GENERIC TRIGGER 50 QJ50 Scooter Workshop Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

REPAIR MANUAL

D01 - TRIGGER 50 Vers. 2015_01

It is important that you read this repair manual carefully before the start of work.

Only use GENERIC/ KSR spare parts.

KSR Motot Motorcycles is a registered brand by KSR Group GmbH.

This vehicle can only fulfil the demands placed on it if the service work is made by qualified experts and in accordance

with the service schedule.

The repair manual was written to correspond to the current state of this model.

We reserve the right to make changes in this manuals in the interest of technical advancements and improvements

without a notice.

It is recommended that repair work will be done by a fully educated mechanic.

We will not provide descriptions of general workshop methods, safety rules that necessary in a workshop.

All specifications refers to the current state and are nonbinding. KSR Group GmbH specifically reserves the right to

modify the information in this manual without notice and without specifying reasons.

KSR Group GmbH accepts no liability deviations from illustrations and descriptions or misprints and other errors.

The models in this manual partly contain special equipment that does not belong to the regular scope of delivery fur-

ther the illustrations and pictures are symbolic images, and may differ from the actual components.

© 2012 by KSR Group GmbH, Krems Austria

All rights reserved

Reproduction of this manual is permitted only with the express written permission of the copyright owner.

Within the meaning of the international quality management standard ISO 9001, KSR Group GmbH uses quality as-

surance processes that lead to the maximum possible quality of the products.

KSR Group GmbH

A-3500 Krems, Austria

INTRODUCTION

2

IMPORTANT NOTES 6

LOCATION OF SERIAL NUMBERS

VIN (VEHICLE IDENTIFICATION NUMBER)

AND FRAME PLATE 7

ANTI TEMPERING LABEL 7

ENGINE NUMBER 7

DECRYPTING THE VEHICLE IDENTIFICATION NUMBER 7

GENERAL SPECIFICATIONS

VEHICLE SPECIFICATION 8

SPECIFIC TIGHTENING TORQUE 10

GENERAL TIGHTENING TORQUE 11

SPECIAL TOOLS

SPECIAL TOOLS 12

1. PERIODIC MAINTENANCE

PERIODIC MAINTENANCE CHART

CHECKLIST OF CONSTANT MAINTENANCE 15

IMPORTANT PREPARATION REFERENCES

IMPORTANT PREPARATION REFERENCES 18

FUEL SYSTEM

AIR CLEANER 21

CHANGING INTERVALS 21

THROTTLE WIRE INSPECTION/ ADJUSTMENT 21

IDLE ADJUSTMENT 22

CARBURETTOR ADJUSTMENT 22

FUEL HOSE INSPECTION 22

FUEL FILTERS CLEANING 23

ENGINE

ENGINE OIL LEVEL INSPECTION 23

ENGINE OIL LEVEL SENSOR INSPECTION 24

OIL PUMP INSPECTION 24

OIL PUMP ADJUSTMENT 26

TRANSMISSION OIL LEVEL INSPECTION 27

SPARK PLUG INSPECTION 27

SPARKPLUG IMAGES AND ANALYSIS 28

SPARK PLUG REPLACEMENT 28

CYLINDER PRESSURE INSPECTION 28

CLUTCH

CLUTCH CABLE FREE PLAY ADJUSTMENT 29

ADJUSTING THE CLUTCH CABLE FREE PLAY

ON THE ENGINE SIDE 29

CLUTCH ADJUSTMENT 30

WHEELS

AIR PRESSURE INSPECTION 30

WHEEL BEARING AND WHEEL AXLE

DAMAGE INSPECTION 31

BRAKES

BRAKE FLUID LEAK INSPECTION FRONT 31

BRAKE FLUID LEAK INSPECTION REAR 31

BREAK OPERATION INSPECTION FRONT 31

BREAK OPERATION INSPECTION REAR 32

BRAKE FLUID LEVEL INSPECTION FRONT 32

BRAKE FLUID LEVEL INSPECTION REAR 32

FRONT BRAKE PADS INSPECTION 33

REAR BRAKE PADS INSPECTION 33

FRONT BRAKE DISC INSPECTION 34

REAR BRAKE DISC INSPECTION 35

FRONT BRAKE LEVER/ MASTER BRAKE

CYLINDER REPLACEMENT 35

FOOT BRAKE LEVER/ MASTER BRAKE

CYLINDER REPLACEMENT 36

FRONT BRAKE CALLIPER REPLACEMENT 36

REAR BRAKE CALLIPER REPLACEMENT 36

FRONT BRAKE HOSE REPLACEMENT 37

REAR BRAKE HOSE REPLACEMENT 37

FRONT BRAKE LEVER ADJUSTMENT 38

REAR BRAKE LEVER ADJUSTMENT 38

DRIVE CHAIN

DRIVE CHAIN SLACK INSPECTION 39

DRIVE CHAIN SLACK ADJUSTMENT 39

DRIVE CHAIN LUBRICATION 39

DRIVE CHAIN WEAR INSPECTION 40

SUSPENSION

FRONT FORK OPERATION INSPECTION 40

FRONT FORK OIL LEAK INSPECTION 40

REAR SHOCK OPERATION INSPECTION 41

REAR SHOCK OIL LEAK INSPECTION 41

STEERING

STEERING PLAY INSPECTION 41

STEERING BEARING LUBRICATION 42

ELECTRICAL SYSTEM

BATTERY INSPECTION/ CHARGING 43

FUSES 44

LIGHT AND SWITCHES OPERATION INSPECTION 44

HEADLIGHT AIMING INSPECTION 45

2. REPAIR AND DIAGNOSTIC

CHASSIS

EXPLODED VIEW / PART LOCATION - FRAME 47

EXPLODED VIEW / PART LOCATION - REAR

SWING ARM 48

EXPLODED VIEW / PART LOCATION - SEAT 48

FUEL SYSTEM

EXPLODED VIEW / PART LOCATION - FUEL SYSTEM 50

SPECIFICATION 51

CARBURETTOR

EXPLODED VIEW / PART LOCATION - CARBURETTOR 52

CARBURETTOR REMOVAL 53

CHOKE/ CABLE REMOVAL 53

CARBURETTOR UPPER COVER REMOVAL 54

CARBURETTOR ADJUSTMENT 54

FUEL SUPPLY

FUEL SUPPLY INSPECTION 54

FUEL TANK REMOVAL 55

FUEL COCK 56

ENGINE

EXPLODED VIEW / PART LOCATION - CYLINDER/

CYLINDER COVER 57

EXPLODED VIEW / PART LOCATION - CRANK

ASSEMBLY 58

EXPLODED VIEW / PART LOCATION - CRANKCASE 59

SPECIFICATION 60

TROUBLESHOOTING 61

ENGINE OVERHAUL/ REMOVAL 62

ENGINE PREPARATION 62

ENGINE REMOVAL 62

ENGINE TOP END

CYLINDER COVER REMOVAL 63

CYLINDER REMOVAL 63

PISTON REMOVAL 63

OIL PUMP REMOVAL 64

WATER PUMP REMOVAL 64

CRANKCASE (RIGHT) REMOVAL 64

CLUTCH REMOVAL 65

CRANKSHAFT GEAR AND MAIN SHAFT GEAR REMOVAL 66

MEMBRANE 66

SPROCKET REMOVAL 66

CRANKCASE COVER (LEFT) REMOVAL 67

INDEX

3

INDEX

4

STARTER REMOVAL 67

STARTER GEAR REMOVAL 67

STATOR REMOVAL 67

CRANKCASE SEPARATION 68

CRANKSHAFT REMOVAL 68

TRANSMISSION DISASSEMBLY 69

INPECTION OF TRANSMISSION AND GEAR SHIFT

MECHANISM 70

EXPLODED VIEW / PART LOCATION - PRIMARY

SHAFT ASSY/ SECONDARY SHAFT ASSY 71

EXPLODED VIEW / PART LOCATION - SHIFT

MECHANISM 72

EXPLODED VIEW / PART LOCATION - REDUCTION

GEAR 73

INSPECTION OF TRANSMISSION AND SHIFT

MECHANISM 74

TRANSMISSION ASSEMBLING 75

CRANKSHAFT INSPECTION 76

TOP END PARTS INSPECTION 78

PISTON INSTALLATION 80

CYLINDER INSTALLATION 81

CYLINDER COVER INSTALLATION 81

LEFT CRANKCASE ASSEMBLING 82

SPROCKET INSTALLATION 83

MEMBRANE INSPECTION 83

MEMBRANE INSTALLATION

RIGHT CRANKECASE ASSEMBLING 83

CLUTCH INSPECTION 84

EXPLODED VIEW / PART LOCATION CLUTCH 85

CLUTCH ASSEMBLING 86

OUTWARD RELEASE LEVER ADJUSTMENT 87

ACTUATING LEVER INSPECTION 87

ACTUATING LEER ASSEMBLING 87

RIGHT CRANKCASE ASSEMBLING 87

ACTUATING LEVER ADJUSTMENT 88

EXPLODED VIEW / PART LOCATION - OIL PUMP 89

INSPECTION OF THE OIL PUMP 89

OIL PUMP ASSEMBLING 89

LUBRICATION SCHEME 90

COOLING SYSTEM SCHEME 91

WATER PUMP INSPECTION 91

WATER PUMP ASSEMBLING 91

WHEELS AND TIRES

EXPLODED VIEW / PART LOCATION - FRONT WHEEL 92

EXPLODED VIEW / PART LOCATION - REAR WHEEL 93

WHEELS (RIMS) 94

TIRES 94

WHEEL BEARING REPLACEMENT FRONT WHEEL 94

WHEEL BEARING REPLACEMENT REAR WHEEL 95

WHEEL BEARING INSPECTION 95

WHEEL AXLE INSPECTION 95

RIM INSPECTION 95

BRAKES

EXPLODED VIEW / PARTLOCATION - FRONT BRAKE 96

EXPLODED VIEW / PART LOCATION - REAR BRAKE 97

BRAKE LEVERS / FRONT BRAKE LEVER 98

BRAKE LEVERS / REAR BRAKE PEDAL 98

BRAKE FLUID 99

BRAKE HOSE 99

REAR BRAKE PAD WEAR INSPECTION 99

BRAKE PEDAL REPLACEMENT 100

SUSPENSION

EXPLODED VIEW / PART LOCATION - FRONT

SUSPENSION 101

EXPLODED VIEW / PART LOCATION - ADJUSTABLE

REAR-SUSPENSION 103

FRONT SUSPENSION REPLACEMENT 104

FRONT SUSPENSION WHOLE FORK REPLACEMENT 105

REAR SUSPENSION REPLACEMENT 105

REAR SWING ARM REPLACEMENT 106

STEERING

EXPLODED VIEW - PART LOCATION / STERRING 107

HANDLEBAR REPLACEMENT 108

CLUTCH LEVER REPLACEMENT 109

BRAKE LEVER REPLACEMENT 110

EXHAUST

EXHAUST REPLACEMENT 110

SECONDARY AIR SYSTEM

SECONDARY AIR SYSTEM INSPECTION 112

ELECTRICAL SYSTEM

WIRING DIAGRAM 114

LOCATION - ELECTRICAL SYSTEM 115

LOCATION - LIGHTS / INSTRUMENTS SWITCHES 116

SPECIFICATION 117

FUSES

FUSE REPLACEMENT 118

SPECIFICATION 118

TROUBLESHOOTING 118

BATTERY

BATTERY GENERAL INFORMATION 118

BATTERY REMOVAL 119

BATTERY AND CHARGING SYSTEM 119

CHARGING SYSTEM

CHARGING SCHEME 120

CHARGING PERFORMANCE TEST 120

REGULATOR - RECTIFIER INSPECTION 121

GENERATOR CHARGING COIL 121

IGNITION SYSTEM

IGNITION SYSTEM 122

PREPARATORY DATA 122

SPECIFICATION 123

FAULT DIAGNOSIS 123

IGNITION SYSTEM INSPECTION 124

PRIMARY VOLTAGE OF IGNITION COIL 124

TRIGGER (PICK UP) 124

TRIGGER INSPECTION 125

CDI ASSEMBLY 125

IGNITION COIL REMOVAL 125

PRIMARY COIL INSPECTION 125

SECONDARY COIL INSPECTION 126

STARTING SYSTEM

STARTING DIAGRAM 126

FAULT DIAGNOSIS 127

STARTING MOTOR 127

STARTING MOTOR INSPECTION 127

STARTING RELAY 127

STARTING RELAY ACTUATION INSPECTION 127

STARTING RELAY VOLTAGE INSPECTION 128

LIGHTNING SYSTEM

BULBS REPLACEMENT GENERAL INFORMATION 129

HEADLAMP BULB REPLACEMENT 129

POSITION LIGHT BULB REPLACEMENT 130

WHOLE HEADLIGHT REPLACEMENT 130

REAR WINKER REPLACEMENT 131

FRONT WINKER REPLACEMENT 131

BULB WINKER REPLACEMENT 132

BULB TAILLIGHT REPLACEMENT 132

TAILLIGHT REPLACEMENT 133

LICENSE PLATE BULB REPLACEMENT 133

SPEEDOMETER

SPEEDOMETER DESCRIPTION 134

SPEEDOMETER REPLACEMENT 134

INDEX

5

SWITCHES AND SENSORS

IGNITION SWITCH INSPECTION 134

IGNITION SWITCH REPLACEMENT 134

STEERING LOCK 134

ELECTRIC HORN INSPECTION 135

ELECTRIC HORN REPLACEMENT 135

LEFT HANDLE SWITCH 135

RIGHT HANDLE SWITCH 135

LEFT HANDLE SWITCH INSPECTION 136

LEFT HANDLE SWITCH REPLACEMENT 136

RIGHT HANDLE SWITCH INSPECTION 136

RIGHT HANDLE SWITCH REPLACEMENT 137

FRONT BRAKE LIGHT SWITCH

INSPECTION / REPLACEMENT 137

REAR BRAKE LIGHT SWITCH INSPECTION 138

REAR BRAKE LIGHT SWITCH REPLACEMENT 138

NEUTRAL SENSOR INSPECTION 139

NEUTRAL SENSOR REPLACEMENT 139

SPEED SENSOR INSPECTION 140

SPEED SENSOR REPLACEMENT 140

FAULT DIAGNOSIS 142

CHASSIS

SEAT REMOVAL 143

LEFT / RIGHT SIDE COVER REMOVAL 143

LEFT / RIGHT LOWER SIDE COVER REMOVAL 143

LEFT / RIGHT TANK SIDE COVER REMOVAL 144

REAR BODY PANEL REMOVAL 144

REAR SIDE COVER REMOVAL 145

REAR FENDER REMOVAL 145

FRONT FENDER REMOVAL 146

HEADLIGHT COVER REMOVAL 146

COVER FRONT SHOCK ABSORBER LEFT REMOVAL 147

COVER FRONT SHOCK ABSORBER RIGHT REMOVAL 148

MIRROW

BACK VIEW MIRROWS 149

BACK VIEW MIRROWS REMOVAL 149

SECOND SPEEDOMETER

SECOND SPEEDOMETER 150

SWITCH BUTTON FUNCTION LIST 150

REMOVAL OF POWER LIMITATION

REMOVAL OF POWER LIMITATION 151

LEVEL 1 151

LEVEL 2 151

WARRANTY

The work prescribed in the service schedule must be carried out in an authorized workshop and confirmed in the cus-

tomer‘s service card, otherwise no warranty claims will be recognized. No warranty claims can be considered for dam-

age resulting from manipulations and/or alterations to the vehicle.

NOTES AND WARNINGS

Pay attention to the notes/warnings in this manual.

• Identifies dangers that will lead to environmental damage if the measures are not taken.

• Identifies dangers that is likely to lead to fatal or serious injury if the measures are not taken.

• Identifies dangers that will lead to considerable machine and material damage if the measures are not taken.

• Identifies dangers that will immediately lead to fatal or serious permanent injury if the appropriate measures are not

taken.

REPAIR MANUAL

It is important that you read this manual completely before the start of work. It contains useful information how to

repair and maintain the vehicle.

FUEL AND LUBRICANTS

Use only the fuels, oils and lubricants according to specifications as listed in this manual.

Please consider that KSR Group GmbH give no approval for Bio- Ethanol (E 10 or higher) fuel.

SPARE PARTS AND ACCESSORIES

Only use spare parts and accessory that have been approved or recommended by KSR Group GmbH.

PRACTICE

Special tools are required for some work but mostly professional work shop equipment is enough for service, repair and

maintenance of the vehicle. Special tools mentioned inside of this manual.

When thread locker is used on connections (e.g., Loctite®), follow the instructions for use from the manufacturer.

After disassembly, clean the parts that are to be reused and check them for damage and wear. Replace damaged or

worn parts.

IMPORTANT

• After each repair or maintenance work security check and a test drive must be done.

• Before you delivery the vehicle to the customer a road safety test must be done.

! WARNING

IMPORTANT NOTES

6

VIN (CHASSIS NUMBER) AND FRAME PLATE

The vehicle identification number (VIN) (1) is punched into the

right side of the steering tube. The frame plate (2) is located

on the right side in front of the frame.

ANTI TEMPERING LABEL

The anti tempering label (3) is fixed on the inner side of the

seat bench.

ENGINE NUMBER

The engine number (4) is stamped into the left side of the

engine case.

DECRYPTING THE VEHICLE IDENTIFICATION NUMBER

EXAMPLE: VA4D0115XDB775449

VA4 - WORLD MANUFACTURER INDEX (NAME OF MANUFACTURER)

D01 - MODEL TYPE

1 - VARIANT OF MODEL

5 - VERSION OF MODEL

X - RANDOM NUMBER

D - YEAR OF PRODUCTION (CB = 2012/ DB = 2013,.........)

B - ASSEMBLING PLANT (LOCATION OF FACTORY)

775449 SERIAL NUMBER

LOCATION OF SERIAL NUMBERS

7

1

2

3

4

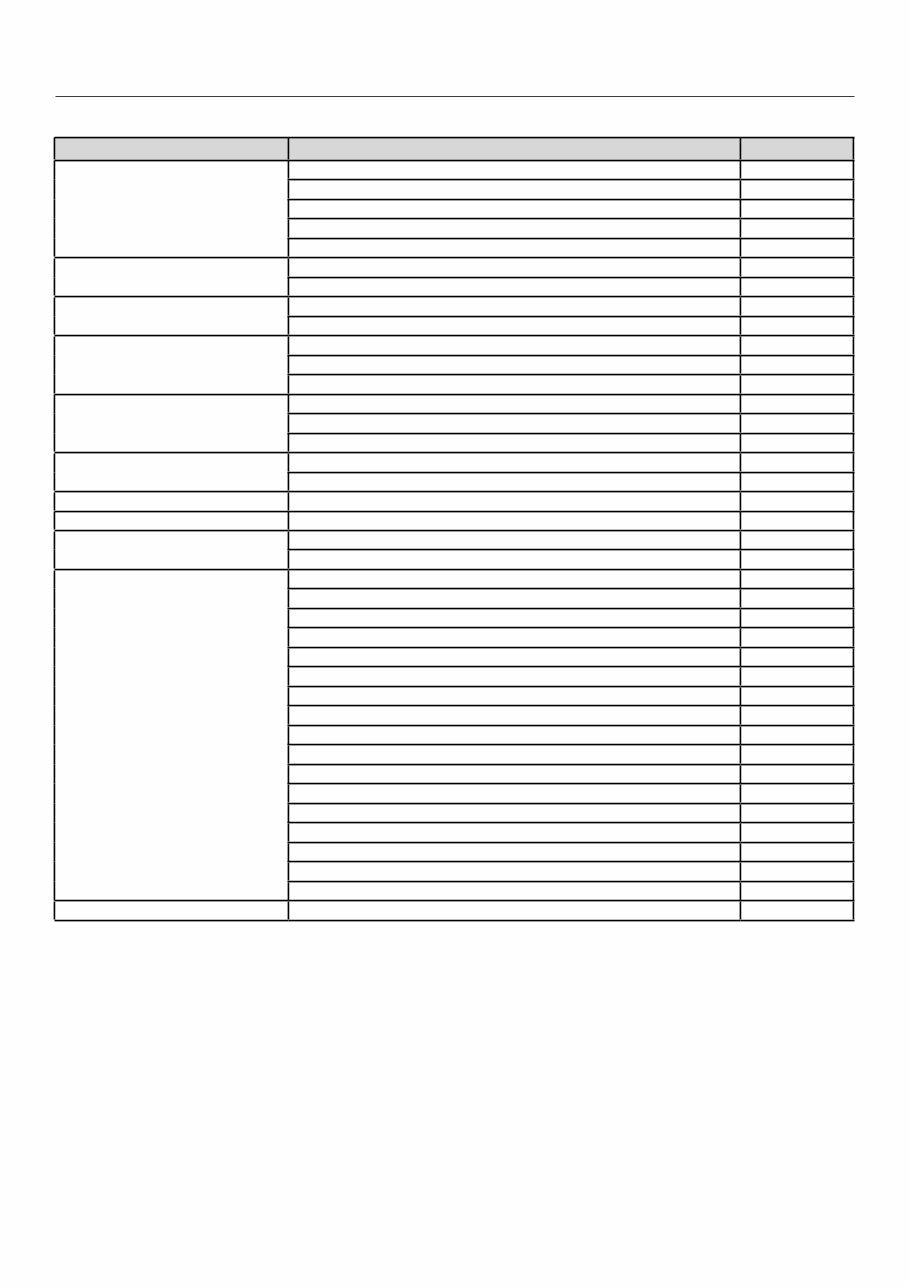

ENGINE

Engine type: Liquid cooled 2 - stroke

Cylinder arrangement: Horizontal (+60°) single cylinder

Displacement: 49.6 cm³

Compression ratio: 7.0:1

Max. output (kw/rpm): 2.2 kW/ 6500 rpm

Max. torque (Nm/rpm): 3.6 Nm/ 5500 rpm

Starting system: Electric starter and Kick starter

Lubrication system: Fresh oil lubrication

ENGINE OIL QUANTITIY

Capacity: 1 L

Recommended type: CASTROL Power 1-Racing 2T Fully Synthetic

TRANSMISSION OIL

Quantity 0.5 L for disassemble/ 0.4 for replacement

Recommended type: CASTROL Power 1-Racing 4T 10W-40

AIR FILTER ELEMENT

Foam filter

FUEL

Recommended fuel: Unleaded gasoline only ≥ 95 Oct

Do not use Bio-Ethanol fuel - E10 is not permitted

Fuel tank capacity: 10 L ± 0.2 L

CARBURETTOR

Type/ Manufacturer: PZ19JB JB-4/ LEADER or QJ

Main jet: 95

Idle jet: 22.5

SPARK PLUG

Manufacturer/ model: NGK/BR8ES

CLUTCH

Clutch type: Multi-disc in oil bath

TRANSMISSION TYPE

Manual, 5 speed

CHASSIS

Frame type: Steel tube

TIRES (Version 0 = Trigger X)

Front tire

Type: Tubeless/ Pressure on cold tire: 2.25 bar

Size: Rim: 1.6*21

Tire: 3.00-21

Rear tire

Type: Tubeless/ Pressure on cold tire: 2.25-2.5 bar

Size: Rim: 1.85*18

Tire: 4.10-18

TIRES (Version 1 = Trigger SM)

Front tire

Type: Tubeless/ Pressure on cold tire: 2.25 bar

Size: Rim: 2.5*17

Tire: 100/80-17

Rear tire

Type: Tubeless/ Pressure on cold tire: 2.25-2.5 bar

Size: Rim: 3.00*17

Tire: 130/80-17

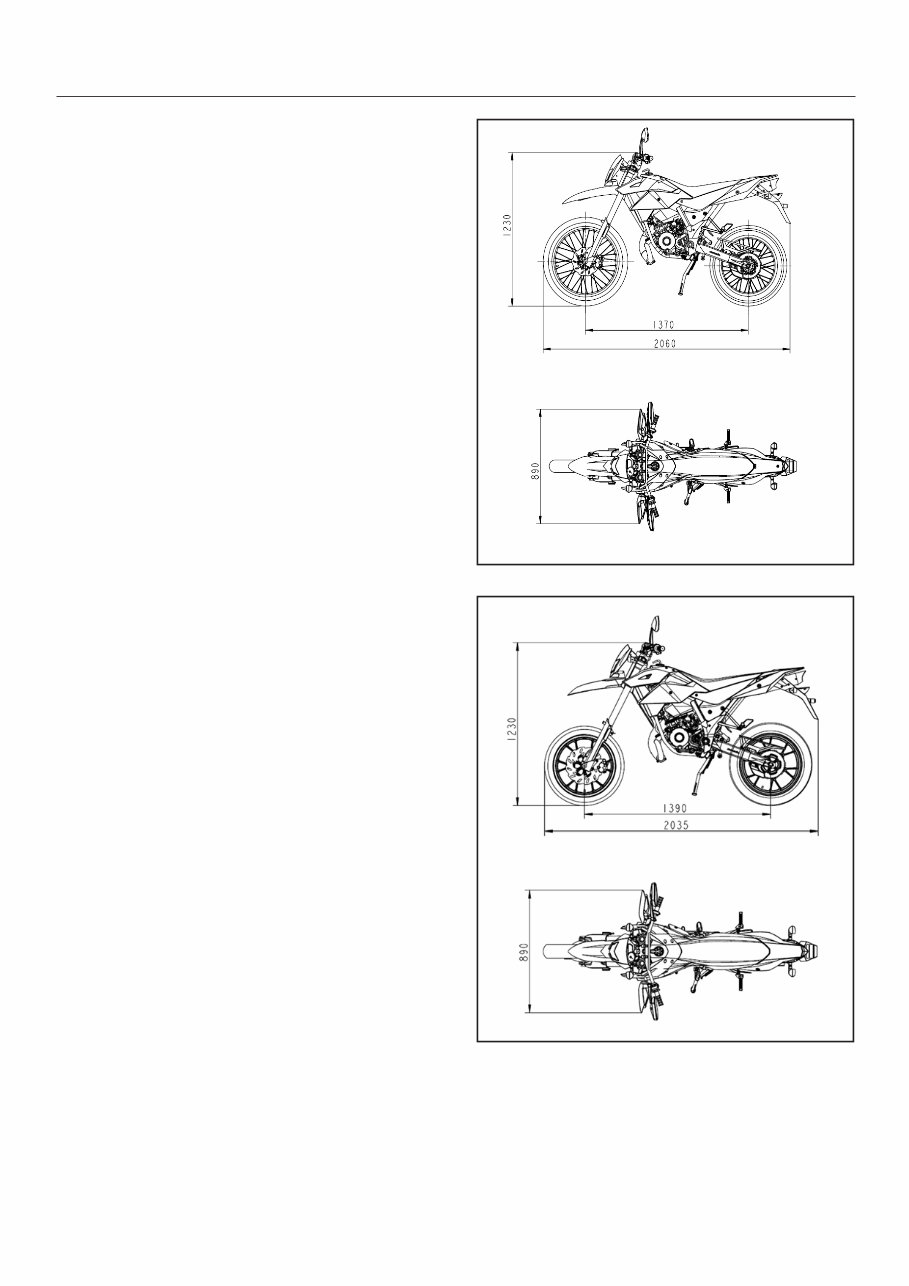

Version 0

Version 1

GENERAL SPECIFICATION

8

GENERAL SPECIFICATION

9

BRAKES

Front brake

Type: Single Hydraulic disc brake (280 mm)/ Right hand operation

Brake fluid: DOT4

Recommended brake fluid: (CASTROL SUPER DISK BRAKE

FLUID DOT 4.)

Rear brake

Type: Hydraulic disc brake (220 mm)/ Right foot operation

Brake fluid: DOT4

Recommended brake fluid: (CASTROL SUPER DISK BRAKE

FLUID DOT 4.)

FRONT SUSPENSION

Type: Telescopic fork

Spring/shock absorber type: Coil spring/oil damper

REAR SUSPENSION

Type: Unit swing

Spring/shock absorber type: Coil spring/oil damper

ELECTRICAL SYSTEM

Ignition system: CDI

Charging system: Magneto

BATTERY

Model: YT4L-BS/ 12V, 3 Ah

LIGHT AND BULBS

Headlight : 12 V , 35.0 W

Tail/brake light: 12 V , 21.0 W / 5.0W

Position light 12 V, 35.0 W

Front turn signal light: 12 V, 10.0 W

Rear turn signal light: 12 V, 10.0 W

License plate light: 12 V, 5.0 W

High beam indicator light: 12 V, 2 W

Turn signal indicator lights: 12 V, 3 W

N signal indicator light: 12V, 3 W

Instrument lights (2x): 12V, 3 W

MAIN FUSES

10.0 A

SPECIFIC TIGHTENING TORQUES

10

MODULE PART TORQUE / Nm

Electrical System

Starting motor clutch cover bolt 12

Starting motor clutch locknut 95

Rectifier bolt 5

Fixing bolt of ignition coil 9

Fixing bolt of flywheel 35-40

Wheel Axles

Front wheel spindle 55 - 62

Rear wheel spindle nut 85 - 98

Fuel tank

Fixing bolt for fuel tank 5-9

Cushion mounting bolt 9-10

Front brake system

Fixing bolt of brake disc 22-29

Mounting bolt of brake caliper 22-29

Fixing bolt of hand brake lever braket 5-9

Rear brake system

Fixing bolt of brake disc 22-29

Mounting bolt of brake caliper 22-29

Fixing bolt of hand brake lever braket 5-9

Rear shock absorber

Top nut of rear shock absorber 37-44

Bottom nut of rear shock absorber 37-44

Front fork

Front shock absorber mounting bolt 37-44

Handlebar

Upper bracket assembly mounting bolt 40-60

Muffler

Mounting bolt for muffler 5-9

Combined screw for muffler protecting plate 5-9

Engine

Cylinder cover nut 18-22

Fixing nut in the power gear of clutch 50-60

Stud bolt of air cylinder 18-22

Clutch locknut 50-60

Spark plug 10-15

Limiting screw of the feet starter lever 35-40

Shift positioned bolt 10-16

Mould assembling bolt 10-12

Bolts on the right and left crankcase cover 10-12

Loop bolt 10-12

Motor fixing bolt 10-12

Seperating disk bolt of clutch 10-16

Fixing bolt of inlet valve 10-12

Setscrew of shift display 4-7

Setscrew of constant temperature set 4-7

Setscrew of electric wire clamp 4-7

Fixing bolt of water pump 10-12

Frame

Rear swing arm shaft nut 70-83

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

Viewed 53 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

This workshop repair manual is a comprehensive guide containing all the necessary information for repairing, maintaining, and restoring your vehicle. It is an invaluable resource for both professional technicians and DIY enthusiasts.

- All repair procedures are meticulously covered from A-Z

- Includes high-quality photos, illustrations, and diagrams

- Compatible with Microsoft Windows 95, 98, 98SE, 2000, NT, ME, XP, Vista, and Windows 7, and also works on all Mac computers

Whether you are looking to save on service and repair costs or prefer the convenience of accessing and printing repair procedures easily, this workshop repair manual is the ideal solution. Say goodbye to cumbersome and worn-out manuals, and get your hands on this trusted resource today.