Honda CBF600S/SA/N/NA Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

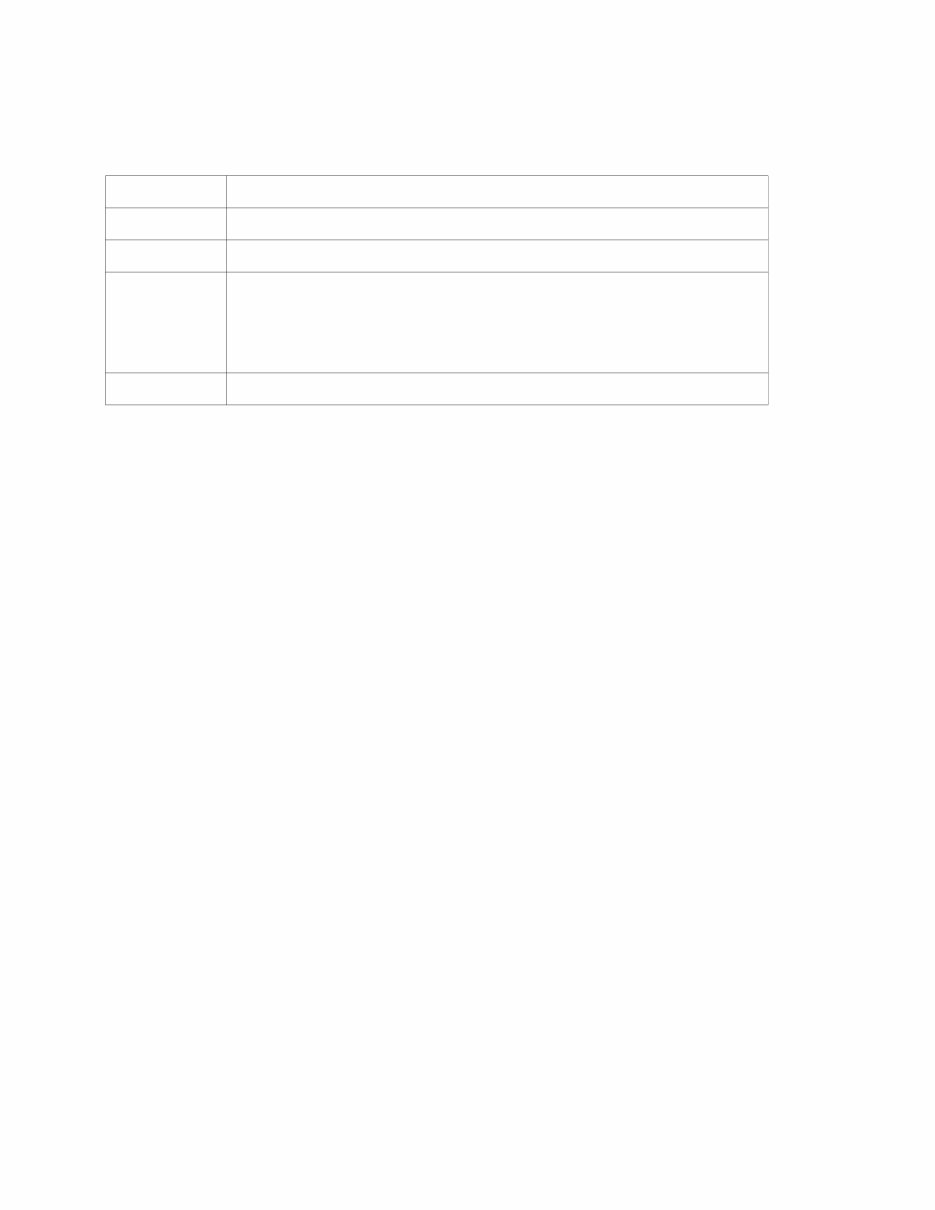

TYPE CODE

• Throughout this manual, the following abbreviations are used to identify individual model.

CODE AREA TYPE

E U.K, Ireland

F France, Belgium

ED

EUROPEAN DIRECT SALES

(Spain, Holland, Austria, Portugal, Belgium, Denmark, Greece, Italy, Macedonia,

Romania, Burgaria, Ukuraine, Israel, Finland, Germany, Sweden, Island, Russia,

Poland, Slovenia, Croatia, Latvia, Norway, Swiss, Luxemburug, Hungary, Czech,

Slovakia)

III ED Germany

A Few Words About Safety

Service Information

The service and repair information contained in this manual is intended for use by qualified, professional technicians.

Attempting service or repairs without the proper training, tools, and equipment could cause injury to you or others. It could also

damage the vehicle or create an unsafe condition.

This manual describes the proper methods and procedures for performing service, maintenance, and repairs. Some procedures

require the use of specially designed tools and dedicated equipment. Any person who intends to use a replacement part, service

procedure or a tool that is not recommended by Honda, must determine the risks to their personal safety and the safe operation of

the vehicle.

If you need to replace a part, use genuine Honda parts with the correct part number or an equivalent part. We strongly recommend

that you do not use replacement parts of inferior quality.

For Your Customer’s Safety

Proper service and maintenance are essential to the customer’s safety and

the reliability of the vehicle. Any error or oversight while servicing a vehicle

can result in faulty operation, damage to the vehicle, or injury to others.

For Your Safety

Because this manual is intended for the professional service technician, we

do not provide warnings about many basic shop safety practices (e.g., Hot

parts–wear gloves). If you have not received shop safety training or do not

feel confident about your knowledge of safe servicing practice, we

recommended that you do not attempt to perform the procedures described

in this manual.

Some of the most important general service safety precautions are given

below. However, we cannot warn you of every conceivable hazard that can

arise in performing service and repair procedures. Only you can decide

whether or not you should perform a given task.

Important Safety Precautions

Make sure you have a clear understanding of all basic shop safety practices and that you are wearing appropriate clothing and

using safety equipment. When performing any service task, be especially careful of the following:

• Read all of the instructions before you begin, and make sure you have the tools, the replacement or repair parts, and the skills

required to perform the tasks safely and completely.

• Protect your eyes by using proper safety glasses, goggles or face shields any time you hammer, drill, grind, pry or work around

pressurized air or liquids, and springs or other stored-energy components. If there is any doubt, put on eye protection.

• Use other protective wear when necessary, for example gloves or safety shoes. Handling hot or sharp parts can cause severe

burns or cuts. Before you grab something that looks like it can hurt you, stop and put on gloves.

• Protect yourself and others whenever you have the vehicle up in the air. Any time you lift the vehicle, either with a hoist or a jack,

make sure that it is always securely supported. Use jack stands.

Make sure the engine is off before you begin any servicing procedures, unless the instruction tells you to do otherwise.

This will help eliminate several potential hazards:

• Carbon monoxide poisoning from engine exhaust. Be sure there is adequate ventilation whenever you run the engine.

• Burns from hot parts or coolant. Let the engine and exhaust system cool before working in those areas.

• Injury from moving parts. If the instruction tells you to run the engine, be sure your hands, fingers and clothing are out of the way.

Gasoline vapors and hydrogen gases from batteries are explosive. To reduce the possibility of a fire or explosion, be careful when

working around gasoline or batteries.

• Use only a nonflammable solvent, not gasoline, to clean parts.

• Never drain or store gasoline in an open container.

• Keep all cigarettes, sparks and flames away from the battery and all fuel-related parts.

Improper service or repairs can create an

unsafe condition that can cause your customer

or others to be seriously hurt or killed.

Follow the procedures and precautions in this

manual and other service materials carefully.

Failure to properly follow instructions and

precautions can cause you to be seriously hurt

or killed.

Follow the procedures and precautions in this

manual carefully.

HOW TO USE THIS MANUAL

This service manual describes the service procedures for the

CBF600S/SA/N/NA.

Follow the Maintenance Schedule (Section 3) recommendations to

ensure that the vehicle is in peak operating condition.

Performing the first scheduled maintenance is very important. It

compensates for the initial wear that occurs during the break-in

period.

Sections 1, 2 and 3 apply to the whole motorcycle. Section 2

illustrates procedures for removal/installation of components that may

be required to perform service described in the following sections.

Section 4 through 21 describe parts of the motorcycle, grouped

according to location.

Find the section you want on this page, then turn to the table of

contents on the first page of the section.

Most sections start with an assembly or system illustration, service

information and troubleshooting for the section. The subsequent

pages give detailed procedure.

If you don't know the source of the trouble, go to section 23

Troubleshooting.

Your safety, and the safety of others, is very important. To help

you make informed decisions we have provided safety

messages and other information throughout this manual. Of

course, it is not practical or possible to warn you about all the

hazards associated with servicing this vehicle.

You must use your own good judgement.

You will find important safety information in a variety of forms

including:

• Safety Labels – on the vehicle

• Safety Messages – preceded by a safety alert symbol and

one of three signal words, DANGER, WARNING, or CAU-

TION.

These signal words mean:

You WILL be KILLED or SERIOUSLY

HURT if you don’t follow instructions.

You CAN be KILLED or SERIOUSLY

HURT if you don’t follow instructions.

You CAN be HURT if you don’t follow

instructions.

• Instructions – how to service this vehicle correctly and safely.

As you read this manual, you will find information that is preceded by a

symbol. The purpose of this message is to help prevent

damage to your vehicle, other property, or the environment.

ALL INFORMATION, ILLUSTRATIONS, DIREC-

TIONS AND SPECIFICATIONS INCLUDED IN

THIS PUBLICATION ARE BASED ON THE

LATEST PRODUCT INFORMATION AVAIL-

ABLE AT THE TIME OF APPROVAL FOR

PRINTING. HONDA MOTOR CO., LTD.

RESERVES THE RIGHT TO MAKE CHANGES

AT ANY TIME WITHOUT NOTICE AND WITH-

OUT INCURRING ANY OBLIGATION WHATSO-

EVER. NO PART OF THIS PUBLICATION MAY

BE REPRODUCED WITHOUT WRITTEN PER-

MISSION. THIS MANUAL IS WRITTEN FOR

PERSONS WHO HAVE ACQUIRED BASIC

KNOWLEDGE OF MAINTENANCE ON HONDA

MOTORCYCLES, MOTOR SCOOTERS OR

ATVS.

Honda Motor Co., Ltd.

SERVICE PUBLICATION OFFICE

CONTENTS

GENERAL INFORMATION

FRAME/BODY PANELS/EXHAUST SYSTEM

MAINTENANCE

ENGINE AND DRIVE TRAIN

LUBRICATION SYSTEM

FUEL SYSTEM (PGM-FI)

COOLING SYSTEM

ENGINE REMOVAL/INSTALLATION

CYLINDER HEAD/VALVES

CLUTCH/STARTER CLUTCH/

GEARSHIFT LINKAGE

ALTERNATOR

FRONT WHEEL/SUSPENSION/

STEERING

REAR WHEEL/SUSPENSION

HYDRAULIC BRAKE

ANTI-LOCK BRAKE SYSTEM

(ABS; CBF600SA/NA)

BATTERY/CHARGING SYSTEM

IGNITION SYSTEM

ELECTRIC STARTER

LIGHTS/METER/SWITCHES

CHASSIS

ELECTRICAL

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

2

3

1

IMMOBILIZER SYSTEM (HISS)

CRANKSHAFT/PISTON/CYLINDER

CRANKCASE/TRANSMISSION

WIRING DIAGRAMS

TROUBLESHOOTING

23

Date of Issue: November, 2007

©honda Motor Co., Ltd.

INDEX

24

SYMBOLS

The symbols used throughout this manual show specific service procedures. If supplementary information is required pertaining to

these symbols, it would be explained specifically in the text without the use of the symbols.

Replace the part(s) with new one(s) before assembly.

Use recommended engine oil, unless otherwise specified.

Use molybdenum oil solution (mixture of the engine oil and molybdenum grease in a ratio of 1: 1).

Use multi-purpose grease (Lithium based multi-purpose grease NLGI #2 or equivalent).

Use molybdenum disulfide grease (containing more than 3% molybdenum disulfide, NLGI #2 or

equivalent).

Example: Molykote

®

BR-2 plus manufactured by Dow Corning U.S.A.

Multi-purpose M-2 manufactured by Mitsubishi Oil, Japan

Use molybdenum disulfide paste (containing more than 40% molybdenum disulfide, NLGI #2 or

equivalent).

Example: Molykote

®

G-n Paste manufactured by Dow Corning U.S.A.

Honda Moly 60 (U.S.A. only)

Rocol ASP manufactured by Rocol Limited, U.K.

Rocol Paste manufactured by Sumico Lubricant, Japan

Use silicone grease.

Apply a locking agent. Use a middle strength locking agent unless otherwise specified.

Apply sealant.

Use DOT 4 brake fluid. Use the recommended brake fluid unless otherwise specified.

Use Fork or Suspension Fluid.

1-1

1

1. GENERAL INFORMATION

SERVICE RULES ········································· 1-2

MODEL IDENTIFICATION··························· 1-3

GENERAL SPECIFICATIONS······················ 1-6

LUBRICATION SYSTEM

SPECIFICATIONS········································ 1-8

FUEL SYSTEM (PGM-FI)

SPECIFICATIONS········································ 1-8

COOLING SYSTEM SPECIFICATIONS ······ 1-8

CYLINDER HEAD/VALVES

SPECIFICATIONS········································ 1-9

CLUTCH/STARTER CLUTCH/

GEARSHIFT LINKAGE SPECIFICATIONS·· 1-9

CRANKCASE/TRANSMISSION

SPECIFICATIONS······································ 1-10

CRANKSHAFT/PISTON/CYLINDER

SPECIFICATIONS······································ 1-10

FRONT WHEEL/SUSPENSION/STEERING

SPECIFICATIONS ····································· 1-11

REAR WHEEL/SUSPENSION

SPECIFICATIONS ····································· 1-11

HYDRAULIC BRAKE SPECIFICATIONS··· 1-12

BATTERY/CHARGING SYSTEM

SPECIFICATIONS ····································· 1-12

IGNITION SYSTEM SPECIFICATIONS ···· 1-12

ELECTRIC STARTER SPECIFICATIONS ·· 1-13

LIGHTS/METERS/SWITCHES

SPECIFICATIONS ····································· 1-13

STANDARD TORQUE VALUES··············· 1-14

ENGINE & FRAME TORQUE VALUES ···· 1-14

LUBRICATION & SEAL POINTS ·············· 1-21

CABLE & HARNESS ROUTING ··············· 1-24

EMISSION CONTROL SYSTEMS ············ 1-48

GENERAL INFORMATION

1-2

GENERAL INFORMATION

SERVICE RULES

1. Use genuine Honda or Honda-recommended parts and lubricants or their equivalents. Parts that don't meet Honda's

design specifications may cause damage to the motorcycle.

2. Use the special tools designed for this product to avoid damage and incorrect assembly.

3. Use only metric tools when servicing the motorcycle. Metric bolts, nuts and screws are not interchangeable with

English fasteners.

4. Install new gaskets, O-rings, cotter pins, and lock plates when reassembling.

5. When tightening bolts or nuts, begin with the larger diameter or inner bolt first. Then tighten to the specified torque

diagonally in incremental steps unless a particular sequence is specified.

6. Clean parts in cleaning solvent upon disassembly. Lubricate any sliding surfaces before reassembly.

7. After reassembly, check all parts for proper installation and operation.

8. Route all electrical wires as show in the Cable and Harness Routing (page 1-24).

ABBREVIATION

Throughout this manual, the following abbreviations are used to identify the respective parts or systems.

Abbrev. term Full term

ABS Anti-lock Brake System

CKP sensor Crankshaft Position sensor

DLC Data Link Connector

DTC Diagnostic Trouble Code

ECM Engine Control Module

ECT sensor Engine Coolant Temperature sensor

EEPROM Electrically Erasable Programmable Read Only Memory

EOP switch Engine Oil Pressure switch

HDS Honda Diagnostic System

HISS Honda Ignition Security System

IACV Idle Air Control Valve

IAT sensor Intake Air Temperature sensor

IDC solenoid valve Intake Duct Control solenoid valve

MAP sensor Manifold Absolute Pressure sensor

MIL Malfunction Indicator Lamp

PAIR Pulsed Secondary Air Injection

PCV Proportional Control Valve

PGM-FI Programmed Fuel Injection

SCS connector Service Check Short connector

TP sensor Throttle Position sensor

VS sensor Vehicle Speed sensor

GENERAL INFORMATION

1-3

MODEL IDENTIFICATION

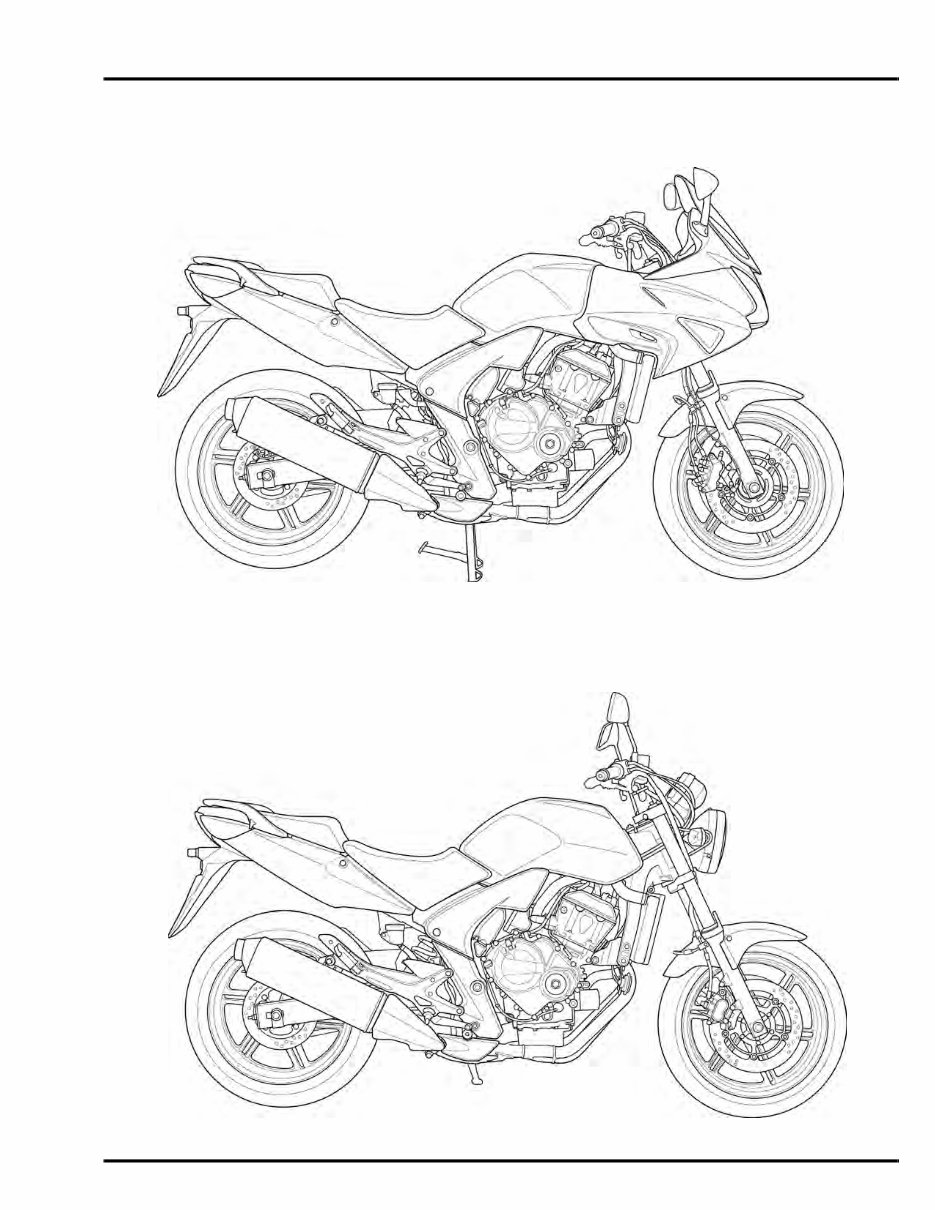

CBF600SA shown:

CBF600N shown:

GENERAL INFORMATION

1-4

SERIAL NUMBERS

The Vehicle Identification Number (V.I.N) is stamped on the right side

of the steering head.

The registered number plate is located on left side of the frame tube.

The engine serial number is stamped on the right side of the upper

crankcase.

The throttle body identification number is stamped on the throttle

body as shown.

VEHICLE IDENTIFICATION NUMBER

REGISTERED NUMBER PLATE

ENGINE SERIAL NUMBER

THROTTLE BODY IDENTIFICATION NUMBER

GENERAL INFORMATION

1-5

LABEL

The color label is attached to the frame under the seat. When ordering

color-coded parts, always specify the designated color code.

COLOR LABEL

GENERAL INFORMATION

1-6

GENERAL SPECIFICATIONS

ITEM SPECIFICATIONS

DIMENSIONS Overall length 2,160 mm (85 in)

Overall width 765 mm (30 in)

Overall height CBF600S/SA Wind screen STD 1,240 mm (49 in)

Wind screen HIGH 1,285 mm (51 in)

CBF600N/NA 1,110 mm (44 in)

Wheelbase 1,490 mm (59 in)

Seat height 785 ± 15mm (31 ± 0.6in)

Footpeg height 325 mm (12.8 in)

Ground clearance 136 mm (5.4 in)

Curb weight CBF600S 217 kg (478 lbs)

CBF600SA 222 kg (489 lbs)

CBF600N 213 kg (470 lbs)

CBF600NA 218 kg (481 lbs)

Maximum weight capacity 195 kg (430 lbs)

FRAME Frame type Diamond

Front suspension Telescopic fork

Front axle travel 108 mm (4.3 in)

Rear suspension Swingarm

Rear axle travel 120 mm (4.7 in)

Front tire size 120/70 ZR 17M/C (58W)

Rear tire size 160/60 ZR 17M/C (69W)

Front tire brand BT-57F RADIAL U

(Bridgestone)

PILOT ROAD B (Michelin)

Rear tire brand BT-57R RADIAL E

(Bridgestone)

PILOT ROAD A (Michelin)

Front brake Hydraulic double disc

Rear brake Hydraulic single disc

Caster angle 26° 00’

Trail length 110 mm (4.3 in)

Fuel tank capacity 20 liter

(5.28 US gal, 4.40 lmp gal)

Fuel reserve capacity 4.0 liter

(1.06 US gal, 0.88 lmp gal)

ENGINE Cylinder arrangement 4 cylinders in-line, inclined 30°

from vertical

Bore and stroke 67.0 X 42.5 mm (2.64 X 1.67 in)

Displacement 599 cm

3

(36.5 cu-in)

Compression ratio 11.6: 1

Valve train Chain driven, DOHC

Intake valve opens at 1 mm (0.04 in)

lift

15° BTDC

closes at 1 mm (0.04 in)

lift

15° ABDC

Exhaust valve opens at 1 mm (0.04 in)

lift

30° BBDC

closes at 1 mm (0.04 in)

lift

0° ATDC

Lubrication system Forced pressure and wet sump

Oil pump type Trochoid

Cooling system Liquid cooled

Air filtration Paper element

Engine dry weight 57.3 kg (126.4 lbs)

Firing order 1 - 2 - 4 - 3

FUEL

DELIVERY

SYSTEM

Type PGM-FI

(Programmed Fuel Injection)

Throttle bore 32 mm (1.3 in)

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 85 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

The Honda CBF600S/SA/N/NA Factory Service Repair Manual printed in 2007 consists of 620 pages in English. This comprehensive manual is utilized by professional mechanics at dealerships for vehicle maintenance, service, diagnosis, and repair. It provides detailed step-by-step instructions and repair information, making it valuable for both professional technicians and DIY enthusiasts.

- General Information

- Periodic Maintenance

- Tune-up Procedures

- Engine

- Fuel and Lubrication System

- Electrical System

- Chassis

- Servicing Information

The manual is available in a printable PDF format and is compatible with both Windows and Mac operating systems. It requires Adobe Reader for access. By utilizing this manual, individuals can save money by performing their own repairs.