West System Fiberglass Boat Repair & Maintenance Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

A guide to Fiberglass Boat Repair & Maintenance, Gelcoat Blister

Repair and Final Fairing & Finishing with WEST SYSTEM

®

Epoxy.

002-550

Fiberglass Boat Repair

& Maintenance

WEST SYSTEM, 105 Epoxy Resin, 205 Fast Hardener, 206 Slow Hardener, G/5, G/flex, 410 Microlight

and Six10 are registered trademarks of Gougeon Brothers, Inc. Scarffer, 209 Extra Slow Hardener, 207

Special Clear Hardener and 422 Barrier Coat Additive are trademarks of Gougeon Brothers, Inc., Bay

City, MI USA.

Copyright © 2014 by Gougeon Brothers, Inc.

Published by Gougeon Brothers, Inc., Bay City, MI USA. All Rights reserved. No part of the contents

of this book may be reproduced or transmitted in any form or by any means without the written

permission of the publisher.

Printed in the USA.

1st Edition—December 2014

e techniques described in this manual are based on the handling characteristics

and physical properties of WEST SYSTEM Epoxy products. Because physical properties

of resin systems and epoxy brands vary, using the techniques in this publication with

coatings or adhesives other than WEST SYSTEM is not recommended. is manual is

updated as products and techniques change.

e information presented herein is believed to be reliable as of publication date,

but we cannot guarantee its accuracy in light of possible new discoveries. Because

Gougeon Brothers, Inc. cannot control the use of its products in customer possession,

we do not make any warranty of merchantability or fitness for a particular use

or purpose. In no event, shall Gougeon Brothers, Inc. be liable for incidental or

consequential damages.

Table of contents

1 Introduction

1.1 Typical fiberglass boat construction 1

12 WEST SYSTEM Epoxy for fiberglass repair 4

2 Repairing Minor Cracks and Holes

21 Minor crack and abrasion repair 6

3 Repairing Stringers and Floors

31 Reinforcing to improve panel stiffness 8

32 Repairing local core damage 9

33 Stringer repair guidelines 10

34 Replacing active core sections 10

35 Replacing stringers 11

36 Reinforcing to improve panel stiffness 14

4 Repairing Damaged Skins

41 Assessing and preparing the damaged area 19

42 Backing a repair patch 20

43 Laminating a repair patch 23

5 Repairing Core Related Damage

51 Repairing skin delamination 26

52 Replacing damaged cores 29

53 Repairing transom delamination 31

54 Repairing holed panels 37

6 Repairing and Upgrading Soles and Decks

61 Repairing delaminated soles and decks 40

62 Installing a teak deck 42

7 Installing Hardware

71 Bonding fasteners 45

72 Bonding fasteners and hardware 46

73 Casting epoxy bases for hardware 50

74 Making fasteners removable 51

75 Removing bonded hardware 51

8 Repairing Keels and Rudders

81 Repairing internal ballast keels 53

82 Repairing external ballast keels 54

83 Repairing a keel hull joint 55

84 Repairing worn rudder bearings 56

9 The Problem of Gelcoat Blisters in Fiberglass Boats

91 Factors affecting blister formation 58

92 WEST SYSTEM Epoxy for repair and coating 61

93 Recommendations for the repair and prevention of gelcoat blisters 63

10 Hull Preparation

101 Evaluating blister damage 64

102 Minor isolated blister damage 65

104 Exposing and removing interlaminate damage 67

105 Special preparations for new boats 68

11 Drying the Laminate

111 How dry is dry? 69

112 Passive drying 70

113 Active drying 70

12 Repairing Blister Damage

121 Minor isolated blister damage 72

122 Extensive blister damage 73

123 Interlaminate damage 74

13 Barrier Coating

131 Preparation 78

132 Applying the barrier coat 79

133 Bottom paint 80

134 Recommendations for blister prevention 81

14 Final Fairing

141 Establishing a fair level 83

142 Removing high areas 84

143 Filling low areas 85

144 Local fairing 92

15 Finishing

151 Epoxy barrier coating 94

152 Final surface preparation 96

153 Finish coatings 96

16 Using WEST SYSTEM Epoxy

161 Epoxy safety 104

162 Epoxy products 105

163 Handling epoxy 107

164 Basic techniques 112

Appendix A

Tools 123

Lofting foil shapes for rudders and keels 126

Cold temperature bonding 127

Additional reading 129

Appendix B

Estimating guides for WEST SYSTEM products 130

Epoxy handling 132

Appendix C

Applying fiberglass overhead 133

Appendix D

Repairing machined holes in fiberglass laminate 135

Appendix E

Problem solving guide 140

Problem solving notes 142

Index 143

Introduction 1

1 Introduction

Over the last several decades the popular perception of fiberglass boats is that they are

maintenance free and far more durable than the wooden boats that preceded them. While

fiberglass boats do, on average, require less maintenance, they are not without problems.

In addition to the usual damage from collisions, groundings and the forces of nature,

fiberglass boats also suffer from many of the same age related problems of fatigue and

moisture that have long been associated with older traditionally built wooden boats.

is manual provides repair and maintenance solutions to many of the problems that

afflict fiberglass boats.

1.1 Typical fiberglass boat construction

A fiberglass boat is a composite structure, made of many layers of various reinforcing

fabrics and core materials, bonded together with plastic resins. You could also look at it as

a plastic resin shell reinforced with various fibers, or Fiber Reinforced Plastic (FRP). Most

loads in the structure are carried by the fibers in the laminate. Resin and core materials

support the fibers in positions to effectively carry and spread the loads. Generally, the

higher the proportion of fiber to resin in a laminate, the greater its strength and stiffness.

e continuity of these resin/fiber skins is critical to the integrity of the structure. It is

often necessary to cut through the skin while carrying out repairs, even though the skin

itself may not be damaged. Keep in mind that one objective will always be to rebuild for

skin continuity to return the load carrying ability of the fibers in the laminate to original

or greater strength.

111 Fiberglass resins

e vast majority of fiberglass boats in use today are built with polyester resin. Modern

unsaturated polyesters used in boat construction are made up of three basic components:

glycol, organic acid and reactive diluents (usually styrene). If you were to look at uncured

polyester resin at a molecular level, you would see what appear to be thousands of chains

made up of alternating glycol and acid units. ese chains are polyester pre-polymers.

Adding a peroxide catalyst, typically MEKP, to the polyester resin mixture initiates a

cross-linking reaction, that causes the styrene to create bridges, linking adjacent pre-

polymer chains together. As the mixture cures, more and more bridges are established, and

the free-flowing glycol/acid chains begin to gel, becoming a solid mass. Eventually, enough

bridges are built to form a rigid, three-dimensional matrix. e mixture has become a

thermoset plastic solid, used in this case, to hold bundles of fibers together in the shape of

a boat.

112 Fibers

Fibers used in production fiberglass boats take the form of various types of fabrics,

including mat (chopped-strand mat), woven cloth and roving, and uni-directional, bi-axial

and tri-axial cloth. Each fabric type offers different properties and they are often used

in combination to provide specific strength or stiffness properties in different parts of a

laminate. Fabric selection may also be based on handling characteristics and cost. Most

fabrics are woven or stitched together bundles of individual continuous pultruded fibers

of various synthetic plastics. e least expensive and most common fiber used in production

boats is E-glass. It is widely available and used extensively for repair. Fibers may also be made

of more exotic and expensive materials like aramid or graphite. ese fibers offer much higher

strengths as well as higher costs and are used primarily in one-off, high-performance boats

where saving weight is worth the higher cost. Stitched fabrics represent a major advancement

2 Introduction

in composite technology, by allowing higher fiber-to-resin ratios and stiffer laminates than

woven fabrics of equal weight.

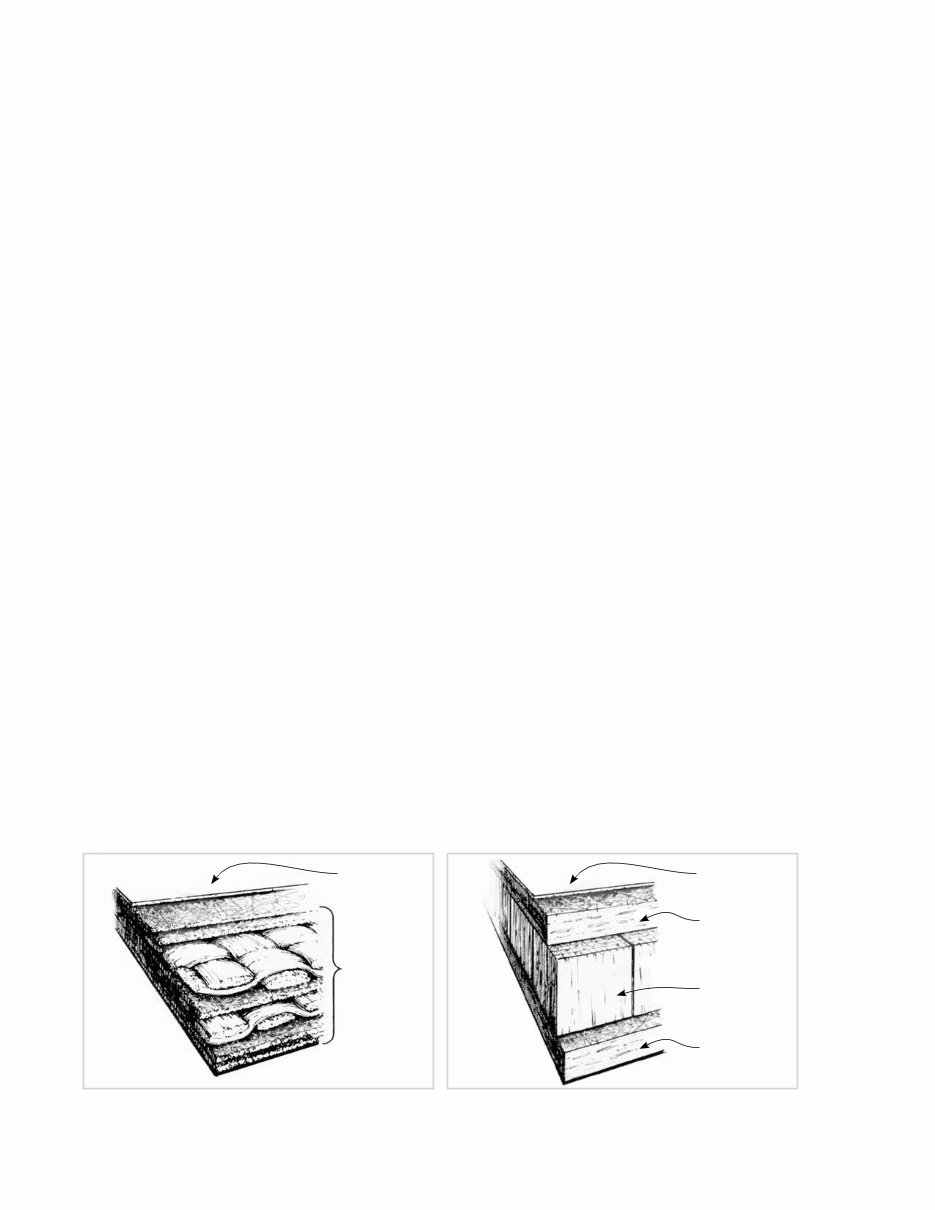

113 Cores

Cores are used in laminates to increase stiffness of a panel without adding a proportional

increase in weight. Doubling a panel’s thickness can result in a panel that is eight times

stiffer. By laminating a lightweight core between two fiber/resin skins a lot of stiffness can

be gained with a minimum amount of added weight. e skins still take all of the tensile

and compressive loads caused by bending the panel but the “I” beam effect produced

by the addition of the core allows the panel to withstand much greater bending loads.

End-grained balsa is the most widely used core material in production boats. It offers low

cost and good impact resistance and compressive strength to resist the collapsing of skins

under load. PVC foam cores are available with a variety of characteristics. ey are more

expensive than balsa, but more resistant to moisture damage. Honeycomb core is an open

corrugated pattern of paper or other thin material on edge. Honeycomb is often used in

prefabricated panels for bulkheads and other interior components.

114 Construction methods

Generally, production fiberglass boat hulls are built in a female mold. A release agent is

first applied to the surface of the mold, over which the gelcoat material is applied. Gelcoat

is usually a pigmented, unsaturated polyester resin and may be anywhere from 12 to 22

mils thick. It is designed to act as a moisture barrier for the underlying laminate, as well as

to provide a smooth, glossy, cosmetic finish. Subsequent layers of fabric are saturated with

resin and laid up over the gelcoat. ere are as many lay-up schedules as there are boats. A

typical hull section might consist of the layer of gelcoat, several alternating layers of mat

and woven roving, and in many cases a core material such as end grain balsa or foam,

followed by several more alternating layers of saturated mat and woven roving (Figures 1-1

and 1-2). Hull thickness may vary from boat to boat. Older boats were often laid up with

a solid glass laminate thickness of 1 ½" (3.8 cm) to as much as 5" (12.7 cm) in the keel

areas of the more heavily-built boats. Today, however, the trend is toward thinner, lighter

laminates, making the structural integrity of each of the laminate components all the

more critical.

Standard lay-up relies on gravity to hold all of the resin saturated material in place until

cured. e technique of vacuum bag laminating has advanced composite construction by

allowing the builder to compress the entire wet-out laminate evenly in the mold, and more

accurately control the resin content and the strength-to-weight ratio of the laminate.

Although it’s not often associated with fiberglass boats, wood is used extensively in

fiberglass boat construction for primary and secondary structural members like bulkheads,

frames and stringers, core material, blocking and trim. Stringers, bulkheads and other

Figure 1-1 Typical solid (single skin) fiberglass laminate. Various

reinforcing fabrics are bonded together with polyester resin.

Figure 1-2 A typical cored laminate consists of end-grained balsa

or other core material sandwiched between two resin/fiber skins.

Gelcoat Gelcoat

Outer skin–

Alternating mat

and roving

Inner skin–

Alternating mat

and roving

Core material

Alternating layers

of mat and woven

roving

Introduction 3

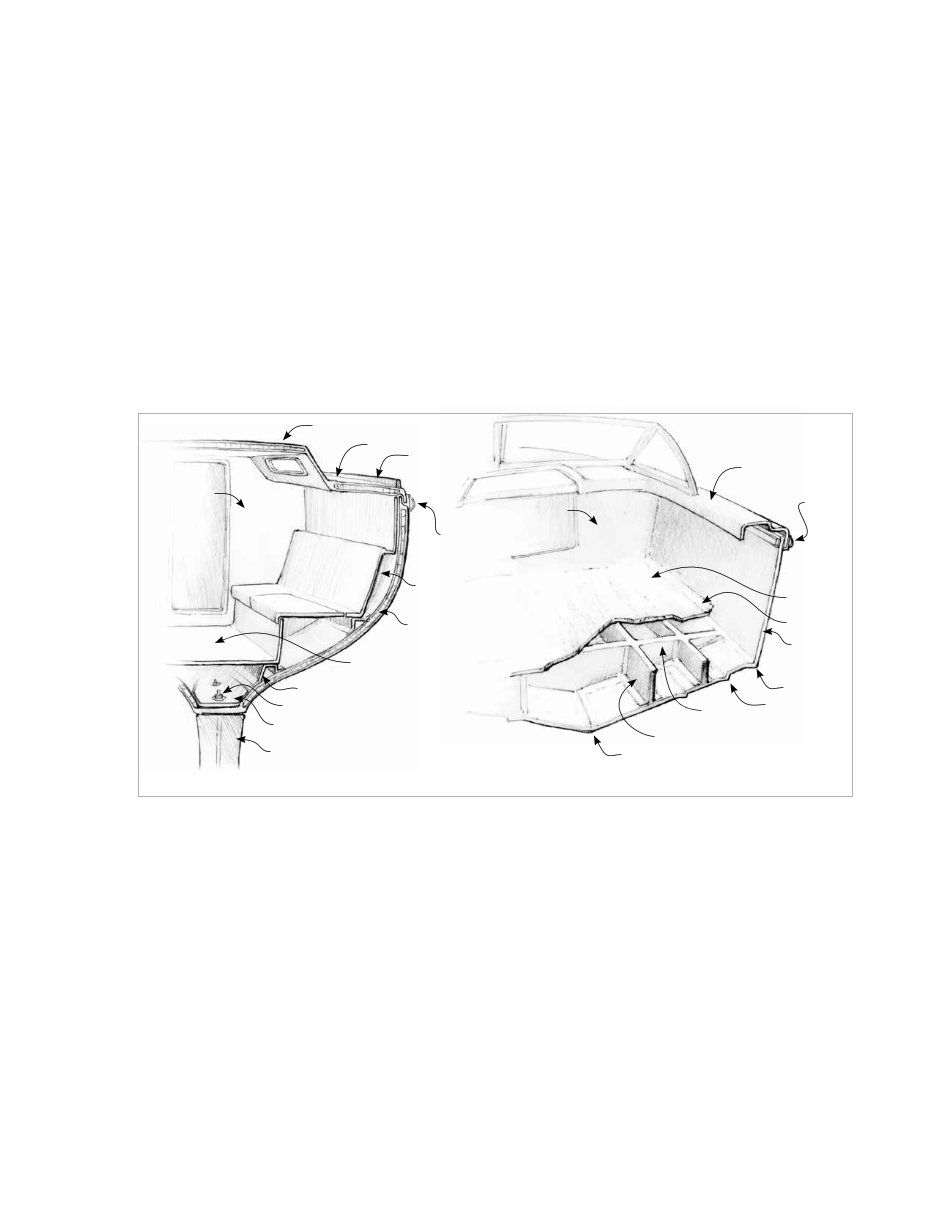

interior fixtures are bonded in after the shell is laid up. Many fiberglass boat repairs

involve wood and the problems associated with using polyester resins to bond to wood.

Terminology used to describe the structure of fiberglass boats is not always the same

terminology used to describe wooden boats. Where fiberglass boat components serve the

same functions as wooden boat components, their names are often the same. However,

materials, and manufacturing methods vary from small boat to large boat, from power to

sail and from manufacturer to manufacturer. Here is a general guide to the fiberglass boat

terminology used in this manual (Figure 1-3).

115 Hydrolysis and gelcoat blisters

e repair procedures in this manual address problems most often associated with mechanical

damage–abrasion, bending, fatigue, impacts and the resulting water damage to cores or other

structural components. Another type of damage common to fiberglass boats is chemical in

nature. Hydrolysis (and its symptom, gelcoat blisters) is a widespread and growing problem in

the fiberglass boat world.

Hydrolysis is more than a cosmetic problem. When water soluble materials in a polyester

resin laminate mix with moisture that has penetrated the laminate it creates an acidic fluid.

e fluid collects in cavities under the gelcoat layer to form blisters. is acidic mixture also

attacks the polyester resin, severing the chemical bonds that hold the resin matrix together,

as well as the resin to fiber bonds. Once hydrolysis has started in a polyester hull, the hull’s

strength has been compromised and the potential for serious additional hydrolysis will never

go away.

If you own a fiberglass boat built with polyester resin, you should be aware that the

potential for this problem is high, especially in warmer climates. Any damage due

to hydrolysis should be included in an assessment of a boat’s condition before repairs

are made. Hydrolysis and gelcoat blisters can be treated with WEST SYSTEM Epoxy to

limit further damage and in many cases restore a hull’s structural integrity. For more

information about hydrolysis and gelcoat blisters refer to Section 9.

Figure 1-3 Components of typical fiberglass sail and power boats

Bulkhead

Bulkhead

Cabin top

Toe rail

Rub rail

Rub rail

Cabin liner

Keel

(external ballast)

Stringer Chine

Keel

Strake

Floor

Stringer

Keel bolt

Keel boss

Cabin sole

Cockpit sole

Tabbing

Hull

(cored laminate)

Hull

(solid laminate)

Deck

Deck

4 Introduction

12 WEST SYSTEM Epoxy for fiberglass repair

Unsaturated polyester resins perform fairly well during the construction of a structure

when all of the layers of resin are applied and allowed to cure together. is type of

bond is considered a primary bond. Problems can occur, however, when you try to bond

polyester resin to a previously cured laminate as is necessary in every repair application.

is type of bond is secondary or post-bonding.

To effectively repair damage typical of fiberglass boats, the repair material must be a

superior structural adhesive, capable of bonding not only to polyester resin, but also to

glass fiber, wood, metal and other materials.

ere are several important reasons to use WEST SYSTEM Epoxy rather than a polyester

resin or other material for fiberglass boat repair. Polyester resin can shrink from 5% to 8%,

creating stress concentrations at the repair joint wheras epoxy doesn’t shrink. In addition,

epoxy is more effective as a moisture barrier and it forms a superior mechanical bond with

the cured polyester and other materials in secondary bonding. Since epoxy is more durable

than polyester, the epoxy repair actually may be stronger than the original structure.

When you consider ease and practicality of application, availability, safety and access to

technical assistance, WEST SYSTEM Epoxy is an excellent choice for fiberglass boat repair.

121 Using this manual

Study and become familiar with all of the steps in a procedure before beginning a repair.

e procedures described in this manual assume a working knowledge of WEST SYSTEM

products and the basic techniques of epoxy use. If you are unfamiliar with or have

any questions about the application and handling techniques of WEST SYSTEM Epoxy

products, read Section 16–Using WEST SYSTEM Epoxy thoroughly before proceeding

with repairs. e WEST SYSTEM User Manual & Product Guide also provides basic epoxy

handling information as well as complete current product descriptions and selection and

coverage information. It is a free publication available through WEST SYSTEM dealers and/

or can be downloaded at westsystem.com.

Some fiberglass repair procedures can be hazardous. Always wear appropriate eye

protection, skin protection and a dust mask when cutting or grinding fiberglass. Follow

safety guidelines when handling epoxy (Section 16.1).

If you have additional questions after reading the Using WEST SYSTEM Epoxy section,

contact the WEST SYSTEM technical staff:

WEST SYSTEM

P.O. Box 665

Bay City, MI 48707

866-937-8797 (8:00 AM-5:00 PM EST)

technical@gougeon.com

westsystem.com

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

$46.99

Viewed 90 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

$46.99

The Fiberglass Boat Repair & Maintenance Manual provides comprehensive guidance on repairing, restoring, and prolonging the life of fiberglass boats. Whether you are a professional mechanic or a DIY enthusiast, this manual equips you with the necessary information to effectively maintain and repair fiberglass boats.