Derbi Manuals for mechanics

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

This manual has been prepared by DERBI Nacional Motor, S.A. Sociedad

Unipersonal for use by concessionaires and DERBI sub-agency workshops. It is

assumed that persons using this work for the maintenance and repair of

DERBI vehicles will have a basic grounding in the principles of mechanics

and the necessary technical methods used in the repair of such vehicles.

Major variations in the technical specifications of the vehicles or in specific

repair operations will be communicated by means of updates to this manual.

Nevertheless, completely satisfactory work cannot be performed without the

necessary installations and tools: for this reason we strongly recommend that

you consult the pages in this manual which refer to specific tools and equip-

ment.

Information in this manual which is of particular importance is indicated by

the following notes:

N.B. This indicates a note which gives key information for performing the

procedure more easily and clearly.

This indicates specific procedures which should be followed to

avoid causing damage to the vehicle.

This indicates procedures which should be followed to avoid

possible injury to the person carrying out the repairs to the vehicle.

Caution!

Warning !!!

All data may be changed without prior notice.

Derbi declines all responsibility for the use of non-original parts and accessories

which have not been tested and approved.

1

DERBI - NACIONAL MOTOR Sociedad Unipersonal / 2002 • Dep. Leg. GI-1302-2000 • N.º 80881158407

fourth edition - May 2002

2

3

INDEX

Predator-LC / O2 Atlantis-LC / O2 / 100 Models

Hunter - Paddock - Vamos Models

Technical specifications of the engine _4

Special tools_____________________5

Regular maintenance table _________6

Torque settings___________________7

Front forks - HUNTER _____________8

Front forks - PADDOCK ____________9

Front forks - VAMOS ______________9

Withdrawing the engine

from the frame ________________10

Stripping the engine ______________11

Assembly of the engine ___________16

Crankshaft inspection_____________18

Assembly of right hand crankcase

bearing ______________________19

Water pump ____________________20

Assembly of sliding weight hub _____22

Clutch assembly_________________23

Reduction gear__________________24

Left hand crankcase cover _________24

Cylinder head, cylinder,

and piston ____________________27

Carburettor _____________________30

Cylinder sleeve cover,

radiator and filter box ___________33

Fitting the engine in the frame ______35

Electrical system ________________36

Electrical wiring diagrams _________45

Regular Maintenance Table ________50

Torque settings__________________51

Front forks _____________________52

Rear suspension ________________54

Removing the engine

from the frame ________________56

Magneto _______________________57

Cylinder head, cylinder and piston ___58

Crankshaft - Variable speed unit ____60

Carburettor _____________________61

Electrical system ________________62

Electrical wiring diagrams _________65

Engine Piaggio Models

Special tools_________________________74

Regular Maintenance Table __________77

Torque settings ______________________78

Paioli front forks _____________________79

Engine ______________________________80

Magneto_____________________________81

Electronic ignition ____________________83

Transmission - mixer_________________84

Cylinder head - cylinder - piston

(Liquid cooled models) ____________95

Crankcase halves - crankshaft _______98

Secondary air system_______________102

Cylinder head - cylinder - piston

(Air cooled models) ______________104

Vehicle service data ________________107

Carburettors ________________________110

Electrical system____________________111

Electrical wiring diagrams ___________113

1

2

3

4

Engine

Number of cylinders .................1

Cycle ........................................2-stroke

Stroke and Bore .......................41 x 37.4 mm

Cubic capacity..........................49cc

Fuel admission .........................reed valve direct to crankcase

Compression ratio ....................11.5 : 1

Starter system ..........................electric start

Engine cooling system .............fan-driven pressurised air

LC: liquid cooling

Fuel ..........................................Unleaded fuel

Lubrication system ...................petrol-oil mixture, using constant flow pump driven lubrication

Atlantis 100:

Stroke and Bore .......................50 x 43 mm

Cubic capacity..........................85cc

Compression ratio ....................9.5 : 1

Carburettor

Type .........................................DELL’ORTO PHVA 10.GD / PHVA12 DD / PHVA 14 DD / PHVA 17.5

WEBER 14 OM 1 AA / WEBER 14 OM 1 BA / WEBER 12 OM 1 QA

WEBER 12 OM 1 SA / WEBER 14 OM 1 FA

Primary drive...............................automatic variable speed unit through trapezoidal belt drive

Clutch ..........................................automatic centrifugal dry clutch

Ignition

System .....................................magneto 12V 80W.

Ignition advance .......................18º before T.D.C.

Spark plug ................................NGK B8 HS / CHAMPION L.78 C.

NGK B9 ES / CHAMPION N.2.C / NGK B8 ES / CHAMPION N3C

Battery......................................12V 4Ah

TECHNICAL SPECIFICATIONS OF THE ENGINE

5

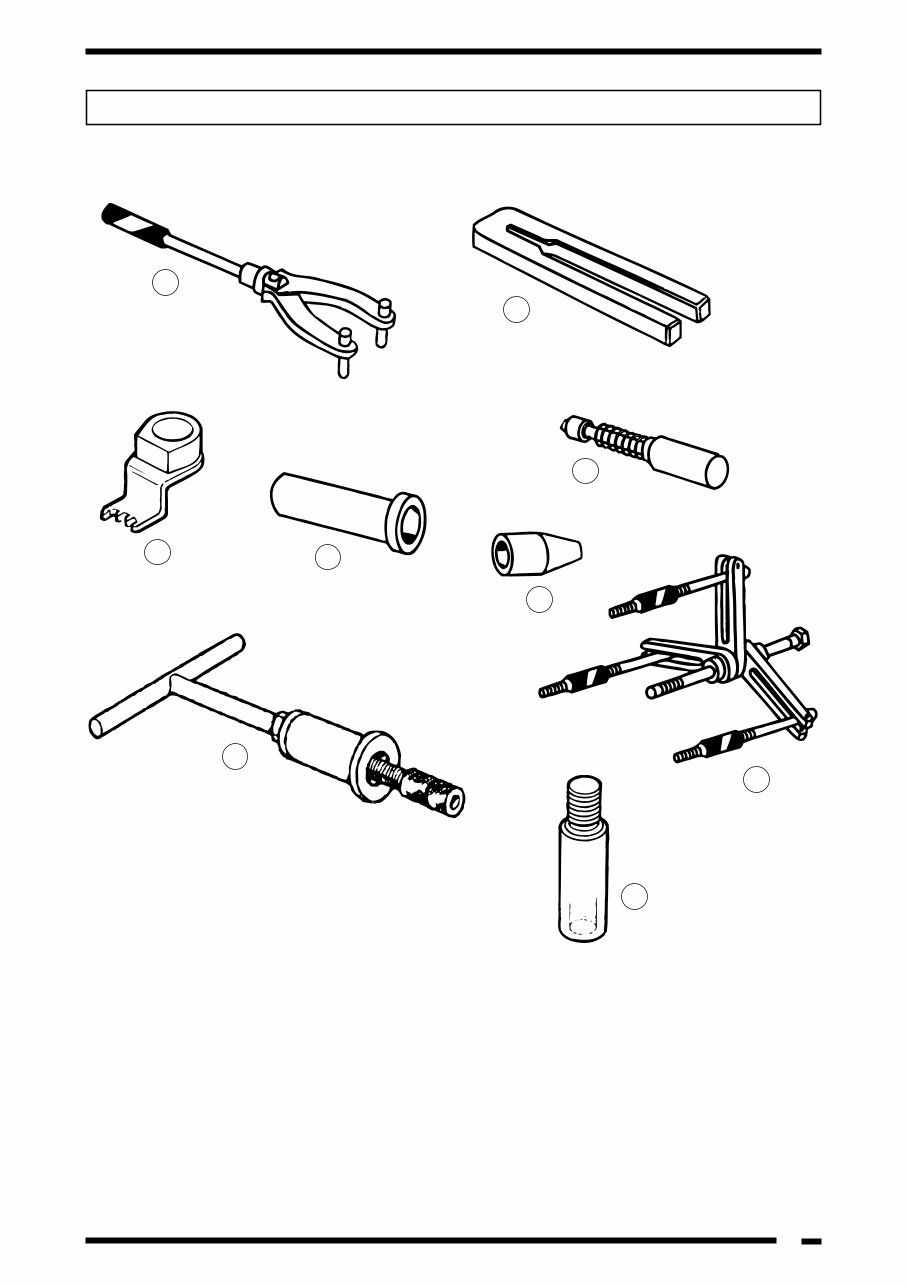

Part Name Reference Number

1.- Magneto disassembly tool unit ..............................................................0.0G.053.0.001.1

2.- Connecting rod blocking tool .................................................................0.0G.056.0.037.1

3.- Water pump shaft extractor tool ............................................................0.0G.056.0.042.1

4.- Crankshaft assembly tool (use for water pump shaft) ...........................0.0G.056.0.036.1

5.- Crankshaft seal guide bush ...................................................................0.0F .053.0.084.1

6.- Crankshaft seal assembly punch ..........................................................0.0F .054.0.045.1

7.- Gudgeon pin circlip assembly tool ........................................................0.0G.056.0.041.1

8.- Water pump pinion blocking tool ...........................................................0.0G.053.0.098.1

9.- Engine splitting tool ...............................................................................0.0G.053.0.015.1

SPECIAL TOOLS

1

8

6

4

5

3

9

7

2

6

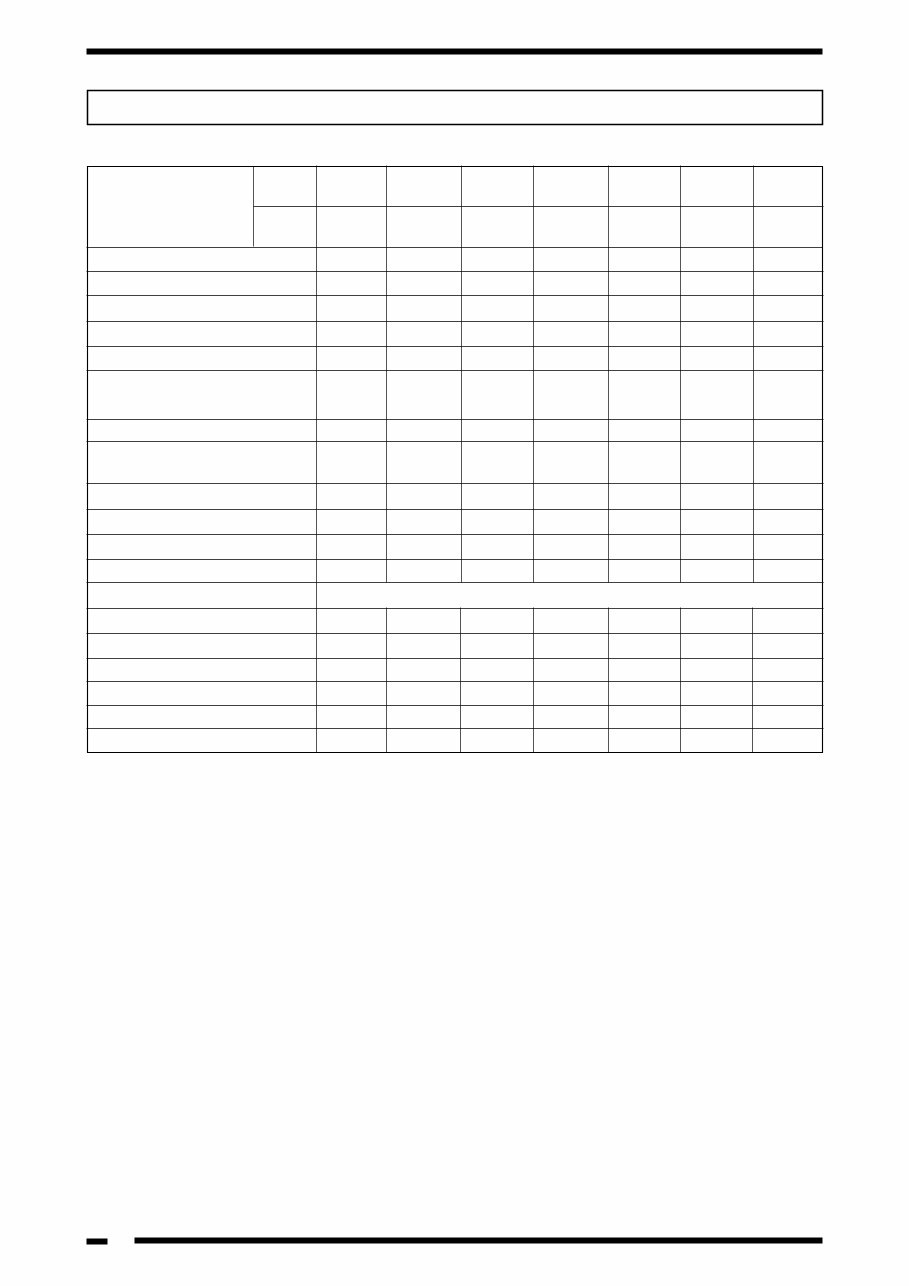

REGULAR MAINTENANCE TABLE

Período: este período puede Km 1000 2500 5000 10000 15000 20000 25000

valorarse según los kilómetros

Months 2 6 12 24 36 recorridos o el tiempo en meses

Reduction gear or crankcase oil Replace Check Check Replace Check Replace Check

Suspensions Check Check Check Check Check

Tighten all fastenings Check Check Check Check Check Check Check

Electrical connections Check Check Check Check Check Check Check

Spark plug Clean Adjust Replace Replace Replace Replace Replace

Carburettor Adjust Adjust Adjust Adjust Adjust Adjust

Clean Clean Clean Clean Clean Clean

Water pump drive belt Replace

Variable speed drive rollers Check

drive belt transmission Replace

Oil filter Check Replace Check Replace Check

Air filter Clean Clean Clean Clean Clean

Brakes / hose / pads Check Check Check Check Check

Brake equipment Check Check

Brake fluid EVERY 2 YEARS EVERY 2 YEARS

Tyres Check Check Check Check Check

Tyres pressures Check Check Check Check Check Check Check

Fuel or oil hoses Check Replace Check Replace Check

Transmission Lubricate Lubricate Lubricate Lubricate Lubricate

Cylinder head nuts Tighten up Tighten up

Inlet valve reeds Check Check

Period: the period may be calcu-

lated by kilometres run or by

time in months

7

PART NAME TORQUE SETTING

(Nw x m.)

BRAKE SHOE ROTATION SHAFT 8M125 17 - 19 LOCTITE

CYLINDER STUD 6M100 STUD 10 - 12

CRANKCASE HALVES 6M100 SCREW 9 - 10 LOCTITE

CYLINDER HEAD 6M100 NUT 10 - 12

INLET MANIFOLD VALVE BRACKET 4M70 SCREW 1 - 2 LOCTITE

CRANKCASE INLET MANIFOLD 6M100 SCREW 9 - 10 LOCTITE

OIL PUMP 5M80 SCREW 4 - 5 LOCTITE

COIL TO BASE PLATE 6M100 SCREW 8 - 10 LOCTITE

BASE PLATE TO CRANKCASE 6M100 SCREW 8 - 10 LOCTITE

MAGNETO 10M100 NUT 35 - 40 LOCTITE

STARTER MOTOR 6M100 SCREW 9 - 10 LOCTITE

FAN TO MAGNETO 6M100 SCREW 8 - 10 LOCTITE

ENGINE BRACKET PLATE A.E. 6M100 SCREW 9 - 10 LOCTITE

LEFT HAND SIDE CRANKSHAFT 10M100 NUT 35 - 40 LOCTITE

REDUCTION GEAR COVER 6M100 SCREW 9 - 10 LOCTITE

PULLEY SHAFT 10M100 NUT 35 - 40 LOCTITE

PLASTIC OIL FILLER CAP 14M150 CAP HAND TIGHT

LEFT HAND CRANKCASE COVER 6M100 SCREW 9 - 10 LOCTITE

OIL DRAIN PLUG 8M125 SCREW 17 - 19

CYLINDER SLEEVE 6M100 SCREW 9 - 10

FRONT WHEEL 12M150 NUT 50 - 60

REAR WHEEL 16M150 NUT 100 - 105

SWINGING ARM 10M150 NUT 40 - 45

SHOCK ABSORBER UPPER/LOWER 10M150 NUT 40 - 45

HANDLEBAR 8M125 SCREW 20 - 25

EXHAUST PIPE TO CYLINDER 6M100 SCREW 8 - 12

EXHAUST PIPE - INTERMEDIATE 6M100 NUT 8 - 12

EXHAUST PIPE TO CRANKCASE 10M150 SCREW 40 - 45

FORK LEG CLOSURE 6M100 NUT 8 - 12

STEERING 25M100 NUT 70 - 90

FRONT BRAKE 8M125 SCREW 20 - 25

KICK START PEDAL 6M100 SCREW 08 - 12 LOCTITE

SILENCER PROTECTOR 4M70 SCREW 1 - 2 LOCTITE

TORQUE SETTINGS

8

HUNTER MODELS

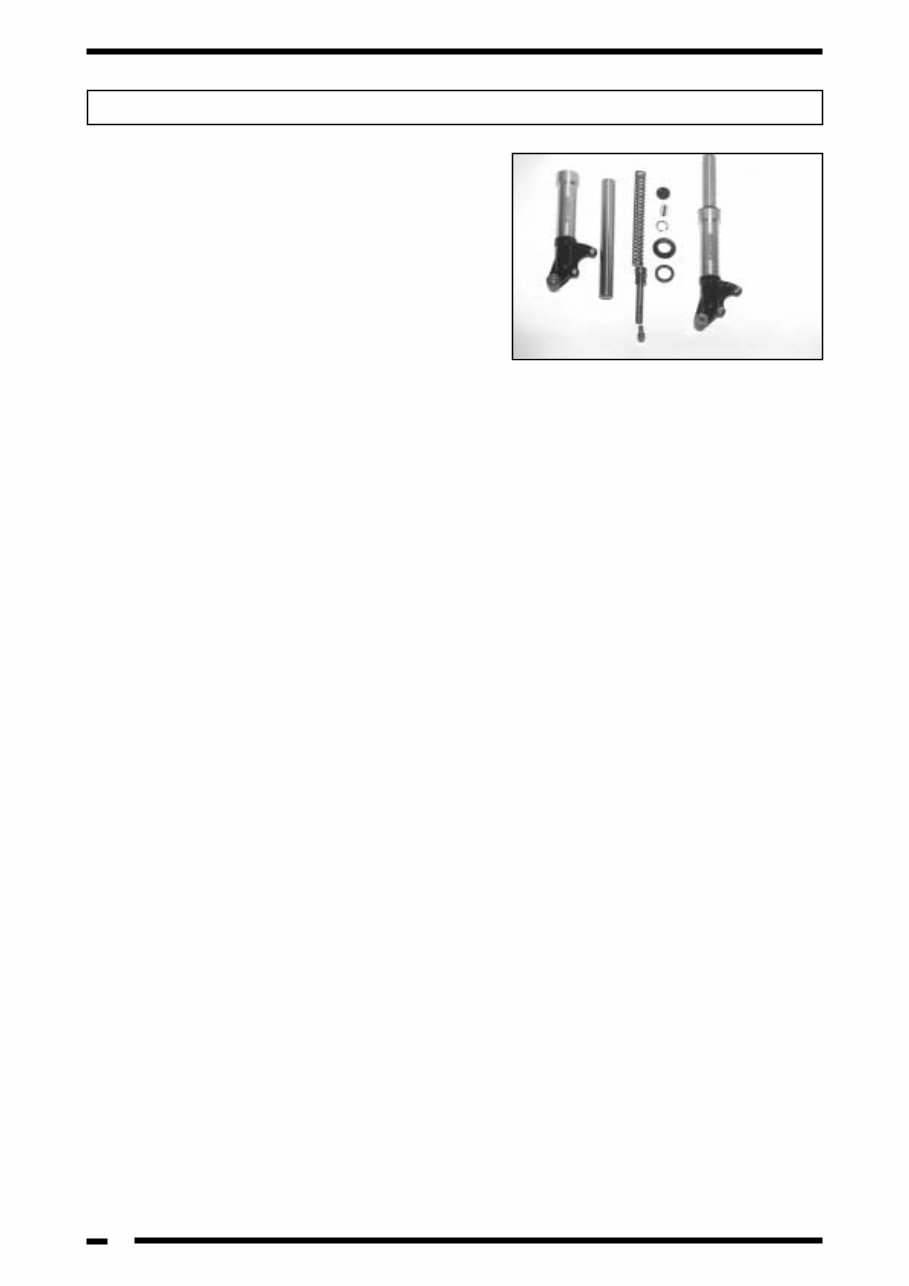

Stripping the fork legs

- Withdraw the two screws from the brake caliper.

- Withdraw the front wheel axle nut and slacken

the lock screw.

- Withdraw the front wheel axle, the wheel DIS-

TANCE PIECE, and leave the transfer box and

the separator hanging free.

- Withdraw the fork protection plate screw so as to

be able to extract the external fork leg cap.

- Loosen the 10 x 25 screw from the fork plate and

while pushing upwards on the fork leg, release

the fork bar securing clip.

- Withdraw the fork leg from the vehicle.

Both fork legs are the same.

Stripping the left or right hand fork bar

- Withdraw the safety circlip.

- Undo the fork leg tube cap and seal.

- Drain the hydraulic fluid from the bar.

- Extract the fork leg spring.

- Loosen and extract the fork leg screw.

- Withdraw the hydraulic tube and the bar from the

fork leg.

- Extract the dustguard, the seal securing circlip,

and finally the seal.

Note: Clean thoroughly all the parts which are

to be re-fitted; it is mandatory under all cir-

cumstances to replace the O-rings and seals.

Re-assembly of the fork leg

- Fit the seal into the fork leg size 30-40-7/9. Using

special tool 0.0H.054.0.045.1 and insert the seal

securing circlip.

- Insert the hydraulic tube inside the fork bar.

- Insert the bar inside the fork leg, fit the fork spring

and tighten the 10 x 25 screw using a copper

washer and Loctite to a torque of 35 - 40 Nw x m.

- Re-fill using 80 cc of AGIP FORK SAE10W

hydraulic oil.

FRONT FORKS

- Insert the fork leg tube cap with the O-

ring seal, the safety circlip and the dust-

guard.

- Assemble the fork leg into the vehicle.

- Insert the complete fork leg assembly

into the fork plate.

- Fit the safety circlip and the exterior fork

leg cap.

- Tighten the fork plate securing screw.

- Tighten the mudguard/fork plate protec-

tor securing screw.

- Locate the wheel axle, the transfer box,

the transfer box bushing, the wheel, and

fit the brake caliper onto the brake disc;

then the distance piece, the washer, the

spring washer and nut, tightening to a

torque of 50 - 60 Nw x m.

- Tighten the fork leg closure screw to a

torque of 8 - 12 Nw x m.

- Locate the two brake caliper securing

screws (8 x 60) to a torque of 20 - 25

Nw x m. using Loctite. Finally turn the

wheel and operate the brake lever.

9

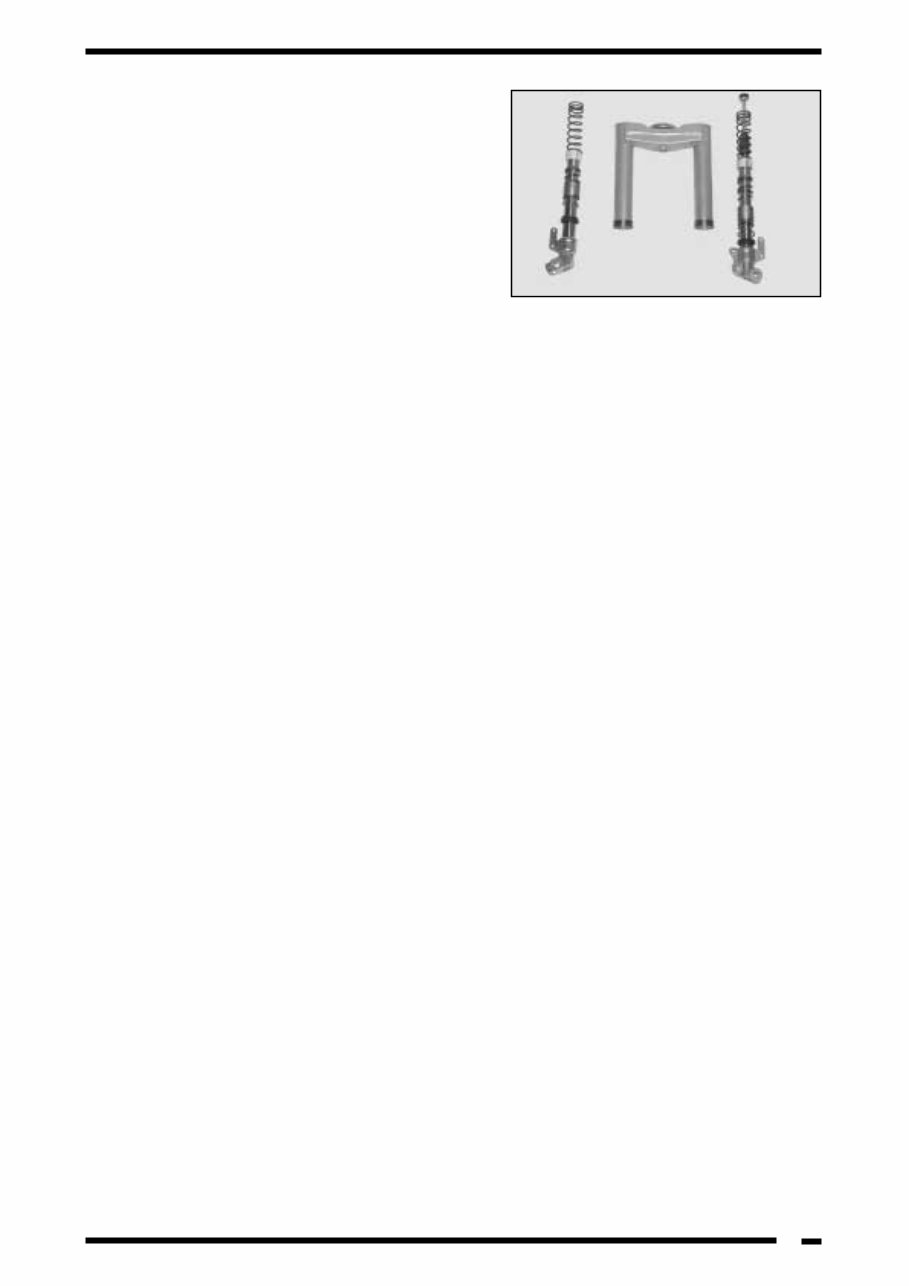

PADDOCK MODELS

Stripping the fork legs

- Withdraw the four mudguard screws and remove

the mudguard.

- Slacken off the wheel axle nut, withdraw the was-

her, loosen the 2 front brake caliper screws, loo-

sen the locking screw, extract the wheel axle, the

axle distance piece and leave the transfer box

and the separator hanging free.

Stripping the left hand fork bar

- To disassemble the left hand fork bar without

stripping the fork the following procedure should

be followed:

- Remove the dustguard and extract the safety cir-

clip.

- Withdraw the two screws securing the bag carrier

hook.

- Withdraw the seven screws securing the inner

shield and remove the inner shield.

- Drill a hole using a 15 mm drill through the fork

plate protector so as to be able to insert a tube

spanner and loosen the 6 x 100 nut and washer;

this way it is possible to withdraw the left hand

fork leg, with the hydraulic cartridge with bushing

and silentbloc, the boss, the rubber stop spring

and the guide washer.

If the hydraulic cartridge loses oil it must be

replaced, since it cannot be repaired.

Right hand fork bar

- Remove the dustguard and the safety circlip.

- Withdraw the right hand fork leg, the lower spring

washer, the rubber stop and the spring.

This fork leg should be filled with AGIP GR MU

3 type grease only.

Re-fitting the two fork legs is carried out in the

reverse order from stripping.

VAMOS MODELS

Stripping the fork legs

- Withdraw the 2 front brake caliper

screws (“separate the caliper”).

- Remove the wheel axle nut, the spring

washer and the washer.

- Withdraw the wheel axle, the transfer

box bushing and the whole transfer box

assembly.

- Loosen the end piece screws, and with-

draw the end pieces.

- Extract the fork leg dustguard and the

safety circlip.

- Withdraw the fork leg, the stop and the

spring.

When re-assembling, carry out the same

procedures in reverse order.

The fork legs should be filled with AGIP

GR MU 3 type grease.

10

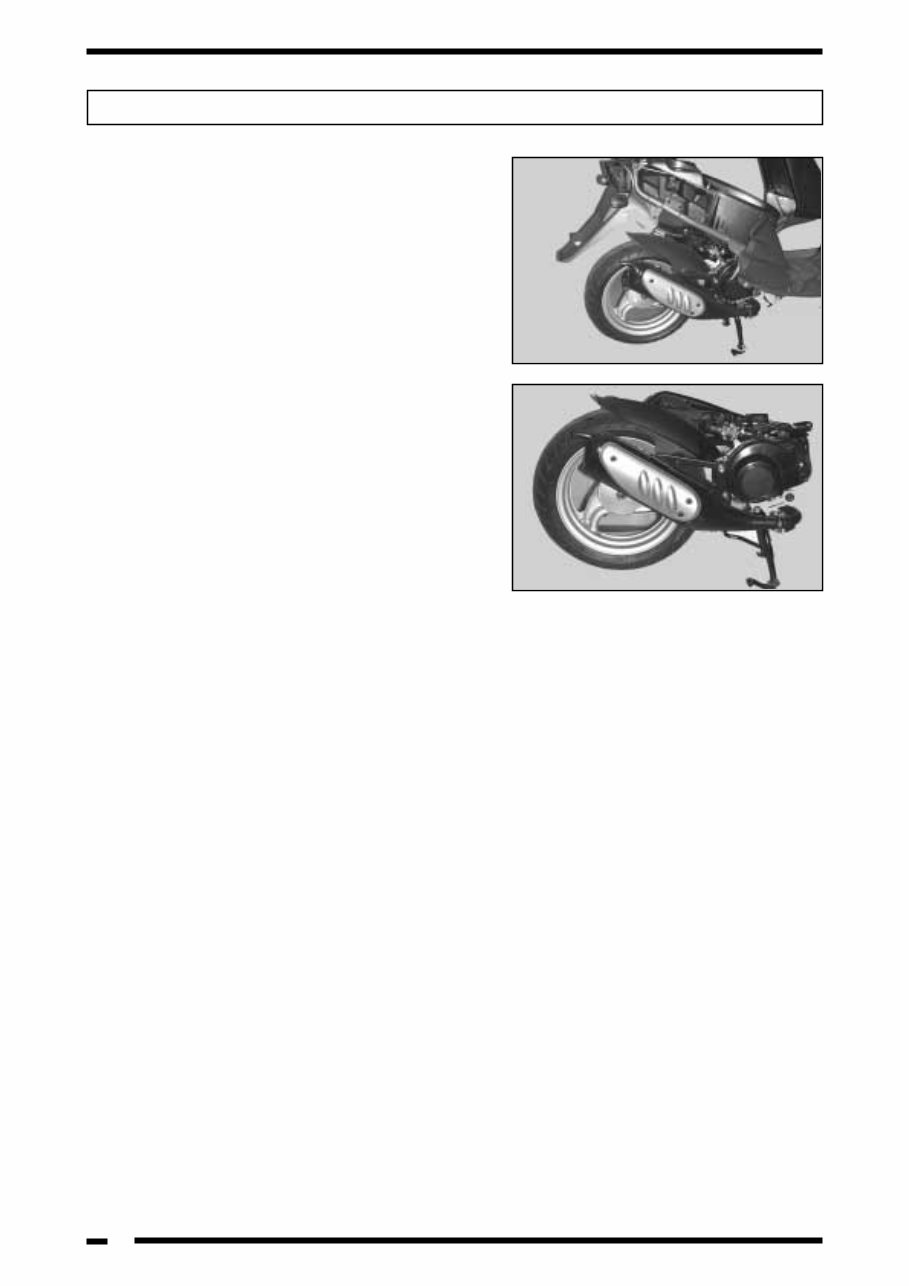

STRIPPING

- Remove the luggage carrier ( 4 screws).

- In PADDOCK models separate the electrical con-

nectors on the turn indicators.

- The left hand footrest cover (1 screw).

- The left hand side panel (2 screws).

- The right hand footrest cover (1 screw).

- The right hand side panel (2 screws).

- Raise the saddle.

- Remove the side panels (5 screws).

- Remove the oil reservoir cap.

- Remove the fuel tank filler cap.

- Remove the anti-freeze reservoir cap on PAD-

DOCK-LC models.

- Remove the helmet carrier box (6 screws).

- Remove the rear brake cable nut.

- Remove the rear brake guide stop (1 screw).

- Remove the engine earth screw.

- Remove the throttle cable union.

- Disconnect the electrical connectors for the mag-

neto, the stop light, the choke, the starter, the

high tension coil and the coil earth cable.

- On the LC models, also disconnect the thermo-

contact spade connector.

- Disconnect the two pipes from the connector on

the carburettor: the fuel pipe and the vacuum line.

- Disconnect the oil hose at the reservoir outlet.

- In PADDOCK-LC models extract the antifreeze

drain plug.

- Remove the cooling hoses where they connect to

the antifreeze reservoir.

- Remove the 2 fixing screws which secure the

engine to the frame.

- Remove the 1 shock absorber screw.

- Separate the engine from the frame.

WITHDRAWING THE ENGINE FROM THE FRAME

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 55 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

These Derbi workshop manuals are a valuable resource for both professional mechanics and DIY enthusiasts. The self-running DVD contains 26 service books, including illustrated parts manuals, making it convenient to access the necessary information. The DVD includes folders for Derbi images and parts manuals, with detailed parts lists for various models such as Atlantis Aire, GPR, Senda, and more. Additionally, it provides workshop manuals for 50cc, 6-speed, service, and specific models like Predator LC and RS50 Motorparts. This comprehensive collection covers a wide range of Derbi models, ensuring that all your repair and maintenance needs are met.

- 26 service books included

- Illustrated parts manuals

- Convenient self-running DVD format

- Valuable resource for professional mechanics and DIY enthusiasts

- Includes detailed parts lists for various models

- Comprehensive workshop manuals for different models