Vintage Old School Go-Kart Plans

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

By S. Calhoun Smith

T

HE "go kart" has taken the U. S. by

storm. A happy wedding of lawn

mower engine and steel tubing on four

little wheels, it has become a craze

among kids and adults with a yen for

racing or just plain driving fun.

Kart racing originated in California

and has spread eastward since 1956.

Now the GKCA (Go Kart Club of

America) is firmly established and has

set up sensible rules governing design

and power for stable, safe "karting."

Even the lowest powered Class A, 2.5

102

hp karts are capable of 30 to 35 mph

with an adult aboard and more when

driven by a lightweight 10-year-old.

Races are run on paved parking lots and

small dirt ovals and regular sports car

type raceways have been built with

tracks four-tenths of a mile in length

and 20 feet wide. Such tracks incorpor-

ate eleven turns, both banked and flat.

The MI Kart was designed and built

by Bob Peru of Red Bank, N. J. and

can be considered a basic Class A kart.

It complies in all respects with GKCA

Mechanix Illustrated

A 2-1/2,-hp lawn mower engine drives this kart at

more than 30 mph. It's Class A fun for anyone.

specifications. Cost runs from $100 to

$110 complete with an A-400 Clinton

engine. Peru did the welding himself

but anyone not equipped to do it would

have to spend $20 to $30 extra. The

building time was about 25 hours and

the tools required were a square, hack

saw, tin snips, files, hammer, large vise

and an electric hand drill or drill press.

To help hold cost down, the frame is

made of thin-wall conduit, but more ex-

pensive chrome-moly tubing could be

substituted throughout. Some parts,

the seat and steering hoops, steering

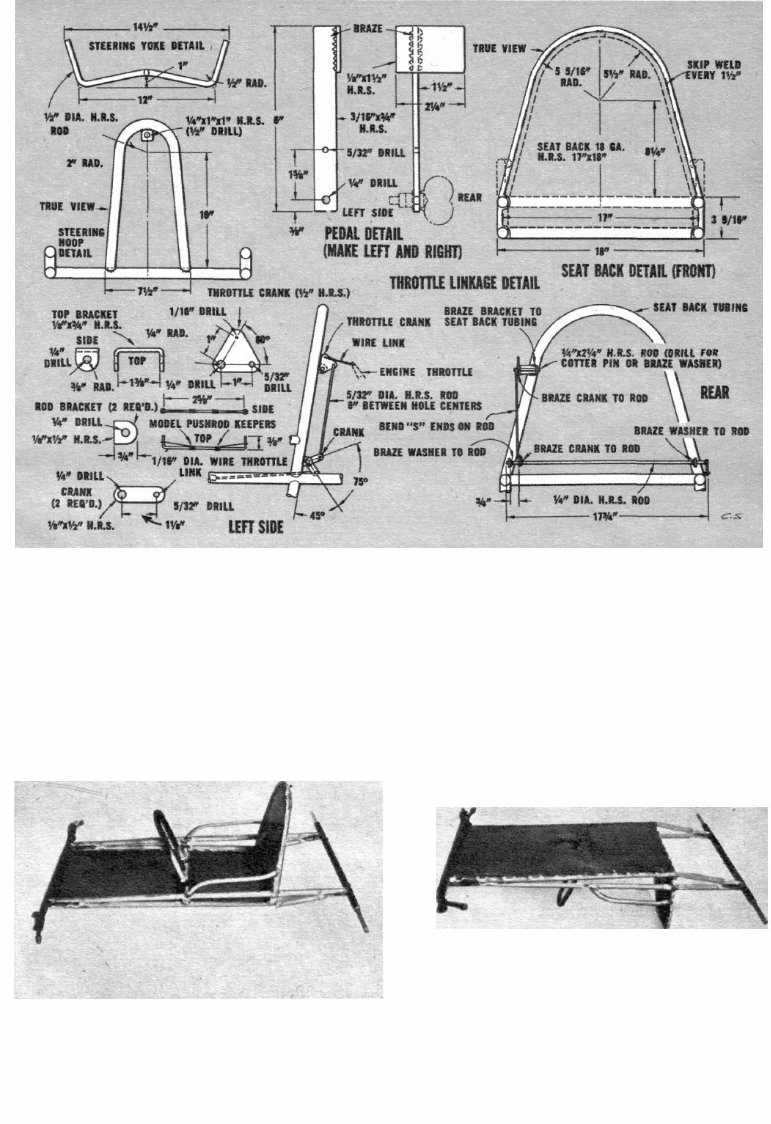

COMPLETED FRAME with axles installed;

a thin-wall conduit is used to reduce cost

BELLY PAN and seat back are sheet steel;

they're spot-welded to the conduit frame.

January, 1960 103

FRONT END view shows brake and throttle

pedals and the simple steering mechanism.

SPOT BRAKE pivots flush against inside

face of sprocket. Note engine mount plate.

104 Mecha.nlx Illustrated

yoke, front wheel spindle

brackets and engine

mount plate, can be pur-

chased ready-formed from

various kart manufac-

turers. Their use will

speed building consider-

ably-

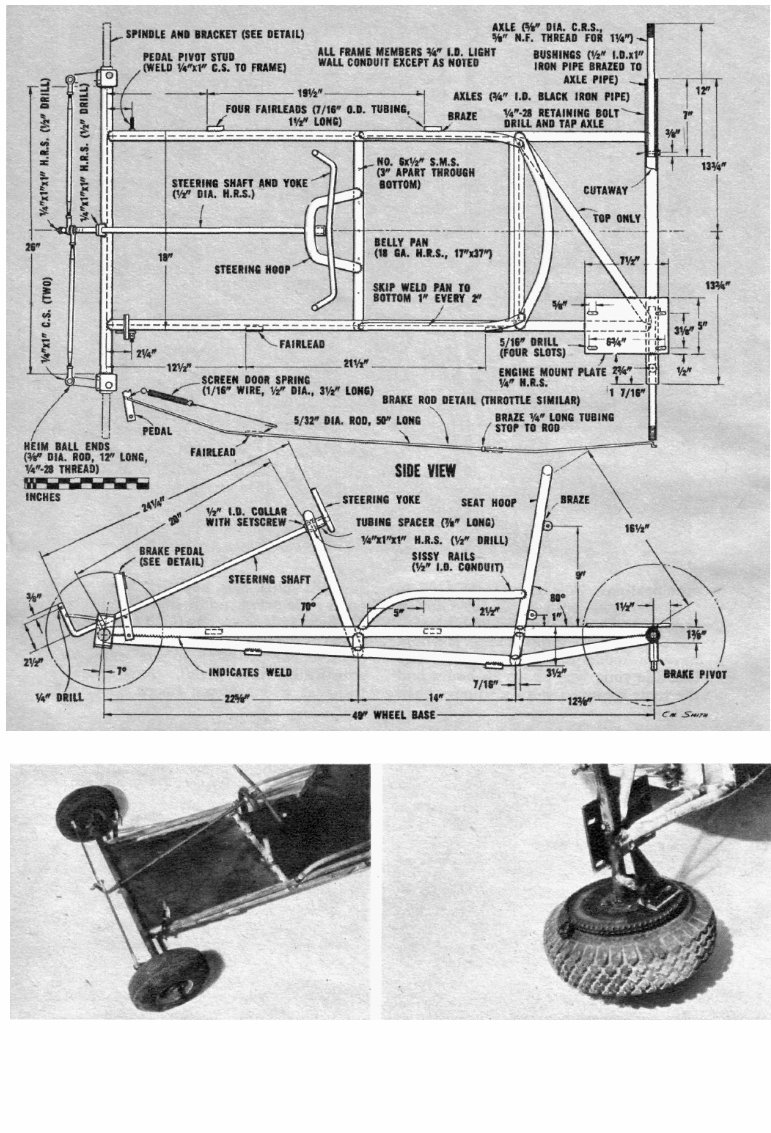

Begin construction by

drawing a side frame out-

line on a piece of scrap

lumber. Cut and flare the

tubing required and heat

the lower piece to make

the bend. Fit the pieces

over the outline and clamp

them. Then tack weld all

joints and remove the

framing from the board.

Using the first side as a

pattern, clamp the parts of

the second to it and tack

weld them together. This

will insure uniformity.

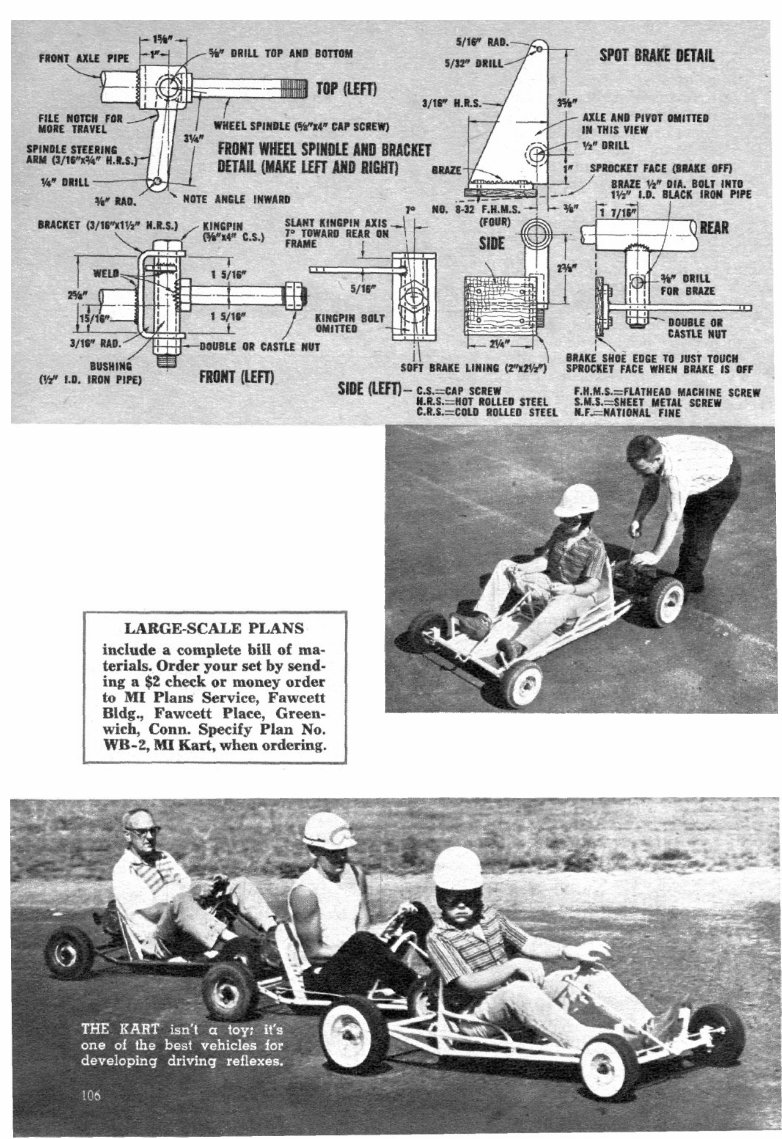

Next fabricate the front

and rear axles. Bend

the front wheel spindle

brackets to shape and drill

them for the kingpin bolts.

Then weld them to the

front axle tube. Align

them carefully, square on

the tube ends and parallel

to each other. The rear

axle tube ends are bushed

CLINTON 2-1/2-hp engine drives MI kart at more than 30

mph with adult load; note throttle crank on seat hoop.

SPANKING NEW kart is ready to go. You can upholster

seat but boat cushion from marine supplier does nicely.

with a length of pipe to reduce the

inside diameter for the 5/8-inch

round stock axles. The axles are

held in the tube with a quarter-

inch bolt near each inner end.

They can be tapped for short bolts

or holes [Continued on page 150]

RECOIL STARTER is pulled as youthful driver

sits with his left foot depressing brake pedal.

Build MI's Kart

[Continued from page 106]

can be drilled all the way through for bolts

and nuts.

The side frames, axles and crosspieces

can now be assembled. Cut and flare the

pieces and tack weld them, using a try

square to make sure they're aligned. Add

the axles to the frame ends, squaring up

the assembly as it progresses. Note that

the front axle is rotated slightly in the side

frame ends so that the kingpin axis has a

7° rearward slant. The frame-axle assem-

bly can now be completely welded at all

joints. As the last step, add the diagonal

crosspiece at the rear.

The front wheel spindle units are made

up next. Cut the kingpin bushing tubes to

fit snug inside the brackets. Then weld the

wheel spindle bolts to the sides of the bush-

ings. Follow this by welding the spindle

steering arm pieces to the bushings. Note

that right- and left-hand units are required

since the steering arm pieces slant inward.

The steering and seat hoops are now

formed and cut to fit onto the frame. To

make the curves, apply heat and bend a

little at a time so that the tubing will not

deform. Tack weld the hoops in position

after clamping them at the proper angles;

then complete the welds. Next cut the

belly pan and seat back to shape, checking

the pieces against the frame for correct di-

mensions. Tack weld the belly pan in place

on the bottom of the frame and then skip

weld the pan edges to the frame. Welds

should be about one inch long and two

inches apart. Where the pan touches the

crosspiece at the steering hoop rosette,

welds can be used or the sheet and tubing

can be drilled for self-tapping sheet metal

screws. To prevent the sheet steel from

buckling during welding, use a chill block

clamped about a quarter-inch from the

edge along the area to be welded. The chill

block can be a piece of 1/2xlx24-inch

steel bar stock. The seat back is skip

welded to the front of the seat hoop in the

same manner as the belly pan. Make half-

round cuts to clear the side frame tubes.

Sissy rails can now be bent to shape, fitted

to the sides and seat hoop and welded in

place.

The steering assembly is made next. Cut

and drill the steering shaft support

brackets of 1/4xl-in strip steel. Bend the

steering shaft front end and drill it for the

tie-rod bolt. Then bend the yoke to shape.

Put brackets and collars on the steering

shaft and weld the yoke to the shaft end.

Next slide the shaft through the top

bracket to spread out the collars and weld

the bracket to the underside of the hoop

curve. Hold the lower end of the shaft at

the proper angle to align the top bracket

while welding. Finish by sliding the shaft

into position and welding the front bracket

to the top of the front axle.

The tie-rod ends are threaded for about

one inch to match the Heim ball end fit-

tings. Clevis end or Ford brake rod ends

could be substituted if the ball ends are

not readily available. Adjust the rod ends

at the center to align the wheel spindles

at zero degrees. Toe-in or toe-out can be

adjusted later when the kart's running

qualities have been checked. While work-

ing on the front end, weld the pedal pivot

bolts to the side frames.

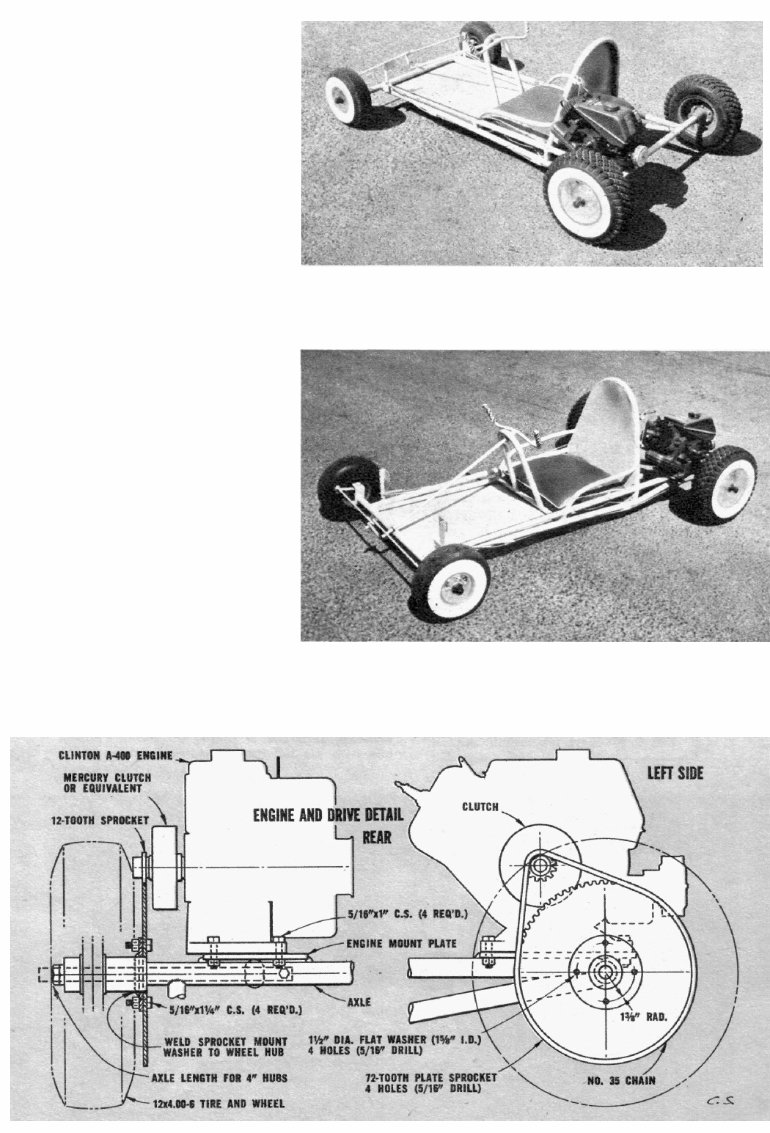

Drive and engine mount parts are next

on the list. The wheel hub is first fitted

with a large washer for bolting on the

large sprocket. This permits removal of the

sprocket if different sizes are to be fitted.

(If you do not wish to bother with removal,

the sprocket can be welded flush to the

wheel hub inside face.) The large washer

and sprocket are drilled for mounting

bolts. Disassemble the wheel to make

welding on the hub easier. The large

washer is welded to the hub 3/16-in from

the inside face so that the hub forms a

shoulder for centering the sprocket. Weld

the washer from behind, aligning it care-

fully so that it and the sprocket will track

without any wobble. After assembly,

mount the drive wheel and sprocket on the

axle. Next bolt the engine to the mount

plate, install the clutch (if used) and the

chain. Now carefully align the chain and

sprockets, moving the engine and mount

on the frame. When set, mark the position

and clamp the mount plate to the frame.

Then remove the engine and wheel and

weld the mount plate to the frame. The

engine mounting bolts should be in the

center of the slots so that the engine can

be shifted to correct for wear on the chain

150 January, 1960

Build MI's Kart

and sprocket.

The spot brake is made and installed

next. Detail drawings are self-explanatory,

but follow this procedure for mounting on

the axle: mount drive wheel on axle;

mount brake on pivot bolt and tube; clamp

brake firmly to sprocket in "brake" posi-

tion (this will position pivot tube on bot-

tom of axle tube); then clamp and weld

pivot tube to axle.

The throttle linkage is made next. Cut

out and drill all parts shown on the detail

drawing. Then put the engine in place on

the mount so that the upper linkage parts

can be aligned with the engine throttle.

The brackets, rods and cranks can be as-

sembled by brazing. Complete the throttle

and brake linkage by making the pedals

and push rods. Note that there are right-

and left-hand pedals. Remember to slide

the fairleads and stop tubes onto the push

rods before bending the S ends. Rods can

be fitted with clevis ends if desired so that

adjustments can be made. Fit one end of

the rod to the brake at the rear and put the

pedal on the other end. Next put the pedal

on the pivot bolt at the front, clamp the

fairleads to the side frames and braze them

in place. Braze the stop to the rod ahead of

the fairlead with the brake off and clear of

the sprocket. The throttle push rod and

pedal are assembled in a similar manner.

Last, make and install return springs on

both pedals.

This completes the metal work on the

kart. All welds should be wire brushed.

Welding splatters and braze flux should be

chipped off all metal surfaces and the

metal cleaned before painting. It's a good

idea to clean up the welds during fabrica-

tion for easy access to the tight corners.

The Clinton engine, of course, is not the

only one which can be used; West Bend,

Briggs & Stratton, Continental, Power

Products and McCulloch engines fill the

bill with slight mount modifications. The

builder who wishes to customize his kart

will find such items as mufflers, drum

brakes, chromed tanks, steering wheels

and racing slicks available from the many

kart manufacturers. You can add what-

ever your pocketbook will allow—but sim-

ple or dressed up, the MI kart is a kartload

of fun. •

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

Viewed 67 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

Explore vintage plans reprints from the 1960s to construct a classic go-kart, perfect for enthusiasts and professional mechanics alike. These meticulously restored and enlarged plans offer superior clarity and intricate details, allowing for easy viewing and printing as required. The 7-page manual is available in PDF format, compatible with Adobe Reader or Acrobat on all computer systems. While the original engines recommended in these plans are older models like Clintons and McCullochs, they can be effortlessly substituted with newer parts and engines for modern customization.