Caterpillar TH360B & TH560B Telehandler OEM Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Section Title Manual No.

Service Manual Contents 31200265

Torque Specifications 31200268

Engine

Disassembly & Assembly Engine Supplement 31200299

Power Train

Systems Operation, Testing & Adjusting Power Train 31200270

Disassembly & Assembly Power Train 31200300

Vehicle Systems

Schematic Hydraulic System 31200304

Systems Operation, Testing & Adjusting Hydraulic System 31200302

Systems Operation, Testing & Adjusting Steering System 31200273

Systems Operation, Testing & Adjusting Brake System 31200274

Machine Components Specs Machine Systems 31200306

Disassembly & Assembly Machine Systems 31200308

Electrical Systems

Schematic - TH360B Electrical System 31200310

Schematic - TH560B Electrical System 31200311

Machine Troubleshooting

Hydrostatic Transmission

Electronic Control System

31200279

Systems Operation, Testing & Adjusting LSI System 31200280

Systems Operation, Testing & Adjusting Monitoring System 31200281

TH360B & TH560B

Telehandler Service Manual

S/N TBH00100 & After

S/N TBP00100 & After

31200264

31200265 A

Specifications

31200268

December 15, 2006

Torque Specifications - TH220B, TH330B,

TH360B, TH560B & TH580B Telehandlers

S/N TBF00100 & After

S/N TBG00100 & After

S/N TBH00100 & After

S/N TBP00100 & After

S/N TBJ00100 & After

Important Safety Information

Most accidents that involve product operation, maintenance and repair are caused by failure to observe

basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous

situations before an accident occurs. A person must be alert to potential hazards. This person should also

have the necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard warnings

are not heeded, bodily injury or death could occur to you or to other persons.

The hazards are identified by the "Safety Alert Symbol" and followed by a "Signal Word" such as

"DANGER", "WARNING" or "CAUTION". The Safety Alert "WARNING" label is shown below.

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either written or pictorially

presented.

Operations that may cause product damage are identified by "NOTICE" labels on the product and in

this publication.

Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard.

The warnings in this publication and on the product are, therefore, not all inclusive. If a tool,

procedure, work method or operating technique that is not specifically recommended by Caterpillar

is used, you must satisfy yourself that it is safe for you and for others. You should also ensure that

the product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The information, specifications, and illustrations in this publication are on the basis of information that was

available at the time that the publication was written. The specifications, torques, pressures,

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before you

start any job. Caterpillar

®

dealers have the most current information available.

When replacement parts are required for this

product Caterpillar recommends using

Caterpillar replacement parts or parts with

equivalent specifications including, but not

limited to, physical dimensions, type, strength

and material.

Failure to heed this warning can lead to

premature failures, product damage, personal

injury or death.

31200268 1

Table of Contents

Table of Contents

Specifications Section

General Information .............................................. 3

Introduction to Torque ...................................... 3

Torque-Turn ..................................................... 3

Torque Sequence ............................................ 3

Metric (ISO) Fasteners .......................................... 4

Metric (ISO) Nuts and Bolts ............................. 4

Metric (ISO) Taperlock Studs ........................... 4

Metric (ISO) Machine Screws .......................... 4

Hex Button Head Screw and Set

Screw ............................................................... 4

English (SAE) Fasteners ....................................... 5

English (SAE) Nuts and Bolts .......................... 5

English (SAE) Taperlock Studs ........................ 5

English (SAE) Machine Screws ....................... 5

Hex Button Head Screw and Set Screws......... 6

Ground Engaging Tool (G.E.T.) Fasteners ........... 6

Installation of Fittings ............................................ 7

Installation of Split Flange Couplings ............... 7

Installation of Adjustable STOR Fittings........... 8

Straight Thread O-Ring Fittings ............................ 8

Plugs ................................................................... 10

Straight Thread O-Ring Plugs (Hex Drive) ..... 10

Straight Thread O-Ring Plugs (Socket Drive) 11

Drain Plugs with Straight Thread .................. 11

Straight Thread O-Ring Plugs (Mechanical Joint

Tube Assemblies) .......................................... 11

O-Ring Face Seal Fittings ................................... 12

Bulkhead Nuts ..................................................... 12

Flare Fittings ....................................................... 13

37 Degree Flare Fitting .................................. 13

45 Degree Flare and 45 Degree Inverted Flare

Fittings ........................................................... 13

Air Conditioning Fittings ...................................... 14

Air Brake Fittings ................................................. 14

Tapered Pipe Thread Fittings .............................. 14

Miscellaneous Fittings ......................................... 15

Hi Duty Tube Fittings (Shear Sleeve)............. 15

SAE Flareless Fittings .................................... 15

Flex Fittings .................................................... 15

Hose Clamps ....................................................... 15

Worm Drive Band Type Clamps..................... 15

Constant Torque Hose Clamps ...................... 16

Table of

2 31200268

Table of Contents

31200268 3

Specifications Section

Specifications Section

General Information

Mismatched or incorrect fasteners can result in

damage or malfunction, or personal injury.

Take care to avoid mixing metric dimensioned fasteners

and inch dimensioned fasteners.

Introduction to Torque

"Torque" is measured in terms of force and distance.

Force is the amount of pushing or pulling applied at the

end of the lever. Distance is the length of the lever that

is being used. Torque values are given in the following

units: NEWTON meters (Nm), pound inches (lb in), and

pound feet (lb ft)

This manual is intended to provide the operator with a

reference. This manual will provide the standard torque

settings for the following: bolts, nuts, plugs, fittings, and

clamps.

Exceptions to these torques are given in the Service

Manual, if necessary.

Be sure to use a torque wrench that has the proper

range. Torque wrenches must be used properly in

order to ensure that the correct torque is applied.

Always use a smooth pull for torque wrenches. Do not

jerk a torque wrench. Do not use adapters that change

the length of the torque wrench. For the correct use of

your torque wrench, refer to the instructions that were

packaged with your torque wrench.

Prior to installation of any hardware, ensure that

components are in near new condition. Bolts and

threads must not be worn or damaged. Threads must

not have burrs or nicks. Hardware must be free of rust

and corrosion. Clean reused fasteners with a

noncorrosive cleaner. Lightly lubricate the threads of

reused fasteners. Lightly lubricate the mating surface of

the head of reused fasteners. Other applications for

lubricating fasteners may also be specified in the

Service Manual. The Service Manual may also specify

the use of sealants and compounds.

Note: Do not use sealants that are not specified in

the Service Manual. Do not use compounds that

are not specified in the Service Manual. Clean old

compound from the bolt and from the hole before

installation.

Torque-Turn

The torque-turn method is used when precise control

over clamping force is required. There is an initial

torque and an additional turn. The initial torque is

required to bring all parts of the joint into contact. The

additional turn provides the desired clamping force.

Ensure that all fasteners have been torqued before you

perform the additional turns. Turn the fastener

according to the specified amount. The specified

amount will normally be equal to or greater than 90°.

The specified amount will normally be in 30°

increments. Turns of 120° or 180° are preferred. Turns

of 120° or 180° are easily measured by the points of

the hex head of the fastener. Lubrication may be

specified in order to reduce the effort that is required for

the final turn. The use of the torque-turn method will

allow the following:

• Increase the life of the fastener.

• Maximize the potential clamping force of a fastener.

Typical applications are the following:

• Track bolts

• Sprocket bolts

• Connecting rod bolts

• Engine Cylinder Heads

• Drive Shaft bolts

Note: Too much tension on the bolt will cause the bolt to

be stretched beyond the point of yield. The bolt will be

permanently stretched. The bolt will loosen the grip on

the parts that are being fastened. If the bolt is

tightened again, the bolt will break. Do not reuse bolts

that have been permanently stretched.

Torque Sequence

Unless the bolt tightening sequence is specified by the

Service Manual, the fasteners should be tightened in a

cross pattern. Use Step 1 through Step 5 unless the

tightening sequence is specified:

1. Hand tighten all fasteners. Larger fasteners may

require the use of a small hand wrench.

2. Torque all fasteners to 40% of full torque.

3. Torque all fasteners to 70% of full torque.

4. Torque all fasteners to full torque by using a cross

pattern. Large flanges may require additional

passes.

5. Apply at least one final full torque to all fasteners

in a clockwise direction until all torque is uniform.

Large flanges may require additional passes.

Note: Final torque may be a turn.

4 31200268

Specifications Section

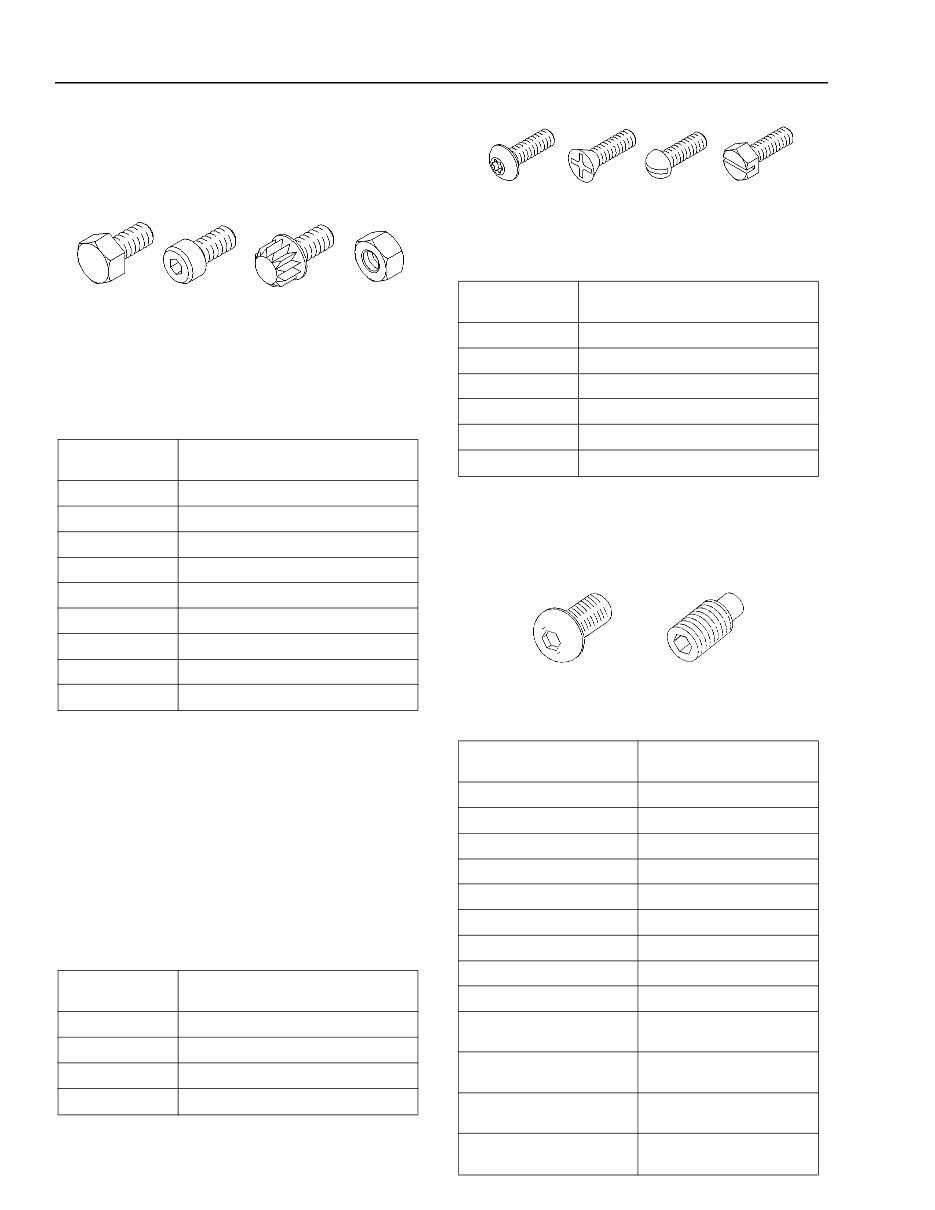

Metric (ISO) Fasteners

Metric (ISO) Nuts and Bolts

Illustration 1 g00909614

Note: The following table has the recommended

standard torque values for Metric nuts and bolts for use

on Perkins engines.

Table 1

Note: The difference between Caterpillar standard

torque values and Perkins standard torque values are

due to different classes of fasteners. Caterpillar uses

class 10.9 fasteners. Perkins uses class 8.8 fasteners.

The different class of fasteners have different tensile

strengths.

Metric (ISO) Taperlock Studs

Note: The following table has the recommended

standard torque values for metric nuts and bolts for use

on Perkins engines.

Table 2

Metric (ISO) Machine Screws

Illustration 2 g00908932

Table 3

Hex Button Head Screw and Set

Screw

Illustration 3 g01186742

Table 4

Thread Size

mm

Torque

M6 5 Nm (44 lb in)

M8 22 Nm (16 lb ft)

M10 44 Nm (32 lb ft)

M12 78 Nm (60 lb ft)

M14 124 Nm (90 lb ft)

M16 177 Nm (130 lb ft)

M18 200 Nm (150 lb ft)

M20 400 Nm (300 lb ft)

M24 790 Nm (580 lb ft)

Thread Size

mm

Torque

M6 5 Nm (44 lb in)

M8 11 Nm (97 lb in)

M10 18 Nm (13 lb ft)

M12 25 Nm (18 lb ft)

Thread Size

mm

Torque

M1.6 0.10 ±0.01 Nm (0.9 ±0.1 lb in)

M2 0.15 ±0.01 Nm (1.3 ±0.1 lb in)

M2.5 0.35 ± 0.05 Nm (3.1 ±0 . 4 lb in)

M3 0.50 ± 0.05 Nm (4.4 ±0 . 4 lb in)

M4 1.70 ± 0.25 Nm (15.0 ± 2.2 lb in)

M5 2.25 ± 0.25 Nm (19.9 ± 2.2 lb in)

Thread Size

mm

Torque

M3 .6± .1 Nm (5 ± 0.9 lb in)

M4 2± .3 N m ( 1 8 ± 3 l b i n )

M5 4± .5 Nm (35 ± 4 lb in)

M6 6± 1 N m ( 5 5 ± 9 l b in)

M8 15 ±3 Nm (11 ± 2 lb ft)

M10 30 ± 7 Nm (22 ± 5 lb ft)

M12 50 ± 10 Nm (37 ± 7 lb ft)

M14 80 ± 15 Nm (60 ± 11 lb ft)

M16 125 ± 20 Nm (90 ± 15 lb ft)

M20 250 ± 40 Nm(185 ± 30 lb ft)

M24

425 ± 50 Nm

(310 ± 37 lb ft)

M30

850 ± 100 Nm

(620 ± 75 lb ft)

M36

1500 ± 200 Nm

(1100 ± 150 lb ft)

31200268 5

Specifications Section

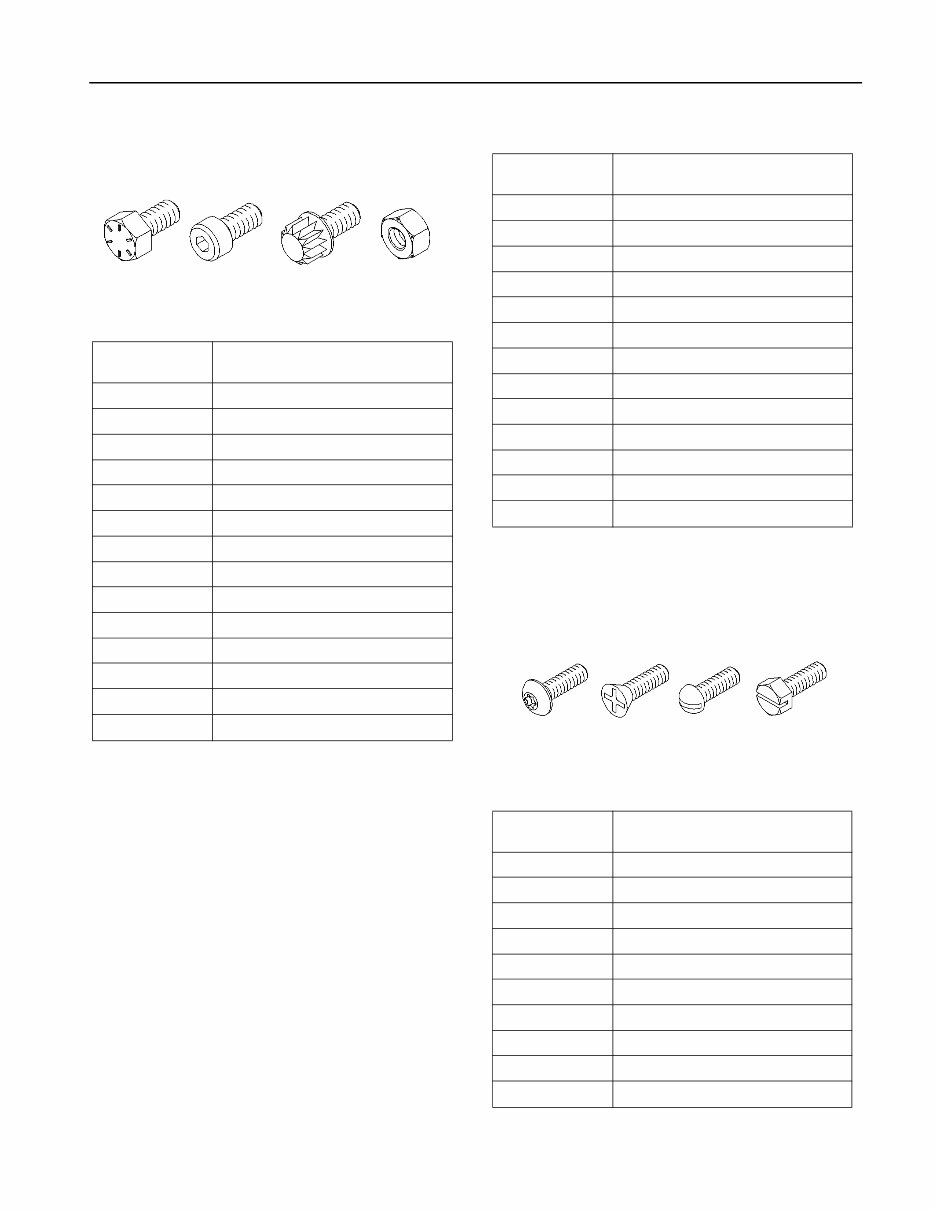

English (SAE) Fasteners

English (SAE) Nuts and Bolts

Illustration 4 g00908911

Table 5

English (SAE) Taperlock Studs

Table 6

English (SAE) Machine Screws

Illustration 5 g00908932

Table 7

Thread Size

Inch

Torque

1/4 12 ± 3 N m ( 9 ± 2 lb ft)

5/16 25 ± 6 Nm (18 ± 4 lb ft)

3/8 47 ± 9 Nm (35 ± 7 lb ft)

7/16 70 ± 15 N m ( 5 0 ± 11 lb ft)

1/2 105 ±20 N m ( 7 5 ± 15 lb ft)

9/16 160 ± 30 N m ( 1 2 0 ± 2 2 lb ft)

5/8 215 ±40 N m ( 1 6 0 ± 30 lb ft)

3/4 370 ± 50 Nm (275 ± 37 lb ft)

7/8 620 ± 80 Nm (460 ± 60 lb ft)

1 900 ± 100 Nm(660±75 lb ft)

1 1/8 1300 ± 150Nm(960± 110 lb ft)

1 1/4 1800 ± 200 Nm (1320 ± 150 lb ft)

1 3/8 2400 ± 300 Nm (1780 ± 220 lb ft)

1 1/2 3100 ± 350 Nm (2280 ± 260 lb ft)

Thread Size

Inch

Standard Torque

1/4 8 ± 3 Nm (6 ± 2 lb ft)

5/16 17 ± 5 Nm (13 ± 4 lb ft)

3/8 35 ± 5 Nm (26 ± 4 lb ft)

7/16 45 ± 10 N m ( 3 3 ± 7 lb ft)

1/2 65 ± 10 N m ( 4 8 ± 7 lb ft)

5/8 110 ±20 N m ( 8 0 ± 15 lb ft)

3/4 170 ± 30 N m ( 1 2 5 ± 2 2 lb ft)

7/8 260 ±40 N m ( 1 9 0 ± 30 lb ft)

1 400 ± 60 Nm (300 ± 44 lb ft)

1 1/8 525 ± 60 Nm (390 ± 44 lb ft)

1 1/4 750 ± 80 Nm (550 ± 60 lb ft)

1 3/8 950 ± 125 Nm(700±90 lb ft)

1 1/2 1200 ± 150Nm(880± 110 lb ft)

Thread Size

No.

Torque

0-80 0.10 ±0.01 Nm (0.9 ±0.1 lb in)

1-64 0.15 ±0.01 Nm (1.3 ±0.1 lb in)

2-56 0.25 ± 0.02 Nm (2.2 ± 0.2 lb in)

3-48 0.35 ± 0.05 Nm (3.1 ± 0.4 lb in)

4-40 0.50 ± 0.05 Nm (4.4 ± 0.4 lb in)

5-40 0.70 ± 0.10 Nm (6.2 ± 0.9 lb in)

6-32 0.90 ± 0.10 Nm (8.0 ± 0.9 lb in)

8-32 1.70 ± 0.25 Nm (15.0 ± 2.2 lb in)

10-24 2.25 ± 0.25 Nm (19.9 ± 2.2 lb in)

12-24 3.40 ± 0.60 Nm (30.1 ± 5.3 lb in)

6 31200268

Specifications Section

Hex Button Head Screw and Set

Screws

Illustration 6 g01186972

Table 8

Ground Engaging Tool (G.E.T.)

Fasteners

Ground Engaging Tools (G.E.T.) are secured by many

types of bolts. Refer to Table 9 for the correct torque for

the following combinations of fasteners for G.E.T.:

• plow bolts and nuts

• hex head bolts and nuts

Table 9

(1) These values are only for Caterpillar bolts for cutting edges.

Thread Size

inch

Torque

#4  .6± .1 Nm(5±0.9 lb in)

#6 & #8 2± . 3 N m ( 1 8 ± 3 lb in)

#10  4± . 5 N m ( 3 5 ± 4 lb in)

1/4 6± 1 N m ( 5 5 ± 9 lb in)

5/16 13±3Nm(115±27 lbin)

3/8 25±6Nm(18±4 lb ft)

7/16 40±8Nm(20±6 lb ft)

1/2 60 ± 1 2 N m ( 4 4 ± 9 l b f t )

9/16 85 ± 1 5 N m ( 6 5 ± 11 lb ft)

5/8 115±20Nm(85± 15 lb ft)

3/4

200 ± 40 Nm

(150 ± 30 lb ft)

7/8

325 ± 40 Nm

(240 ± 30 lb ft)

1

500 ± 65 Nm

(370 ± 48 lb ft)

1 1/8

700 ± 90 Nm

(520 ± 65 lb ft)

1 1/4

1000 ± 125 Nm

(740 ± 90 lb ft)

1 3/8

1300 ± 150 Nm

(960 ± 110 lb ft)

1 1/2

1700 ± 200 Nm

(1260 ± 150 lb ft)

Thread Size Torque(1)

Inch Nm lb ft

5/8 inch 270 ± 40 200 ± 30

3/4 inch 475 ± 60 350 ± 45

7/8 inch 750 ± 90 550 ± 65

1 inch 1150 ± 150 850 ± 110

1 1/4 inch 2300 ± 300 1700 ± 220

31200268 7

Specifications Section

Personal injury can result when installing plow bolts.

The appropriate safety equipment must be worn when

striking the plow bolts. To avoid injury to your eyes and

ears, wear protective glasses and hearing protection

during this procedure.

Illustration 7 g00909058

Plow bolts must be installed properly. Refer to the

following procedure for the correct installation of plow

bolts.

1. Clean all surfaces that contact the bolt. Remove

all occurrences of the following conditions:rust,

paint, nicks, and burrs

2. Tighten the nut to the correct torque. Refer to

Table 9 for the correct torque.

3. Use a hammer to strike the head of the bolt. The

bolt must be struck with significant force.

Note: The head of the bolt may be recessed below the

mounting surface. Use a suitable punch in order to

transfer the hammer blow to the bolt head.

4. Tighten the nut to the correct torque. Refer to

Table 9 for the correct torque.

Installation of Fittings

Note: The tightening sequence of the fasteners that

attach a tube assembly or hose assembly to the

machine is very critical to the proper function of the

machine. The sealing surfaces of the tube assembly or

hose assembly should be secured squarely. The

sealing surfaces of the tube assembly or hose assembly

should be tightened to the serviced component (control

valve, cylinder, hydraulic motor, etc). Perform this

procedure prior to the final tightening of any clamps or

clips that are used in order to fasten the tube

assembly or the hose assembly to the machine.

Fittings have different connections. Fittings may have

two completely different ends. Be sure to use the

proper torque for the end of the fitting that is used. The

following list contains some common types of fittings.

• Straight Thread O-Ring (STOR)

• Adjustable Straight Thread O-Ring (STOR)

• O-Ring Face Seal (ORFS)

• Tapered Pipe Thread (NPT and NPTF)

• 37 Degree Flare Fitting

• 45 Degree Flare Fitting

• 45 Degree Inverted Flare Fitting

• Split Flange Coupling

Installation of Split Flange

Couplings

1. For a metal tube to hose installation, install the

tube and tighten all bolts finger tight at the rigid

end.

2. Install the hose and tighten all bolts finger tight.

3. Put the hose in a position so that the hose does

not make contact with the machine or with another

hose.

Illustration 8 g00906528

4. Tighten the bolts on both connections to the

proper torque. Follow the prescribed torque

sequence for split flange connections. Refer to

Illustration 8. Add the measurement of gap (A) to

the measurement of gap (B). The total must not

exceed 4.0 mm (0.16 inch).

5. Start the engine.

6. Move the implement control levers to all of the

positions.

7. Look at the hose during movement of the

implement. Ensure that the hose is not in contact

with the machine or with other hoses.

Note: For hoses that cross an articulation hitch, check

for contact during articulation. For hoses that connect to

the steering system, check for contact during steering.

8. Shut off the engine.

9. If the hose contacts other hoses or the machine

during the test, loosen the bolts and reposition

the hose. Repeat steps 3 through 8 until there is

no contact.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

Viewed 77 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

The Caterpillar CAT Factory Service Manual is an essential resource for both professional mechanics and DIY enthusiasts. This comprehensive manual provides detailed technical information, diagrams, and instructions for the maintenance, repair, and troubleshooting of Caterpillar CAT vehicles. Whether you are working on the engine, transmission, electrical system, or hydraulic components, this manual offers in-depth guidance to ensure the job is done right. With its clear and concise format, the manual is designed to assist users in efficiently addressing a wide range of mechanical issues. It is available in .PDF format, making it easily accessible for reference whenever needed.