ZF ECOLITE Transmission Gearbox Workshop Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

6 S 850

6 S 890

1290 751 105a

Subject to alterations in design

Copyright by ZF

These repair instructions are protected by copyright. Any reproduction and dissemination in whatever

form – also in adapted, paraphrased or extracted form – in particular as a reprint, photomechanical or

electronic reproduction or as a storage in data-processing equipment or data networks without approval

by the holder of the copyright is prohibited and will be prosecuted under civil and criminal law.

Printed in Germany

Edition: 10.00

1290 751 105a

6 S 850 / 6 S 890 Contents

Page

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Important information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Instructions for carrying out repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Adjustment data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table of springs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Special tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Output flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Speedometer worm or pulse disc and radial sealing ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Speedometer connection piece or pulse sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 Reversing lamp switch and pawl stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 Shift mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Removing and installing selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Removing and installing peripheral parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3 Dismantling and reassembling selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 Shift patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

3 Reverse gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

4 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Clutch housing, separate version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Clutch housing, integrated version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3 Thrust rods, selector clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.4 Output bearing and radial sealing ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

5 Transmission housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

6 Input shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Removing and dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Assembling and installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

7 Main shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

8 Layshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Index a: 00-10-01

Contents 6 S 850 / 6 S

890

Page

9 Synchronizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1 Checking wear limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 Version ZF-BK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.3 Version ZF-D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

10 Adjusting shafts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.1 Main shaft - input shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.2 Layshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.3 Connection plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Index a: 00-10-01

ZF FRIEDRICHSHAFEN AG

Division Comm. Vehicle/Special Transmissions

Service Werk 2

Tel.: (0 75 41) 77-0

Fax: (0 75 41) 77-8000

This manual is intended for skilled personnel who have

been trained by ZF Friedrichshafen AG to carry out

maintenance and repair work on ZF products.

This manual deals with the standard ZF product in

accordance with the state of development on the date

of issue.

However, due to continuing development of the product,

repair work might require work practices and test or

adjustment data which are not contained in this manual.

We therefore recommend that work done on your ZF

product is carried out only by skilled mechanics who

have had their practical and theoretical knowledge upda-

ted on a regular basis at our After-Sales Service training

courses.

Service points equipped by ZF Friedrichshafen AG all

over the world offer you:

1. Well-trained personnel

2. Specified equipment, e.g. special tools

3. Genuine ZF spares, to our latest specifications

All work performed at these service points is carried out

conscientiously and with care.

Repair work carried out at ZF service points is

guaranteed in accordance with the prevailing

contractual conditions.

Damage resulting from work performed by non-ZF

personnel in an improper and unprofessional manner,

together with follow-on costs caused by such work, is

excluded from the contractual guarantee agreement.

This also applies where genuine ZF spares have not

been used.

Preface

5 Index a: 00-10-01

SAFETY NOTICE

Companies who repair ZF units are responsible for their

own work safety.

To avoid injury to personnel and damage to pro-

ducts, all safety regulations and legal requirements

which apply to repair and maintenance work must

be adhered to.

Before starting work, mechanics must familiarize

themselves with these regulations.

Personnel required to carry out repairs on ZF products

must receive appropriate training in advance. It is the

responsibility of each company to ensure that their

repair staff is properly trained.

The following safety instructions appear in this

manual:

NOTE

Refers to special processes, techniques, data, use

of auxiliary equipment, etc.

CAUTION

This is used when incorrect, unprofessional

working practices could damage the product.

DANGER

This is used when lack of care could lead to

personal injury or death.

GENERAL INFORMATION

Read this manual carefully before starting any tests or

repair work.

CAUTION

Pictures, drawings and components do not always

represent the original object, but are used to illustrate

working procedures.

Pictures, drawings and components are not to scale

and no information about size and weight should be

inferred (even within a complete illustration).

Always follow the working steps as described in the

text.

After completion of repair work and testing, skilled staff

must satisfy themselves that the product is functioning

correctly.

THREATS TO THE ENVIRONMENT !

Lubricants and cleaning agents must not be allowed

to enter the soil, ground water or sewage system.

• Ask your local environment agency for

safety information on the relevant products

and adhere to their requirements.

• Collect used oil in a suitably large container.

• Dispose of used oil, dirty filters, lubricants

and cleaning agents in accordance with

environmental protection guidelines.

• When working with lubricants and cleaning

agents always refer to the manufacturer’s

instructions.

CAUTION

The transmission must NOT be hung on the

input shaft NOR on the output flange.

!

!

Important information

6 Index: 98-01-12

7 Index: 98-01-12

In any cases of doubt always turn to the the relevant

department within ZF After-Sales Services for

advice.

After removing the transmission from the vehicle clean

thoroughly before opening.

Pay particular attention to the corners and angles of

housings and covers when cleaning.

Parts held on with Loctite can be slightly loosened if

warmed with a hot air blower.

CLEANING PARTS

Remove the old remains of gaskets on all gaskets.

Carefully remove burrs or other similar patches of

roughness using a oil-stone

Lube bores and grooves must be free of anti-corrosion

agents and foreign matter, check that they can move

without encountering any problems.

Carefully cover opened transmissions to prevent the

entry of foreign matter..

REUSING PARTS

Parts such as ball or roller bearings, multi-discs, thrust

washers etc., must be inspected by a competent person,

who should decide whether or not they can be re-used.

Replace parts which are damaged or have suffered from

excessive wear.

GASKETS, LOCKING PLATES

Parts which cannot be removed without being damaged

must always be replaced with new parts (e.g. gaskets

and locking plates).

SHAFT SEALS

Always change shaft seals with rough, ripped or

hardened packing washers. Seal contact surfaces must

be totally clean and in perfect condition.

REWORKING

Rework may only be carried out on the seal contact

surfaces using plunge-cut grinding, never use an emery

cloth. Ensure that there are no traces of grinding traces

or rifling from grinding.

If rework is needed on distance washers, shims etc.

because of clearance settings, ensure that the reworked

areas contain no face runout and have the same surface

quality.

TRANSMISSION ASSEMBLY

Find a clean site to assemble the transmission. Gaskets

are installed without the use of sealing compound or

grease. When measuring silicon-coated gaskets, take

care not to include the silicon layer in the measure-

ment.

During assembly, comply with all adjustment data,

checking data and tightening torques in the Repair

Manual.

Instructions for carrying out repairs

8 Index: 98-01-12

BEARINGS

If the bearings are filled while hot, these should be

warmed up accordingly (e.g. in a heating cabinet).

The temperature should be approx. 85 °C and may not

exceed 120 °C. All bearings must be coated with trans-

mission oil after assembly.

SEALING

If a sealing agent* is to be used for carrying out sealing,

comply with the manufacturer’s directions for use.

Apply a thin layer of sealing agent to the surfaces and

spread evenly. Do not allow sealing to enter oil ducts

and bores. On oil-carrying ducts and bores wipe off the

sealing agent on the surfaces to be sealed near apertures

to ensure that no sealing agent penetrates the oil feeds

when the surfaces are sealed.

SHAFT SEALS

a) Apply a light coat of sealing agent on outer edge of

shaft seals with “steel surround”.

b) Never apply sealing agent to shaft seals with

“rubber surround” but apply a thin coat of Vaseline

8420 to the outer edge or wet with a lubricant, e.g. a

water-soluble, concentrated washing-up liquid (e.g.

Pril, Coin, Palmolive).

c) Shaft seals with steel and rubber surrounds should be

treated on the outer edge of the rubber surround as

described above in section b).

d) Duo shaft seals have two packing

washers. The dust-proof packing

washer (X) must face outwards.

e) Fill the gap between the packing

washers so it is 60% filled with grease (use a grease

e.g. produced by Aral such as Aralub HL2 or by

DEA such as Spectron FO 20).

f) If possible heat shaft seal bores to between 40 and

50°C (this makes fitting easier). Press the seal shaft

with mounting or faceplate onto the relevant installa-

tion depth plan.

RETAINING AGENTS

Retaining agents* may only be used in places as

specified in the parts list.

Always comply with manufacturer’s directions for use

when using retaining agents (e.g. Loctite).

During assembly, comply with all adjustment data,

checking data and tightening torques.

TRANSMISSION OIL

After completing repairs, fill the transmission with

transmission oil. For the procedure and approved oils,

refer to the transmission operating manual and List of

Lubricants TE-ML (refer to identification plate) which

are available from any ZF After-Sales Service Point.

After filling the transmission with oil, tighten the screw

plugs at the oil filling point and the oil overflow to the

specified torques.

* refer to expendable material

Instructions for carrying out repairs

X

Tightening torques

9 Index: 98-01-12

Tightening torques for nuts and bolts, extract from

ZFN 148

This standard applies to bolts acc. to DIN 912, DIN 931,

DIN 933, DIN 960, DIN 961 and to nuts acc. to DIN 934.

This Standard contains data on tightening torques (M

A

)

for bolts in strength categories 8.8, 10.9 and 12.9 and

nuts in strength categories 8, 10 and 12.

Surface condition of bolts: thermally blackened and

oiled or galvanized and oiled or galvanized, chrome-

plated and oiled.

Tighten screws with a calibrated torque spanner.

NOTE

Irregular tightening torques are listed separately in the

Repair Manual.

Edition: August 1991 / checked 1997

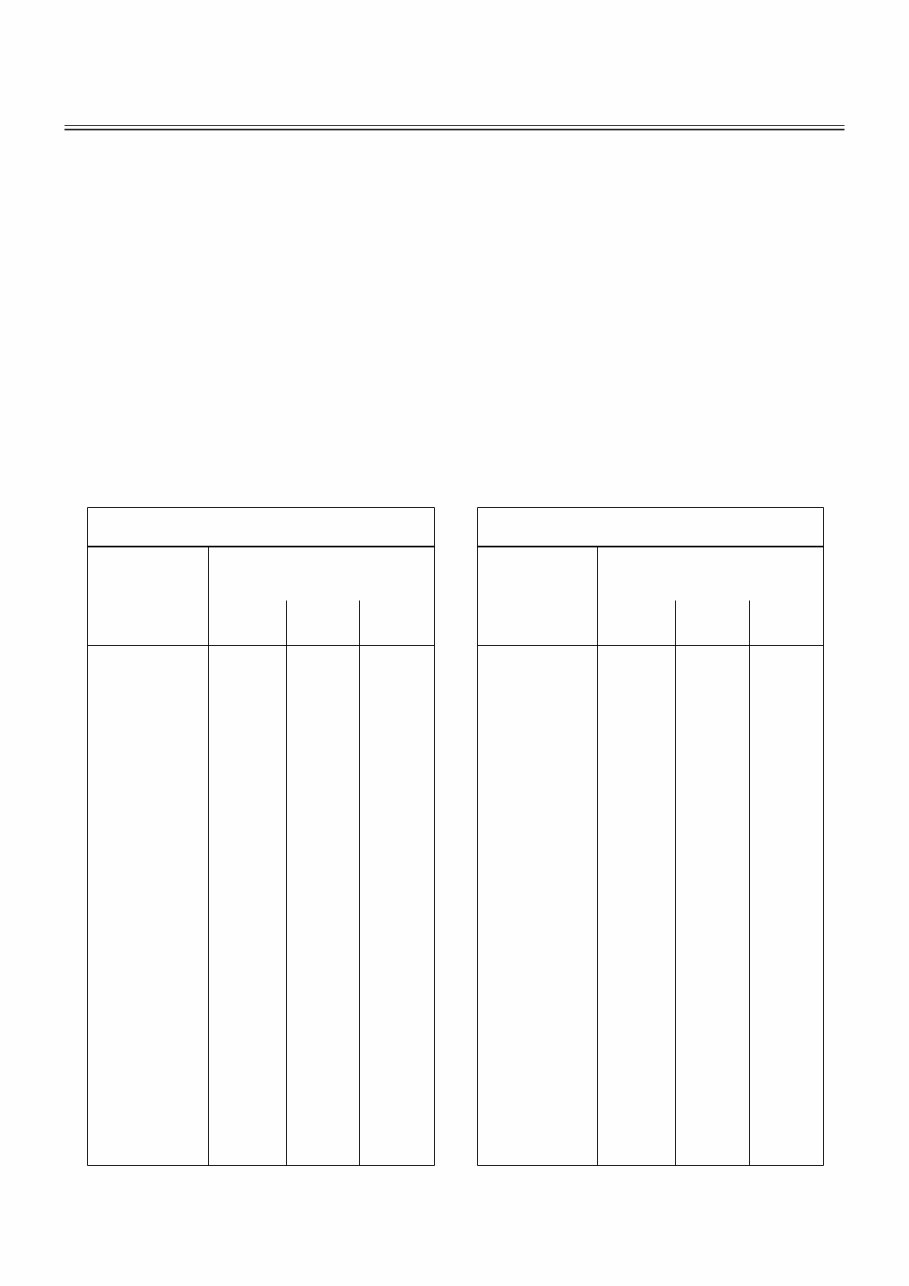

Regular thread Fine screw thread

Size Tightening torque Size Tightening torque

M

A

(Nm) for M

A

(Nm) for

Bolt 8.8 10.9 12.9 Bolt 8.8 10.9 12.9

Nut 8 10 12 Nut 8 10 12

M 4 2,8 4,1 4,8 M 8 x 1 24 36 43

M 5 5,5 8,1 9,5 M 9 x 1 36 53 62

M 6 9,5 14 16,5 M 10 x 1 52 76 89

M 7 15 23 28 M 10 x 1,25 49 72 84

M 8 23 34 40 M 12 x 1,25 87 125 150

M 10 46 68 79 M 12 x 1,5 83 122 145

M 12 79 115 135 M 14 x 1,5 135 200 235

M 14 125 185 215 M 16 x 1,5 205 300 360

M 16 195 280 330 M 18 x 1,5 310 440 520

M 18 280 390 460 M 18 x 2 290 420 490

M 20 390 560 650 M 20 x 1,5 430 620 720

M 22 530 750 880 M 22 x 1,5 580 820 960

M 24 670 960 1100 M 24 x 1,5 760 1100 1250

M 27 1000 1400 1650 M 24 x 2 730 1050 1200

M 30 1350 1900 2250 M 27 x 1,5 1100 1600 1850

M 27 x 2 1050 1500 1800

M 30 x 1,5 1550 2200 2550

M 30 x 2 1500 2100 2500

Tightening torques

10

Screw plugs DIN 908, 910 and 7604

The screw plug tightening torques M

A

were determined

according to DIN 7604, for screwing into steel, grey

cast, and aluminium alloys.

The values are based on experience, and are

intended as reference values for the designer.

The values for the tightening torque M

A

shall also be

used for screw plugs according to DIN 908 and

DIN 910, as the thread geometries are almost identical.

General rule: Screw/bolt class 5, ZFN 148-1

Screw/bolt material: steel acc. to

DIN 7604. Surface condition: as manu-

factured (without surface protection) and

lightly oiled or galvanized, chromated

and lightly oiled

Union screws DIN 7643

The tightening torques M

A

were determined for

screwing into steel, grey cast and aluminium alloys.

The values are based on experience and are inten-

ded as reference values for the designer.

General rule: screw/bolt class 5, ZFN 148-1

Material 9SMnPb28K acc. to DIN 1651

Surface conditions: as manufactured

(without surface protection) and lightly

oiled or galvanized, chromated and

lightly oiled

Status October 1995

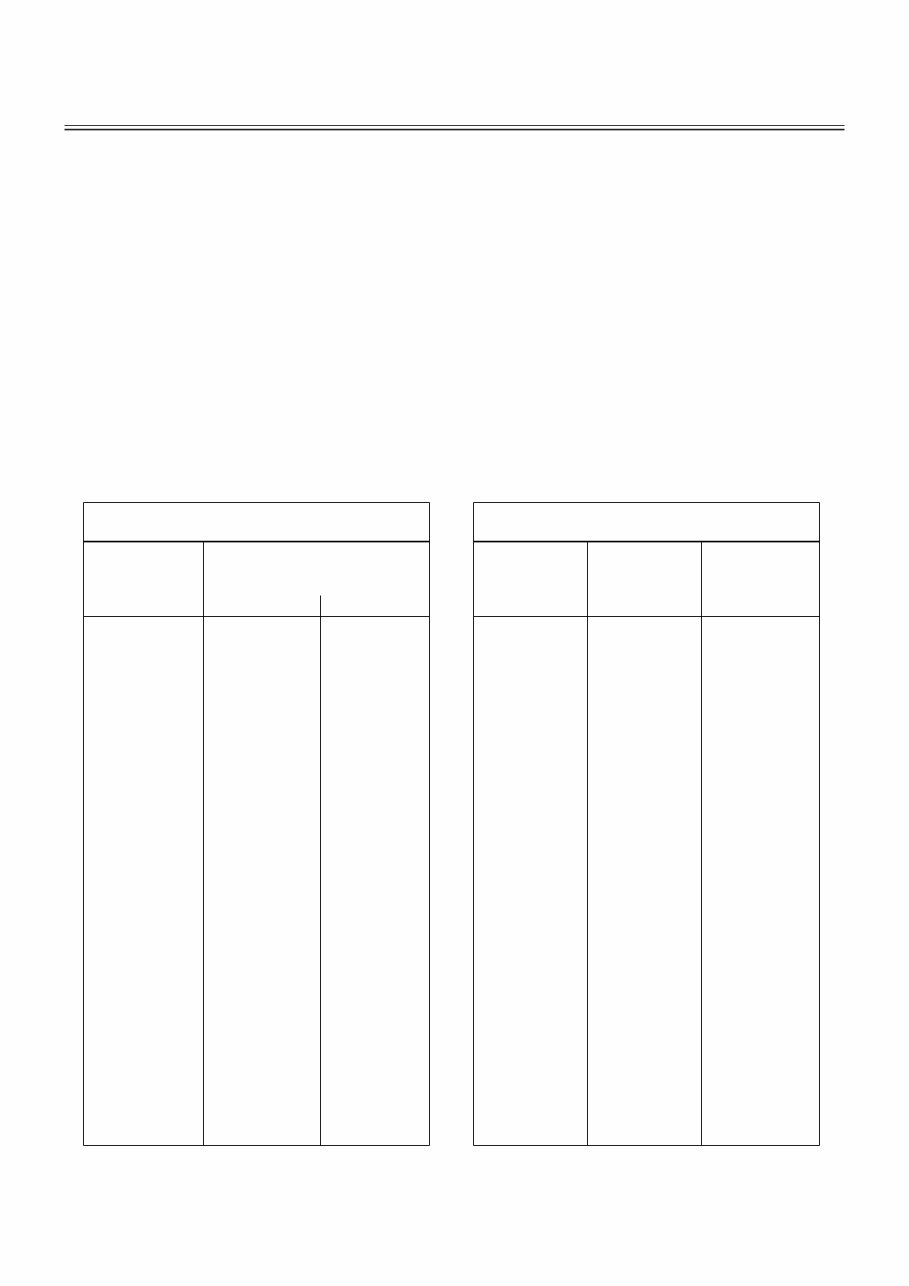

Screw plugs (DIN 908, 910, 7604)

Dimensions Tightening torque

screwed into

steel/grey cast Al alloy

M 8 x 1 20 10

M 10 x 1 25 / 30* 15 / 20*

M 12 x 1.5 35 25

M 14 x 1.5 35 25

M 16 x 1.5 40 30

M 18 x 1.5 50 35

M 20 x 1.5 55 45

M 22 x 1.5 60 / 80* 50 / 65*

M 24 x 1.5 70 60

M 26 x 1.5 80 / 105* 70 / 90*

M 27 x 2 80 70

M 30 x 1.5 100 / 130* 90 / 130*

M 30 x 2 95 85

M 33 x 2 120 110

M 36 x 1.5 130 115

M 38 x 1.5 140 120

M 42 x 1.5 150 130

M 42 x 2 145 125

M 45 x 1.5 160 140

M 45 x 2 150 130

M 48 x 1.5 170 145

M 48 x 2 160 135

M 52 x 1.5 180 150

M 60 x 2 195 165

M 64 x 2 205 175

* DIN 7604 Form C

Union screws (DIN7643)

Pipe Thread Tightening-

outer torque M

A

diameter in Nm

4 - 5 M 8 x 1 30

6 M 10 x 1 35

8 M 12 x 1.5 40

10 M 14 x 1.5 40

12 M 16 x 1.5 45

15 M 18 x 1.5 50

18 M 22 x 1.5 60

22 M 26 x 1.5 90

28 M 30 x 1.5 130

35 M 38 x 1.5 140

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$46.99

Viewed 32 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$46.99

ZF ECOLITE TRANSMISSION GEARBOX WORKSHOP REPAIR MANUAL 6 S 850 & 890 provides important information, instructions for carrying out repairs, tightening torques, consumables, adjustment data, table of springs, and special tools. It covers various components such as output, output flange, speedometer worm, pulse disc, radial sealing ring, speedometer connection piece, pulse sensor, reversing lamp switch, pawl stop, shift mechanism, selector, peripheral parts, shift patterns, reverse gear, input, clutch housing (separate and integrated versions), thrust rods, selector clamp, output bearing, radial sealing ring, transmission housing, input shaft, main shaft, and layshaft.