GENIE Telehandler MASTER Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Parts Manual

GTH-844

GTH-842

GTH-644

after GTH05-12345

after GTH05-12345

after GTH05-12345

Serial Number Range

Service Manual

GTH-636

GTH-644

GTH-842

Part No. 97487

Rev D

June 2007

from GTH0806A-8418

from GTH0806B-6958

Serial Number Range

from GTH0606A-8418

from GTH0606A-8418

from GTH0606B-6271

GTH-844

GTH-1048

GTH-1056

GTH-844

from GTH1006A-8418 to

GTH-1007A-11442

from GTH0806A-8418

from GTH0806B-6956

from GTH1006A-8418 to

GTH1007A-11442

June 2007

GTH-636 • GTH-644 • GTH-842 • GTH-844 • GTH-1048 • GTH-1056 Part No. 97487 ii

Introduction

Important

Read, understand and obey the safety rules and

operating instructions in the appropriate Operator's

Manual on your machine before attempting any

maintenance or repair procedure.

This manual provides detailed scheduled

maintenance information for the machine owner

and user. It also provides troubleshooting and

repair procedures for qualified service

professionals.

Basic mechanical, hydraulic and electrical

skills are required to perform most procedures.

However ,several procedures require specialized

skills, tools, lifting equipment and a suitable

workshop. In these instances, we strongly

recommend that maintenance and repair be

performed at an authorized Genie dealer

service center.

Technical Publications

Genie Industries has endeavored to deliver the

highest degree of accuracy possible. However,

continuous improvement of our products is a Genie

policy. Therefore, product specifications are

subject to change without notice.

Readers are encouraged to notify Genie of errors

and send in suggestions for improvement. All

communications will be carefully considered for

future printings of this and all other manuals.

Contact Us:

PO Box 97030

Redmond, WA 98073-9730 USA

www.genieindustries.com

e-mail: techsup@genieind.com

Copyright © 2006 by Genie Industries

97487 Rev D June 2007

First Edition, Fourth Printing

"Genie" is a registered trademark of Genie

Industries in the USA and many other countries.

"GTH" is a trademark of Genie Industries.

Printed on recycled paper

Printed in U.S.A.

Introduction

June 2007

Part No. 97487 GTH-636 • GTH-644 • GTH-842 • GTH-844 • GTH-1048 • GTH-1056 iii

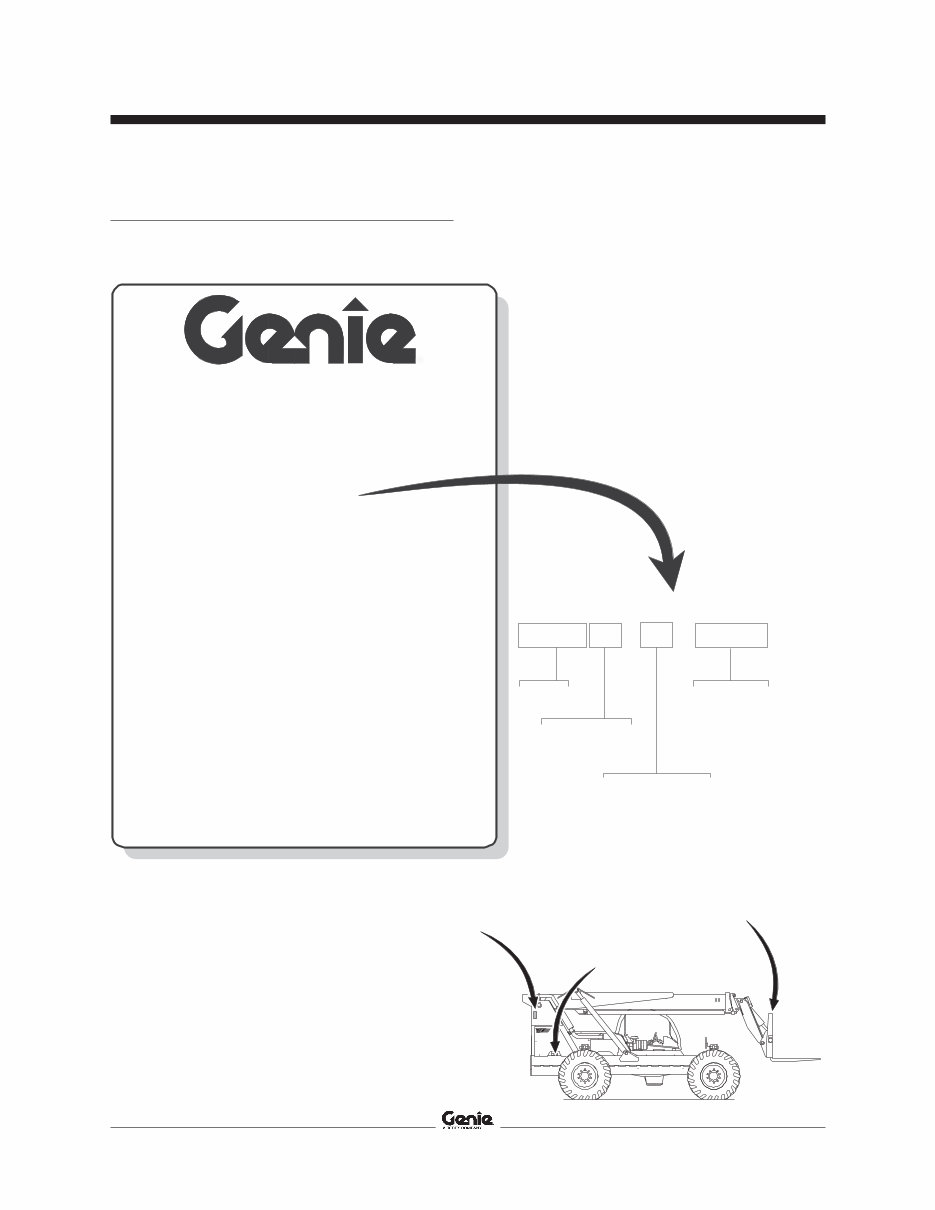

Serial Number Legend

INTRODUCTION

TH08 06 A - 1234

Model

Y ear of

manufacture

Facility code

Sequence

number

MODEL:

Genie Industries

18340 NE 76th S treet

Redmond, WA 98052

USA

GTH844

A TEREX COMPANY

SERIAL NUMBER: GTH0806A-8454

ATTACHMENT:

MANUFACTURE DATE: 02/20/06

TOTAL TRUCK WEIGHT(LBS): 22,010lbs / 9,984kg

MAX LIFT CAPACITY(LBS):

8000 LBS

LIFT CAPACITY(LBS)

AT MAX LIFT HEIGHT:

OUTRIGGERS UP:

OUTRIGGERS DOWN: N/A

N/A

6000 LBS

THIS FORKLIFT TRUCK COMPLIES

WITH:

ASME B56.6-2002 SAFETY STD FOR

ROUGH TERRAIN FORKLIFT TRUCK

Serial label

(located inside fork frame)

(models with quick attach frame)

Serial label

(located inside chassis

upright at cab side of machine)

Serial number

stamped on chassis

June 2007

GTH-636 • GTH-644 • GTH-842 • GTH-844 • GTH-1048 • GTH-1056 Part No. 97487 iv

This page intentionally left blank.

June 2007

Part No. 97487 GTH-636 • GTH-644 • GTH-842 • GTH-844 • GTH-1048 • GTH-1056

Safety Rules

Section 1 • Safety Rules

v

Danger

Failure to obey the instructions and safety rules

in this manual and the appropriate Operator's

Manual on your machine will result in death or

serious injury.

Many of the hazards identified in the

operator’s manual are also safety hazards

when maintenance and repair procedures

are performed.

Do Not Perform Maintenance

Unless:

You are trained and qualified to perform

maintenance on this machine.

You read, understand and obey:

- manufacturer’s instructions and safety rules

- employer’s safety rules and worksite

regulations

- applicable governmental regulations

You have the appropriate tools, lifting

equipment and a suitable workshop.

June 2007

GTH-636 • GTH-644 • GTH-842 • GTH-844 • GTH-1048 • GTH-1056 Part No. 97487

SAFETY RULES

vi

Section 1 • Safety Rules

Personal Safety

Any person working on or around a machine must

be aware of all known safety hazards. Personal

safety and the continued safe operation of the

machine should be your top priority.

Read each procedure thoroughly. This

manual and the decals on the machine,

use signal words to identify the following:

Safety alert symbol—used to alert

personnel to potential personal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor or moderate

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may result in property damage.

Be sure to wear protective eye wear and

other protective clothing if the situation

warrants it.

Be aware of potential crushing hazards

such as moving parts, free swinging or

unsecured components when lifting or

placing loads. Always wear approved

steel-toed shoes.

Workplace Safety

Be sure to keep sparks, flames and

lighted tobacco away from flammable and

combustible materials like battery gases

and engine fuels. Always have an

approved fire extinguisher within easy

reach.

Be sure that all tools and working areas

are properly maintained and ready for

use. Keep work surfaces clean and free of

debris that could get into machine

components and cause damage.

Be sure any forklift, overhead crane or

other lifting or supporting device is fully

capable of supporting and stabilizing the

weight to be lifted. Use only chains or

straps that are in good condition and of

ample capacity.

Be sure that fasteners intended for one

time use (i.e., cotter pins and self-locking

nuts) are not reused. These components

may fail if they are used a second time.

Be sure to properly dispose of old oil or

other fluids. Use an approved container.

Please be environmentally safe.

Be sure that your workshop or work area

is properly ventilated and well lit.

June 2007

Part No. 97487 GTH-636 • GTH-644 • GTH-842 • GTH-844 • GTH-1048 • GTH-1056

Table of Contents

vii

Introduction

Important Information ......................................................................................... ii

Serial Number Legend ...................................................................................... iii

Section 1 Safety Rules

General Safety Rules ........................................................................................ v

Section 2 Rev Specifications

D Machine Specifications ................................................................................ 2 - 1

Performance Specifications ......................................................................... 2 - 3

Hydraulic Specifications ............................................................................... 2 - 4

Manifold Component Specifications ............................................................. 2 - 6

John Deere 4045TF270 Engine ................................................................... 2 - 7

John Deere 4045TF275 Engine ................................................................... 2 - 8

Deutz BF4 2012 Engine ............................................................................... 2 - 9

Perkins 1104C-44T Engine ........................................................................ 2 - 10

Perkins 1104C-44TA Engine ..................................................................... 2 - 11

Dana T12000 Transmission ....................................................................... 2 - 12

Dana T20000 Transmission ....................................................................... 2 - 12

Dana Planetary 212 Drive Axle .................................................................. 2 - 13

Dana Planetary 213 Drive Axle .................................................................. 2 - 13

Hydraulic Hose and Fitting Torque Specifications ...................................... 2 - 14

SAE and Metric Fasteners Torque Charts ................................................. 2 - 15

Section 3 Rev Scheduled Maintenance Procedures

Introduction .................................................................................................. 3 - 1

Pre-delivery Preparation Report .................................................................. 3 - 3

Maintenance Inspection Report ................................................................... 3 - 5

June 2007

GTH-636 • GTH-644 • GTH-842 • GTH-844 • GTH-1048 • GTH-1056 Part No. 97487

TABLE OF CONTENTS

viii

Section 3 Rev Scheduled Maintenance Procedures, continued

C Checklist A Procedures

A-1 Inspect the Manuals and Decals ......................................................... 3 - 7

A-2 Perform Pre-operation Inspection ....................................................... 3 - 8

A-3 Perform Function Tests ...................................................................... 3 - 8

A-4 Lubricate the Machine ........................................................................ 3 - 9

A-5 Perform Engine Maintenance - John Deere and Perkins Models ...... 3 - 11

A-6 Perform Transmission Maintenance ................................................. 3 - 11

A-7 Perform Engine Maintenance - Deutz Models .................................. 3 - 12

A-8 Perform 30 Day Service ................................................................... 3 - 12

A-9 Perform Transmission Maintenance -

GTH-636, GTH-644, GTH-842 and GTH-844 Models ...................... 3 - 13

A-10 Perform Engine Maintenance - Perkins Models ................................ 3 - 13

A-11 Perform Axle Maintenance ............................................................... 3 - 14

A-12 Perform Engine Maintenance - John Deere Models ......................... 3 - 14

A-13 Perform Transmission Maintenance -

GTH-636, GTH-644, GTH-842 and GTH-844 Models ..................... 3 -- 15

A-14 Perform Transmission Maintenance ................................................. 3 - 15

A-15 Perform Axle Maintenance ............................................................... 3 - 16

B Checklist B Procedures

B-1 Inspect the Battery ........................................................................... 3 - 17

B-2 Inspect the Electrical Wiring ............................................................. 3 - 17

B-3 Check the Exhaust System .............................................................. 3 - 18

B-4 Inspect the Engine Air Filter .............................................................. 3 - 19

B-5 Inspect the Tires, Wheels and Lug Nut Torque ................................. 3 - 19

B-6 Perform Hydraulic Oil Analysis ......................................................... 3 - 20

B-7 Inspect the Fuel and Hydraulic Tank Cap Venting Systems ............. 3 - 21

B-8 Check the Boom Wear Pads ............................................................ 3 - 22

B-9 Lubricate the Driveshafts .................................................................. 3 - 23

B-10 Perform Engine Maintenance - John Deere Models ......................... 3 - 23

June 2007

Part No. 97487 GTH-636 • GTH-644 • GTH-842 • GTH-844 • GTH-1048 • GTH-1056

TABLE OF CONTENTS

ix

Section 3 Rev Scheduled Maintenance Procedures, continued

B Checklist C Procedures

C-1 Perform Engine Maintenance - Deutz Models .................................. 3 - 24

C-2 Perform Engine Maintenance - John Deere Models ......................... 3 - 24

C-3 Perform Axle Maintenance ............................................................... 3 - 25

C-4 Perform Transmission Maintenance -

GTH-1048 and GTH-1056 Models .................................................... 3 - 25

C-5 Perform Engine Maintenance - Perkins Models ................................ 3 - 26

C-6 Perform Axle Maintenance ............................................................... 3 - 26

C-7 Perform Axle Maintenance ............................................................... 3 - 27

B Checklist D Procedures

D-1 Inspect the Forks .............................................................................. 3 - 28

D-2 Adjust the Boom Sequencing Chains ............................................... 3 - 28

D-3 Replace the Hydraulic Tank Return Filter Element ........................... 3 - 31

D-4 Perform Engine Maintenance - Deutz Models .................................. 3 - 32

D-5 Perform Transmission Maintenance ................................................. 3 - 32

D-6 Perform Axle Maintenance ............................................................... 3 - 33

D-7 Perform Engine Maintenance - Perkins Models ................................ 3 - 33

D-8 Perform Engine Maintenance - Deutz Models .................................. 3 - 34

C Checklist E Procedures

E-1 Test or Replace the Hydraulic Oil ..................................................... 3 - 35

E-2 Perform Engine Maintenance - John Deere Models ......................... 3 - 36

E-3 Perform Engine Maintenance - Perkins Models ................................ 3 - 36

E-4 Perform Engine Maintenance - Perkins Models ................................ 3 - 37

E-5 Perform Engine Maintenance - Perkins Models ................................ 3 - 37

E-6 Perform Engine Maintenance - John Deere Models ......................... 3 - 38

E-7 Perform Engine Maintenance - Perkins Models ................................ 3 - 38

E-8 Perform Engine Maintenance - Deutz Models .................................. 3 - 39

E-9 Perform Engine Maintenance - Perkins Models ................................ 3 - 39

June 2007

GTH-636 • GTH-644 • GTH-842 • GTH-844 • GTH-1048 • GTH-1056 Part No. 97487

TABLE OF CONTENTS

x

Section 4 Rev Repair Procedures

Introduction .................................................................................................. 4 - 1

C Boom Components

1-1 Boom Angle Limit Switch (all models except GTH-636) ..................... 4 - 2

1-2 Boom ................................................................................................. 4 - 3

1-3 Boom Lift Cylinder ............................................................................ 4 - 15

1-4 Boom Extension Cylinder ................................................................. 4 - 17

1-5 Fork Level Cylinder .......................................................................... 4 - 18

1-6 Fork Rotate Cylinder (option) ........................................................... 4 - 20

B Operator's Compartment

2-1 Operator's Compartment .................................................................. 4 - 23

2-2 Machine Controls ............................................................................. 4 - 32

C Fuel and Hydraulic Tanks

3-1 Fuel Tank ......................................................................................... 4 - 38

3-2 Hydraulic Tank ................................................................................. 4 - 39

B Engines

4-1 Engines ............................................................................................ 4 - 40

4-2 Engine Fault Codes - John Deere 4045TF275 Engine ..................... 4 - 41

C Transmission

5-1 Transmission .................................................................................... 4 - 42

B Hydraulic Pumps

6-1 Hydraulic Pump ................................................................................ 4 - 44

C Manifolds

7-1 Main Valve Manifold Components .................................................... 4 - 48

7-2 Tilt Limiter Manifold Components ..................................................... 4 - 49

7-3 Dual Pilot Check Manifold Components ........................................... 4 - 50

7-4 Boom Activated Rear Lock-up Manifold Components ...................... 4 - 51

7-5 Fork Rotate Speed Manifold Components (option) ........................... 4 - 52

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

Viewed 70 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

Our service manuals are essential resources for professional mechanics and DIY enthusiasts alike. Whether you're working on the GTH-844, GTH-842, GTH-644, or any other model within the serial number range, our manuals provide comprehensive guidance. The manual, part number 97487, revision D, dated June 2007, covers models 636, 644, 842, and more. For models from GTH0806A-8418, GTH0806B-6958, GTH0606A-8418, GTH0606B-6271, and others like the GTH-1048 and GTH-1056, our manuals offer detailed insights to support your repair and maintenance needs.