Daelim Roadwin VJ125 VJ 125 Scooter Service Repair Workshop Manual INSTANT

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SM48-0401-01E

HOW TO USE THIS MANUAL

This manual describes effective maintenance procedure

for the VJ125 manufactured by DAELIM Motor Co., Ltd.

To ensure safety and optimal operating conditions of the

vehicle, carry out regular inspections according to the

maintenance schedule (Section 2).

Sections 1 through 2 provide information on overall

vehicle; and section 3 describes maintenance procedure

for the engine, frame and electrical systems.

To facilitate use of this manual, each page starts with

disassembly and system diagrams, service information,

and troubleshooting guide. If you cannot find the cause of

trouble, refer to Section 21: Troubleshooting.

Contents of this manual and specifications are

subject to change without prior notice for

improvement of vehicle quality.

CONTENTS

GENERAL INFORMATION

INSPECTIONS / ADJUSTMENTS

LUBRICATION

FUEL SYSTEM

ENGINE

1

2

3

4

COOLING SYSTEM 5

ENGINE REMOVAL

CLUTCH / GEARSHIFT

A.C.GENERATOR / STARTER CLUTCH

CYLINDER HEAD / VALVES

CYLINDER / PISTON

CRANKCASE / TRANSMISSION /

CRANKSHAFT

EXTERNAL PARTS

REAR WHEEL /REAR SUSPENSION

FRONT WHEEL/FRONT FORK/STEERING

HYDRAULIC BRAKE

FRAME ELECTRICAL SYSTEM

BATTERY / CHARGING SYSTEM

ELECTRIC STARTER

LIGHTS/METER/SWITCHES

IGNITION SYSTEM

6

7

8

9

10

11

12

13

14

15

16

17

WIRING DIAGRAM

18

TROUBLESHOOTING

19

20

21

1-1

1. GENERAL INFORMATION

SERVICE INFORMATION······· 1-1

SERVICE RULES·········· 1-1

CAUTION WHEN WIRING ····· 1-5

MODEL IDENTIFICATION ····· 1-9

SPECIFICATIONS ········· 1-10

TORQUE VALUES········· 1-12

SYMBOLS / ABBREVIATIONS ··· 1-14

TOOLS·············· 1-15

WIRING DIAGRAM ········ 1-16

SERVICE INFORMATION

1. Do not run the engine for a long time in closed or not well-ventilated area because the exhaust gas contains toxic

substances such as carbon monoxide, hydrocarbon, nitric oxide.

2. The battery fluid(lean sulfuric acid) is extremely toxic. It is dangerous if skin is exposed to it or if it enters into the eye.

Be careful in handling. When exposed to the battery fluid, wash it with water and get a medical check up.(store the

battery fluid in a safe place to avoid touching by the children)

3. Pay attention not to be burned and always put on the protection gears because the engine or the muffler is hot right after

engine stops.

4. Gasoline is extremely flammable. Maintenance must be performed in the place free of the open fire or electric spark.

5. When more than two person are working, always pay attention to other worker’s action and always have safety in mind.

6. The skin exposed to used engine oil can be a major reason of the skin cancer. Pay attention not to be exposed and wash

carefully with soap and water after handling.

7. If compressed air is used to clean the brake, dust scattered in the air can be breathed in by workers. Please take action not

to scatter dust in the brake cleaner, etc.

8. Flammable nitrogen gas is generated during charging the battery so charging must be performed in well-ventilated area

and free of the open fire and spark.

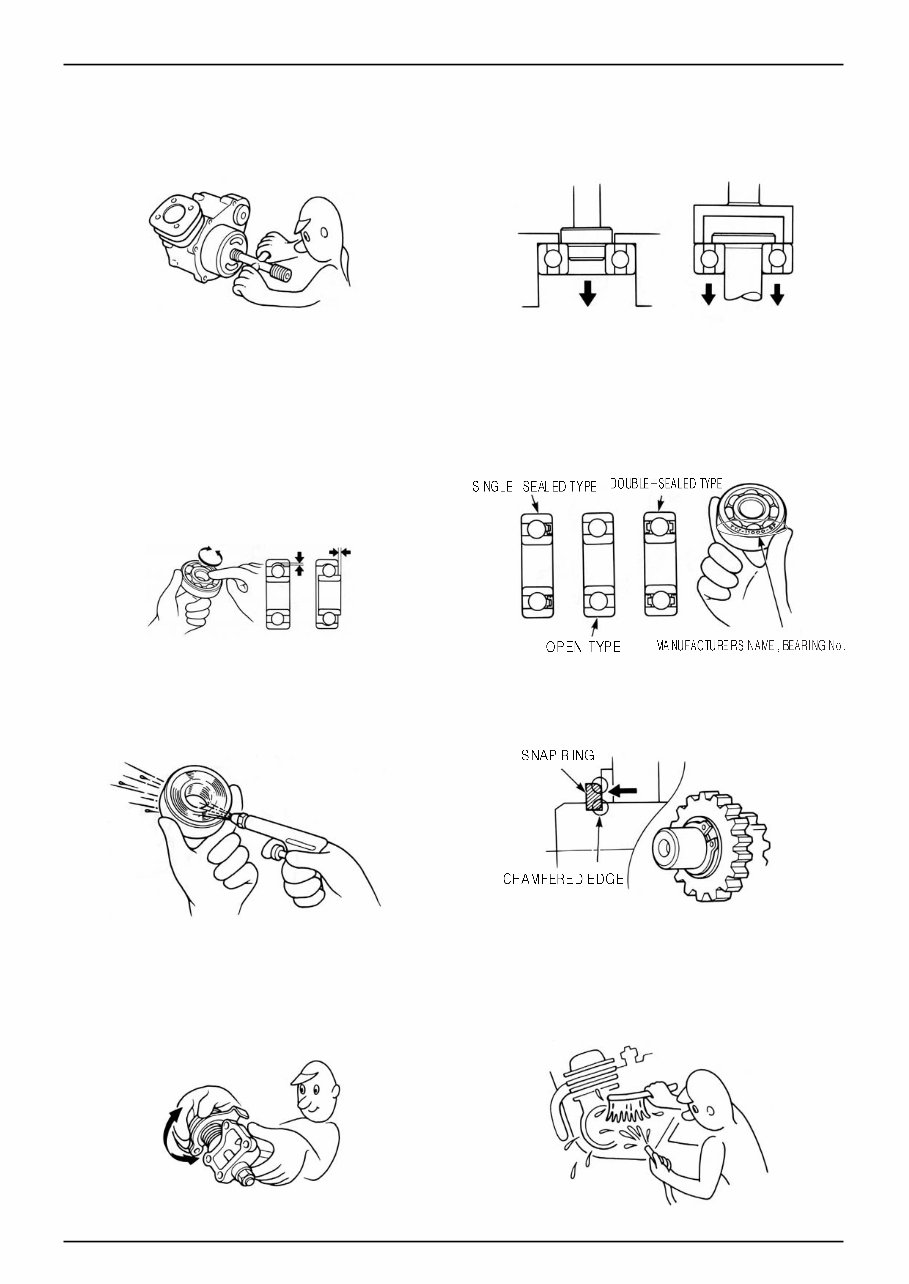

SERVICE RULES

1. Parts and lubrication oil must be DAELIM genuine or

recommended parts.

2. Before maintenance, remove deposit or dust from the

chasis.

1

1-2

GENERAL INFORMATION

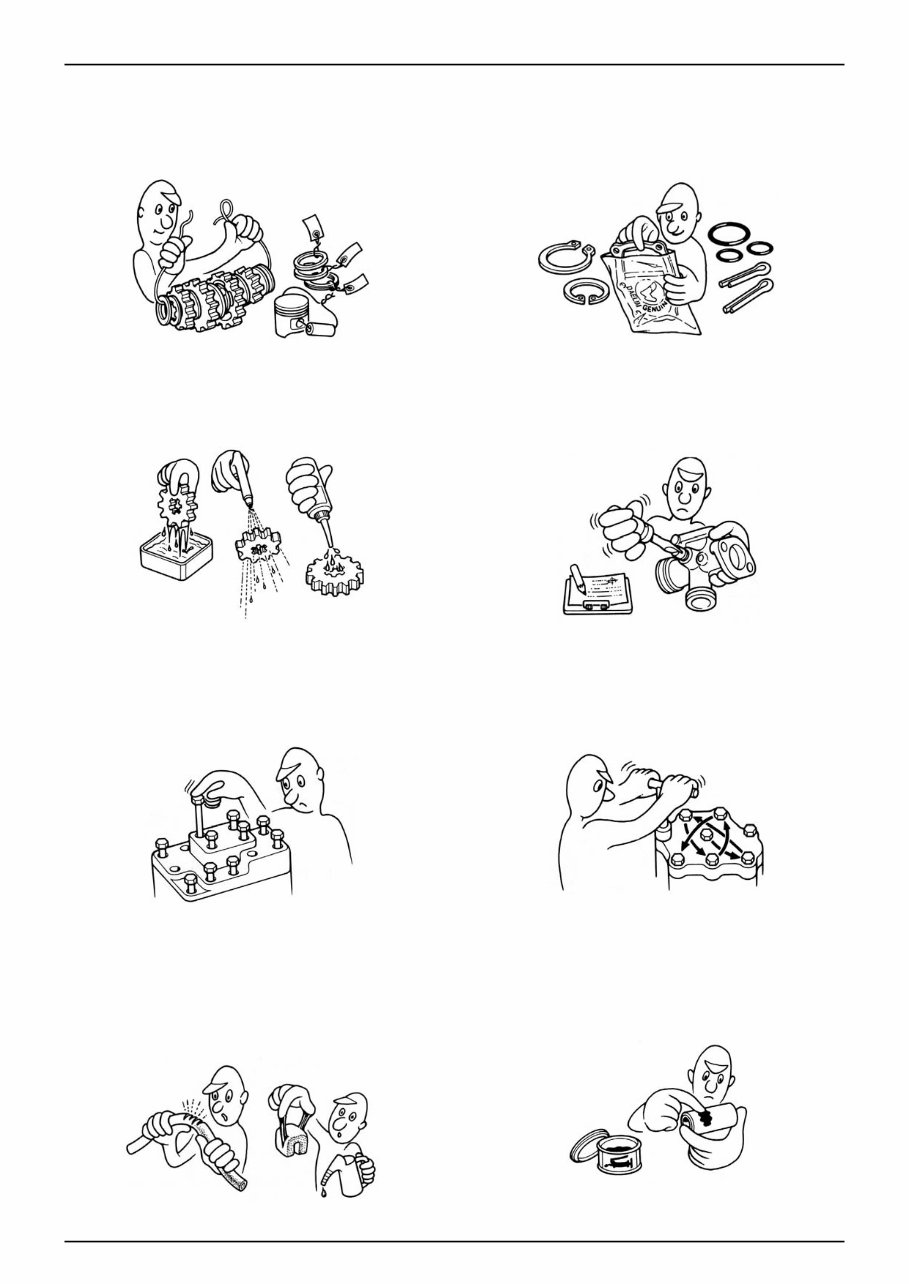

9. Check to see if the rubber part is worn out when

removing it and replace it if necessary. Some rubber part

is weak to gasoline and kerosene, so pay attention not to

soak with gasoline or oils.

10. Recommended grease must be applied to or filled in

the specified place.

7. Align the bolts to uniform the tightening points before

tightening them when you don’t know the bolt length.

8. Bolts, nuts and pieces must be tightened from the bigger

diameter to the smaller one, from inside to outside and

diagonally with the specified torque.

5. Clean the parts after the overhaul and before the test and

remove the cleaning oil with compressed air. Apply oil

to seal face during installation.

6. Check necessary place and measure necessary data

during installation. When installing, return to the state

before removing.

3. Store the parts of each system discriminatively to install

each part in the right place.

4. After removing gasket, O-ring, piston pin clip and cotter

pin, always replace them with the new one. When

removing the snap ring, it can be easily missed after

transformation or installation.

1-3

GENERAL INFORMATION

11. Maintenance needed to use the specialized tools must

be performed with the right tool.

12. Never reuse the ball bearing removed with the ball

applied pressure when removing press-fitted the

bearing.

13. Check the smooth rotation of inner or outer race of the

ball bearing by rotating it manually.

Replace the ball bearing having excessive axial/

longitudinal hanging.

Wipe the ball bearing likely to have hanging with

cleaning oil.(except double-sided sealed type ball

bearing)

Replace the ball bearing of which press-fitted part is

slacked at the case or shaft.

14. Pay attention to installation direction in case of the

single-sided sealed ball bearing. Install the open-

direction or double-sided sealed bearing in the way

that the face marked with manufacturer and size

should direct to the outer axle.

15. When blowing the ball bearing with compressed air

after cleaning, keep the race from rotating. High speed

rotation of the race may damage the bearing. Prior to

installation, apply oil or grease to the bearing.

16. Install the snap ring so that chamfered side directs to

the load-applied side. After installation, check the

proper installation by rotating the snap ring.

17. Check each part for proper tightening and operation

after installation.

18. The brake fluid and coolant can damage the painted

plastic or rubber parts. Keep these parts from

contacting with them and wash these parts with water

in case of contact.

’

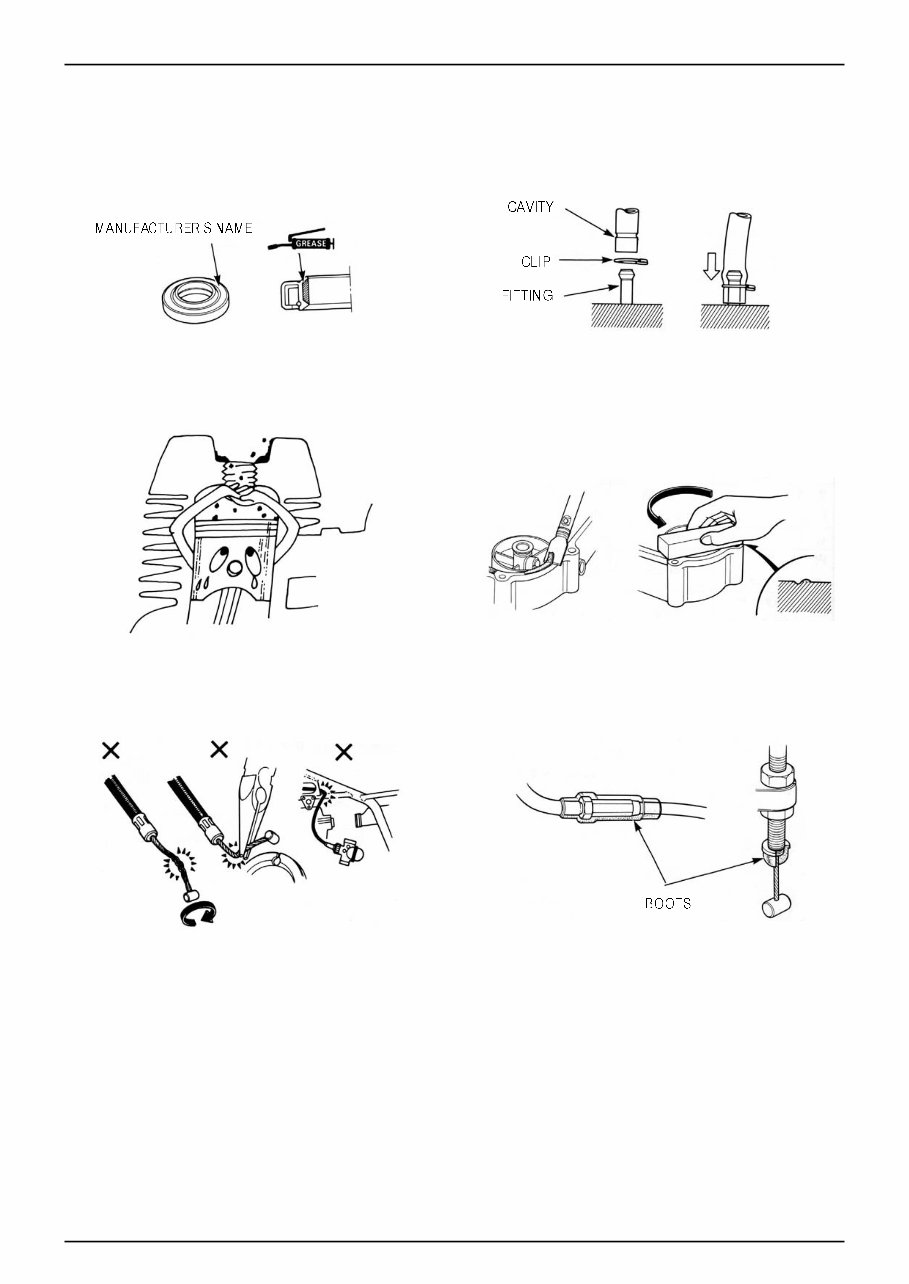

1-4

GENERAL INFORMATION

21. Keep the pneumatic system interior or the engine

interior from the infiltration of dust.

22. Install the gasket mounted in the contact surface of

each case of the engine while removing gasket

material completely. Remove damaged contact surface

by wiping with the oil stone equally.

19. Install the oil seal so that the manufacturer marked

surface directs outer surface.(direction not covered

with oil)

Pay attention not to bend or damage the lip.

Apply the grease to the lip.

20. Connect the tube until the tube fully inserted in the

joint. Install the clip if it is supplied. Replace the tube

having slacked end.

23. Pay attention not to bend the cable excessively.

Transformed or damaged cable may cause malfunction

or damage.

24. Install the boots with the installing groove by inserting

the boots into the groove.

’

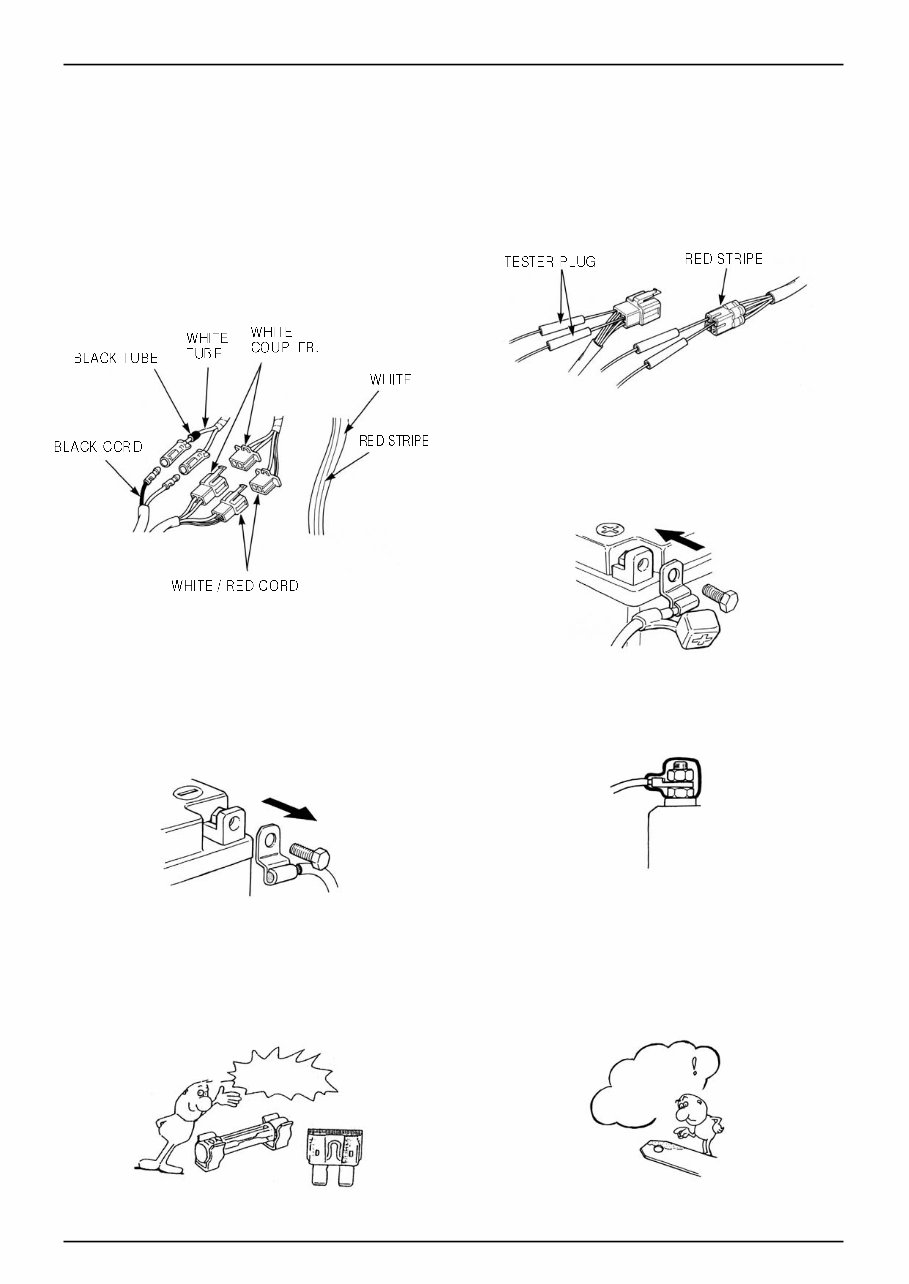

1-5

GENERAL INFORMATION

Each cord must be connected depending on its color.

When connecting different cord, attach color tube

around the connector. Connect the coupler to the

connector with same color and same pin number.

Identify the two-colored cord by main color first and

then spriped color .

When measuring voltage or resistance of the cord

terminal using tester, contact the tester plug behind of

the coupler. Pay attention not to open the cord terminal

and contact the tester plug from the front of the coupler

in case of water-proof coupler.

Recheck the condition of contact, securing and

continuity of each part after maintenance.

When connecting the battery, the plus terminal must be

connected first.

After connecting the terminal, apply the grease to the

terminal.

When disconnecting the battery, the minus terminal

must be disconnected first.

Make sure that the tool such as spanner do not contact

with the frame.

Connect covers to the terminal after maintenance.

If the fuse is short-circuited, find out the cause and

repair. Replace with the fuse having the specified

capacity.

If there is rust in the terminal, remove the rust with sand

paper prior to connecting.

CAUTION WHEN WIRING

VALIDATION

OF CAPACITY!

REMOVE

THE

RUST!

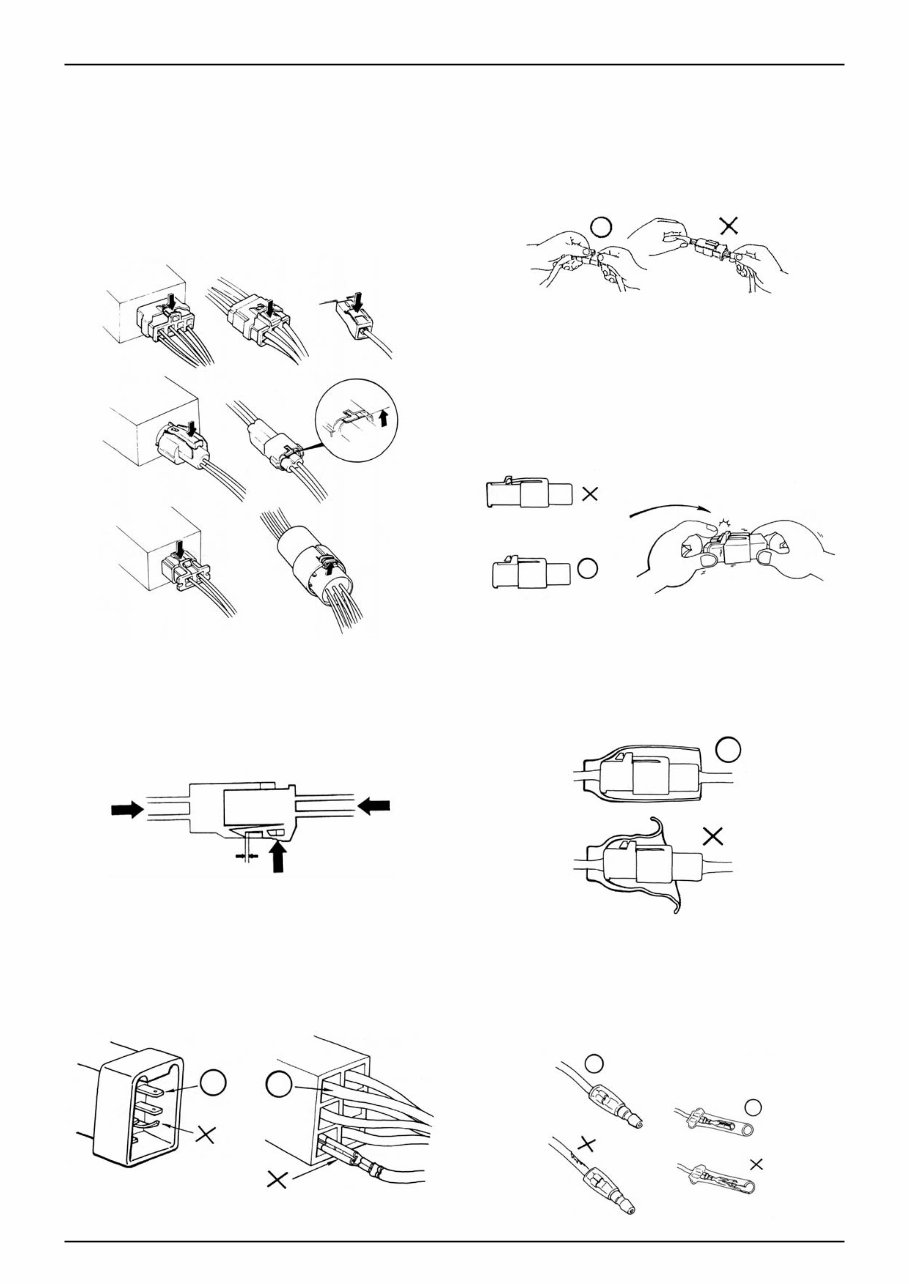

1-6

GENERAL INFORMATION

Insert the lock of the coupler until the lock is fully

secured.

Turn off the main switch before connecting/dis-

connecting.

Release the lock to disconnect the lock of the coupler.

The lock of the coupler has two types according to

releasing method(press type and pull type) so release it

properly according to the shape.

- Typical releasing method of the coupler is illustrated in

the following.

When disconnecting the coupler, disconnect it while

holding the coupler body. Pull while holding the wire

harness cord and do not remove the coupler connection.

Release the lock by inserting the coupler slightly and

then narrowing connection to remove the coupler.

Pay attention not to damage the vinyl cover of the

coupler.

Check to see if there is bended terminal and secure it to

avoid disconnecting.

If the wire harness coating is damaged, repair by

winding vinyl tape or replace it.

Prior to connecting the connector, make sure that the

cover is not damaged and the mess terminal is not

opened.

1-7

GENERAL INFORMATION

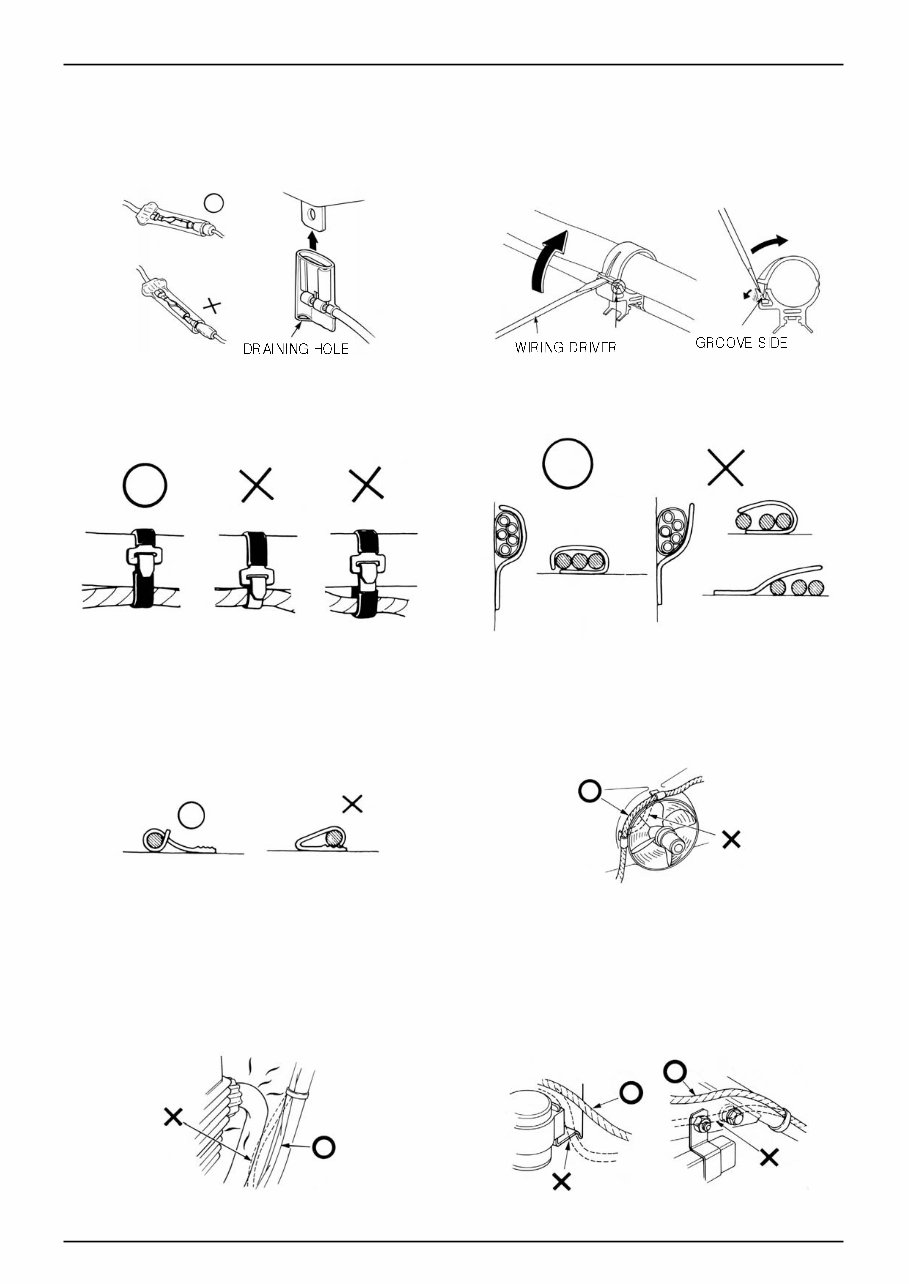

Wire band must be secured firmly in the specified

location of the frame. In case of aluminium band,

secure the wire harness to the coated part.

Secure the wire harness firmly using the clamp.

Insert the connector until the vinyl cover is fully

inserted into the terminal.

The opening of the vinyl cover must face at the ground

direction but in case of the plain connector, the draining

opening must face at the sky direction.

When removing T-start, broaden the groove of T-start

using the wiring driver and release the torque.

Connect the harness and the hose to T-start and then

insert until the groove is locked.

When removing T-start from the frame, replace it with

the new one.

In case of the weld clamp, do not clamp in the welded

part.

When clamping the wire harness, make sure that the

harness is not contacted with the shaft or rotating part.

When clamping the wire, pay attention not to contact

with hot part.

The wire harness must be routed without contacting

with the end of the lamp or any sharp edge.

The wire harness must be routed without contacting

with the end of the bolt or the piece.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 20 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Complete service repair manual for the Daelim Roadwin VJ125 VJ 125 Scooter. This manual covers all the essential topics such as Engine, General Information, Transmission, Chassis, Lighting, Steering, Seats System, Clutch, Suspension, Locks, Brakes, Lubrication, Electrical, Frame Fuel System, Battery, and more. It is useful for both professional mechanics and DIY enthusiasts. The manual is available in Adobe Acrobat format and is compatible with both PC and Mac. Instant delivery ensures no waiting for a CD to arrive via mail. For other similar manuals, please message us for availability.

- Instant delivery

- Useful for professional mechanics and DIY enthusiasts

- Available in Adobe Acrobat format

- Compatible with PC and Mac