13.3 in)

338 mm (13.3 in)

102.0 kg (225 Ibs)

__ ---l~'0f'3C!.1 kg (227 I bsl

Twin tube

Telescopic fork

270 mm (10.63 in)

281 mm (1'.06 in)

305 mm (12.0 in)

315 mm (12.4 in)

Pro-Link

front suspensio n axle travel (,02)

(After '02)

Front suspensio n cushion stroke ('02)

Rear suspension

Rear wheel travel

Rear damper

Front tire size

Rear tire size

Tire brand (Dunlop)

Front brake swept area

Rear brake

Rear brake swept area

Casler angie (,02)

('03)

(Afte r '03)

Traillength (,02)

k

(,03)

(After '03)

cit

(After '02)

('02-'03)

(After '03)

('02-'03)

(After '03)

314 mm (12.36 in)

319 mm (12.56 in)

Decarbon type with nitrogen gas filled damper

80/100-21 51M, 80/100-21 M/C 51M

110/90-19 62M, 110190-19 M/C 62M

Front: K490G/Rear: K695

Front: D745F/Rear: 0756

Hydraulic single disc

334.5 cm' (51.8 in')

Hydraulic single disc

391,1 cm' 160.6 in')

21'50'

27" 1'

26"91 '

114 mm (4,5 in)

109 mm (4.3 in)

108 mm (4.3 in)

7.4 lite;'/2.0 US "al 1.6 lmn nail

1-3

GENERAL INFORMATION

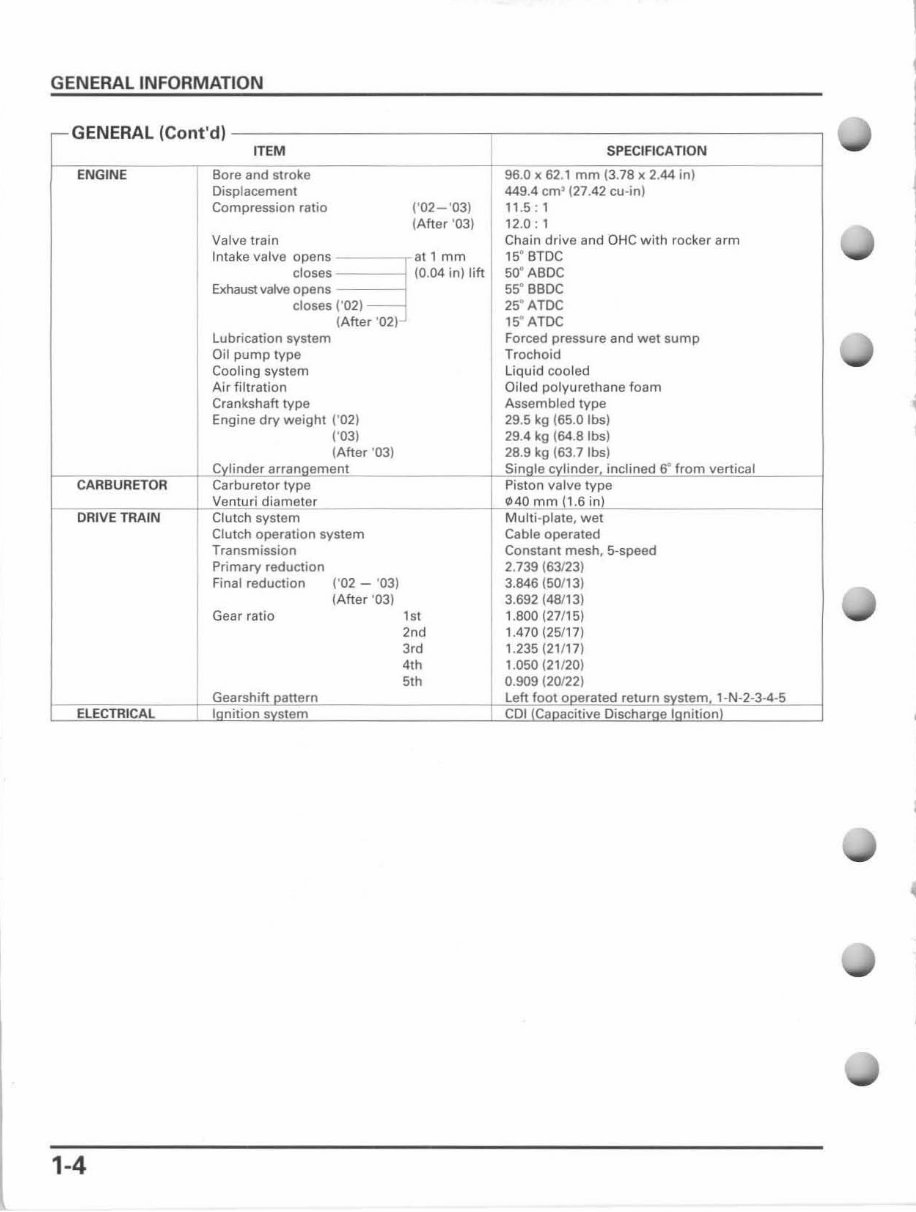

- GENERAL (Cont'd)

ITEM SPECIFICATION

ENGINE Bore and stroke 96.0 x 62.1 mm (3.78 x 2.44 in )

Displacement 449.4 em' (27. 42 cu·in)

Compression ratio ('02 -' 03) 11 .5 : 1

(After '03) 12 .0: 1

Valve train Chain drive and OHC with rocker arm

In"', "'v. open' ~ " , mm

15· BTDC

doses (0 .04 in) lift 50· ABDC

Exhaust valve opens 55

0

BBDC

closes ('021 25- ATOe

(After '02) 15- ATOC

lubrication system Forced pressure and wet sump

Oil pump type Trochoid

Cooling system liquid cooled

Air filtration Oiled polyurethane foam

Crankshaft type Assembled type

Engine dry weight (' 021 29.5 kg (65.0 Ibs)

('03) 29.4 kg (64.8 Ibs)

(After '03) 28.9 kg (63.7 Ibs)

Cylinder arrangement Single cylinder inc li ned ff' from vertical

CARBURETOR Carburetor type Piston valve type

Venturi diameter \1140 mm (1.6 i'~)

DRIVE TRAIN Clutch system Multi -plate, wet

Clutch operation system Cable operated

Transmission Constant mesh, 5-speed

Primary reduction 2.739 (63123 )

Final reduction ('02 - '03) 3.846 (50' 13)

(After '03) 3.692 (48113)

Gear ratio

, ,,

1.800 (27/15)

2nd 1.470 (25/17)

3,d 1.235 (21 /17)

4th 1.050 (21 /20)

5th 0.909 (20122 )

Gearshift panern left foot operated return system 1-N-2-3-4-5

ELECTRICAL I nition s stem COl Ca acitive Dischar e I nilion

1-4

GENERAL INFORMATION

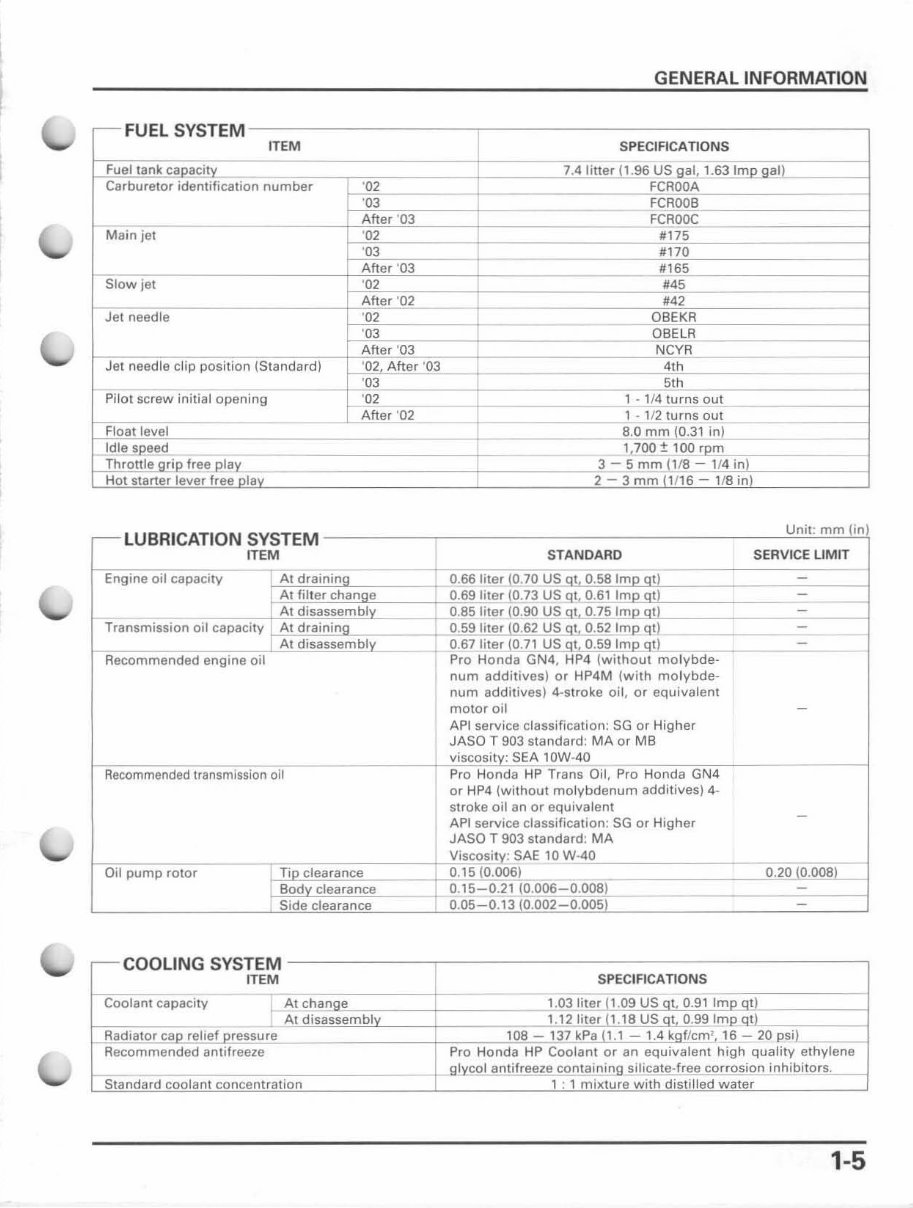

,-- FUEL SYSTEM

ITEM SPECI FI CATIONS

fuel tank caoacl!y 7.4 liner (1.96 US gal l.63~al '--

Carburetor identification number '02 FCROOA

'03 FCROOB

Aher '03

-

I-

FeROOC

Main jet '02 #115

'03 #170

After '03 #165

Slow jet '02 #45

-

After ' 02 #42

-

Jet needle '02 OBEKR

'03 OBE LR

After ' 03 NeYR

Jet needle clip position (Standard) '02 After ' 03

I-

4th

'03 5th

Pilot screw initial opening ' 02 1 - 1/4 1 urns out

- After '02 1 - 1/2 turns out

Float level 8.0 mrn 10.31 in)

__ I~l1e speed 1,700 + 100 rpm

Throttle~e~ay: 3 5 mm (1 18 114 in)

.-

Hot starter lever !reeDis 2 3 mm Ill'S l iB in

- LUBRICATION SYSTEM

m:

,

U 't mm Cn)

I TEM STANDARD SER VICE LIMIT

Engine oil capacity

-

At draininQ

I

0.66 liter (0.70 US qt, 0.58 Imp gt)

AI filt er change

t

0.69IilerJO.73 US qt, O.61J!!!Q gIl

-

At disassembl

O.85Iite~ :~.90 US~51mp gIl

Transmission oil capacity At draining 0.59 liter 0.62 US gt, 0.52 Ime gt)

At disassembl 0.67 liter (0.71 US gt, 0.59 Imp gtl

Recommended engine oil Pro Honda GN4, HP4 (without mo l ybde·

num additives) or HP4M (with mo l ybde·

num additives ) 4-stroke oil, or equivalent

motor oi l -

API service classification: SG or Higher

JASO T 903 standard: MA or MB

viscosity: SEA 10W·40

Recommended transmission oil Pro Honda HP Trans Oil, Pro Honda GN4

or HP4 (without molybdenum additives) 4-

stroke oil an or equivalent

API service classification: SG or Higher

-

JASO T 903 standard: MA

Viscosity : SAE 10 W·40

Oil pump rotor Ti clearance 0. 15 (0.006) 0.20 0.008

Body clearance 0.15 0.21 (0.006 0.008)

Side clearance 0.05 0.13 (C)'002 0.005)

- COOLING SYSTEM

ITEM SPECIFICATIONS

Coolant capacity , At change 1.03 liter p. 09 US gt, 0.91 Imll' g~

At disassembl 1.1 2 l iter ( 1.1 B US qt, 0.99 Imp gt)

_ ~adiator cap relief pressure 108 137kPa 1.1 1 .4~~gf/cm', 16 20 psi

Recommended antifreeze Pro Honda HP Coolant or an equivalent high quality ethylene

- Standard coolant concentration

glyco l antifreeze containing silicate·free cor rosion inhibitors,--

1 : 1 mixture with distilled water

1-5

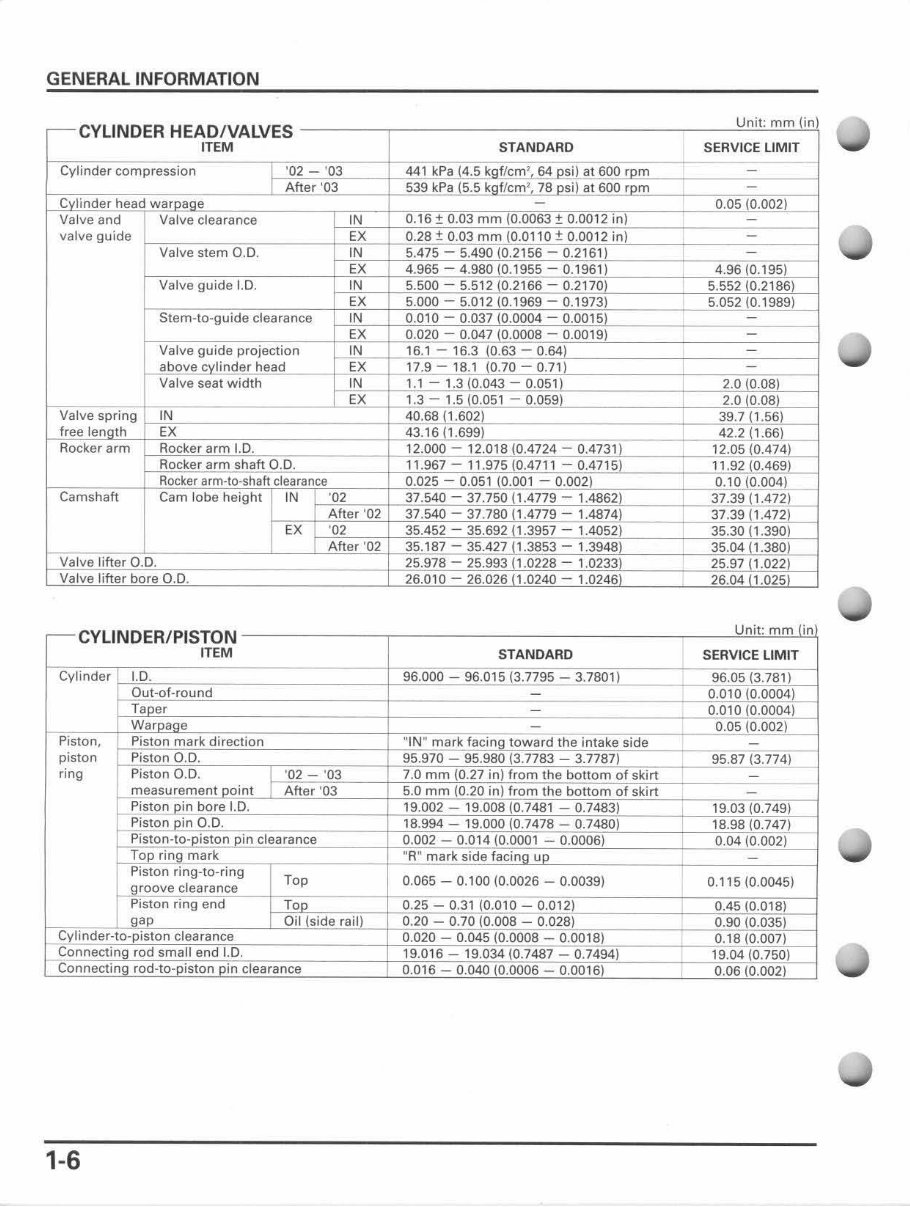

GENERAL INFORMATION

HEAOIVALVES

Uolt mm (0)

ITEM S TANDARD S ER VICE LIMIT

..... yli I

,

- Aii,<'03

539 kPa )5.5 I 78 o,H " 600 com

-

I

Valve and Valve clearance I 0.'6, ).03mm

Ii '

).0012 -

valve guide . 'mm (0.0110 ).00 ' '0)

-

Valv, ",m O.D. I

'l¥oFH

'955 - 0.'96 '

~0:'95)

Valv, 9uld, I.D. I

5.000 - 5.' 1 -0. '97 5.052 (0. '989)

I

-

Ex 10- Ol '

1-

Valv, 9uld, . I -

abo~'- '-h~~d-

Valve seat width I

1-: :04l-~

2.0 10.08)

~:~~e:;;'~'~9

IN

~

'tm: ~0 '8 : ::

Rocker arm

'DO'" "m .D.

J.469)

- Rock"~ ~"

~Fm --~ ~~

Cam lo b, h"9hl I ' 37.39 >' 472)

EX

35.452 -1[ill ~

>.390)

~

2~ - 25.99: := '0ill!: ~

~ CYLINOER/PISTON

Unit: mm lin

ITEM STANDARD SERVICE LIMIT

Cylinder I.D. 9S.000 96.015 (3.7795 3.7801) 96.05 (3.781)

Out-af-round 0.010 (0.0004)

Taoer 0.010 (0.0004)

War a e 0.05 (0.002)

Piston, Piston mark direction ~IN" mark faein toward the intake side

piston Piston D.D. 95.970 95.980 (3.7783 3.7787) 95.87 (3.774)

ring Piston 0.0. 1'02 '03 7.0 mm (0.27 in) from the bottom of skirt

measurement noin! After '03 5.0 mm (0.20 in) from the bottom of skirt

Pislonoin bore t.D. 19.002 19.008 (0.74Bl 0.74B3) 19.03 (0.749)

Piston pin O.D. 18.994 19.000 (0.7478 0.74BO) 18.98 (0.747)

Piston-to- iston in clearance 0.002 0.014 (0.0001 0.0006) 0.04 (0.002)

Top rina mark "R" mark side facin u

Piston ring-Io-ring

Top 0.065 - 0.100 (0.0026 - 0.0039) 0.1 15 (0.0045)

aroove clearance

PiSlon ring end To 0.25 0.31 (0.010 0.012) 0.45 (0.018)

gap Oil (s ide rail 0.20 0.70 (0.008 0.028) 0.90 (0.035)

Cylinder-to-piston clearance 0.020 0.045 (0.0008 0.0018) 0.18 (0.007)

Connecting rod small end I.D. 19.016 19.034 (0.7487 0.7494) 19.04 (0.750)

Conneclin rod-IO- iston in clearance 0.016 0.040 (0.0006 0.0016) 0.06 (0.002)

1-6

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

Viewed 86 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

This Factory Repair Workshop Manual for the Honda CRF450R 2002-2004 is an essential resource for both professional mechanics and DIY enthusiasts. It contains detailed illustrations and step-by-step instructions for easy understanding.

- All pages are printable, allowing you to have the necessary information at hand in your garage or workshop.

- Topics covered include general information, lubrication, maintenance, fuel system, engine removal/installation, cylinder head/valves, clutch/gearshift linkage, and much more.

- The manual provides comprehensive instructions based on the complete disassembly of the machine, accompanied by numerous illustrations to guide you through each service and repair procedure.

File Format: PDF

- Compatible with all versions of Windows & Mac

- Language: English

- Requirements: Adobe Reader

This manual is available instantly with no shipping cost or need to wait for a CD-ROM, making it a convenient and cost-effective solution for maintaining your bike.