2014 Ducati 899 Panigale Service & Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

DUCATI 899 Panigale 2014 Workshop Manual

SBK.01 - General

Symbols - Abbreviations - References

Product specifications

Hazardous Products - Warnings

General maintenance instructions

General safety rules

SBK.02 - Information about the model

Identification data

Identification data

SBK.03 - Technical data

Technical specifications

Lights/instrument panel

Injection system

Fuel system

Injection-ignition system

Charging system/alternator

Hydraulic brakes

Rear suspension

Rear wheel

Front suspension

Front wheel

Gearbox

Cylinder/Piston

Crankshaft

Timing system/valves

Transmission

Colours

General

Dimensions

Dimensions

Fuel, lubricants and other fluids

Fuel, lubricants and other fluids

Torque settings

Engine torque settings

Frame torque settings

SBK.04 - Maintenance operations

Vehicle pre-delivery

Vehicle pre-delivery

Scheduled maintenance chart

Operations to be carried out by the customer

Operations to be carried out by the dealer

Maintenance operations

Adjusting the rear shock absorber

Adjusting the front fork

Adjusting the position of the gear change and rear brake pedals

Adjusting the clutch lever and front brake lever

Checking the rear brake pad wear and changing the brake pads

Checking the front brake pad wear and changing the brake pads

Adjusting the chain tension

Adjusting the steering head bearing play

Filling the clutch circuit

Draining the clutch hydraulic circuit

Changing the clutch fluid

Changing the fluid in the rear brake system

Changing the fluid in the front brake system

Changing the coolant

Checking the coolant level

Changing and cleaning the air filters

Spark plugs replacement

Checking valve clearance

Changing the engine oil and filter cartridge

Check engine oil level

SBK.05 - Fairings

Rear-view mirrors

Refitting the rear-view mirrors

Removal of the rear-view mirrors

Headlight fairing

Refitting the headlight fairing

Removing the headlight fairing

Fairing panels

Refitting the side fairings

Removal of the side fairings

Seat - seat cowling and side panels

Refitting the seat release mechanism

Removal of the seat release mechanism

Refitting the side panels

Removal of the side panels

Refitting the rider seat

Removal of the rider seat

Refitting the pillion seat

Removal of the pillion seat

Front and rear mudguard

Refitting the rear mudguard

Removing the rear mudguard

Refitting the front mudguard

Removing the front mudguard

SBK.06 - Electric system and engine control system

Wiring diagram

Table V

Table T

Table S

Table R

Table Q

Table P

Table O

Table N

Table L

Table K

Table J

Table I

Table H

Table G

Table F

Table D

Table C

Table B

Table A

Routing of wiring on frame

Key to wiring diagram

Battery charging system

Rectifier-regulator

Alternator

Battery

Topping up the electrolyte

Recharging the battery

Checking the battery charging system

Electric starting system

Solenoid starter

Starter motor

Electric starting system

Lights and indicating devices

Headlight aim

Renewal of the headlight

Indicating devices

Checking the indicating devices

Protection and safety devices

Checking the fuses

SBK.07 - Chassis

Front wheel

Refitting the front wheel

Overhauling the front wheel

Removing the front wheel

Rear wheel

Refitting the rear wheel

Overhauling the rear wheel

Removing of the rear wheel

Front brake control

Overhauling the front brake components

Removing the front brake master cylinder

Refitting the front brake system

Refitting the brake discs

Overhauling the front brake components

Removing the brake discs

Removing the front brake system

Refitting the front brake master cylinder

Removing the front brake master cylinder

Rear brake

Refitting the rear brake calliper

Removing the rear brake calliper

Refitting the rear brake control

Removing the rear brake control

ABS system components

Wiring/hose routing

Refitting the ABS control unit

Removing the ABS control unit

Handlebar unit: throttle twistgrip

Refitting the throttle twistgrip

Removal of the throttle twistgrip

Handlebar unit: hydraulic clutch control

Refitting the clutch transmission unit

Removal of the clutch transmission unit

Steering damper

Refitting the steering damper

Removal of the steering damper

Gearchange mechanism

Refitting the gearchange mechanism

Removing the gearchange mechanism

Fork - steering head: front fork

Overhauling the front forks

Refitting the front forks

Removal of the front forks

Rear shock absorber assembly

Refitting the shock absorber support

Removal of the shock absorber support

Refitting the rear suspension

Removal of the rear shock absorber

Swingarm

Refitting the rear swinging arm

Overhauling the rear swinging arm

Removing the swinging arm

Final drive

Lubricating the chain

Washing the chain

Refitting the rear sprocket

Replacing of the rear sprocket

Refitting the front sprocket

Removing of the front sprocket

Inspecting the final drive

Footrest brackets

Reassembling the front footrest brackets

Removing the front footrest brackets

Refitting the front footrests

Removal of the front footrests

Stands

Refitting the side stand

Removing of the side stand

Frame inspection

Reassembling the frame and the lateral footrests

Removing the frame and the lateral footrests

Reassembly of the tool tray

Removal of the tool tray

Reassembly of structural components and the frame

Checking the frame

Disassembly of structural components and the frame

Tail light - number plate holder

Refitting the tail light

Removal of the tail light

Refitting the number plate holder

Removing the number plate holder

SBK.08 - Fuel/Exhaust System

Fuel tank

Replacing the tank flange and fuel sensor.

Refitting the fuel tank

Refitting the filler cap

Removal of the fuel tank filler cap

Removal of the fuel tank

Airbox - Throttle Body

Refitting airbox and throttle body

Removing the airbox and throttle body

Air intake

Refitting the air filters

Removing the air filters

Exhaust system

Refitting the silencer

Refitting the exhaust system

Removing the exhaust system

Removing the silencer

Evaporative emissions canister

Refitting the Canister filter

Removing the Canister filter

Canister filter system

SBK.09 - Engine

Cooling system: radiator

Removal of the radiator

Refitting of the cooling system hoses and unions

Removing the cooling system hoses and unions

Refitting of the radiator

Replacing the cooling fan

Removal of the radiator

Flywheel - alternator

Removal of the flywheel/alternator assembly

Fitting of the alternator-side crankcase cover

Fitting of the flywheel-alternator assembly

Overhaul of the flywheel/alternator assembly

Disassembly of the generator cover

Removal of the generator cover

Clutch assembly: clutch

Refitting of the clutch

Checks and overhaul of the components

Removing the clutch

Description of the clutch assembly

Clutch assembly: clutch cover

Refitting of the clutch cover

Reassembly of the clutch-side crankcase cover

Disassembly of the clutch cover

Removal of the clutch cover

Clutch assembly: primary drive gears

Refitting of the primary drive gears and checking backlash

Removing the primary drive gears

Cooling system: water pump

Refitting of the water pump

Removal of the water pump

Lubrication system: oil delivery pump

Reassembly of the oil delivery pump

Disassembly of the oil delivery pump

Refitting of the oil delivery pump

Removal of the oil delivery pump

Lubrication system: oil heat exchanger

Refitting of the oil heat exchanger

Removal of the oil heat exchanger

Gearbox assembly: gearchange mechanism

Refitting of the gear selector lever

Removing the gearchange mechanism

Cylinder head assemblies: checks and adjustments

Checking the engine timing

Checking and adjusting the valve clearance

Cylinder head assemblies: camshafts

Check of the camshafts and supports

Positioning crankshaft at power stroke TDC

Refitting of the camshafts

Removal of the camshafts

Cylinder head assemblies: rocker arms

Removal of the rocker arms

Cylinder head assemblies: timing system

Refitting of the heads (from removal of the heads with timing chain removal)

Removal of the heads with timing chain removal

Refitting of the heads (from removal of the heads without removing the timing chain)

Removal of the heads without removing the timing chain

Refitting of the chain

Removing of the chain

Cylinder head assemblies: valves

Overhaul of the head components

Refitting of the valves

Removing the valve rocker arms

Sleeve-piston set

Overhaul of the sleeve-piston set components

Crankcase assembly: external components

Refitting of the external components

Removing outer components

Crankcase assembly: crankcase halves

Overhaul of the crankcase halves

Reassembly of the crankcase halves

Refitting of the crankcase halves

Crankshaft main bearings

Separation of the crankcase halves

Crankcase assembly: connecting rods

Refitting the connecting rod assembly

Reassembly of the connecting rods

Overhaul of the connecting rods

Disassembling the connecting rod assembly

Removal of the crankshaft/connecting rods assembly

Lubrication system: scavenge oil pump

Refitting of the scavenge oil pump

Removal of the scavenge oil pump

Gearbox assembly: gearbox shafts

Reassembling the gearbox shafts

Inspecting the fork selector drum

Inspecting the gear selector forks

Overhauling the gearbox

Disassembling the gearbox shafts

Refitting of the gearbox

Removing the gearbox assembly

Symbols - Abbreviations - References

To allow quick and easy consultation, this manual uses graphic symbols to highlight situations in which

maximum care is required, as well as practical advice or information. Pay attention to the meaning of

the symbols since they serve to avoid repeating technical concepts or safety warnings throughout the

text. The symbols should therefore be seen as real "reminders". Please refer to this page whenever in

doubt as to their meaning.

The terms right-hand and left-hand refer to the motorcycle viewed from the riding position.

Warning

Failure to comply with these instructions may put you at risk, and could lead to severe injury or even

death.

Important

Failure to follow the instructions in text marked with this symbol can lead to serious damage to the

motorcycle and its components.

Note

This symbol indicates additional useful information for the current operation.

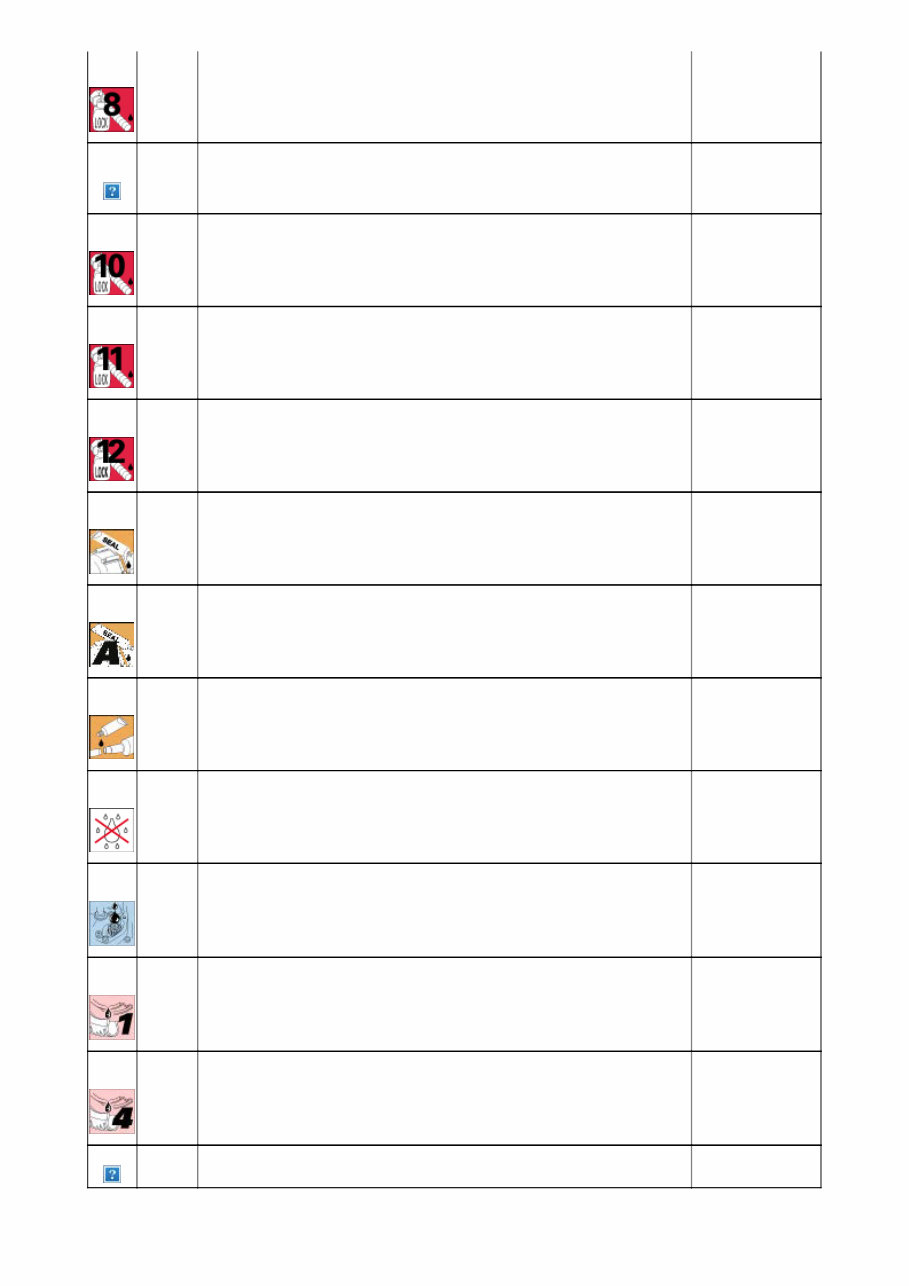

Product specifications

Symbols in the diagram show the type of threadlocker, sealant or lubricant to be used at the points

indicated. The table below shows the symbols used and the specifications of the various products.

Symbol Specifications Recommended

product

Engine oil (for characteristics see Fuel, lubricants and other fluids ). SHELL Advance

4T Ultra

DOT 4 special hydraulic brake fluid. SHELL Advance

Brake DOT 4

SAE 80-90 gear oil or special products for chains with O rings. SHELL Advance

Chain or Advance

Teflon Chain

Anti-freeze (nitride, amine and phosphate free) 30 to 40% + water. SHELL Advance

coolant or

Glycoshell

GREASE

A

Multipurpose, medium fibre, lithium grease. SHELL Alvania R3

GREASE

B

Molybdenum disulphide grease, high mechanical stress and high

temperature resistant.

SHELL Retinax

HDX2 or SHELL

Gadius S2 V220

AD 2

GREASE

C

Bearing/joint grease for parts subject to prolonged mechanical stress.

Temperature range: -10 to 110 °C.

SHELL Retinax

LX2

GREASE

D

Protective grease, with anti-corrosive and waterproofing properties. SHELL Retinax

HD2

GREASE

E

Grease PANKL - PLB 05

GREASE

F

Grease OPTIMOL - PASTE

WHITE T

GREASE

G

Grease PANKL - PLB07

GREASE

H

Grease KLÜBER

STABURAGS NBU

30 PTM

GREASE

I

Copper grease CUPRUM 320

LOCK 1 Low-strength threadlocker. Loctite 222

LOCK 2 Medium-strength threadlocker, compatible with oil. Loctite 243 (or

THREE BOND

TB1324)

LOCK 3 High-strength threadlocker for threaded parts. Loctite 270

LOCK 4 Surface sealant resistant to high mechanical stress and solvents.

Resists high temperatures (up to 200 °C) and pressures up to

350 bar; fills gaps up to 0.4 mm.

Loctite 510

LOCK 5 Permanent adhesive for freely sliding cylindrical couplings or threaded

couplings on mechanical parts. High resistance to mechanical stress

and solvents. Temperature range: 55 to 175 °C.

Loctite 128455

(former 648 BV)

LOCK 6 Pipe sealant for pipes and medium to large fittings. For water and

gases (except oxygen). Maximum filling capacity: 0.40 mm (diameter

clearance).

Loctite 577

LOCK 7 Instant adhesive for rubber and plastics with elastomer charged

ethylic base.

Loctite 480

LOCK 8 High-strength retaining compound for threaded parts, bearings,

bushes, splines and keys. Operating temperature range: 55 to

150 °C.

Loctite 601 (As

an alternative

THREE BOND

TB1378B)

LOCK 9 Medium-strength threadlocker. Loctite 406

LOCK

10

Product for metal parts to seal and lock freely sliding cylindrical

couplings or threaded couplings. Resistant to high mechanical stress

and high temperature, excellent resistance to solvents and chemical

attack.

Loctite 128443

(former 648 AV)

LOCK

11

Medium-strength threadlocker. Loctite 401

LOCK

12

Instant adhesive gel offering tensile/shear strength. Loctite 454 gel

DUCATI sealing compound. THREE BOND

1215

Sealing compound THREE BOND

1207B

Exhaust pipe sealing paste. Self-sealing paste hardens when heated

and resists temperatures exceeding 1000 °C.

Holts Firegum

Spray used to protect electric systems. Eliminates moisture and

condensation and provides excellent corrosion resistance. Water

repellent.

SHELL Advance

Contact Cleaner

Dry lubricant, polymerising on contact with air. Molykote D321R

Molykote M55

Plus

Emulsion for lubrication of rubber. P 80

Protection lubricant emulsion. KLUBERPLUS S

06/100

Lubricant for mechanical elements Castor oil

General maintenance indications

Useful tips

Ducati recommends that you follow the instructions below in order to prevent problems and obtain the

best end result:

- when diagnosing faults, primary consideration should always be given to what the customer reports

about motorcycle operation since this information can highlight anomalies; your questions to the

customer concerning symptoms of the fault should be aimed at clarifying the problem;

- diagnose the problem systematically and accurately before proceeding further. This manual provides

the theoretical background for troubleshooting; this basis must be combined with personal

experience and attendance at periodic training courses held by Ducati;

- repair work should be planned carefully in advance to prevent any unnecessary downtime, for

example obtaining the required spare parts or preparing the necessary tools, etc.;

- limit the number of operations needed to access the part to be repaired. Note that the disassembly

procedures in this manual describe the most efficient way to reach the part to be repaired.

General advice on repair work

- Always use top quality tools. When lifting the motorcycle, only use devices that comply fully with the

relevant European directives.

- When working on the motorcycle, always keep the tools within reach, ideally in the order required,

and never put them on the motorcycle or in hard-to-reach or inaccessible places.

- The workplace must be kept clean and tidy at all times.

- Always replace gaskets, sealing rings and split pins with new parts.

- When loosening or tightening nuts or screws, always start with the largest or start from the centre;

tighten nuts and screws to the specified torque working in a crosswise sequence.

- Always mark any parts and positions which might easily be confused at the time of reassembly.

- Use exclusively Ducati original replacement parts and the recommended brands of lubricants.

- Use special service tools where specified.

- Ducati Technical Bulletins often contain updated versions of the service procedures described in this

manual. Check the latest Bulletins for details.

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

Viewed 14 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

The Ducati 899 Panigale Workshop Service Repair Manual in English covers all aspects of repair and maintenance. It is used by professional technicians and contains detailed instructions and step-by-step diagrams for all workshop procedures, including electrical diagrams, torque settings, fluid capacities, etc. The package also includes the parts catalogue and owners manual, making it a gold mine of information for both professional mechanics and DIY enthusiasts. Whether you need to change the plugs or rebuild the engine, this manual provides all the information you could possibly want. You will receive the 899 Panigale workshop manual, parts catalogue, and owners manual in one package.