ZF ECOSPLIT 16 Transmission Gearbox Workshop Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

®

16 S 221

16 S 181

8 S 181

1316 751 101c

Subject to alterations in design

Copyright by ZF

These repair instructions are protected by copyright. Any reproduction and dissemination in whatever

form – also in adapted, paraphrased or extracted form – in particular as a reprint, photomechanical or

electronic reproduction or as a storage in data-processing equipment or data networks without approval

by the holder of the copyright is prohibited and will be prosecuted under civil and criminal law.

Printed in Germany

Edition: 11.97

1316 751 101c

16 S 221, 16 S 181, 8 S 181 Contents

Page

Contents ......................................................................................................................................... 1-01

Preface............................................................................................................................................ 1-03

General information ....................................................................................................................... 1-04

Safety instructions.......................................................................................................................... 1-06

Tightening torques for nuts and bolts............................................................................................. 1-07

Spring table .................................................................................................................................... 1-08

Adjustment data ............................................................................................................................. 1-09

Special tools ................................................................................................................................... 1-14

View of transmission...................................................................................................................... 1-16

1 Removing components/range-change ........................................................................................ 2-01

1.1 Plastic pipes ................................................................................................................................... 2-01

1.2 Output flange ................................................................................................................................. 2-01

1.3 Cover .............................................................................................................................................. 2-01

1.4 5/2-way valve ................................................................................................................................. 2-02

1.5 Shift cylinder for range-change ..................................................................................................... 2-02

1.6 Housing/range-change .................................................................................................................. 2-03

1.7 Planet gear train with synchronizer................................................................................................ 2-04

1.8 Assembling planet gear train with range-change synchronizer ..................................................... 2-06

1.9 Assembling range-change /housing/output flange/piston .............................................................. 2-09

2 Removing components from centre housing ............................................................................. 2-12

2.1 Splitter (GV) cylinder .................................................................................................................... 2-12

2.2 Shift housing .................................................................................................................................. 2-12

2.3 Shift housing, friction-optimized version ...................................................................................... 2-16

2.4 Shift mechanism/selector patterns ................................................................................................. 2-21

3 Removing components from clutch housing .............................................................................. 2-24

3.1 Release fork ................................................................................................................................... 2-24

3.2 Connection plate with integral pump ............................................................................................. 2-25

3.3 Clutch housing ............................................................................................................................... 2-26

4 Removing components ................................................................................................................. 2-26

4.1 Removing components/clutch housing .......................................................................................... 2-26

4.2 Splitter shift rail /centre housing ................................................................................................... 2-26

4.3 Removing shafts ............................................................................................................................. 2-27

4.4 Removing components/centre housing ......................................................................................... 2-27

4.5 Input shaft ...................................................................................................................................... 2-28

4.6 Mainshaft ....................................................................................................................................... 2-30

4.7 Assembling synchronizer ............................................................................................................... 2-37

4.7.1 Version ZF-BK ............................................................................................................................... 2-37

4.7.2 Version ZF-D ................................................................................................................................. 2-38

4.8 Layshaft .......................................................................................................................................... 2-39

1-01

Contents 16 S 221, 16 S 181, 8 S 181

Page

5 Installing components .................................................................................................................. 2-41

5.1 Centre housing .............................................................................................................................. 2-41

5.2 Clutch housing ............................................................................................................................... 2-41

6 Synchronizer/wear limits ............................................................................................................. 2-42

6.1 Determining wear limit (except 1st and 2nd gears) ....................................................................... 2-42

6.2 Determining wear limit (1st and 2nd gears)................................................................................... 2-42

7 Adjusting mainshaft..................................................................................................................... 2-43

7.1 Selecting thrust washer and shim, straight-cut version .................................................................. 2-43

7.1 Selecting thrust washer and shim, helical-cut version ................................................................... 2-44

8 Installing shafts ............................................................................................................................ 2-45

8.1 Installing input shaft, mainshaft, layshaft and shift rails ............................................................... 2-45

9 Splitter shift fork .......................................................................................................................... 2-46

9.1 Adjusting shift fork ........................................................................................................................ 2-46

10 Clutch housing/centre housing ................................................................................................... 2-48

10.1 Fitting clutch housing to centre housing ....................................................................................... 2-48

11 Adjusting shafts ............................................................................................................................ 2-49

11.1 Input shaft ..................................................................................................................................... 2-49

11.2 Layshaft .......................................................................................................................................... 2-50

12 Fitting clutch housing components ............................................................................................. 2-51

12.1 Connection plate with integral pump ............................................................................................. 2-52

12.2 Release fork ................................................................................................................................... 2-53

13 Fitting centre housing components ............................................................................................. 2-55

13.1 Reverse idler gear/reverse idler pin ................................................................................................ 2-55

13.2 Cylinder.......................................................................................................................................... 2-55

13.3 5/2-way valve ................................................................................................................................. 2-56

13.4 Compressed air test for piston and splitter cylinder ....................................................................... 2-56

13.5 Injection pipe ................................................................................................................................ 2-57

14 Fitting complete range-change ................................................................................................... 2-58

15 Fitting components....................................................................................................................... 2-60

15.1 Shift housing .................................................................................................................................. 2-60

15.3 Plastic pipes ................................................................................................................................... 2-60

16 Compressed air test on breather ................................................................................................ 2-61

1-02

16 S 221, 16 S 181, 8 S 181 Preface

This manual is intended for skilled personnel who have been trained by ZF Friedrichshafen AG to carry out

maintenance and repair work on ZF products.

This manual deals with the standard ZF product in accordance with the state of development on the date of

issue.

However, due to continuing development of the product, repair work might require work practices and test or

adjustment data which are not contained in this manual. We therefore recommend that work done on your ZF

product is carried out only by skilled mechanics who have had their practical and theoretical knowledge updated on

a regular basis at our Service Training Center.

Service points equipped by ZF Friedrichshafen AG all over the world offer you:

1. Well-trained personnel

2. Specified equipment, e.g. specialized tools

3. Genuine ZF spares, to our latest specifications

All work performed in these service points is carried out conscientiously and with care.

Repair work carried out at ZF service points is guaranteed in accordance with the prevailing contractual

conditions.

Damage resulting from work performed by non-ZF personnel in an improper and unprofessional manner, together

with follow-on costs caused by such work, is excluded from the contractual guarantee agreement. This also applies

where genuine ZF spares have not been used.

ZF FRIEDRICHSHAFEN AG

Friedrichshafen Division

Service

1-03

General Information 16 S 221, 16 S 181, 8 S 181

1-04

Description of transmission

The ZF ECOSPLIT 16 S 221, 16 S 181 und 8 S 181 synchromesh transmissions have been developed for heavy

goods vehicle applications (from 220 to 400 kW).

16 S 221, 16 S 181 und 8 S 181 transmissions main components:

- 4-speed section with reverse gear

- rear-mounted range-change of planetary design

- front-mounted integrated splitter group (not in 8 S 181)

ZF Friedrichshafen AG offers the following options with these transmissions:

- NMV 221, engine-dependent PTO

- torque converter clutch (WSK)

- further engine-driven ZF PTO (NMV) together with the torque converter clutch

- various clutch-dependent ZF PTOs

- drive for emergency / dual-circuit steering pumps

- separate heat exchanger for extreme applications

- ZF Intarder

- ZF ES 2 shift system

- silent kit

Repair manual

NOTE: If clamping fixture 1X56 137 944 is used for dismantling the transmission, remove the reverse gear cover

before attaching the clamping fixture.

When reassembling the transmission, insert the reverse gear wheel before fitting the shaft set.

Then install the reverse idler gear pin.

CAUTION

The transmission must not be suspended by the input shaft nor by the output flange when transporting,

removing, installing and repairing.

ENVIRONMENTAL HAZARD !

Lubricants and cleaning agents must not be allowed to enter the ground, the water table or the sewage system.

• Request safety information for the products concerned from your local environmental protection

authority, and follow any instructions herein at all times.

• Always collect used oil in a suitably large container.

• Always dispose of used oil, clogged filters, lubricants and cleaning agents in accordance with

environmental protection laws.

• Always observe manufacturer instructions when dealing with lubricants and cleaning agents.

NOTE: Additional removal and installation instructions 1315 754 007 are available for transmissions with silent kit.

!

16 S 221, 16 S 181, 8 S 181 General Information

General

This repair manual shows how to repair a ZF ECOSPLIT 16 S 221, 16 S 181 und 8 S 181 synchromesh

transmission.

Layout of repair manual:

Section 1 includes adjustment data, tightening torques, spring characteristics and a list of specified ZF

special tools.

Section 2 is a step-by-step guide to transmission repairs.

Directions for removal and assembly, general work instructions

This repair manual is based on the steps necessary for the complete removal of transmission components and their

subsequent reassembly. When circumstances require, the assembly procedure for certain components is described

immediately after the removal procedure. Such cases include the section on the “mainshaft and layshaft’’, in which

assembly instructions are given after removal instructions so as to ensure that only fully repaired components

proceed to the complete assembly phase. This procedure reduces the risk of mixing up individual components and

shortens the overall assembly phase.

Always ensure cleanliness and appropriate high standard of work; therefore, clean all transmissions removed from

vehicles before dismantling.

Specified ZF special tools must be used.

After dismantling, clean all transmission components. Particular attention should be paid to corners, recesses and

protruding edges on housings and covers.

Carefully remove old sealing compound and gaskets. Check for blocked of lubrication oil bores, grooves and pipes.

There must be no build-up of deposits, foreign matter or preservatives. This is especially important in the case of

new components.

It is impossible to avoid damaging some components during dismantling; these must always be renewed ; e.g.shaft

seals, O-rings, grooved rings, flange packing, protective caps etc. Components such as roller bearings, thrust

washers, synchronizer parts, etc., which are subject to normal wear during operation, must be checked by a

specialist to determine whether they can be reused

Gaskets must be fitted dry, i.e. free from oil and grease. Sealing faces without gaskets must be sealed using a

plastic-type, heat- oil-resistant sealing compound (e.g. WEVO-L 100 A).

During assembly, observe all adjustment values, test data and tightening torques.

Fill the transmission with transmission oil after repair. Procedure for this and permitted oil types are given in the

Operating Manual and List of Lubricants TE-ML 02. These documents may be obtained from all ZF After-Sales

Service points.

After filling with oil, tighten oil check plugs and oil drain plugs to specified torque.

1-05

1-06

Important work safety notice:

Companies who repair ZF units are responsible for their own work safety.

To avoid injury to personnel and damage to products, all safety regulations and legal requirements which

apply to repair and maintenance work must be adhered to. Before starting work, mechanics must familiarize

themselves with these regulations.

Personnel required to carry out repairs on these ZF products must receive appropriate training in advance. It is the

responsibility of each company to ensure that repair staff is properly trained.

The following safety instructions appear in this manual:

NOTE Refers to special processes, techniques, data, use

of auxiliary equipment, etc.

CAUTION This is used when incorrect, unprofessional

working practices could damage the product.

DANGER This is used when lack of care could lead to

serious injury or death.

NOTE

Read this manual carefully before starting any tests or repair work.

After completion of repair work and testing, skilled mechanics must satisfy themselves that the product is

functioning correctly.

CAUTION

Pictures, drawings and components do not always represent the original object, but are used to illustrate

working procedures.

Pictures, drawings and components are not to scale, and no information about size and weight should be

inferred (even within a complete illustration).

Always follow the working steps as described in the text.

!

Work Safety 16 S 221, 16 S 181, 8 S 181

1-07

16 S 221, 16 S 181, 8 S 181 Tightening Torques

Tightening torques for bolts and nuts from ZFN 148

This Standard applies for bolts to DIN 912, DIN 931, DIN 933, DIN 960, DIN 961 and for nuts to DIN 934.

This Standard contains data on tightening torques (MA) for bolts in strength categories 8.8, 10.9 and 12.9 and nuts

in strength categories 8, 10 and 12. Coating ZFB 811 Dacromet or coating ZFB 998 Deltatone - Deltaseal.

Surface condition of bolts: heat-treated blackened finish and oiled or galvanized and oiled or galvanized, chrome-

plated and oiled.

NOTE: Tightening torques which differ from the values below are separately listed in the repair instructions.

Edition: August 1991

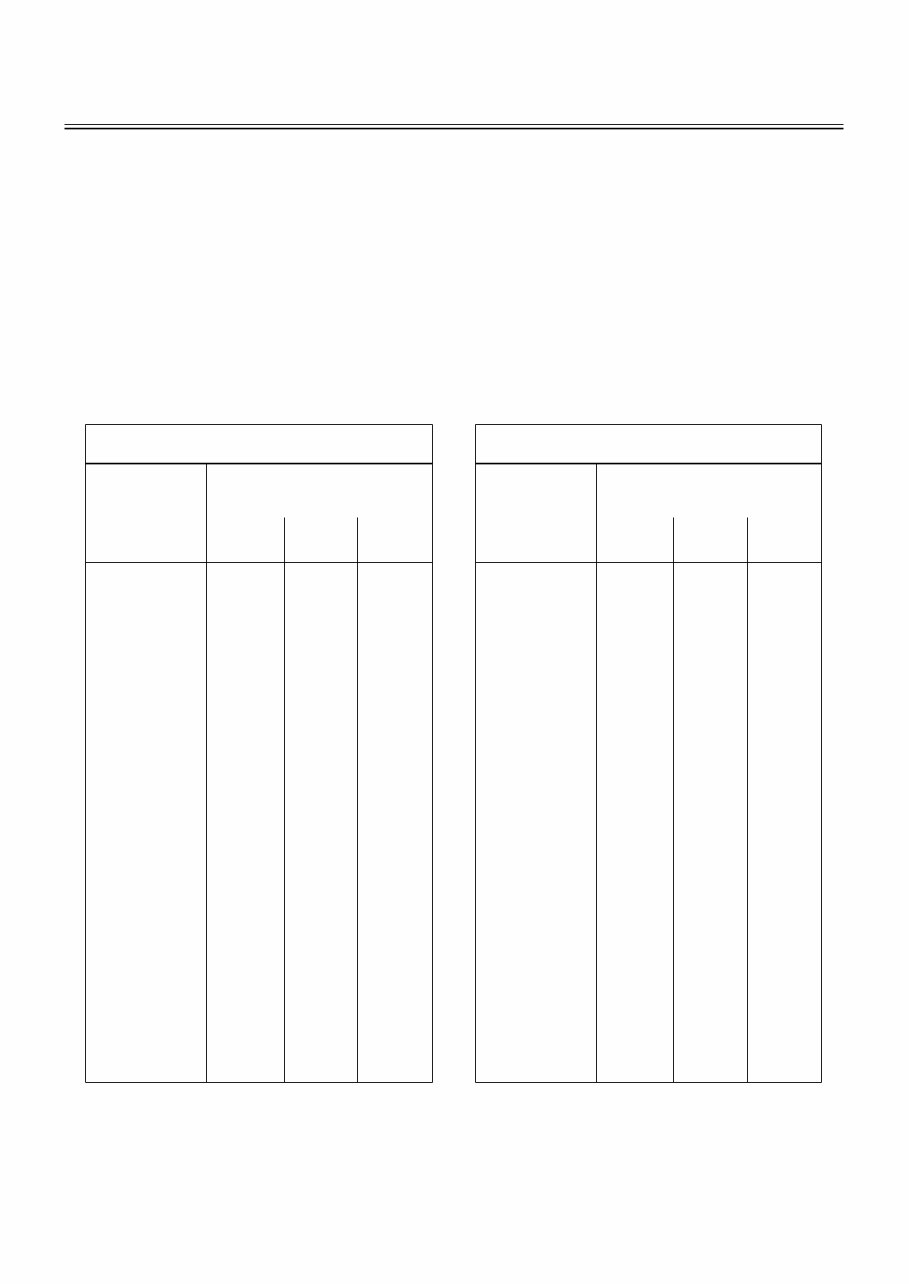

Metric coarse pitch thread Metric fine pitch thread

Size Tightening torque Size Tightening torque

MA (Nm) for MA (Nm) for

Bolt 8.8 10.9 12.9 Bolt 8.8 10.9 12.9

Nut 8 10 12 Nut 8 10 12

M 4 2.8 4.1 4.8 M 8 x 1 24 36 43

M 5 5.5 8.1 9.5 M 9 x 1 36 53 62

M 6 9.5 14 16.5 M 10 x 1 52 76 89

M 7 15 23 28 M 10 x 1.25 49 72 84

M 8 23 34 40 M 12 x 1.25 87 125 150

M 10 46 68 79 M 12 x 1.5 83 122 145

M 12 79 115 135 M 14 x 1.5 135 200 235

M 14 125 185 215 M 16 x 1.5 205 300 360

M 16 195 280 330 M 18 x 1.5 310 440 520

M 18 280 390 460 M 18 x 2 290 420 490

M 20 390 560 650 M 20 x 1.5 430 620 720

M 22 530 750 880 M 22 x 1.5 580 820 960

M 24 670 960 1100 M 24 x 1.5 760 1100 1250

M 27 1000 1400 1650 M 24 x 2 730 1050 1200

M 30 1350 1900 2250 M 27 x 1.5 1100 1600 1850

M 27 x 2 1050 1500 1800

M 30 x 1.5 1550 2200 2550

M 30 x 2 1500 2100 2500

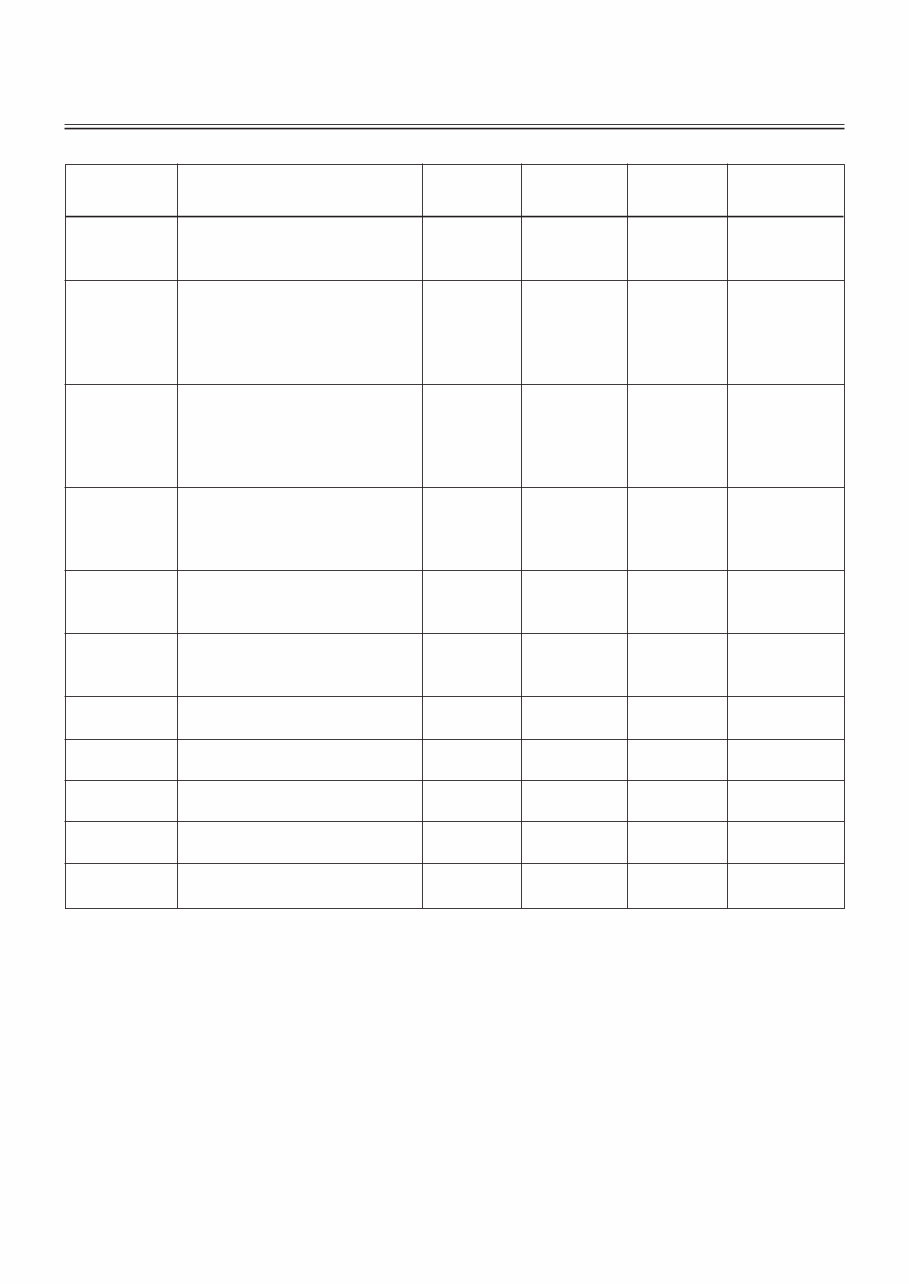

Part number Installation point No. of Wire diam. Spring diam. Untensioned

coils in mm in mm length in mm

0732 040 630 Shift mechanism: on shift shaft 6.5 2.4 39.6 89.9

(depending on version)

0732 040 985 Shift mechanism: spherical 6.5 2.0 14.8 23.4

roller for detent part or reverse

gear interlock

(depending on version)

0732 040 986 Shift mechanism: spherical 5.5 2.25 14.8 21.6

roller for detent part or reverse

gear interlock

(depending on version)

0732 040 984 Shift mechanism: reverse 9.5 1.4 9.4 23.3

gear interlock

(depending on version)

0732 040 736 Shift mechanism: for detent pin 13.5 1.6 9.8 36.0

and locking pin interlock

0732 040 409 Synchronizers 12.5 1.4 6.65 23.7

input shaft and mainshaft

0732 042 126 Detent piece (compression spring) 9.5 1.0 9.4 25.0

0732 042 365 Detent piece (compression spring) 5.5 1.7 20.44 31.49

0732 042 366 Detent piece (compression spring) 4.5 1.5 15.03 15.6

0732 042 400 Detent piece (compression spring) 10.5 2.25 15.5 39.7

0732 042 401 Detent piece (compression spring) 12.5 1.5 10.1 36.0

1-08

Spring Table 16 S 221, 16 S 181, 8 S 181

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$46.99

Viewed 10 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$46.99

- Transmission gearbox workshop repair manual for ZF ECOSPLIT 16 S 151 & 8 S 151

- Component/Area Group Disassembly:

- Plastic Pipes

- Output Flange

- Cover

- 5/2-Way Valve

- Shift Cylinder for Area Group

- Housing/Area Group

- Planetary Gear with Synchronization

- Assembling Planetary Gear with Group Synchronization

- Area Group/Housing/Output Flange/Piston Assembly

- Mid-Housing Component Disassembly

- GV Cylinder

- Shift Housing

- Shift Housing, Friction-Optimized Version

- Shifting/Selection Images

- Clutch Housing Component Disassembly

- Release Fork

- Connection Plate with Integrated Pump

- Clutch Housing

- Parts Removal

- Parts Removal/Clutch Housing

- Split Group Shift Rail/Mid-Housing

- Shaft Removal

- Parts Removal/Mid-Housing

- Drive Shaft

- Main Shaft

- Assembling Synchronization

- ZF-BK Version

- ZF-D Version

- Input Shaft

- Parts Installation

- Mid-Housing

- Clutch Housing

- Synchronization/Wear Limit

- Determining Wear Limit (except 1st and 2nd Gear)

- Determining Wear Limit 1st and 2nd Gear

- Main Shaft Adjustment

- Determining Ring and Axial Disc, Straight-Toothed Version

- Determining Ring and Axial Disc, Helical-Toothed Version

- Shaft Installation

- Installing Drive/Main/Input Shafts and Shift Rails

- Split Group Shift Fork

- Shift Fork Adjustment

- Clutch/Mid-Housing

- Attaching Clutch Housing to Mid-Housing

- Shaft Adjustment

- Drive Shaft

- Input Shaft

- Clutch Housing Component Attachment

- Connection Plate with Integrated Pump

- Release Fork

- Mid-Housing Component Attachment

- Return Wheel/Bolt

- Cylinder

- 5/2-Way Valve

- Air Pressure Testing for Piston and GV Cylinder

- Spray Pipe

- Complete Area Group Attachment

- Component Attachment

- Shift Housing

- Plastic Pipes