2004 Honda CBR1000RR Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

HOW TO USE THIS MANUAL

This service manual describes the servic e procedures lor the

CBR 1000 RR-4.

Follow the Maintenance SChedule (Section 4) recommendations to

ensure that the vehicle is in peak operating condition and the emission

levels are within the standards set by the U.S. Environmental Protection

Agency, California Air Resources Board and Transport Canada .

Perlorming the first scheduled maintenance is very important. 1\

compensates for the initial wear that occurs during the break-in period.

Sections 1 and 4 apply to the whole motorcycle. Section 3 illustrates

procedures tor removal/installation of components thai may be required

10perform service described in the following sections.

Section 5 through 20 descri be pari s of the motorcycle , grouped

acco rding to location.

Find the section you want on this page, then turn to the table of contents

on the first page of the sectio n.

Most sectio ns start with an assembly or system illustra tion , service

information and troubleshooting lor the section. The subsequent pages

give detailed procedure.

If you are not familiar with this motorcycle , read Technical Featu res in

Section 2.

If you don't knOW" the source 'of the trouble, go to section 22

TroubleShooting .

Your safety, and the safety of others, is very important. To help you

make informed decisions we have provide d safety messages and

other informalion throughout this manual. Of course, it is not

practical or possible to warn you about all the hazards associated

with ser vicing this vehicle.

You must use your own good judgement.

You will find important safety information in a variety of forms

including: .

• Safety Labels - on the vehicle

• Safety Messages - preceded by a safety alert symbol & and

one of three signal words, DANGER, WARN ING , or CAUTION.

These signal words mean :

~ You WILL be KILLED or SERIOUSLY

~ HURT if you don't fellow instructions.

~ You CAN be KILLED or SERIOUSLY HURT

~ if you don't f ollOW" instructions.

~ You CAN be HURT if you don 't follow

~ instructions.

• Instructions - how to service this vehicle correctly and safely.

As you read this manual, you will find information mat is preceded by a

CNOnC(] symbol . The purpose of this message is to help prevent

damage to your vehicle, other property, Of the environment.

Date of Issue: March, 2004

CONTENTS

GENERAL INFORMATION

TECHNICAL FEATURES

FRAME/BODY PANELS/EXHAUST

SYSTEM

MAINTENANCE

LUBRICATION SYSTEM

z

« COOLING SYSTEM

II:

I-

w ENGINE REMOVAUINSTALLATION

>

0:

CYLINDER HEADNALVES c

c

z

CLUTCH/STARTER CLUTCH

«

w

z

ALTERNATOR

a

z

w

TRANSMISSION/GEARSHIFT LINKAGE

CRANKCASE/CRANKSHAFT/BALANCER/

PISTON/CYLINDER

FRONT WHEEUSUSPENSION/

(J)

STEERING

Cii

(J)

REAR WHEEUSUSPENSION

«

J:

o

HYDRAULIC BRAKE

BATTERY/CHARGING SYSTEM

..J

IGNITION SYSTEM

«

o

0:

ELECTRIC STARTER

I-

U

W

..J

LIGHTS/METERS/SWITCHES

w

WIRING DIAGRAM

TROUBLESHOOTING

INDEX

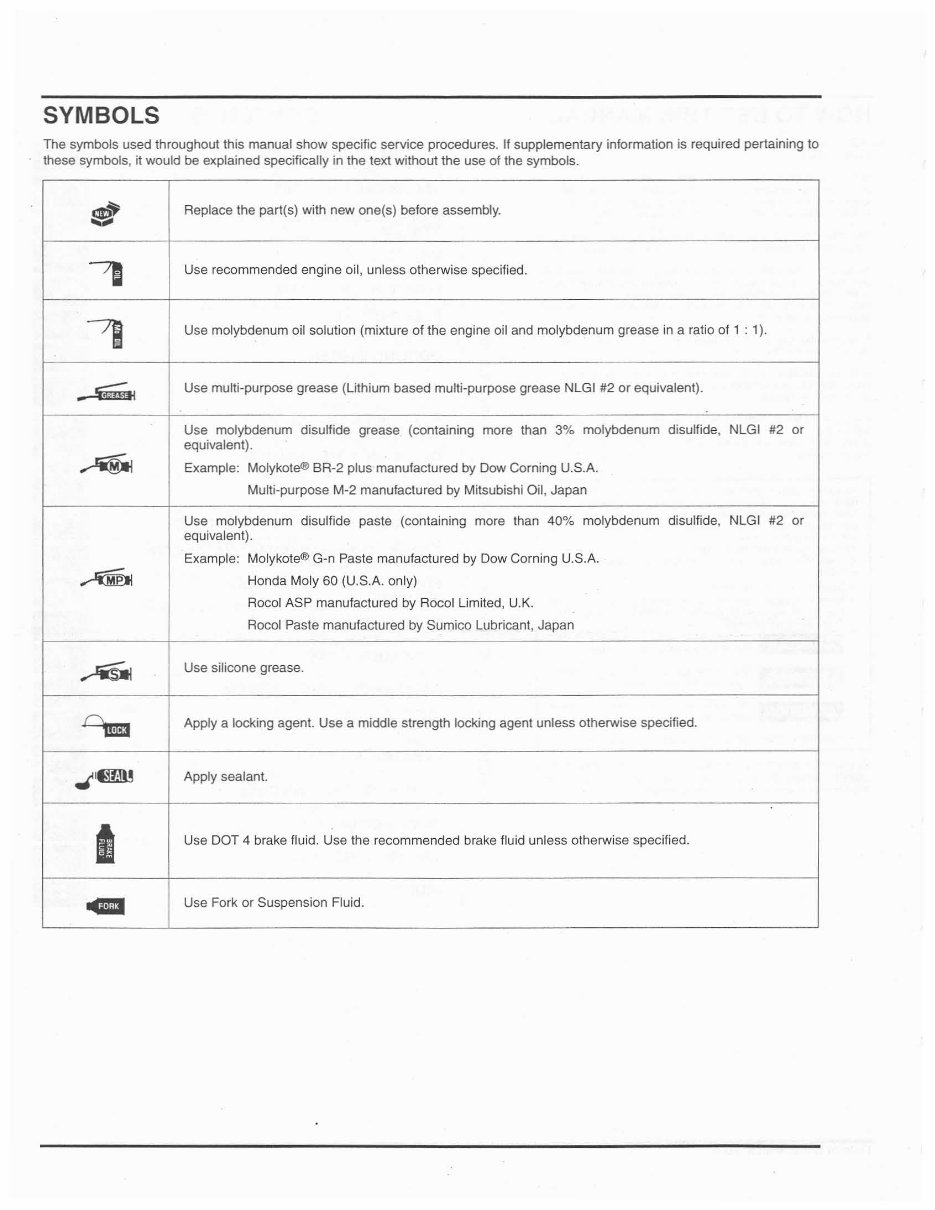

SYMBOLS

The symbols used throughout this manual show specific service procedures. If supplementary information is required pertaining to

these symbols, it would be explained specifically in the text without the use of the symbols.

~

Replace the part(s) with new one(s) before assembly.

S

-,

Use recomme nded engine oil, unless otherwise specified.

~

Use molybdenum oil solution (mixture of the engine oil and molybdenum grease in a ratio of 1 : 1).

_-$iiiffi

Use multi-purpose grease (Lithium based multi-purpose grease NLGI #2 or equivalent).

Use molybdenum disulfide grease (containing more than 3% molybdenum disulfide, NLGI #2 or

equivalent).

~

Example: Molykote® BR-2 plus manufactured by Dow Corning U.S.A.

MUlti-purpose M-2 manufactured by Mitsubishi Oil, Japan

Use molybdenum disulfide paste (containing more than 40% molybdenum disulfide, NLGI #2 or

equivalent).

Exampl e: Molykote® G-n Paste manufactu red by Dow Corning U.S.A.

~ Honda Moly 60 (U.S.A. only)

Rocol ASP manufactured by Rocol Limited, U.K.

Rocol Paste manufactured by Sumico Lubricant, Japan

~

Use silicone grease.

0

Apply a locking agent. Use a middle strength locking agent unless otherwise specified.

MJ

",,'Uill

Apply sealant.

I

Use DOT 4 brake fluid. Use the recommended brake fluid unless otherwise specified.

..

Use Fork or Suspension Fluid.

1. GENERAL INFORMATION

•

SERVICE RULES 1-2

MODEL IDENTIFiCATION..···························· 1-2

GENERAL SPECiFiCATIONS..·..·..··..··..· ........ 1-4

LUBRICATION SYSTEM

SPECiFiCATIONS··..····..··..·..··..··..··..· ....··..····· 1-6

FUEL SYSTEM (Programmed Fuel

Injection) SPECiFiCATIONS · · 1-6

COOLING SYSTEM SPECIFICATIONS ......... 1-6

CYLINDER HEADIVALVES

SPECiFiCATIONS .... ·· ...... ·..··..·····..··..···..··· ....· 1-7

CLUTCH/STARTER CLUTCH

SPECiFiCATIONS ..........··..··....···· ........· ....· ....· 1-7

TRANSMISSION/GEARSHIFT LINKAGE

SPECIFICATIONS 1-8

CRANKCASE/CRANKSHAFT/BALANCER/

PISTON/CYLINDER SPECIFICATIONS 1-8

FRONT WHEEl/SUSPENSION/STEERING

SPECiFiCATIONS ·..·..··..· ...... · ....·..· ........ ·..······ 1-9

REAR WHEEL:/SUSPENSION

SPECIFICATIONS · · · ·..1-9

HYDRAULIC BRAKE

SPECIFICATIONS..··..···..·..··..··..·· ...... ·..·....·..·1-10

BATTERY/CHARGING SYSTEM

SPECIFICATIONS..··..· ....·· .... ···..·..·..··..···..··..·1-10

IGNITION SYSTEM SPECIFICATIONS ........ 1-10

ELECTRIC STARTER SPECIFICATIONS ·.... ·1-10

LIGHTS/METERS/SWITCHES

SPECIFICATIONS··..·..·· ...... ··· ........···..·..·· ...... 1-11

STANDARD TORQUE VALUES ...... ··..··..· .... 1-12

ENGINE & FRAME TORQUE VALUES ....··..1-12

LUBRICATION & SEAL POINTS ...... ·........ ·..1-20

. CABLE & HARNESS ROUTING ·..1-24

EMISSION CONTROL SYSTEMS ..··.... ····..··1-36

EMISSION CONTROL INFORMATION

LABEL (U.S.A. ONLY)·...... ···· ....··..··..··· ........ ·1-39

1-1

GENERAL INFORMATION

SERVICE RULES

1. Use genuine Honda or Honda-reco mmended parts and lubricants or their equivalents. Parts that don 't meet Honda's

design specificat ions may cause damage to the moto rcycle.

2. Use th e special too ls des igned for this product to avoid damage and inco rrect assembly.

3. Use on ly metric tools when servicing the motorcycle . Metric bolts, nuts and screws are not interchangeable with

English fasteners.

4. Install new gaskets, Ovrinqs, cotter pins, and lock plat es when reassembling.

5. Wh en t ighte ning bolts or nuts, begin with the large r diameter or inner bolt first. Then tighten to the spec ified torque

diag onall y in in crem ental steps unless a parti cular sequence is specified.

6. Clean part s in cleani ng solve nt upon disassembly. Lubricate any slidi ng surfaces before reassembly .

7. Aft er reassem bly, check all parts for proper in sta llation and operation.

S. Route all electrical w ires as shown in the Cab le an d Harness Rout ing (page 1-24).

MODEL IDENTIFICATION

1-2

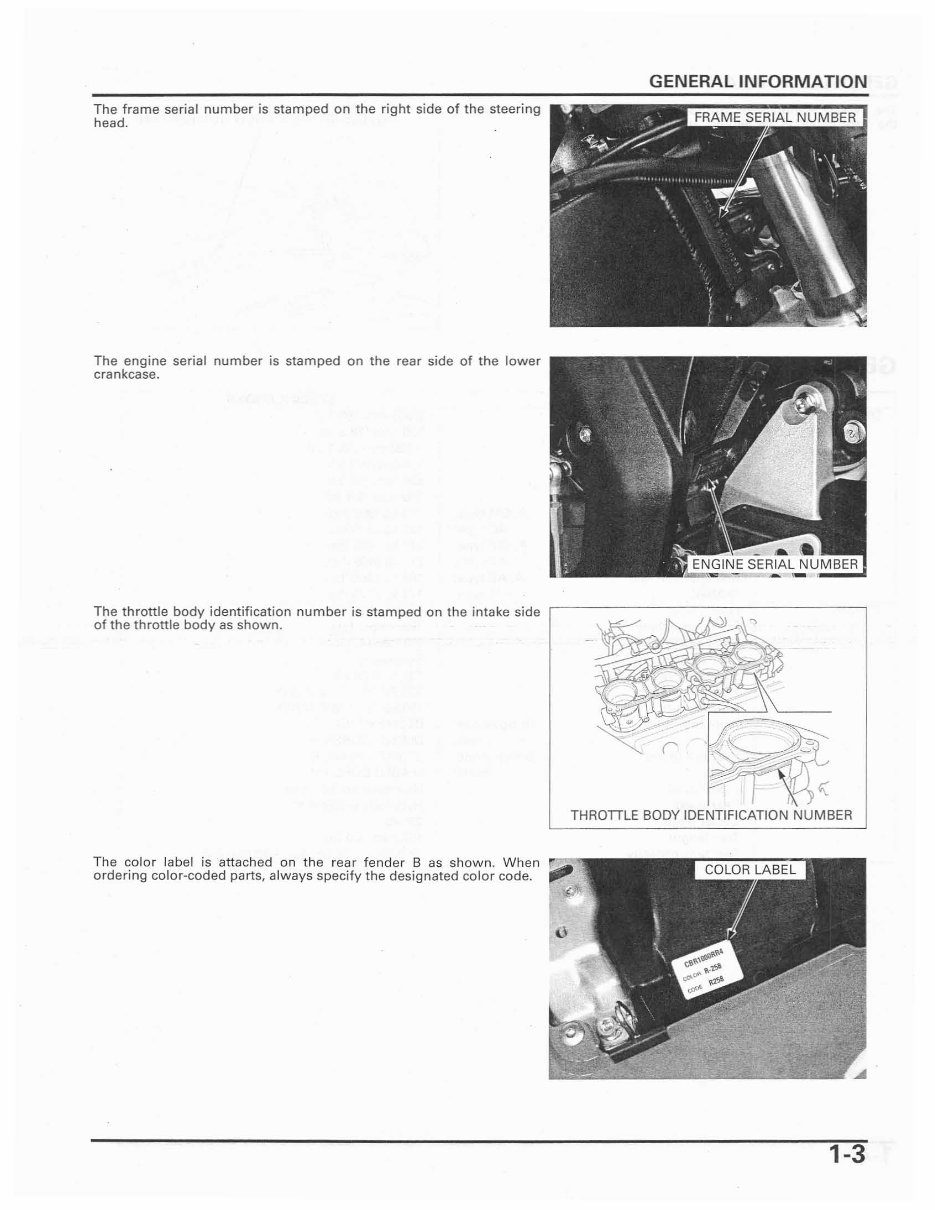

The frame serial nu mber is stamped on the right side of the stee ring

head.

The engine serial number is stamped on the rear side of the lower

crankcase.

The th rottle body ide ntificat ion num ber is stamped on the intake side

of the throttl e body as shown .

The co lor label is attached on the rear fender B as show n. When

order ing color-coded parts, always specify the designated color code.

GENERAL INFORMATION

"

THROTTLE BODY IDENT IFICATION NUMBER

1-3

GENERAL INFORMATION

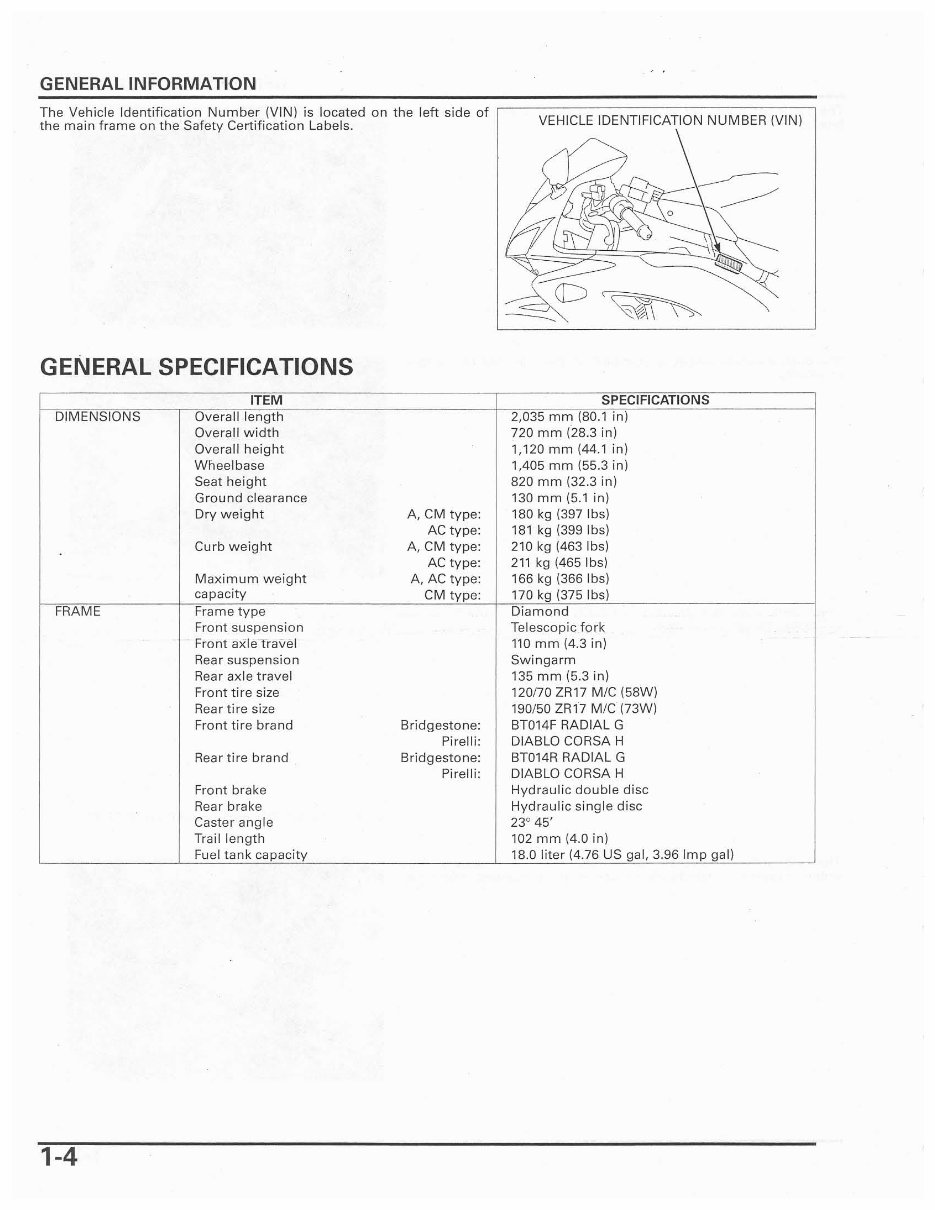

The Vehicle Ident ificat ion Number (VIN) is located on the l eft side of

the main frame on the Safety Certification Labels.

GENERAL SPECIFICATIONS

VEHICLE IDENTIFICATiON NUMBER (VIN)

ITEM SPECIFICATIONS

DIMENSIONS Overall length 2,035 mm (80.1 in )

Overa ll width 720 mm (28.3 in )

Overa ll height 1,120 mm (44.1 in)

Wheelbase 10405 mm (55.3 in )

Seat heig ht 820 mm (32.3 in)

Ground clea rance 130 mm (5.1 in)

Dry weig ht A, CM type : 180 kg (397 Ibs)

AC type: 181 kg (399 Ibs)

Curb weight A, CM type: 210 kg (463 lbs)

AC ty pe: 211 kg (465 Ibs)

M ax imum weight A. AC t ype : 166 kg (366 Ibs)

capac ity

CM type : 170 kg (375 Ibs)

FRAME Frame type Diamo nd

Fro nt suspens ion Telescopi c fork

Front axle tra vel 110 mm (4.3 in)

Rear suspension Swinga rm

Rear axle tra ve l 135 mm (5.3 in)

Front tire size 120170 ZR17 M /C (58W)

Rear tire size 190 /50 ZR17 M /C (73W)

Front tire brand Bridgestone: BT014F RADIAL G

Pirell i: DiAB LO CORSA H

Rear tire brand Bridgestone: BT014R RADIAL G

Pirelli: DIABLO CORSA H

Front brake Hydraulic double disc

Rear brake Hydraulic single disc

Caster angle 23

04

5'

Trail length 102 m m (4.0 in )

Fuel tank capacity 18.0 liter (4.76 US gal, 3.96 Imp gal )

1-4

GENERAL INFORMATION

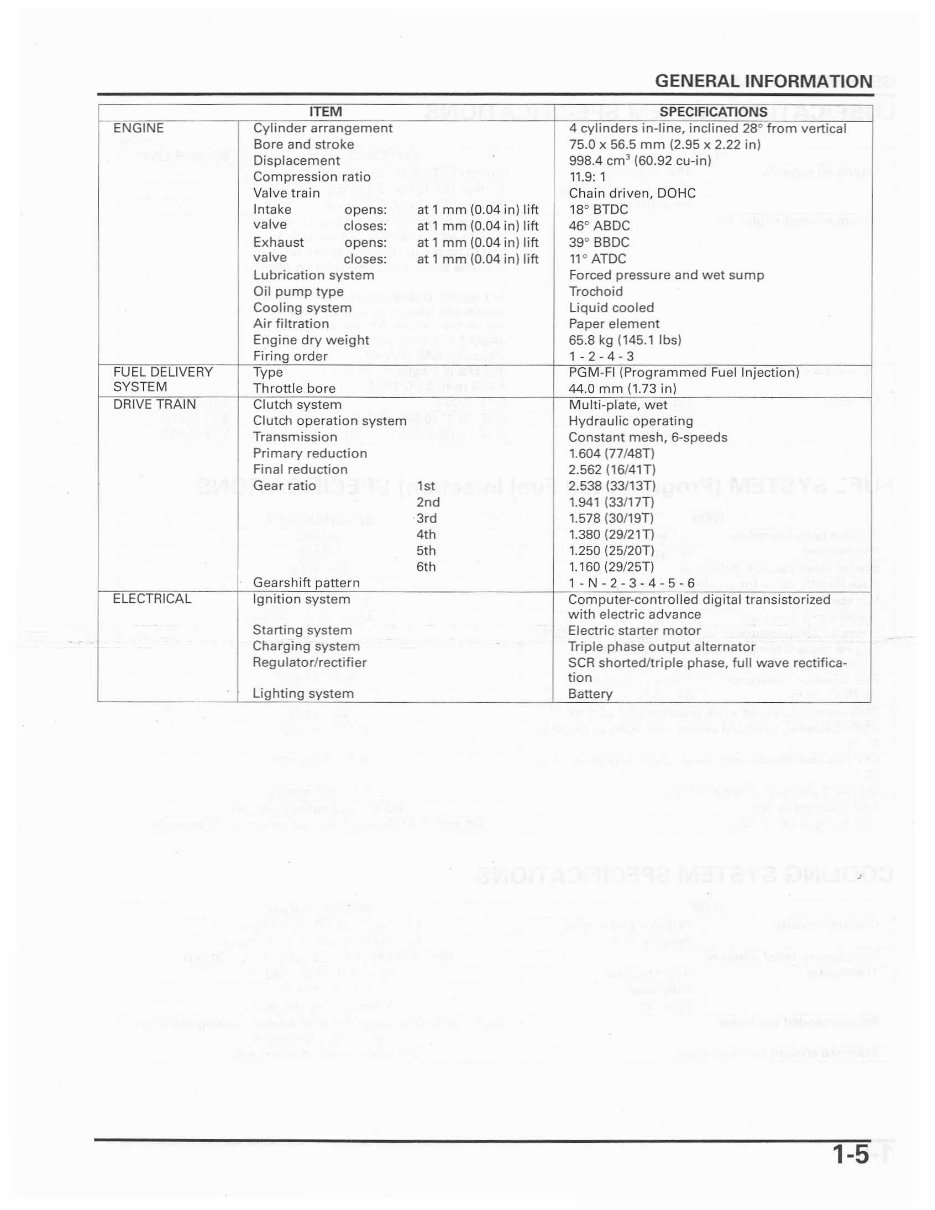

ITEM SPECIFICATIONS

ENGINE Cylinder arra ngement 4 cylinders in-line, inclined 28° from vertical

Bore and stroke 75.0 x 56.5 mm 12.95 x 2.22 in )

Displacem ent 998.4 em' (60.92 cu -ln]

Compression ratio 11 .9: 1

Valve train Chain driven, DOHC

Intake opens: at 1 m m 10.04 in ) lift 18' BTDC

va lve

closes: at 1 m m 10.04 in) lift 46' ABDC

Exh aust opens: at 1 m m (0.04 in) lift 39' BBDC

valve

closes: at 1 mm (0.04 in) lift 11 ' ATDC

Lubrication system Fo rced pressu re and w et sump

Oil pump type Trochoid

Cooling system Liquid cooled

Air filtration Paper eleme nt

Engi ne dry weigh t 65.8 kg (145.1 Ibs)

Firing order 1 -2 -4 -3

FUEL DELIVERY Type PGM-FI (Programmed Fuel Inj ection )

SYSTEM

Th rottle bore 44.0 mm (1.73 in)

DRIVE TRAIN Clutch system Multi -plate, wet

Clutch operation system Hydr aulic ope rati ng

Transmission Constant mes h, 6-speeds

Primary reduc tion 1.604 (77/48T)

Final reduction 2.562 (16/41T)

Gear ratio 1st 2.538 (33/13T)

2nd 1.941 133/17T)

3rd 1.578 130/19T)

4th 1.380 (29/21T)

5th 1.250 (25/20T)

6t h 1.160 (29/25T)

Gearshift pattern 1- N-2 -3 -4 -5-6

ELECTRICAL Ign ition syste m Co mp ute r-co nt rolle d digital transistorized

w ith electric adva nce

Starting system Electric starter motor

Charging system Triple phase output alternator

Regulator/rectifier SCR shorted/triple phase, full wave rectifica-

tion

Lighting system Battery

1-5

GENERAL INFORMATION

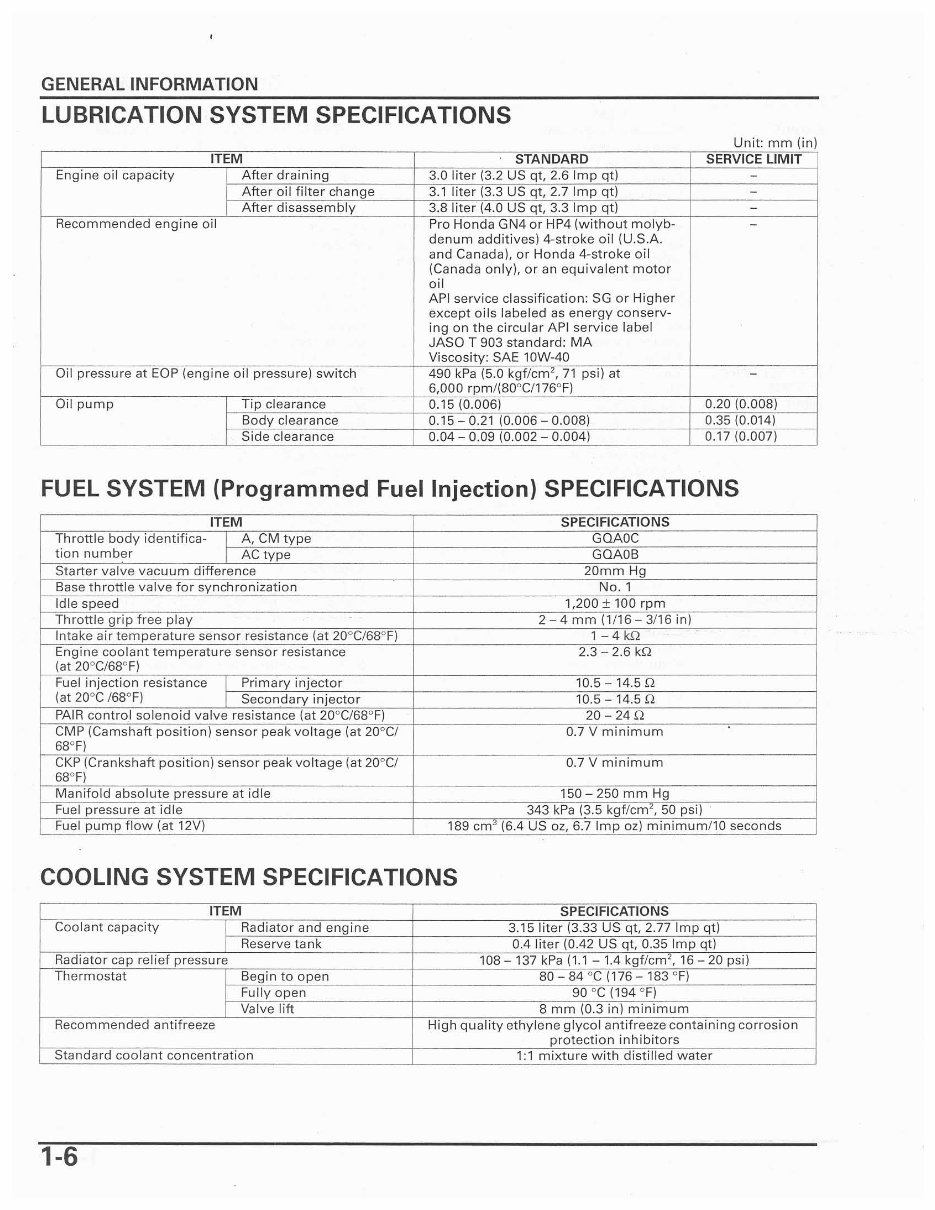

LUBRICATION SYSTEM SPECIFICATIONS

Unit: mm (in)

ITEM STAN DARD SERVICE LIMIT

Eng i ne oil capacity After draining 3.0 liter (3.2 US qt. 2.6 Imp qt) -

After oil filter change 3.1 liter (3.3 US qt, 2.7 Imp qt )

After disassembly 3.8 liter (4.0 US qt, 3.3 Imp qt )

Recommended engine oil Pro Honda GN4 or HP4 (w ithout molyb- -

denum additives) 4·stroke oil (U.S.A.

and Canada), or Honda 4-stroke oil

(Canada only), or an equivalent motor

oil

API service classificat ion: SG or Highe r

except oils labeled as energy conserv-

ing on the circular API service label

JASO T 903 sta nda rd : MA

Viscosity: SAE 10W-40

Oil pressure at EOP (engine oil pre ssure ) swit ch 490 kPa 15.0 kgfle m ' , 7 1 p si) at

6,000 rpm /(80°C/176°F)

Oil pump Tip cl earance 0. 15 (0.006 ) 0.20 (0.008)

Body clearance 0.15 - 0.21 (0.006 - 0.008 ) 0.3510.014)

Side clearance 0.04 0.0910.002 0.004) 0.17 (0.007)

FUEL SYSTEM (Programmed Fuel Injection) SPECIFICATIONS

ITEM SPECIFICATIONS

Thr ottle body identifica-

I

A, CM typ e GQAOC

tion number

I

AC type GQAOB

Starter valve vacuum difference 20mm Hg

Base throttle valve for synchronization No .1

Idle speed 1,200 ± 100 rpm

Throttle grip free play

.

2-4 mm (1/16 - 3/16 in)

Intake air temperature sensor resistance (at 20°C/68°F) 1 4 kQ

Engine coolant t empe rature sensor resistance 2.3 2.6 kQ

(at 20°C/68°F)

Fuel injection resistance

I

Primary injector 10.5 14.5 Q

(at 20°C 168' F)

I Secondary injector 10.5 - 14.5 Q

PAIR control solenoid valve resistance (at 20°C/68°F) 20 24 Q

CMP (Camshaft position) sensor peak voltage (at 20°CI 0.7 V minimum

68' F)

CKP (Crankshaft position ) sensor peak voltage (at 20°CI 0.7 V min imum

68'F )

Manifold absolute pressure at idle 150 250 mm Hg

Fuel pressure at idle 343 kPa (3.5 kgf/em ' , 50 psi )

Fuel pump flow (at 12V ) 189 em (6.4 US oz, 6.7 Imp oz) mi nimum /10 seconds

COOLING SYSTEM SPECIFICATIONS

ITEM SPECIFICATIONS

Coolant capacity Radiator and engine 3.15 liter (3.33 US qt. 2.77 Imp qt)

I

Reserve tank 0.4 liter 10.42 US qt , 0.35 Imp qt)

Radiator cap relief pressure 108- 137 kPa 11.1 - 1.4 kgf/em ' , 16 - 20 psi)

The rmost at Begin to open 80 84 °C (176 183 OF)

Full y op en 90 °C 1194 'F)

Valve lift 8 mm (0.3 in) minimum

Recommended antifreeze High qual ity ethy lene glyco l ant ifreeze conta ining corrosion

protection inhibitors

Standard coolant concentration 1:1 mixture with distilled water

1-6

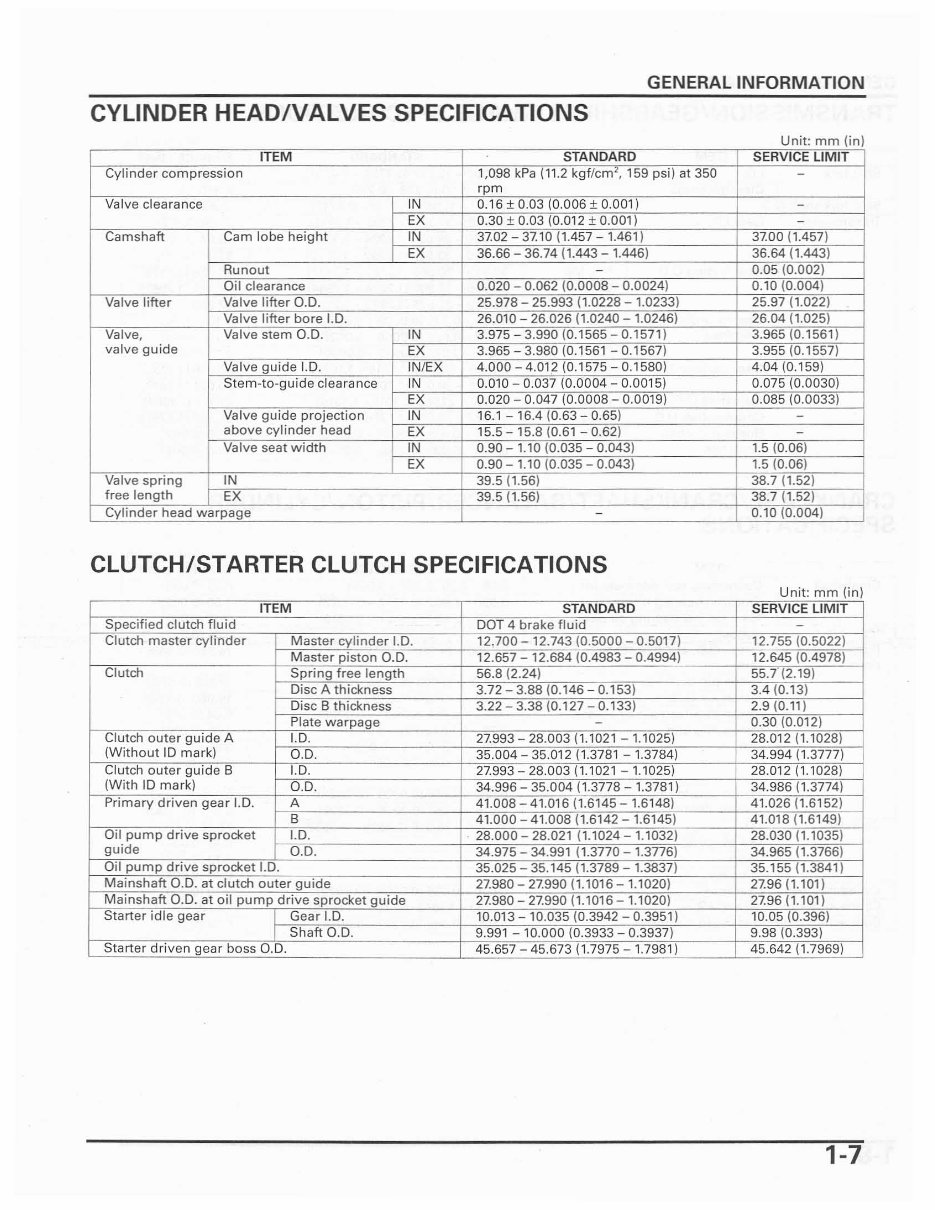

CYLINDER HEAD/VALVES SPECIFICATIONS

GENERAL INFORMATION

Unit· mm (in)

ITEM STANDARD SERVICE LIM IT

Cylinder compression 1,098 kPa (11.2 kgflc m', 159 psi ) at 350 -

rpm

Valve clearance IN 0.1 6 + 0.03 (0.006 ± 0.001)

-

EX 0.30 ± 0 .03(0 .012 + 0.001)

-

Cam sh aft Cam lo be he ig ht IN 37.02 - 37.10 (1.457 1.461 ) 37 .00 (1.457)

EX 36 .66 - 36 .74 (1.443 - 1.446 ) 36.64 (1.443)

Runout 0.05 (0.002)

Oil clearance 0.020 0.062 (0.0008 0 .0024) 0.10 (0.004)

Valve lifter Valve lifter 0.0. 25.978 - 25.993 (1.0228 - 1. 0233 ) 25.97 (1.022)

Valve lifter bore 1. 0. 26 .010 26.026 (1.0240 1.0246) 26.04 (1.025)

Valve , Valve stem 0 .0 . IN 3.975 3.990 (0.1565 0 .1571 ) 3.965 (0.1561)

valve guide

EX 3.965 - 3.980 (0.1561 - 0.1567) 3.955 (0.1557)

Valve guide 1. 0. iN/E X 4.000 4.01.2(0.1575 0.1580) 4.04 (0.159)

Ste m-ta -guide clearance IN 0.010 - 0.037 (0.0004 0.00 15) 0. 075 (0.0 030 )

EX 0.020 - 0.047 (0.0008 - 0 .0019 ) 0.085 (0.0033)

Valve guide projection IN 16.I 16.4 (0.63 0.65) -

above cylinder head

EX 15.5 - 15.8(0 .61 0.62 )

Valve seat width IN 0.90 - 1.10 (0.035 - 0.043) 1.5 (0.06)

EX 0.90 1.10 (0 .03 5 0.043) 1.5 (0.06)

Valve spring IN 39 .5 (1.56) 38 .7 (1.52)

fre e leng th

EX 39 .5 (1.56) 38.7 (1.52)

Cylinder head warpage - 0.10 (0.004)

CLUTCH/STARTER CLUTCH SPECIFICATIONS

Unit: mm (in)

ITEM STANDARD SERVICE LIMIT

Spe cified clutch fluid DOT 4 brak e flu id -

Clutch master cylinder Ma ster cylinder 1.0. 12,7 00 - 12.743 (0.5000 0.5017) 12.755 (0.5022)

Mast er piston 0 .0 . 12.657 - 12.684 (0.4983 - 0.4994 ) 12.645 (0.4978)

Clutch Spring free length 56.8 (2.24) 55 .7 (2.19 )

Disc A thickn ess 3.72 3.88 (0.146 0.153) 3.4 (0.13)

Disc 8 th ickness 3.22 3.38 (0.127 0.133) 2.9 (0.11)

Plate warpage -

0.30 (0.012)

Clutch oute r guide A 1. 0. 27.993 28.003( 1.1021 1.1025) 28.012 (1.1028)

(Wit ho ut 10 mark)

0.0. 35.004 - 35.012 (1.3781 1.3784 ) 34.99 4( 1.3777)

Clutch outer guide 8 1. 0. 27.993 - 28. 003 (1.102 1 - 1.1025 ) 28. 012 (1.1028 )

(With iD ma rk)

0 .0 . 34.996 - 35.004 (1.3778 - 1.3781) 34.986( 1.3774)

Prim ary d rive n gea r 1. 0. A 41 .008 41.0 16(1.6145 -1.6 148 ) 4 1.026 (1.6152)

B 41.000 - 41.008 (1.6142 - 1.6145) 41.018 (1.6149)

Oil pump drive spro cket 1. 0. . 28 .000 28.021 (1.1024 - 1.10321 28 .030 (1.103 5)

guide

0 .0 . 34.975 34 .99 1 (1.377 0 1.3776) 34 .965 (1.376 6)

Oil pump dri ve sprock et I.D. 35.025 - 35.145 (1.3789 1.38 37 ) 35.155 (1.384 11

Main shaft 0 .0. at clutch oute r guide 27.980 - 27.990 (1.1016 - 1.10201 27.96 (1.1011

Mainshaft 0. 0 . at oil pump drive sprocket guide 27.980 27.990 (1.1016 - 1.10201 27.96 (1.101)

Starter idle gear I Ge ar 1. 0. 10.013 -1 0.035 (0.3942 - 0.39511 10.05 (0.396)

I S ha ft 0.0. 9.991 - 10.000 (0.3933 0.3937) 9.98 (0.393)

Starter driven gear boss 0. 0 . 45.657 - 45.673 (1.7975 1.798 1) 45.642 (1.7969)

1-7

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 95 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

This Service Repair Manual for the 2004 Honda CBR1000RR covers a wide range of essential topics, making it the most comprehensive guide ever compiled for this model. It includes high-quality diagrams and detailed instructions to effectively service and repair your vehicle. Whether you're a professional mechanic or a dedicated DIY enthusiast, this manual is an indispensable resource.

- General information

- Frame/body panels/exhaust system

- Maintenance

- Lubrication system

- Cooling system

- Fuel system

- Engine removal/installation

- Cylinder head/valve

- Clutch/gearshift linkage

- Alternator/starter clutch

- Crankcase/transmission

- Crankshaft/piston/cylinder

- Front wheel/suspension/steering

- Rear wheel/suspension

- Hydraulic brake

- Battery/charging system

- Ignition system

- Electric starter

- Lights/meters/switches

- Wiring diagram

- Troubleshooting

- Index

This service repair manual is available for instant access, saving you time and money on postage and packaging. It is compatible with all versions of Windows and Mac, and can be viewed using Adobe Reader. Don't miss out on the opportunity to enhance your repair and maintenance capabilities. Get your copy now and take control of your vehicle's upkeep.