1997-1998 Honda CBR1100XX Service & Repair -

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

IMPORTANT SAFETY NOTICE

mm:m:m:B Indicates a strong possibility of severe personal injury or death if instructions are not followed.

CAUTION : Indicates a possibility of equipment damage if instructions are not followed.

NOTE: Gives helpful information.

Detailed descriptions of standard workshop procedures, safety princip les and service operations are not included. It is

important to note that this manual contains some warnings and cautions against some spec ifi c service methods which

cou ld cause PERSONAL INJURY to service personnel or could damage a vehicle or render it unsafe. Please

understand that those warnings could not cover all conceivable way s in which service, whether or not recommended

by Honda, might be done or of the possibly hazardous consequences of each conceivable way, nor could Honda

investigate all such ways . Anyone using service procedures or too ls, whether or not recommended by Honda, must

satisfy h imself thoroughly that neither personal safety nor veh icle safety will be jeopardi zed by the service methods or

tools selected.

SYMBOLS

The symbo ls used th rougho ut th is manu al show specific servi ce pro cedures. If s upp lementary inform ation is requi red

perta in ing to these symbols, it wou ld be expl ained specifically in the text w ithout the use of the symbo ls.

~

S

Repla ce t he pa rt ts) wi th new o ne(s) befor e assem bly .

~

Use reco m m ended engi ne oil, un less oth erw ise spe cif ied .

~

Use m o lybdenum oil so lut ion (m ixtu re of t he en g ine oil and mo ly bdenum g rease in a rat io of 1: 1).

-~

Use m ulti -purpose grease (Lithium based m ulti -pu rpo se g rease NLGI # 2 or eq uivalent).

~

Use m o ly bden um d is ulf ide gr ease (co nt ai ning m o re t han 3% m olybdenum dis ulf id e, NL GI # 2 or

eq uiv alent).

Exam pl e: Mo lv kote'" BR-2 plu s manufact ured by Dow Co rn ing , U.S.A.

M ulti-purp ose M-2 man ufact ured by M itsu bis hi Oil , Ja pan

~

Use molybde num dis ulf id e paste (co ntaining mor e t han 40% m o lybd en um d isulfid e, NLGI # 2 or

eq uiva lent).

Exam ple: Mol vkot e" G-n paste, ma nufact ured by Dow Co rning , U.S.A.

Hond a Mo ly 60 (U.S.A. on ly )

Roco l AS P manuf act ure d by Roco l Limi ted, U.K.

Rocol Paste manufa ctured by Sum ico Lubricant, J apan

~

Use sil ico ne grease.

L1mI

Apply a lock ing agent. Use a mi ddle st rengt h lock ing agent un less ot herwi se specif ied.

J 1um

Appl y sealant .

I

Use DOT 4 brake f luid. Use the recomm ende d br ake fl uid unless ot herwi se spe cifie d.

ell

Use Fo rk or Sus pe nsio n Fluid.

..

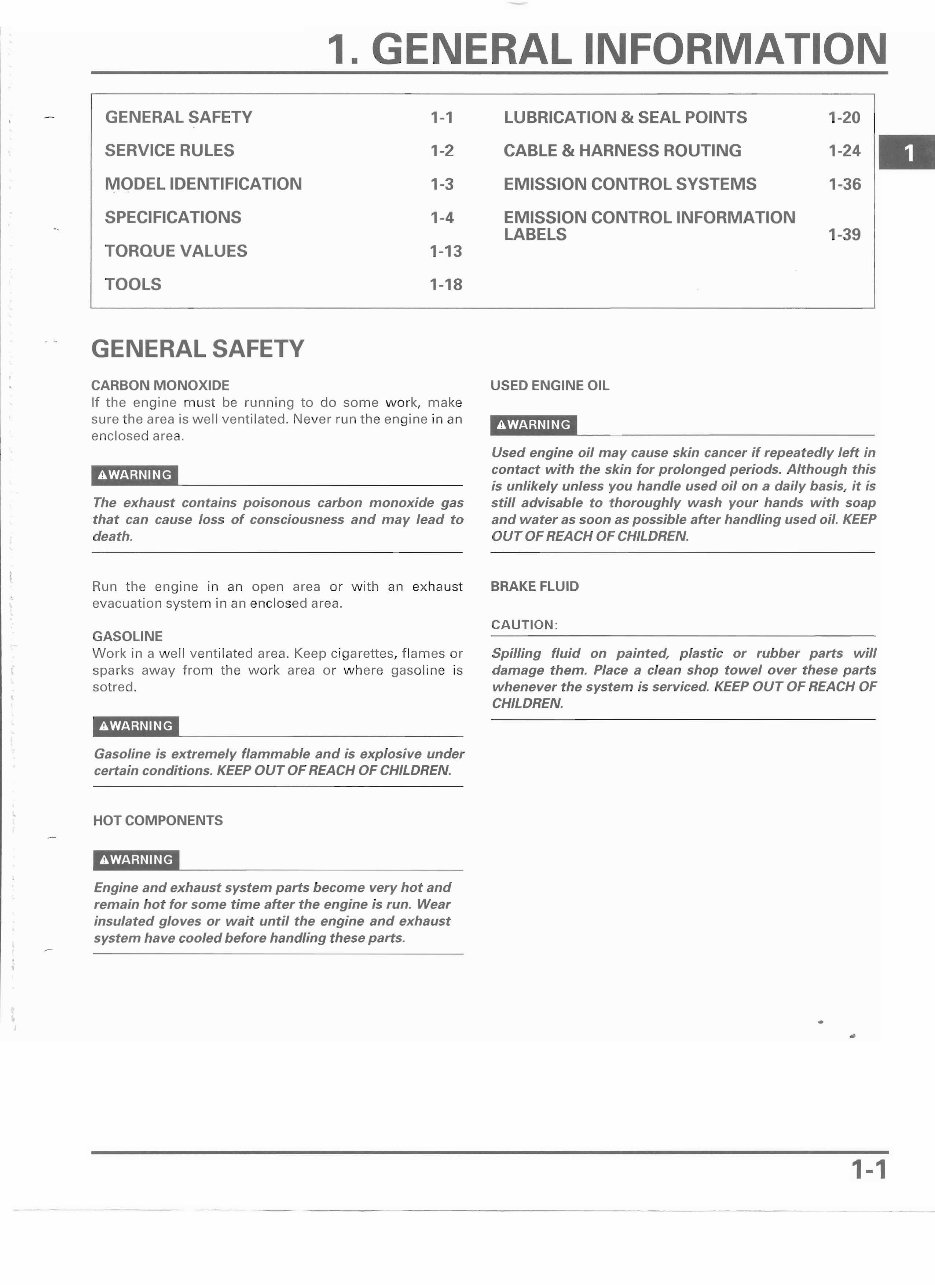

1. GENERAL INFORMATION

..

GENERAL SAFETY 1-1 LUBRICATION & SEAL POINTS 1-20

SERVICE RULES 1-2 CABLE & HARNESS ROUTING 1-24

MODEL IDENTIFICATION 1-3 EMISSION CONTROL SYSTEMS 1-36

SPECIFICATIONS 1-4 EMISSION CONTROL INFORMATION

LABELS 1-39

TORQUE VALUES 1-13

TOOLS 1-18

GENERAL SAFETY

CARBON MONOXIDE

If the engine mu st be runnin g to do so me wo rk, ma ke

sure t he area is we ll ventilated. Ne ver run th e engine in an

enclosed area.

~

'-------- - - - - - - - - - - -

The exhaust contains poisonous carbon monoxide gas

that can cause loss of consciousness and may lead to

death.

Run th e engine in an ope n area or w ith an exh aust

evacuation syste m in an enclosed area.

GASOLINE

Work in a well vent ilated area. Keep cigarettes, flames or

sparks away fro m th e work area or wh ere gasoline is

sotred.

~'--- ---------

Gasoline is extremely flammable and is explosive under

certain conditions. KEEP OUT OF REACH OF CHILDREN.

HOT COMPONENTS

~'---- --------

Engine and exhaust system parts become very hot and

remain hot for some time after the engine is run. Wear

insulated gloves or wait until the engine and exhaust

system have cooled before handling these parts.

USED ENGINE OIL

~L-- _

Used engine oil may cause skin cancer if repeatedly left in

contact with the skin for prolonged periods. Although this

is unlikely unless you handle used oil on a daily basis, it is

still advisable to thoroughly wash your hands with soap

and water as soon as possible after handling used oil. KEEP

OUT OF REACH OF CHILDREN.

BRAKE FLUID

CAUTION:

Spilling fluid on painted, plastic or rubber parts will

damage them. Place a clean shop towel over these parts

whenever the system is serviced. KEEP OUT OF REACH OF

CHILDREN.

1-1

GENERAL INFORMATION

COOLANT BATTERY HYDROGEN GAS & ELECTROLYTE

Under some conditions, the ethylene glycol in engin e

coolant is combustib le and its f lame is not visible. If the

aBmmI'----- _

ethylene glycol do es ign ite , you will not see any flame, but

yo u can be burned. • The battery gives off explosive gases; keep sparks,

flames and cigarettes away. Provide adequate ventilation

when charging.

aBmmIL-- _

• The battery contains sulfuric acid (electrolyte). Contact

• Avoid spilling engine coolant on the exhaust system or with skin or eyes may cause severe burns. Wear

engine parts. They may be hot enough to cause the protective clothing and a face shield.

coolant to ignite and burn without a visible flame. - If electrolyte gets on your skin, flush with water.

• Coolant (ethylene glycol) can cause some skin irritation - If electrolyte gets in your ~yes, flush with wa ter for at

and is poisonous if swallowed , KEEP OUT OF REACH OF least 15 minutes and call a physician immediately.

CHILDREN. • Electrolyte is poisonous.

• Do not remove the radiator cap when the engine is hot. - If swallowed , drink large quantities of water or milk

The coolant is under pressure and could scaled you. and follow with milk of magnesia or vegetable oil and

-

• Keep hands and clothing away from the cooling fan, as it call a physician. KEEP OUT OF REACH OF CHILDREN.

starts automatically.

SERVICE RULES

1. Use genuine HONDA or HONDA-recom mended parts and lubricants or the ir equivalents. Parts that don't meet HONDA's

design specifications may cause damage to the mot orcycle.

2. Use the special tools designed for th is prod uct to avo id dam age and incorrect asse mb ly.

3. Use only m etr ic tools when serv icing the motor cycle. Metr ic bolts, nuts and screws are not interchangeable with English

fasteners.

4. Install new gaskets, a -rings, corter pins, and lock plates w hen reass emb lin g.

5. Whe n tighten ing bolts or nuts, begin with th e larger diameter or i nner bolt first. Then tighten to the specified torque

diagonally in incremental steps unless a particu lar sequence is specified. _

6.Clean parts in cleaning solvent upon disasse mbly. Lubricate any sliding surfac es befo re reassembly.

7. After reassembly, check all parts for prope r i nsta llat ion and operation.

8. Route all electrical w ires as show on pages 1-24 thr ough 1-35, Cable and Harness Routing .

-

-

1-2

- - - - - - - - - -- - - - - - - - - -- - - - - - - - - - - --- - - - - -- --

GENERAL INFORMATION

MODEL IDENTIFICATION

(1) The frame ser ial number is stamped on the right

side of th e steering head.

(2) The engine seria l number is stamped on the right

side of the upper crankcase.

VEHICLE IDENTIFICATION NUMBER (VIN)

(3) The Veh icle Identification Number (VIN ) is

located on right side of the frame near the

steering head on the Safety Cert if ication Label.

CARBURETOR IDENTIFICATION NUM BER

(4) The carburetor ident ificat io n n umb ers are

sta mped on the intake side of the carburetor

body as sho wn.

(5) The color label is attached as shown . When

o rder ing color-coded parts, always specify the

designated color code.

1-3

GENERAL INFORMATION

SPECIFICATIONS

- GENERAL

SPECIFICATIONS ITEM

DIM ENSIONS 2,160 mm (85.0 in)

Overa ll width

Ove rall lengt h

720 m m (28.3 in)

Ove rall height 1,170 mm (46.1 in)

Whee lbase 1,485 m m (58.5 in)

Seat height 810 mm (31.9 in)

Footpeg heig ht 372 mm (14.6 in )

Ground clearance 130 mm (5.1 in)

Dry w eig ht

49 states/Canada type 223 kg (492 lbs )

Cal ifornia ty pe 225 kg (496 lbs )

Curb w eight

49 states/Canada ty pe 250 kg (551 Ibs)

Califo rn ia type 252 kg (556 Ibs)

Max imum w eight capa city

49 state s/Cal ifornia type 174 kg (384 Ibs)

Canad a typ e 178 kq (393 lbs )

FRAM E Frame type Diamond

Front suspension Telescopic fork

Fro nt w hee l trave l 109 mm (4.3 in)

Rear susp ension Swing arm

Rear w hee l t rave l 120 mm (4.7 in)

Rear d amper Nitrog en gas f illed d amper

Front tire size 120/70 ZR17 (Radial)

Rear tire size 180/55 ZR17 (Radial)

Ti re br and

Bridgestone Front: BT57F RADIAL G/ Rear: BT57R RADIAL G

Dunlop Front: D205FJ/ Rear: D205G

Mich el in Front: MACADAM 90X S/ Rear: MACADAM 90X S

Fron t brak e Hydraulic double disc brake with 3 pots caliper

Rear brake Hydraulic single disc brake with 3 pots caliper

Caster angle 25°

Trail length 99 mm (3.9 in)

Fuel tank capac ity 22.0 Q (5.81 US gal , 4.841mp gal )

Fuel tank reserve capac ity 3.0 Q (0.79 US qal r 0.66 Imp ca l)

ENGINE Bore and stro ke 79.0 X 58.0 mm (3.11 X 2.28 in)

Displacement 1,137 ern" (69.4 cu-i n)

Comp ression ratio 11.0 : 1

Va lve train Chain dr iv e and DOHC

Intake valve 20° BTDC

ope " mm f '"

closes (0.04 in) 40° ABD C

Exhaust valve opens lift 40° BBDC

close s 10° ATDC

Lubrication system Forced pressure and w et s ump

Oil pu mp type Trochoid/ double rotor

Cool ing system Liquid cooled

Air filtration Paper fi lter

Crankshaft type Unittype

Engine dry weight 83.0 kg (183.0 lbs)

Cylinde r arranqernent Four cyli nde r, inline 30° inc lind ed f ro m vert ical

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - -_ ._ --

1-4

GENERAL INFORMATION

c - GENERAL ( ont'd)

ITEM SPECIFICATIONS

CV (Constant Veloc ity ) type, wi th f lat valve

42 mm (1.7 in )

CARBUR ETOR Carbureto r ty pe

Thrott le bore

DRIVE TRAIN Clutch system

Clutch operation system

Transmissio n

Pri mary reduction

Fina l reduction

Gear ratio

Gearshift pattern

1st

2nd

3rd

4th

5th

6th

Mu lti-plate, we t

Hydraulic operated typ e

Constant mesh , 6-speed

1.571 (88/56)

2.647 (45/17)

2.769 (36/13)

2.000 (32/16)

1.579 (30/ 19)

1.333 (28/21)

1.167 (28/24)

1.042 (25/24)

Left foot op erated ret urn syst em, 1-N-2-3-4-5-6

ELECTRICA L Ignitio n syst em

Sta rt ing system

Charging system

Regulator/ rec tifie r

l.iq htinq system

Co mp uter-cont rolled dig ita l tr an si st or ized wi t h electric

advanc e

Electric st art er motor

Tr iple phase out put alternator

SCR sh o rte d/t riple phase, ful l wave rectifica t ion

Batt ery

1-5

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - --- - - -- _ .

GENERAL INFORMATION

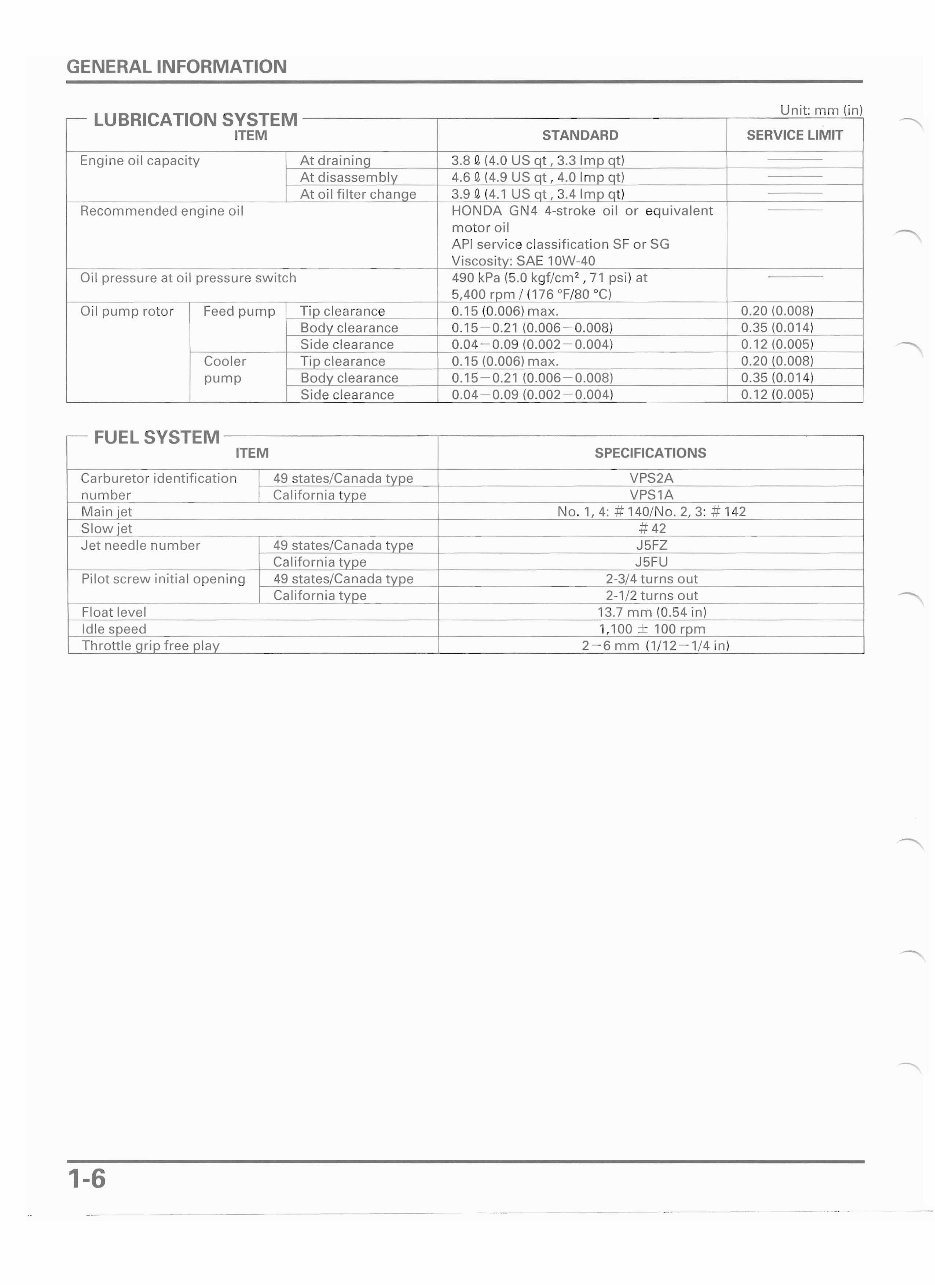

- LUBRICATION SYSTEM

Unit: mm (in)

ITEM STANDARD SERVICE LIMIT

Engin e oil capac ity At dra ininq 3.8 Q (4.0 US qt , 3.3 Im p qt)

At di sasse m bly 4.6 Q(4.9 US qt , 4.0 Im p qt )

At oil f ilter cha nce 3.9 Q(4.1 US ut , 3.4 Im p qt)

Reco mm ende d eng ine oi l HONDA GN4 4-stro ke oi l or eq uivalent

motor oil

API serv ice classifi cat ion SF or SG

Visco sit y : SAE 10W-40

Oi l pressure at oil pressure switch 490 kPa (5.0 kgf/cm

2

r 7 1 psi ) at

5,400 rpm / (176 °F/80 °C)

Oil pu m p roto r Feed pump Tip clearance 0.15 (O .006) max . 0.20 (0.008)

Bod y clea rance 0.15 - 0.21 (0.006 -0. 008) 0.35 (0.014)

Side clearance 0.04 - 0.09 (0.002 - 0.004 ) 0.12 (0.005)

Coo ler Ti p clearance 0.15 (0.006) max. 0.20 (0.008)

pu mp Body clearance 0.15 - 0.21 (0.006 - 0.008) 0.35 (0.014)

Side cle arance 0.04 - 0.09 (0.002 - 0.004) 0.12 (O .005)

FUEL SYSTEM

~

ITEM SPECIFICATIONS

Car buretor identification

nu mber

49 states/Canada type VPS2A

Ca lifornia ty pe VPS1A

Ma in jet No. 1, 4: # 140/No . 2, 3: # 142

Slow iet # 42

J et need le number 49 states/Cana da ty pe J5F Z

California type J5FU

Pilot screw initia l open ing 49 states/Ca nada ty pe 2-3/4 t urn s out

Cal iforn ia typ e 2-1/2 tu rn s ou t

Float level 13.7 mm (0.54 in )

Idle speed 1,100 ± 100 rpm

Th rott le crio free play 2-6 mm (1/ 12 - 1/4 in )

1-6

GENERAL INFORMATION

Unit: m m (i n)

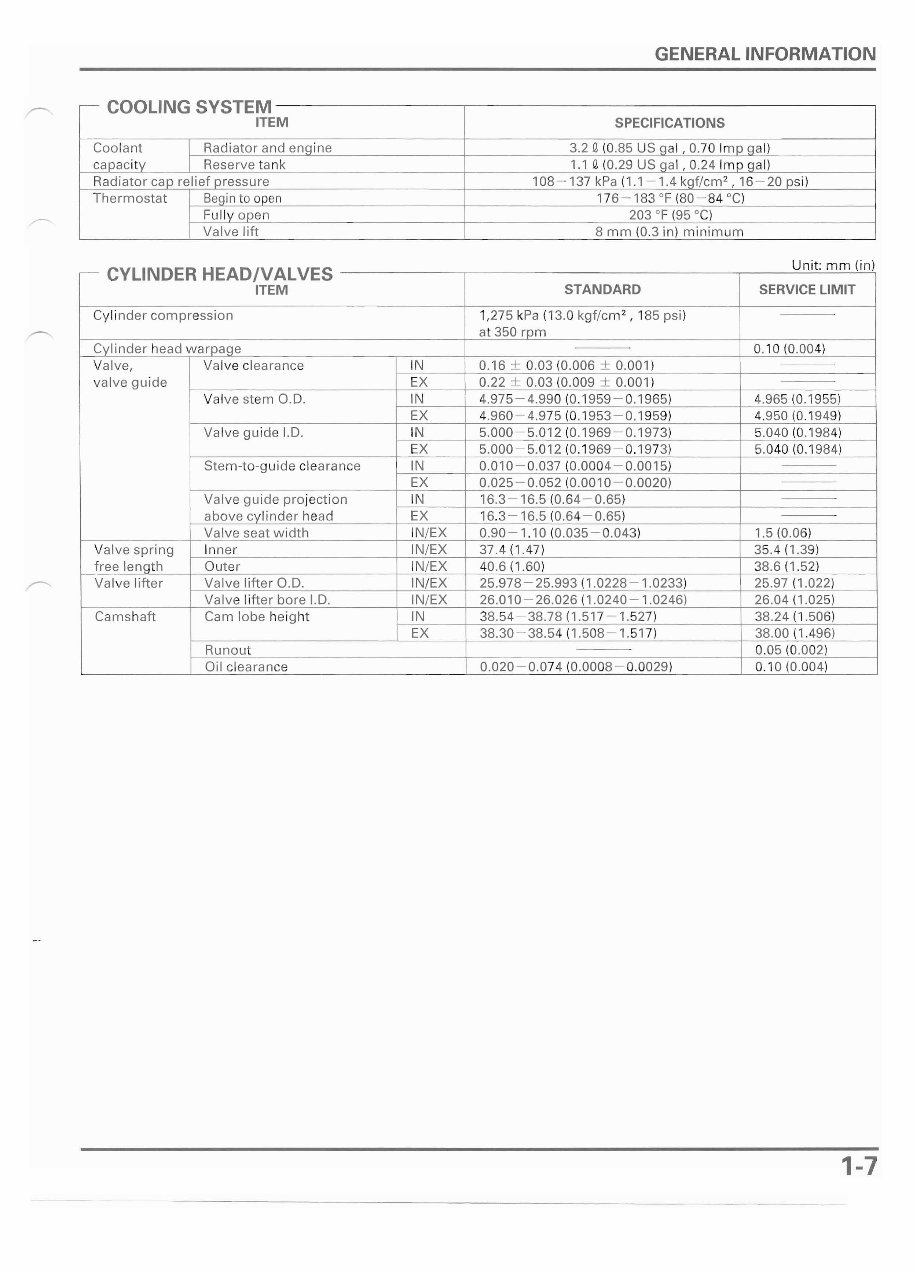

- COOLING SYSTEM

ITEM SPECIFICATIONS

Coo la nt

capac ity

Rad iato r and enq ine 3.2 Q (0.85 US ual , 0.70 Im p qal)

Reserve tank 1.1 Q (0.29 US qa l t 0.24 Imp qa l)

Radiator cap reli ef pressur e 108 -1 37 kPa (1.1- 1.4 kef/ern", 16 -20 psi)

Ther m ostat Beqin to open 176 - 183 of (80 -84 °C)

Fullv open 203 of (95 °C)

Valve lift 8 mm (0.3 in) m ini m um

- CYLINDER HEAD/VALVES

ITEM

Cy l inder compr ess ion

Cyl inder head w arpaue

STANDARD

1,275 kPa (13.0 kqf /c rn" , 185 psi)

at 350 rp m

0.16 + 0.03 (0.006 + 0.001)

SERVICE LIMIT

0.10 (0.004)

Valve,

valve gu ide

Valve cl earance IN

EX 0.22 + 0.03 (0.009 + 0.001)

Valve stem O.D. IN 4.975 - 4.990 (0.1959 - 0.1965) 4.965 (0.1955)

EX 4.960 - 4.975 (0.1953 - 0.1959) 4.950 (0.1949)

Va lve gu ide I.D. IN 5.000 - 5.012 (0.1969 - 0.1973) 5.040 (0.1984)

EX 5.000 -5 .012 (0.1969 - 0.1973) 5.040 (0.1984)

Ste m-to-g uid e clearance IN 0.010 0.037 (0.0004 0.0015)

0.025 0.052 (0.0010 0.0020)

16.3 16.5 (0.64 0.65)

16.3 16.5 (0.64 0.6 5)

0.90 - 1.10 (0.035 - 0.043)

EX

Valve gu ide project ion

ab ove cv linder head

IN

EX

Val ve seat widt h IN/EX 1.5 (0.06)

Valve spr ing

f ree len qt h

Inner IN/EX 37. 4 (1.47)

40.6 (1.60)

25.978 - 25.993 (1.0228 - 1.0233)

35.4 (1.39)

Outer IN/EX 38.6 (1.52)

Va lve lifte r Va lve lifte r O.D. IN/EX 25.97 (1.022)

Valv e lift er bore I.D. IN/EX 26.010 - 26.026 (1.0240 - 1.0246) 26.04 (1.025)

Cams haft Cam lo be hei ght IN 38.54 - 38.78 (1.517 -1 .527) 38.24 (1.506)

EX 38.30 -38 .54 (1.508 - 1.517) 38.00 (1.496)

Runo ut

Oil clearance 0.020 -0 .074 (0.0008 -0 .0029)

0.05 (0.002)

0.10 (0.004)

1-7

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$28.99

Viewed 45 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$28.99

This Workshop Repair Manual for the HONDA CBR1100XX 1997-1998 contains comprehensive information for repairing, maintaining, rebuilding, refurbishing, and restoring your vehicle. It is a valuable resource for both professional technicians and DIY enthusiasts.

- All repair procedures are covered extensively from A-Z.

- Includes high-quality photos, illustrations, and diagrams.

Whether you are a professional or a DIY enthusiast, this manual will help you save significantly on service and repair costs. It provides easy access to complete repair procedures that can be viewed, printed, and utilized without requiring advanced computer skills.

Compatible with Microsoft Windows 95, 98, 98SE, 2000, NT, ME, XP, Vista, and Windows 7, this manual is also suitable for use on all Mac computers.