JCB 520-50/525-50/525-50S (Loadall)-Operator Handbook

Have a question?Ask Us

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SAFETY NOTICES

!

WARNING

Study This Handbook Before Starting The Machine

You must understand and follow the instructions in this handbook. You must

observe all relevant laws and regulations. If you are unsure about anything, ask your

JCB distributor or employer. Do not guess, you or others could be killed or seri-

ously injured.

INT-1-1-1

!

CAUTION

Do not fit an attachment to this machine which is not JCB approved. Consult your

JCB distributor before fitting any non approved attachment.

8-4-1-6

8170-1

In this handbook and on the machine there are safety notices. Each notice starts

with a signal word. The meanings of the signal words are given below.

!

DANGER

Denotes an extreme hazard exists. If proper precautions are not taken, it is

highly probable that the operator (or others) could be killed or seriously

injured.

INT-1-2-1

!

WARNING

Denotes a hazard exists. If proper precautions are not taken, the operator

(or others) could be killed or seriously injured.

INT-1-2-2

!

CAUTION

Denotes a reminder of safety practices. Failure to follow these safety prac-

tices could result in injury to the operator (or others) and possible damage

to the machine.

INT-1-2-3

MACHINE SECURITY

Vandalism and theft of unattended machines is an ever increasing problem and

JCB is doing everything possible to help combat this.

JCB PLANTGUARD is a comprehensive package available to help you safeguard

your machine. It includes such devices as vandal proof covers, window etching,

immobiliser, concealed serial number, battery isolator, Tracker security system

and much more.

Remember that the fitting of any one of these security devices will help to min-

imise not only the damage or loss of your machine but also subsequent lost pro-

ductivity. It could also result in reduced insurance premiums.

Your JCB Distributor or Dealer will be pleased to provide information on any of

these sensible precautions. ACT NOW!

INT-1-2-4

Purchased from www.WorkshopManuals.co.uk

i i

CONTENTS

Page

INTRODUCTION

About this Handbook

Machine Model and Serial Number ....................... 1

Using the Handbook . ............................................. 1

Units of Measurement ............................................ 1

Page Numbering .................................................... 1

Left Side, Right Side . ............................................. 1

Using the Machine ................................................. 1

Page Cross References ......................................... 1

Machine Description ............................................ 2

Safety - Yours and Other People's ..................... 3

Safety Check List

General Safety ....................................................... 3

Operating Safety .................................................... 4

Maintenance Safety ............................................... 5

Safety Decals ........................................................ 7

Identifying Your Machine

Identification Plate . ................................................ 8

Unit Identification . .................................................. 8

JCB Immobiliser Option ...................................... 10

OPERATION

Introduction .......................................................... 21

Before Entering the Cab ...................................... 21

Entering & Leaving the Cab, Doors and Windows 22

Opening and Closing the Door .............................. 23

Open and Closing the Rear Window ..................... 23

Emergency Exit ...................................................... 24

Seat Controls

Adjusting the Seat .................................................. 24

Seat Belt

Fasten the Seat Belt ............................................... 25

Release the Seat Belt ............................................. 25

Adjust the Seat Belt . .............................................. 25

Cab Layout and Controls .................................... 26

Cab Switches and Instruments

Starter Switch ........................................................ 29

Steering Column Switches ..................................... 30

Instrument Panel Switches .................................... 31

Steer Mode Selector (If Fitted) ................................. 32

Phasing 4-Wheel Steer ............................................ 32

Cab Light . .............................................................. 33

Warning Beacon . ................................................... 33

Instruments ............................................................ 34

Page

Warnings (Visual only) ........................................... 35

Warnings (Audible/Visual) ....................................... 35

Heater

Heater On-Off ........................................................ 36

Cab/Windscreen Heating ....................................... 36

Heater Fan ............................................................. 36

Air Conditioning Option ......................................... 36

Boom and Carriage controls

Lever Lock ............................................................. 37

Raise/Lower Boom ................................................ 38

Extend/Retract Boom ............................................ 38

Tilt Carriage Forward/Back .................................... 38A

Auxiliary Operation ................................................. 38B

Before Starting the Engine .................................. 39

Starting the Engine .............................................. 40

Preparing for Road Travel ................................... 41

Preparing for Site Travel ..................................... 42

Getting the Machine Moving

Operating Practices ............................................... 43

Limited Slip Differential ............................................ 43

Stopping and Parking the Machine . ................... 45

Using the Load Charts ......................................... 46

Load Moment Indicator

Checking the Indicator ............................................. 48

Setting Volume and Brightness ............................... 48A

Diagnostic Fault Codes............................................ 48A

Working with the Machine

Introduction ............................................................. 49

Safety Practices ...................................................... 49

Risk Assessment ..................................................... 50

Lifting and Loading Operations ............................... 51

Safety Warnings ...................................................... 52

Fork Ratings ............................................................ 53

Lifting and Handling Loads .................................... 54

Use of Machines on Gradients or Slopes ............... 59

Handling Palleted Loads ........................................ 61

Uneven Loads ........................................................ 62

Lifting Bales ............................................................. 63

Placing Bales ........................................................... 63

Operating in Low Temperatures ......................... 64

Operating in High Temperatures ........................ 64

Transporting the Machine ................................... 65

Re-Aligning the Road Wheels ............................. 66

Towing a Machine ................................................ 67

8170-10

Purchased from www.WorkshopManuals.co.uk

ii ii

CONTENTS

Page

Recovery Hitch ..................................................... 67

Mechanical Tow Hitch Option ............................ 68

Hydraulic Tow (Pickup) Hitch Option ................. 69

MAINTENANCE

Lubricants - Health and Safety

Hygiene .................................................................. 71

Storage .................................................................. 71

Waste Disposal ...................................................... 71

Handling ................................................................. 71

First Aid - Oil .......................................................... 71

Spillage .................................................................. 71

Fires ....................................................................... 71

Service Requirements

Introduction ............................................................ 72

Maintenance .......................................................... 72

Owner/Operator Support ....................................... 72

Service/Maintenance Agreements ......................... 72

Service Schedules ................................................ 72

Boom Safety Strut

Installing ................................................................. 76

Removing ............................................................... 76

Engine Cover

Opening/Closing the Cover . .................................. 77

Rear Grille

Removing/Fitting the Rear Grille ............................ 77

Cleaning the Machine .......................................... 78

ROPS/FOPS Structure

Checking the ROPS/FOPS Structure .................... 79

Boom Wear Pads ................................................. 79

Checking for Damage .......................................... 80

Seat Belt

Checking the Seat Belt Condition and Security .... 80

Greasing ................................................................ 80

50 Hours ................................................................ 81

500 Hours ............................................................... 82

1000 Hours ............................................................ 83

Oiling ..................................................................... 83

Tyres and Wheels

Tyre Inflation .......................................................... 84

Checking Roadwheel Tightness .............................. 84

Page

Engine Air Filter

Cleaning the Pre-Cleaner ....................................... 85

Changing the Outer Element .................................. 85

Changing the Inner Element .................................. 86

Engine Oil and Filter

Checking the Oil Level ........................................... 87

Changing the Oil and Filter .................................... 87

Engine Cooling System

Checking the Coolant Level ................................... 88

Coolant Mixtures .................................................... 88

Changing the Coolant ............................................ 89

Cab Heater Filter

Cleaning the Cab Heater Filter ............................... 90

Fuel System

Types of Fuel . ........................................................ 91

Fuel Standards ....................................................... 91

Low Temperature Fuels . ........................................ 91

Filling the Tank ....................................................... 92

Cleaning the Lift Pump Gauze ................................. 92

Draining the Filter ................................................... 93

Changing the Filter Element ................................... 93

Draining the Sediment Bowl .................................. 94

Cleaning the Sediment Bowl .................................. 94

Bleeding the System .............................................. 95

Transmission

Checking the Oil Level ........................................... 96

Changing the Oil and Filter .................................... 97

Brakes ..................................................................... 98

Front and Rear Axle

Checking the Axle Oil Level ................................... 98

Changing the Axle Oil ............................................ 98

Front and Rear Hub

Checking the Hub Oil Levels .................................. 99

Oil Immersed Brakes................................................ 99

Changing the Hub Oil ............................................. 99

Hydraulic System

Checking the Fluid Level ........................................ 100

Changing the Hydraulic Tank Filler Cap ................. 100

Changing the Filter Element ................................... 100

Hose Burst Protection Valves

Checking the Hose Burst Protection Valves .......... 101

Battery

Warning Symbols ..................................................... 103

Checking the Electrolyte Level .............................. 104

Jump-Starting the Engine . ..................................... 105

8170-9

Purchased from www.WorkshopManuals.co.uk

iii iii

CONTENTS

Page

Electrical System

Typical Fuse Installation ......................................... 106

Bulbs ...................................................................... 107

Adjusting the Alternator Drive Belt ......................... 107

Windscreen Washer ............................................. 108

Obtaining Replacement Parts ............................. 108

Fluids, Lubricants, Capacities and Specifications

520-50 & 525-50 Machines with Type AA Engines . 109

520-5 & 525-50 Machines with Type AR and AK

(Low Emission) Engines .......................................... 110

OPTIONAL ATTACHMENTS

Introduction .......................................................... 131

Quick Release Couplings

Quick Release Couplings - Do’s and Don’ts . ........ 132

Remove Pressure from Service Lines .................... 132

Connecting Quick Release Couplings ................... 132

Disconnecting Quick Release Couplings ............... 132

Installing and Removing Q-Fit Attachments

Installing Attachments ........................................... 133

Removing Attachments .......................................... 135

Fork Mounted Hook

Safety ..................................................................... 137

Installing ................................................................. 137

Removing ............................................................... 137

Operation ............................................................... 138

Maintenance .......................................................... 138

SPECIFICATIONS

Static Dimensions ................................................ 151

Performance Dimensions .................................... 152

Tyres and Pressures ............................................ 153

Noise and Vibration Data .................................... 153

SERVICE RECORD SHEET

REGISTRATION INFORMATION

8170-7

Purchased from www.WorkshopManuals.co.uk

8170-7

1 1

INTRODUCTION

ABOUT THIS HANDBOOK

Machine Model and Serial Number

This handbook provides information for the following

models in the JCB machine range.

520-50 Machines from Serial No. 754000

525-50 Machines from Serial No. 789308

525-50S Machines from Serial No. TBA

Using the Handbook

The illustrations in this handbook are for guidance only.

Where the machines differ, the text and/or the illustration

will specify.

This handbook is arranged to give you a good

understanding of the machine and its safe operation. It

also contains maintenance information and specification

data. Read this handbook from front to back before using

the machine for the first time. Particular attention must be

given to all the safety aspects of operating and

maintaining the machine.

General warnings in this chapter are repeated throughout

the book, as well as specific warnings. Read all the safety

statements regularly, so you do not forget them.

Remember that the best operators are the safest

operators.

Finally, treat this handbook as part of the machine. Keep it

clean and in good condition. Do not operate the machine

without a handbook in the cab. If there is anything you are

unsure about, ask your JCB distributor or employer. Do

not guess, you or others could be killed or seriously

injured.

The manufacturer's policy is one of continuous

improvement. The right to change the specification of the

machine without notice is reserved. No responsibility will

be accepted for discrepancies which may occur between

specifications of the machine and the descriptions

contained in this publication.

INT-1-2-5/1

Units of Measurement

In this handbook, the S.I. system of units is used. For

example, liquid capacities are given in litres. The Imperial

units follow in parenthesis ( ) eg 28 litres (6 gal).

Page Numbering

The page numbering system in this handbook is not

continuous. There is a gap of about ten pages between

sections. This allows for the insertion of new pages in later

issues of the handbook.

Left Side, Right Side

In this handbook, 'left' A and 'right' B mean your left and

right when you are seated correctly in the machine.

Using the Machine

To use the machine efficiently and safely you must know

the machine and have the skill to use it. This handbook

instructs you on the machine, its controls and its safe

operation. It is not a training manual on the art of loading.

If you are a new operator, get yourself trained in the skills

of using a machine before trying to work with it. If you

don't, you will not do your job well, and you will be a

danger to yourself and others.

Page Cross References

In this handbook, page cross references are made by

presenting the subject title printed in bold and italic to

signify a cross reference. (This is followed by the title of

the section containing the subject). For example:

Make sure the tyres are correctly inflated, see Tyre

Pressures (SPECIFICATION section) for the correct tyre

pressures and Inflating the Tyres (MAINTENANCE

section) for a safe procedure for inflating the tyres.

S239980

A

B

Purchased from www.WorkshopManuals.co.uk

2 2

INTRODUCTION

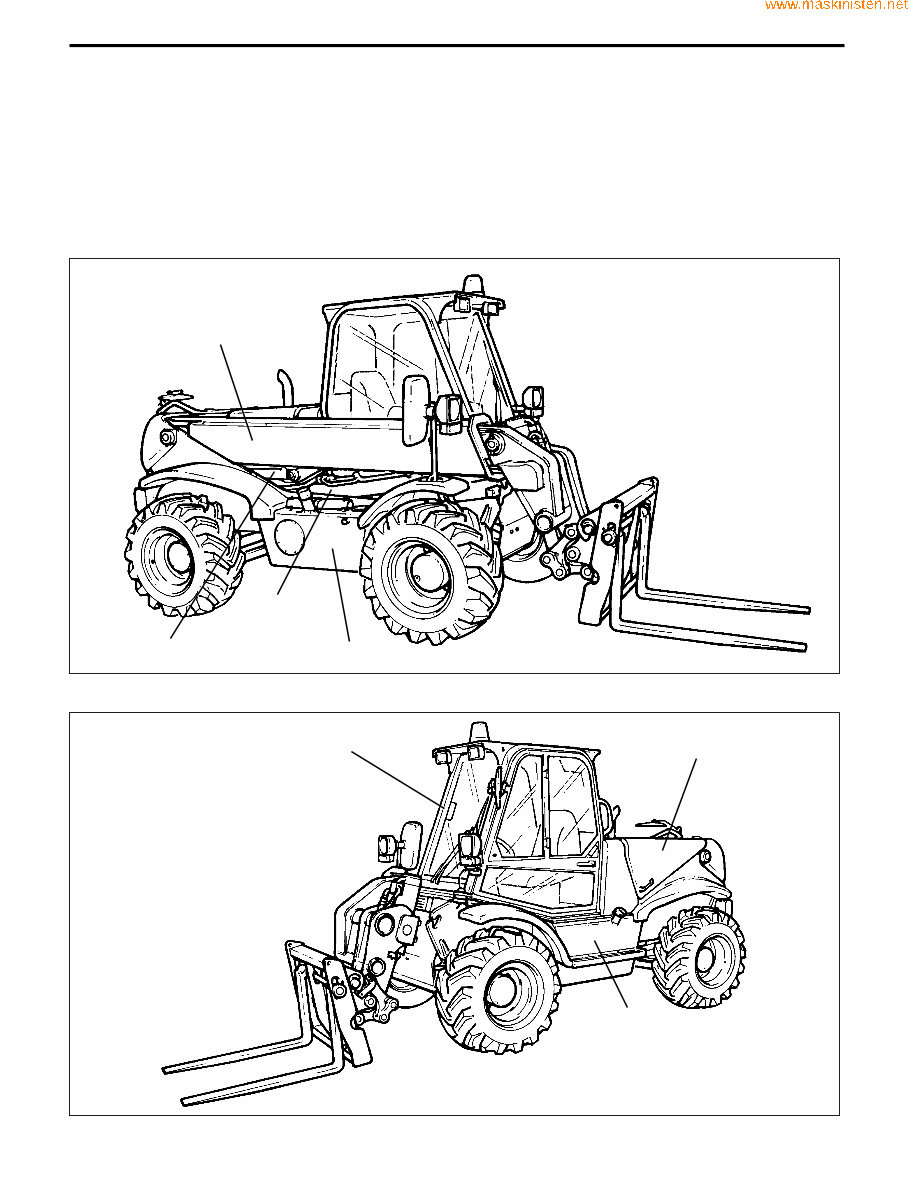

MACHINE DESCRIPTION

S239761

S239771

FUEL TANK

HYDRAULIC TANK

LIFT RAM

Self propelled, seated operator, wheeled machine for operation on unimproved natural terrain and disturbed terrain. A main

structural support is designed to carry an extending boom with a carriage mounted on the front to which forks or an

approved attachment can be fitted.

When used normally the machine lifts and places loads by extending/retracting, raising/lowering the boom.

BOOM

ROPS/FOPS CAB

8170-4

DISPLACEMENT RAM

ENGINE COVER

Purchased from www.WorkshopManuals.co.uk

3 3

INTRODUCTION

SAFETY - YOURS AND OTHER PEOPLE'S

All construction and agricultural equipment can be

hazardous. When the machine is correctly operated and

properly maintained, it is a safe machine to work with. But

when it is carelessly operated or poorly maintained it can

become a danger to you (the operator) and others.

In this handbook and on the machine you will find warning

messages. Read and understand them. They tell you of

potential hazards and how to avoid them. If you do not

fully understand the warning messages, ask your

employer or JCB distributor to explain them.

But safety is not just a matter of responding to the

warnings. All the time you are working on or with the

machine you must be thinking what hazards there might

be and how to avoid them.

SAFETY - CHECK LIST

As well as the warnings in this chapter, specific warnings

are given throughout the book. This section is designed to

give a safety code for use of the machine generally and for

operation and maintenance practices.

General Safety

! WARNING

Handbook

You and others can be injured if you operate or maintain

the machine without first studying this handbook. Read

the safety instructions before operating the machine. If

you do not understand anything, ask your employer or

JCB distributor to explain it. Keep this handbook clean

and in good condition. Do not operate the machine

without a handbook in the cab, or if there is anything on

the machine you do not understand.

INT-1-3-2

! WARNING

Decals

You can be injured if you do not obey the decal safety

instructions. Keep decals clean. Replace unreadable or

missing decals with new ones before operating the

machine. Make sure replacement parts include warning

decals where necessary.

INT-1-3-4

! CAUTION

Hazardous Atmospheres

This machine is designed for use in normal out door

atmospheric conditions. It should not be used in an

enclosed area without adequate ventilation. Do not use

the machine in a potentially explosive atmosphere, ie.

combustible vapours, gas or dust, without first consulting

your JCB Distributor.

INT-2-1-14

Do not work with the machine until you are sure that you

can control it.

Do not start any job until you are sure that you and those

around you will be safe.

If you are unsure of anything, about the machine or the

job, ask someone who knows. Do not assume anything.

Remember

BE CAREFUL

BE ALERT

BE SAFE

INT-1-31/1

! WARNING

Clothing

You can be injured if you do not wear proper clothing.

Loose clothing can get caught in the machinery. Wear

protective clothing to suit the job. Examples of protective

clothing are: a hard hat, safety shoes, safety glasses, a

well-fitting overall, ear-protectors and industrial gloves.

Keep cuffs fastened. Do not wear a necktie or scarf. Keep

long hair restrained.

INT-1-3-6

! WARNING

Care and Alertness

All the time you are working with or on the machine, take

care and stay alert. Always be careful. Always be alert for

hazards.

INT-1-3-5

! DANGER

Lightning

Lightning can kill you. Do not use the machine if there is

lightning in your area.

5-1-1-2

! WARNING

Raised Boom

A raised boom can fall or be lowered accidentally. Do not

walk under a raised boom which is not fitted with a safety

strut, or you could be injured.

5-1-1-1

! WARNING

Lifting Equipment

You can be injured if you use faulty lifting equipment.

Make sure that lifting equipment is in good condition.

Make sure that lifting tackle complies with all local

regulations and is suitable for the job. Make sure the lifting

equipment is strong enough for the job.

INT-1-3-7

8170-1

Purchased from www.WorkshopManuals.co.uk

4 4

INTRODUCTION

SAFETY CHECK LIST

(continued)

Operating Safety

! WARNING

Practice

You and others can be killed or seriously injured if you do

unfamiliar operations without first practising them.

Practice away from the work site on a clear area. Keep

other people away. Do not perform new operations until

you are sure you can do them safely.

INT-2-1-1

! WARNING

Machine Condition

A defective machine can injure you or others. Do not

operate a machine which is defective or has missing parts.

Make sure the maintenance procedures in this handbook

are completed before using the machine.

INT-2-1-2

! WARNING

Machine Limits

Operating the machine beyond its design limits can

damage the machine, it can also be dangerous. Do not

operate the machine outside its limits. Do not try to

upgrade the machine performance with unapproved

modifications.

INT-2-1-4

! CAUTION

Work Site

Work sites can be hazardous. Inspect the site before

working on it. Check for potholes, weak ground, hidden

rocks etc. Check for utilities (electric cables, gas and water

pipes etc.) Mark the positions of underground cables and

pipes. Make sure you have enough clearance beneath

overhead cables and structures. See Working With the

Loadall (OPERATION section) for more information about

the danger of electrical cables.

5-1-3-1/1

! DANGER

Sparks

Explosions and fire can be caused by sparks from the

exhaust or the electrical system. Do not use the machine

in closed areas where there is flammable material, vapour

or dust.

INT-2-2-10

! WARNING

Safe Working Loads

Overloading the machine can damage it and make it

unstable. Study the lifting and/or digging specifications in

this handbook before using the attachments

INT-2-2-11/1

! WARNING

ROPS/FOPS Structure

The machine is fitted with a Roll Over Protection Structure

(ROPS) and a Falling Objects Protection Structure (FOPS).

You could be killed or seriously injured if you operate the

machine with a damaged or missing ROPS/FOPS. If the

ROPS/FOPS has been in an accident, do not use the

machine until the structure has been renewed.

Modifications and repairs that are not approved by the

manufacturer may be dangerous and will invalidate the

ROPS/FOPS certification.

INT-2-1-9/3

! WARNING

Engine/Steering Failure

If the engine or steering fails, stop the machine as quickly

as possible. Do not operate the machine until the fault has

been corrected.

INT-2-1-5

! WARNING

Passengers

Passengers in or on the machine can cause accidents.

The JCB Loadall is a one man machine. Do not carry

passengers.

INT-2-2-2

! WARNING

Exhaust Gases

Breathing the machine exhaust gases can harm and

possibly kill you. Do not operate the machine in closed

spaces without making sure there is good ventilation. If

possible, fit an exhaust extension. If you begin to feel

drowsy, stop the machine at once. Get out of the cab into

fresh air.

INT-2-1-10

! WARNING

Communications

Bad communications can cause accidents. Keep people

around you informed of what you will be doing. If you will

be working with other people, make sure any hand signals

that may be used are understood by everybody. Work

sites can be noisy, do not rely on spoken commands.

INT-2-2-3

! WARNING

Visibility

Accidents can be caused by working in poor visibility.

Keep windows clean and use your lights to improve

visibility. Do not operate the machine if you can not see

properly.

INT-2-1-11

8170-1

Purchased from www.WorkshopManuals.co.uk

5 5

INTRODUCTION

SAFETY CHECK LIST

(continued)

! WARNING

Scaffolding

Overloaded scaffolding can collapse. Never load

scaffolding beyond the regulation capacity.

5-1-4-6

! DANGER

Forks/Working Platform

Using the forks alone as a working platform is hazardous;

you can fall off and be killed or injured. Never use the forks

as a working platform.

5-1-5-3

! CAUTION

Regulations

Obey all laws, work site and local regulations which affect

you or your machine.

INT-1-3-3

Maintenance Safety

! WARNING

Repairs

Do not try to do repairs or any other type of maintenance

work you do not understand. Get a Service Manual from

your JCB distributor, or get the work done by a specialist

engineer.

INT-3-1-1

! WARNING

Modifications and Welding

Non-approved modifications can cause injury and

damage. Parts of the machine are made from cast iron;

welds on cast iron can weaken the structure and break.

Do not weld cast iron. Contact your JCB distributor for

advice before modifying the machine.

INT-3-1-2/1

! WARNING

Metal Splinters

You can be injured by flying metal splinters when driving

metal pins in or out. Use a soft-faced hammer or drift to

remove and fit metal pins. Always wear safety glasses.

INT-3-1-3

! WARNING

Asbestos

Asbestos dust can damage your lungs. Some engine

gaskets contain asbestos. Do not dismantle the engine or

exhaust system; get these jobs done by a qualified person

who has a copy of the engine service manual.

5-1-6-1

! WARNING

Forks/Turning

The forks extend beyond the end of the boom. Make sure

there is enough clearance for the forks when making turns.

5-1-5-4

! WARNING

Fires

If your machine is equipped with a fire extinguisher, make

sure it is checked regularly. Keep it in the operator's cab

until you need to use it.

Do not use water to put out a machine fire, you could

spread an oil fire or get a shock from an electrical fire. Use

carbon dioxide, dry chemical or foam extinguishers.

Contact your nearest fire department as quickly as

possible. Firefighters should use self-contained breathing

apparatus

INT-3-2-7/1

! WARNING

Boom Safety Strut

A raised boom can drop suddenly and cause serious

injury. Before working under a raised boom, fit the boom

safety strut. See Boom Safety Strut (MAINTENANCE

section).

5-1-5-7

! WARNING

Communications

Bad communications can cause accidents. If two or more

people are working on the machine, make sure each is

aware of what the others are doing. Before starting the

engine make sure the others are clear of danger areas;

examples of danger areas are: the rotating blades and belt

on the engine, the attachments and linkages, and

anywhere beneath or behind the machine. People can be

killed or injured if these precautions are not taken.

INT-3-1-5

! WARNING

Oil

Oil is toxic. If you swallow any oil, do not induce vomiting,

seek medical advice. Used engine oil contains harmful

contaminants which can cause skin cancer. Do not handle

used engine oil more than necessary. Always use barrier

cream or wear gloves to prevent skin contact. Wash skin

contaminated with oil thoroughly in warm soapy water. Do

not use petrol, diesel fuel or paraffin to clean your skin.

INT-3-2-3

! WARNING

Counterweights

Your machine may be fitted with counterweights. They are

extremely heavy. Do not attempt to remove them.

INT-3-2-5

8170-1

Purchased from www.WorkshopManuals.co.uk

6 6

INTRODUCTION

SAFETY CHECK LIST

(continued)

! WARNING

Hydraulic Fluid

Fine jets of hydraulic fluid at high pressure can penetrate

the skin. Do not use your fingers to check for hydraulic

fluid leaks. Do not put your face close to suspected leaks.

Hold a piece of cardboard close to suspected leaks and

then inspect the cardboard for signs of hydraulic fluid. If

hydraulic fluid penetrates your skin, get medical help

immediately.

INT-3-1-10/1

! WARNING

Hydraulic Pressure

Hydraulic fluid at system pressure can injure you. Before

disconnecting or connecting hydraulic hoses, stop the

engine and operate the controls to release pressure

trapped in the hoses. Make sure the engine cannot be

started while the hoses are open.

INT-3-1-11/1

! WARNING

Jacking

A machine can roll off jacks and crush you unless the

wheels have been chocked. Always chock the wheels at

the opposite end of the machine that is to be jacked. Do

not work underneath a machine supported only by jacks.

Always support a jacked-up machine on axle stands

before working underneath it.

INT-3-2-8

! WARNING

Hydraulic Hoses

Damaged hoses can cause fatal accidents. Inspect the

hoses regularly for:

Damaged end fittings

Chafed outer covers

Ballooned outer covers

Kinked or crushed hoses

Embedded armouring in outer covers

Displaced end fittings.

INT-3-3-2

! WARNING

Petrol

Do not use petrol in this machine. Do not mix petrol with

the diesel fuel; in storage tanks the petrol will rise to the

top and form flammable vapours.

INT-3-1-6

! CAUTION

Cleaning

Cleaning metal parts with incorrect solvents can cause

corrosion. Use only recommended cleaning agents and

solvents.

INT-3-2-11

! WARNING

Fluoroelastomeric Materials

Certain seals and gaskets (e.g. crankshaft oil seal) on JCB

machines contain fluoroelastomeric materials such as

Viton, Fluorel and Technoflon. Fluoroelastomeric materials

subjected to high temperatures can produce highly

corrosive hydrofluoric acid. THIS ACID CAN SEVERELY

BURN.

New fluoroelastomeric components at ambient

temperature require no special safety precautions.

Used fluoroelastomeric components whose temperatures

have not exceeded 300°C require no special safety

precautions. If evidence of decomposition (e.g. charring) is

found, refer to the next paragraph for safety instructions

DO NOT TOUCH COMPONENT OR SURROUNDING

AREA.

Used fluoroelastomeric components subjected to

temperatures greater than 300°C (e.g. engine fire) must be

treated using the following safety procedure. Make sure

that heavy duty gloves and special safety glasses are

worn:

1 Ensure that components have cooled then remove

and place material into plastic bags.

2 Thoroughly wash contaminated area with 10%

calcium hydroxide or other suitable alkali solution, if

necessary use wire wool to remove burnt remains.

3 Thoroughly wash contaminated area with detergent

and water.

4 Contain all removed material, gloves etc. used in this

operation in sealed plastic bags and dispose of in

accordance with Local Authority Regulations.

DO NOT BURN FLUOROELASTOMERIC MATERIALS.

If contamination of skin or eyes occurs, wash the affected

area with a continuous supply of clean water or with

calcium hydroxide solution for 15-60 minutes. Get medical

attention immediately.

INT-3-3-5/1

! CAUTION

'O' rings, Seals and Gaskets

Badly fitted, damaged or rotted 'O' rings, seals and

gaskets can cause leakages and possible accidents.

Renew whenever disturbed unless otherwise instructed.

Do not use Triochloroethane or paint thinners near 'O'

rings and seals.

INT-3-2-12

! CAUTION

Machine Modifications

This machine is manufactured in compliance with

legislative and other requirements. It should not be altered

in any way which could affect or invalidate any of these

requirements. For advice consult your JCB Distributor.

Reference should also be made to Optional Attachments

section where appropriate.

INT-1-3-10

8170-2

Purchased from www.WorkshopManuals.co.uk

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Viewed 69 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

The Operator Handbook Loadall JCB is a professional reference for the following models:

- 520-50

- 525-50

- 525-50S

This comprehensive guide spans 126 pages in English and offers a wealth of tips and important advice for both professional mechanics and DIY repair enthusiasts. Every machine operator can benefit from these detailed instructions to ensure proper maintenance and repair.

We're currently collecting product reviews for this item. In the meantime, here are some reviews from our past customers sharing their overall shopping experience.

4.5

Out of 5.0

Overall Rating

89%

of customers that buyfrom this merchant give

them a 4 or 5-Star rating.

Verified Buyer

September 19, 2025 by Kenneth C. (Georgia, US)

“It's too easy”

Verified Buyer

September 19, 2025 by Thomas R. (US)

“So far so good, but I haven't downloaded the software yet!”

Verified Buyer

September 19, 2025 by James D. (California, US)

“There are other online sites offering repair manuals, but they make you jump through expensive hoops for one .

I found what I needed quickly, bought it, download it and I was done.”

I found what I needed quickly, bought it, download it and I was done.”

Verified Buyer

September 19, 2025 by Steven S. (US)

“Quick and easy to buy, next I will see if is quick and easy to use.”

Verified Buyer

September 19, 2025 by Jeff M. (US)

“Very Good!”

Verified Buyer

September 19, 2025 by JEREMIAH M. (US)

“GREAT”

Verified Buyer

September 19, 2025 by michael P. (US)

“quick and easy”

Verified Buyer

September 19, 2025 by Chris C. (US)

“Very easy”

Verified Buyer

September 19, 2025 by Reinier F. (US)

“Excelente”

Verified Buyer

September 18, 2025 by Duilio C. (US)

“Great!”