2007 Harley-Davidson FLTR Road Glide Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

2007 FLT MODELS

SERVICE MANUAL

Part Number 99483-07

Section 1: Maintenance

Section 2: Chassis

Section 3: Engine

Section 4: Fuel

Section 5: Starter

Section 6: Drive

Section 7: Transmission

Section 8: Electrical

Appendix

ELECTRICAL DIAGNOSTICS

Part Number 99497-07

Section 1: Starting & Charging

Section 2: Instruments

Section 3: TSM/TSSM/HFSM

Section 4: Engine Management

Section 5: Sound System

Section 6: Cruise Control

Section 7: Wiring

Appendix

SUBJECT PAGE NO.

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.3 Engine Oil/Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4 Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.5 Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1.6 Wheel Spokes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.7 Primary Chain Lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.8 Clutch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.9 Transmission Lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

1.10 Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1.11 Throttle Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

1.12 Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

1.13 Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

1.14 Spark Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

1.15 Front Fork Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

1.16 Steering Head Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

1.17 Critical Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

1.18 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

1.19 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

MAINTENANCE 1

T ab le Of Contents

2007 Touring: Maintenance 1-1

HOME

GENERAL 1.1

REPAIR NOTES

General maintenance practices are given in this section. All

special tools and torque values are noted at the point of use

and all required parts or materials can be found in the appro-

priate PARTS CATALOG.

Safety

Safety is always the most important consideration when per-

forming any job. Be sure you have a complete understanding

of the task to be performed. Use common sense. Use the

proper tools. Don’t just do the job – do the job safely.

Removing Parts

Always consider the weight of a part when lifting. Use a hoist

whenever necessary. Do not lift heavy parts by hand. A hoist

and adjustable lifting beam or sling are needed to remove

some parts. The lengths of chains or cables from the hoist to

the part should be equal and parallel, and should be posi-

tioned directly over the center of the part. Be sure that no

obstructions will interfere with the lifting operation. Never

leave a part suspended in mid-air.

Always use blocking or proper stands to support the part that

has been hoisted. If a part cannot be removed, verify that all

bolts and attaching hardware have been removed. Check to

see if any parts are in the way of the part being removed.

When removing hoses, wiring or tubes, always tag each part

to ensure proper installation.

Cleaning

If you intend to reuse parts, follow good shop practice and

thoroughly clean the parts before assembly. Keep all dirt out

of parts; the unit will perform better and last longer. Seals, fil-

ters and covers are used in this motorcycle to keep out envi-

ronmental dirt and dust. These items must be kept in good

condition to ensure satisfactory operation.

Clean and inspect all parts as they are removed. Be sure all

holes and passages are clean and open. After cleaning,

cover all parts with clean lint-free cloth, paper or other mate-

rial. Be sure the part is clean when it is installed.

Always clean around lines or covers before they are

removed. Plug, tape or cap holes and openings to keep out

dirt, dust and debris.

Always verify cleanliness of blind holes before assembly.

Tightening screws with dirt, water or oil in the holes can

cause castings to crack or break.

Disassembly and Assembly

Always assemble or disassemble one part at a time. Do not

work on two assemblies simultaneously. Be sure to make all

necessary adjustments. Recheck your work when finished.

Be sure that everything is done.

Operate the motorcycle to perform any final check or adjust-

ments. If all is correct, the motorcycle is ready to go back to

the customer.

Checking Torques on Fasteners with Lock

Patches

To check the torque on a fastener that has a lock patch:

1. Set the torque wrench for the lowest setting in the speci-

fied torque range.

2. Attempt to tighten fastener to set torque. If fastener does

not move and lowest setting is satisfied (torque wrench

clicks), then the proper torque has been maintained.

REPAIR AND REPLACEMENT

PROCEDURES

Hardware and Threaded Parts

Install helical thread inserts when inside threads in castings

are stripped, damaged or not capable of withstanding speci-

fied torque.

Replace bolts, nuts, studs, washers, spacers and small com-

mon hardware if missing or in any way damaged. Clean up or

repair minor thread damage with a suitable tap or die.

Replace all damaged or missing lubrication fittings.

Use Teflon tape on pipe fitting threads.

Threadlocking Agents

Always follow specific service manual procedures when

working with fasteners containing preapplied threadlocking

agents when fastener replacement is recommended. When

re-using fasteners containing threadlocking agents, be sure

to completely remove all existing threadlocking agent from

fastener threads with a wire brush or wire wheel. Also, be

sure to remove residual threadlocking agent from fastener

hole using an appropriate thread chasing device and

compressed air when using new or existing fasteners. Always

use the recommended threadlocking agent for your specific

procedure.

1-2 2007 Touring: Maintenance

HOME

Wiring, Hoses and Lines

Replace hoses, clamps, electrical wiring, electrical switches

or fuel lines if they do not meet specifications.

Instruments and Gauges

Replace broken or defective instruments and gauges.

Replace dials and glass that are so scratched or discolored

that reading is difficult.

Bearings

Anti-friction bearings must be handled in a special way. To

keep out dirt and abrasives, cover the bearings as soon as

they are removed from the package.

Wash bearings in a non-flammable cleaning solution. Knock

out packed lubricant inside by tapping the bearing against a

wooden block. Wash bearings again. Cover bearings with

clean material after setting them down to dry. Never use com-

pressed air to dry bearings.

Coat bearings with clean oil. Wrap bearings in clean paper.

Be sure that the chamfered side of the bearing always faces

the shoulder (when bearings installed against shoulders).

Lubricate bearings and all metal contact surfaces before

pressing into place. Only apply pressure on the part of the

bearing that makes direct contact with the mating part.

Always use the proper tools and fixtures for removing and

installing bearings.

Bearings do not usually need to be removed. Only remove

bearings if necessary.

Bushings

Do not remove a bushing unless damaged, excessively worn

or loose in its bore. Press out bushings that must be

replaced.

When pressing or driving bushings, be sure to apply pres-

sure in line with the bushing bore. Use a bearing/bushing

driver or a bar with a smooth, flat end. Never use a hammer

to drive bushings.

Inspect the bushing and the mated part for oil holes. Be sure

all oil holes are properly aligned.

Gaskets

Always discard gaskets after removal. Replace with new gas-

kets. Never use the same gasket twice (unless instructed

otherwise). Be sure that gasket holes match up with holes in

the mating part.

If a gasket must be made, be sure to cut holes that match up

with the mating part. Serious damage can occur if any flange

holes are blocked by the gasket. Use material that is the right

type and thickness.

Lip Type Seals

Lip seals are used to seal oil or grease and are usually

installed with the sealing lip facing the contained lubricant.

Seal orientation, however, may vary under different applica-

tions.

Seals should not be removed unless necessary. Only remove

seals if required to gain access to other parts or if seal dam-

age or wear dictates replacement.

Leaking oil or grease usually means that a seal is damaged.

Replace leaking seals to prevent overheated bearings.

Always discard seals after removal. Do not use the same

seal twice.

O-Rings (Preformed Packings)

Always discard O-rings after removal. Replace with new O-

rings. To prevent leaks, lubricate the O-rings before installa-

tion. Apply the same type of lubricant as that being sealed.

Be sure that all gasket, O-ring and seal mating surfaces are

thoroughly clean before installation.

Gears

Always check gears for damaged or worn teeth.

Remove burrs and rough spots with a honing stone or crocus

cloth before installation. Lubricate mating surfaces before

pressing gears on shafts.

Shafts

If a shaft does not come out easily, check that all nuts, bolts

or retaining rings have been removed. Check to see if other

parts are in the way before using force.

Shafts fitted to tapered splines should be very tight. If shafts

are not tight, disassemble and inspect tapered splines. Dis-

card parts that are worn. Be sure tapered splines are clean,

dry and free of burrs before putting them in place. Press mat-

ing parts together tightly.

Clean all rust from the machined surfaces of new parts.

Part Replacement

Always replace worn or damaged parts with new parts.

CLEANING

Part Protection

Before cleaning, protect rubber parts (such as hoses, boots

and electrical insulation) from cleaning solutions. Use a

grease-proof barrier material. Remove the rubber part if it

cannot be properly protected.

2007 Touring: Maintenance 1-3

HOME

Cleaning Process

Any cleaning method may be used as long as it does not

result in parts damage. Thorough cleaning is necessary for

proper parts inspection. Strip rusted paint areas to bare

metal before repainting.

Rust or Corrosion Removal

Remove rust and corrosion with a wire brush, abrasive cloth,

sand blasting, vapor blasting or rust remover. Use buffing

crocus cloth on highly polished parts that are rusted.

Bearings

Remove shields and seals from bearings before cleaning.

Clean bearings with permanent shields and seals in solution.

Clean open bearings by soaking them in a petroleum clean-

ing solution. Never use a solution that contains chlorine.

Let bearings stand and dry. Do not dry using compressed air.

Do not spin bearings while they are drying.

1-4 2007 Touring: Maintenance

HOME

TOOL SAFETY

AIR TOOLS

● Always use approved eye protection equipment when

performing any task using air-operated tools.

● On all power tools, use only recommended accessories

with proper capacity ratings.

● Do not exceed air pressure ratings of any power tools.

● Bits should be placed against work surface before air

hammers are operated.

● Disconnect the air supply line to an air hammer before

attaching a bit.

● Never point an air tool at yourself or another person.

● Protect bystanders with approved eye protection.

WRENCHES

● Never use an extension on a wrench handle.

● If possible, always pull on a wrench handle and adjust

your stance to prevent a fall if something lets go.

● Never cock a wrench.

● Never use a hammer on any wrench other than a Strik-

ing Face wrench.

● Discard any wrench with broken or battered points.

● Never use a pipe wrench to bend, raise, or lift a pipe.

PLIERS/CUTTERS/PRYBARS

● Plastic or vinyl covered pliers handles are not intended

to act as insulation; don’t use on live electrical circuits.

● Don’t use pliers or cutters for cutting hardened wire

unless they were designed for that purpose.

● Always cut at right angles.

● Don’t use any prybar as a chisel, punch, or hammer.

HAMMERS

● Never strike one hammer against a hardened object,

such as another hammer.

● Always grasp a hammer handle firmly, close to the end.

● Strike the object with the full face of the hammer.

● Never work with a hammer which has a loose head.

● Discard hammer if face is chipped or mushroomed.

● Wear approved eye protection when using striking tools.

● Protect bystanders with approved eye protection.

PUNCHES/CHISELS

● Never use a punch or chisel with a chipped or mush-

roomed end; dress mushroomed chisels and punches

with a file.

● Hold a chisel or a punch with a tool holder if possible.

● When using a chisel on a small piece, clamp the piece

firmly in a vise, and chip toward the stationary jaw.

● Wear approved eye protection when using these tools.

● Protect bystanders with approved eye protection.

SCREWDRIVERS

● Don’t use a screwdriver for prying, punching, chiseling,

scoring, or scraping.

● Use the right type of screwdriver for the job; match the

tip to the fastener.

● Don’t interchange POZIDRIV®, PHILLIPS®, or REED

AND PRINCE screwdrivers.

● Screwdriver handles are not intended to act as insula-

tion; don’t use on live electrical circuits.

● Don’t use a screwdriver with rounded edges because it

will slip – redress with a file.

RATCHETS AND HANDLES

● Periodically clean and lubricate ratchet mechanisms with

a light grade oil. Do not replace parts individually; ratch-

ets should be rebuilt with the entire contents of service

kit.

● Never hammer or put a pipe extension on a ratchet or

handle for added leverage.

● Always support the ratchet head when using socket

extensions, but do not put your hand on the head or you

may interfere with the action of its reversing mechanism.

● When breaking loose a fastener, apply a small amount

of pressure as a test to be sure the ratchet’s gear wheel

is engaged with the pawl.

SOCKETS

● Never use hand sockets on power or impact wrenches.

● Select the right size socket for the job.

● Never cock any wrench or socket.

● Select only impact sockets for use with air or electric

impact wrenches.

● Replace sockets showing cracks or wear.

● Keep sockets clean.

● Always use approved eye protection when using power

or impact sockets.

2007 Touring: Maintenance 1-5

HOME

STORAGE UNITS

● Don’t open more than one loaded drawer at a time.

Close each drawer before opening up another.

● Close lids and lock drawers and doors before moving

storage units.

● Don’t pull on a tool cabinet; push it in front of you.

● Set the brakes on the locking casters after the cabinet

has been rolled to your work.

1-6 2007 Touring: Maintenance

HOME

MAINTENANCE SCHEDULE 1.2

GENERAL

The table below lists the maintenance requirements for Tour-

ing models. If you are familiar with the procedures, just refer

to the table for the recommended service interval. If neces-

sary, see the quick reference table on the next page for the

required specifications. If more detailed information is

needed, turn to the sections which follow for step-by-step

instructions.

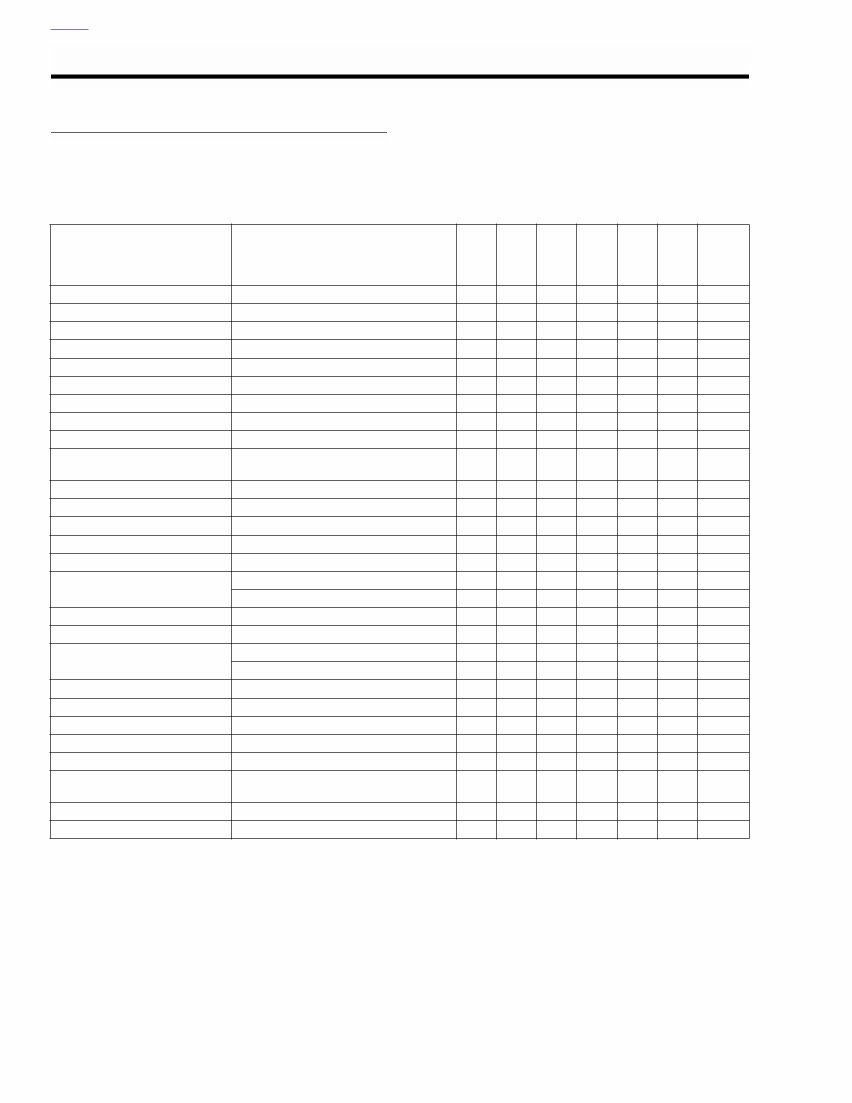

Table 1-1. Scheduled Maintenance Intervals

ITEM PROCEDURE

1000

mi

1600

km

5000

mi

8000

km

10,000

mi

16,000

km

15,000

mi

24,000

km

20,000

mi

32,000

km

25,000

mi

40,000

km

NOTES

Engine oil and filter Replace X X X X X X

Oil lines and brake system Inspect for leaks X X X X X X 1

Air cleaner Inspect, service as required X X X X X X

Tires Check pressure, inspect tread X X X X X X

Wheel spokes Check tightness X X X 1, 4

Primary chaincase lubricant Replace X X X

Clutch Check adjustment X X X X X X 1

Transmission lubricant Replace X X

Drive belt and sprockets Inspect, adjust belt X X X X X X 1

Throttle, brake and clutch

controls

Check, adjust and lubricate X X X X X X 1, 4

Jiffy stand Inspect and lubricate X X X X X X 1

Fuel lines and fittings Inspect for leaks X X X X X X 1, 4

Fuel filter Replace X 1

Brake fluid Check levels and condition X X X X X X 5

Brake pads and discs Inspect for wear X X X X X X

Spark plugs

Inspect X X X X X

Replace X

Electrical equipment and switches Check operation X X X X X X

Front fork oil Replace 1, 2

Steering head bearings

Lubricate X X X 2

Adjust X 1

Air suspension Check pressure, operation and leakage X X X X X X 1

Windshield bushings Inspect X X 1

Cruise control Inspect disengage switch and components X X X X X X 1

Fuel door, Tour-pak, saddlebags Lubricate hinges and latches X X X X X X

Critical fasteners Check tightness X X X 1

Engine mounts and

stabilizer links

Inspect X X 1

Battery Check battery and clean connections 3

Road test Verify component and system functions X X X X X X

NOTES:

1. Should be performed by an authorized Harley-Davidson dealer, unless you have the proper tools, service data and are mechanically

qualified.

2. Disassemble, lubricate and inspect every 50,000 miles (80,000 km).

3. Perform annually.

4. Not all vehicles are equipped with enrichener, fuel valve or spoke wheels.

5. Change DOT 4 brake fluid and flush every two years.

2007 Touring: Maintenance 1-7

HOME

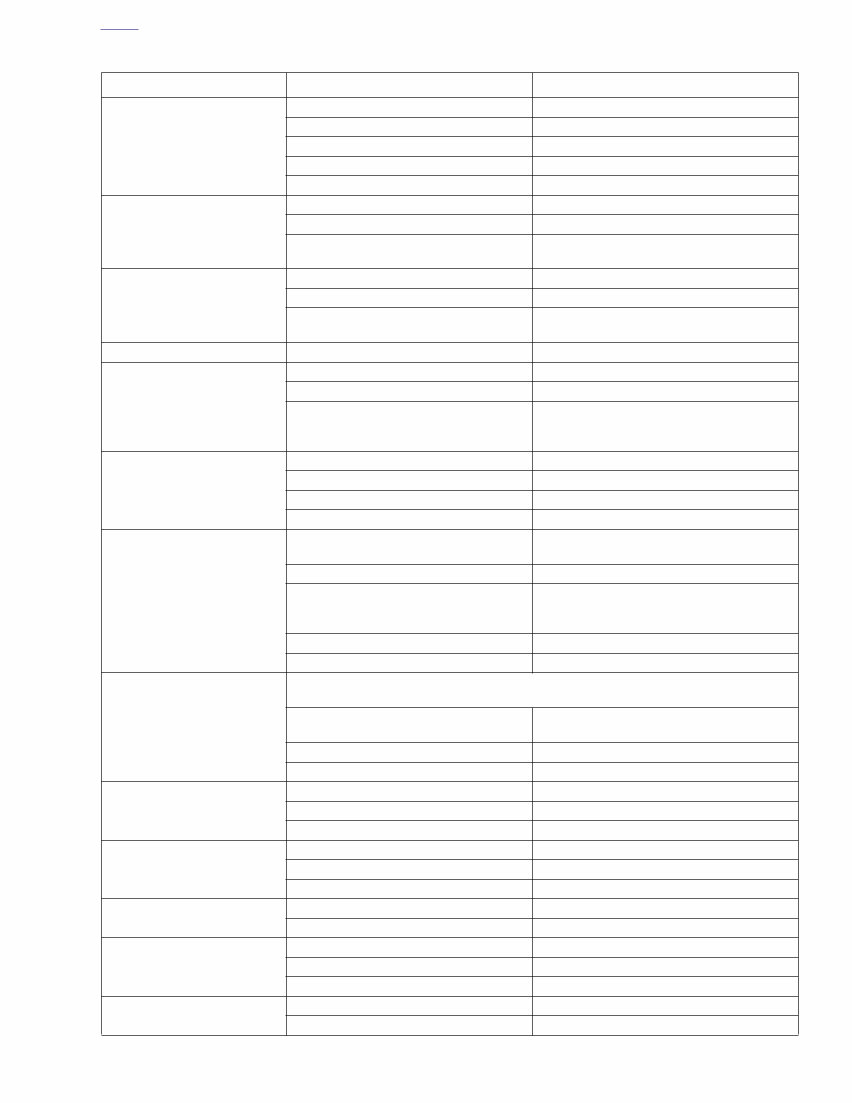

Table 1-2. Quick Reference Data

ITEM SPECIFICATION DATA

Engine oil and filter

Drain plug torque 14-21 ft-lbs (19.0-28.5 Nm)

Oil capacity 4 qt. (3.8 L)

Filter Hand tighten 1/2-3/4 turn after gasket contact

Chrome filter part number 63798-99

Black filter part number 63731-99

Air cleaner

Air cleaner cover bracket screw torque 40-60 in-lbs (5-7 Nm)

Air cleaner cover screw torque 36-60 in-lbs (4-7 Nm)

Air cleaner cover screw threadlocker

Loctite Medium Strength Threadlocker 243

(blue), Part No. 99642-97 (6 ml)

Tire condition and pressure

Pressure: solo rider Front: 36 psi (2.5 bar), Rear: 36 psi (2.5 bar)

Pressure: rider with passenger Front: 36 psi (2.5 bar), Rear: 40 psi (2.8 bar)

Wear

Replace tire if 1/32 in. (0.8 mm) or less

of tread pattern remains

Wheel spokes Spoke nipple torque 40-50 in-lbs (4.5-5.6 Nm)

Primary chaincase lubricant

Lubricant capacity Wet: 38 oz (1124 mL); Dry: 45 oz (1331 mL)

Primary chaincase drain plug torque 14-21 ft-lbs (19.0-28.5 Nm)

FORMULA+ TRANSMISSION AND

PRIMARY CHAINCASE LUBRICANT

part number

99851-05 (qt)

Clutch adjustment

Free play at adjuster screw 1/2-1 turn

Free play at hand lever 1/16-1/8 in. (1.6-3.2 mm)

Adjuster screw locknut torque 72-120 in-lbs (8-14 Nm)

Clutch inspection cover torque 84-108 in-lbs (10-12 Nm)

Transmission lubricant

Lubricant level

Dipstick at FULL with motorcycle on

jiffy stand and filler plug resting on threads

Lubricant capacity 32 oz (946 mL)

FORMULA+ TRANSMISSION AND

PRIMARY CHAINCASE LUBRICANT

part number

99851-05 (qt)

Transmission drain plug torque 14-21 ft-lbs (19.0-28.5 Nm)

Filler plug torque 25-75 in-lbs (3-9 Nm)

Drive belt

Motorcycle upright with rear wheel in air or on jiffy stand without rider or luggage. Check at

loosest spot in belt with transmission in neutral and motorcycle at ambient temperature.

Upward force at midpoint of bottom belt

strand

10 lb. (4.5 kg)

FLHR/C, FLHT/C/U, FLTR 3/8-7/16 in. (9.5-11.1 mm)

FLHRS, FLHX 1/4 - 5/16 in. (6.4-7.9 mm)

Throttle and clutch cables

Lubricant part number Super Oil , 94968-85TV (1/4 fl. oz)

Handlebar clamp screw torque 60-80 in-lbs (6.8-9.0 Nm)

Handlebar switch housing screw torque 35-45 in-lbs (4-5 Nm)

Brake Fluid Reservoir Level

DOT 4 Brake Fluid part number 99953-99A (12 oz)

Level 1/4 inch (6.4 mm) from the top

Master cylinder reservoir cover torque 6-8 in-lbs (0.7-0.9 Nm)

Brake pad linings and discs

Minimum brake pad thickness 0.04 in. (1.02 mm)

Minimum brake disc thickness See stamp on side of disc

Spark plugs

Type HD-6R12

Gap 0.038-0.043 in. (0.97-1.09 mm)

Torque 12-18 ft-lbs (16-24 Nm)

Front Fork Oil

Hydraulic Fork Oil (Type E) part number 99884-80 (16 oz)

Amount See Section 2.15 FRONT FORKS

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 34 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

- Contains troubleshooting and replacement procedures provided by the manufacturer

- Includes step-by-step instructions, clear images, and exploded-view illustrations

- Useful for both professional mechanics and DIY enthusiasts

- Essential for regular maintenance and parts replacement

- Provides manufacturer's recommended troubleshooting charts and procedures

- Convenient digital format for easy access and portability

- Printable and compatible with various electronic devices

- Requires Adobe Reader (free) for access

Whether you prefer a digital copy or a printed version, this motorcycle repair manual is a valuable resource for maintaining and repairing your bike.